Perovskite solar cell with high fill factor and method for preparing perovskite solar cell

A solar cell and fill factor technology, which is applied to circuits, photovoltaic power generation, electrical components, etc., can solve problems such as the inability to prepare large-area solar cell devices, and achieve the effects of improving photoelectric conversion efficiency, meeting commercial use, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

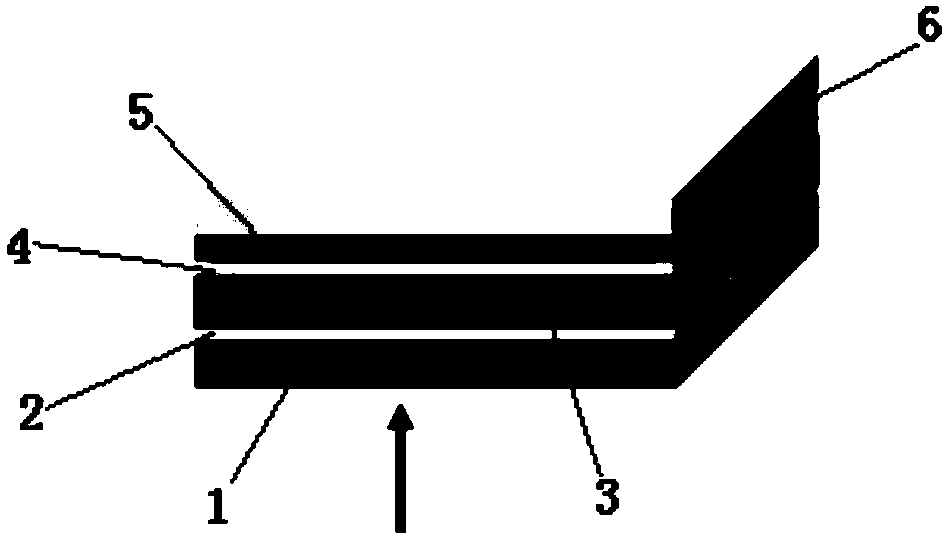

[0036] The present invention also provides a method for preparing the perovskite solar cell with the above-mentioned high fill factor, comprising the following steps:

[0037] In step S1, the transparent conductive substrate 1 is cleaned by three methods of ethanol cleaning, acetone ultrasonic cleaning and deionized water ultrasonic cleaning. dry to obtain a dry transparent conductive substrate 1.

[0038] Preferably, the transparent conductive substrate 1 is glass or a flexible substrate; wherein the flexible substrate is a polyimide compound or a polyesterimide compound.

[0039] Preferably, the conductive film is an inorganic conductive polymer or an organic conductive polymer; the inorganic conductive polymer is indium tin oxide, zinc oxide, tin oxide, gold, copper, silver or zinc; the organic conductive polymer is polythiophene, polyvinylbenzene sodium sulfonate or polyaniline.

[0040] Preferably, the sheet resistance of the conductive film is 15-30Ω, and its thickness...

