z-type heterojunction co 9 s 8 /nh 2 Preparation method of -uio-66 composite material and its application in photocatalysis

A composite material, nh2-uio-66 technology, applied in the field of catalysis, can solve the problems of low output, unsatisfactory heating, expensive use, etc., and achieve the effects of large specific surface area, accelerated catalytic reaction rate, and good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

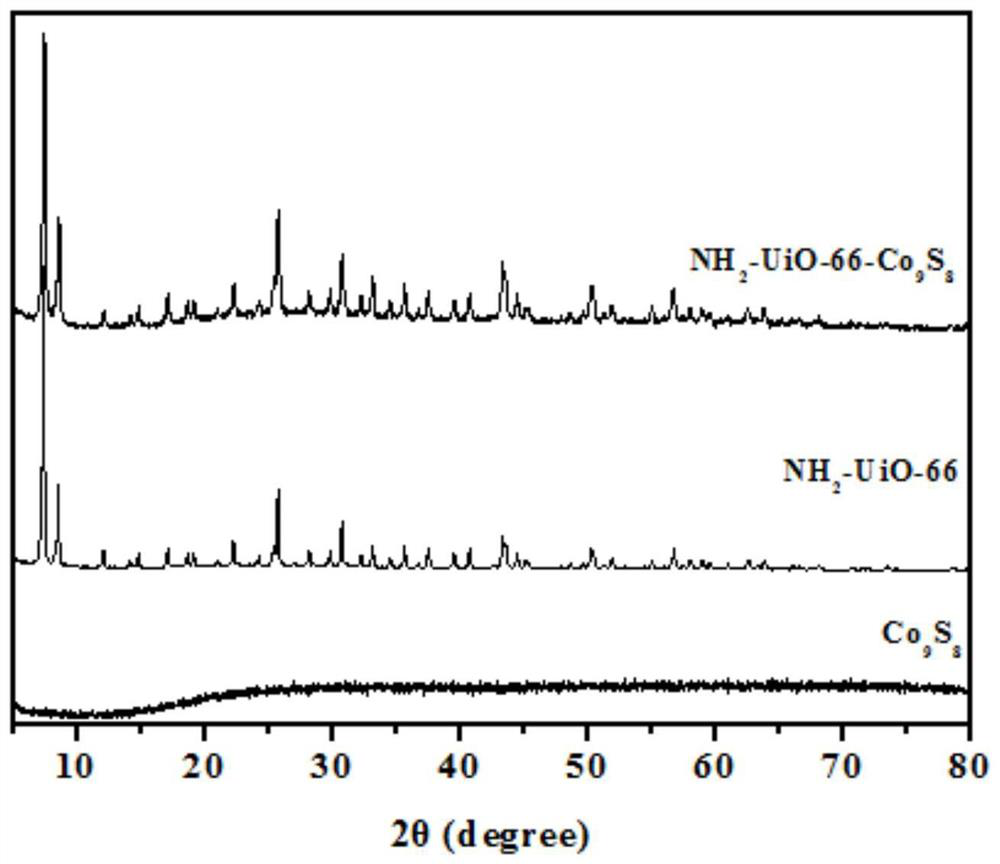

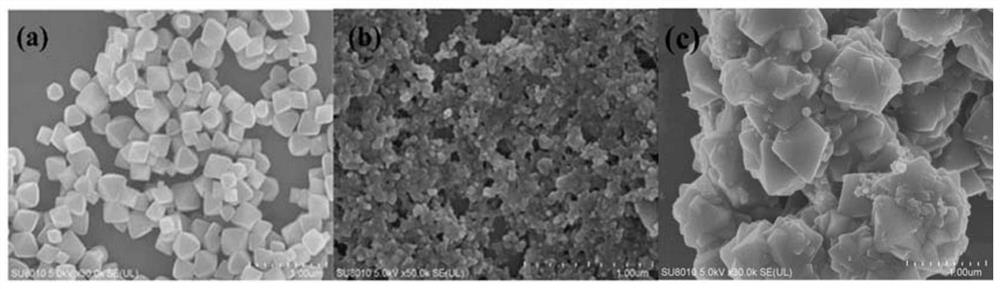

[0029] Example 1 Z-type heterojunction Co 9 S 8 / NH 2 -UiO-66 composite

[0030] (1) The preparation method is as follows:

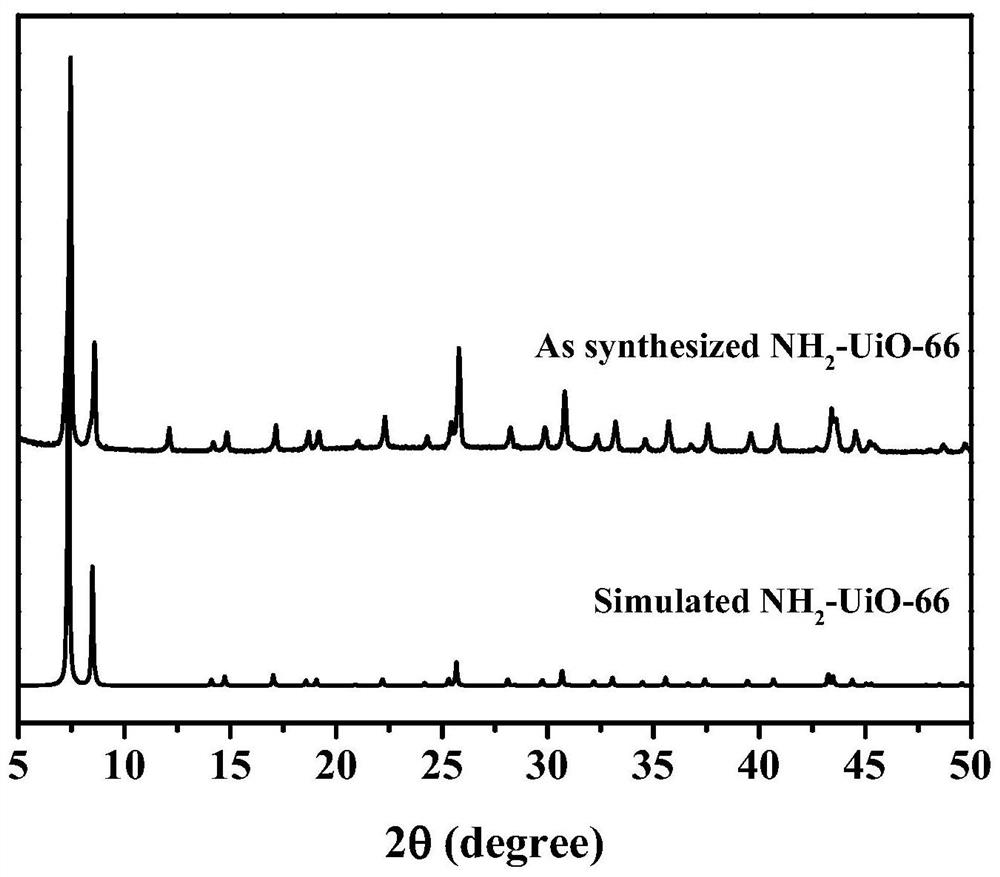

[0031] (1) ZrCl 4(61.2 mg, 0.26 mmol) and 2-aminoterephthalic acid (87 mg, 0.48 mmol) were dissolved in 60 mL of DMF, and after mixing and stirring for 5 min, 7.2 mL of glacial acetic acid solution was added thereto, and the mixture was uniformly mixed. The resulting mixture was continuously heated and stirred in an oil bath at 120 °C for 12 h to produce a yellow solid, which was centrifuged, washed and dried to obtain the product NH 2 - UiO-66.

[0032] (2) CoCl 2 ·6H 2 O (34.04 mg, 0.14 mmol) was dissolved in 15 mL of deionized water, and after stirring, 10 mL of Na 2 S·9H 2 Aqueous O solution (containing Na 2 S·9H 2 O 171.80 mg, 1.79 mmol) was slowly added to CoCl 2 ·6H 2 In the O aqueous solution, the Co / S molar ratio is 1:5. The mixed solution was then continuously stirred for 30 min. Transfer to a 50mL reaction kettle and heat at 120...

Embodiment 2

[0040] Example 2 Z-type heterojunction Co 9 S 8 / NH 2 - Catalytic function of UiO-66 composites for Biginelli reaction

[0041] (1) Co 9 S 8 Effect of Nanoparticle Addition on Catalytic Biginelli Reaction

[0042] Take 50mg NH 2 -UiO-66, add 2.5mg, 5.0mg, 10.0mg Co respectively 9 S 8 The nanoparticles were dispersed in 25 mL of ethanol solution, sonicated for 30 min, and then the resulting mixture was stirred at 70 °C for about 2 h, and the ethanol solvent was evaporated to induce Co 9 S 8 Nanoparticles in NH 2 - Composite on UiO-66. Finally, it was dried in a vacuum drying oven at 60 °C to obtain the target product Co 9 S 8 / NH 2 - UiO-66 composites, labeled 5% Co, respectively 9 S 8 / NH 2 -UiO-66, 10%Co 9 S 8 / NH 2 -UiO-66, 20%Co 9 S 8 / NH 2 -UiO-66.

[0043] Method: Take 20mg of different Co 9 S 8 Loaded Z-type heterojunction Co 9 S 8 / NH 2 -UiO-66 composite material, 1 mmol of benzaldehyde, 1 mmol of ethyl acetoacetate and 1.5 mmol of urea were ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com