Embodiment 1

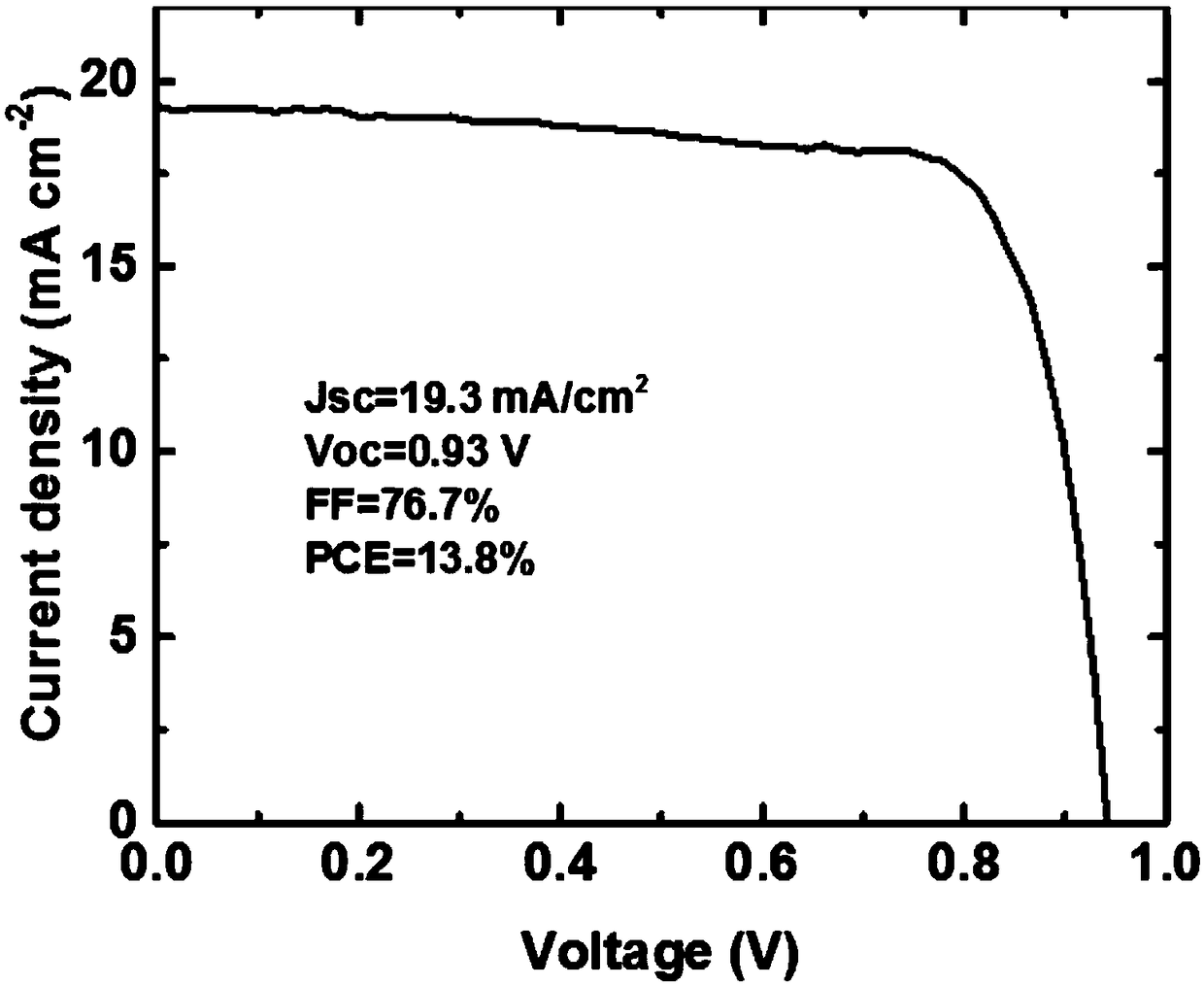

[0049] Preparation of perovskite solar cells, its structure is: transparent conductive substrate / ITO(130nm) / CH3NH3PbI3(400nm) / RbF(3nm) / C60(10nm) / BCP(6nm) / Ag(120nm); the specific process is as follows :

[0050] Step S1, cleaning the transparent conductive substrate pre-engraved with a conductive film, cleaning the transparent conductive substrate by sequentially performing ethanol cleaning, acetone ultrasonic cleaning and deionized water ultrasonic cleaning, and placing it under an infrared lamp after cleaning Drying, wherein the conductive thin film on the transparent conductive substrate is used as the anode layer of the solar cell, the square resistance of the conductive thin film is 15Ω, and the film thickness is 130nm. Wherein the transparent conductive substrate is glass, and the conductive film is indium tin oxide.

[0051] Step S2, treat the transparent conductive substrate processed in step S1 with ultraviolet ozone for 6 minutes; spin-coat the PH1000 solution on the...

Embodiment 2

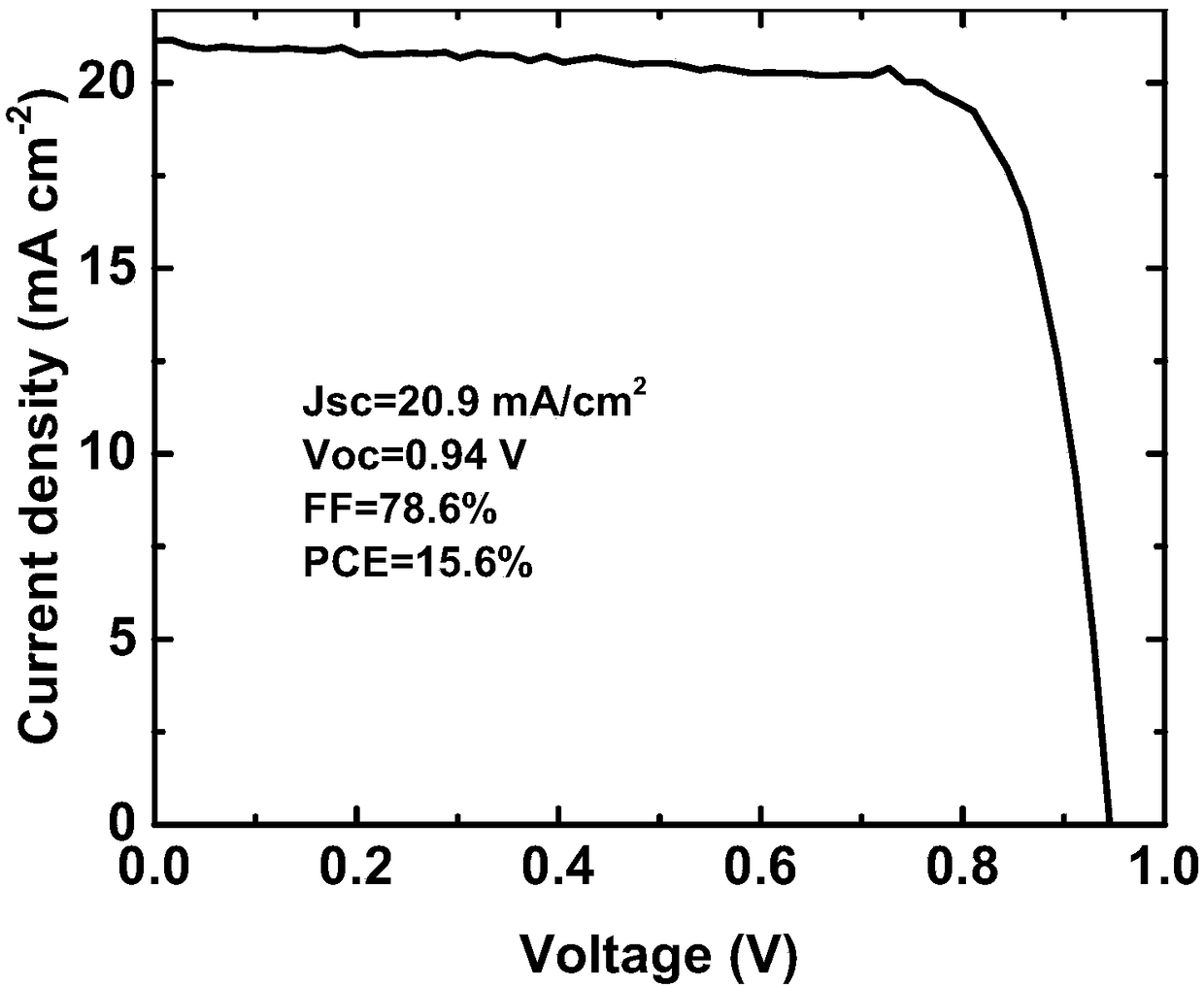

[0059] Preparation of perovskite solar cells, its structure is: transparent conductive substrate / ITO(120nm) / CH3NH3PbI3(400nm) / CsF(3nm) / PCBM(10nm) / BCP(6nm) / Au(100nm); the specific process is as follows :

[0060] Step S1, cleaning the transparent conductive substrate pre-engraved with a conductive film, cleaning the transparent conductive substrate by sequentially performing ethanol cleaning, acetone ultrasonic cleaning and deionized water ultrasonic cleaning, and placing it under an infrared lamp after cleaning Drying, wherein the conductive thin film on the transparent conductive substrate is used as the anode layer of the solar cell, the square resistance of the conductive thin film is 20Ω, and the film thickness is 120nm. Wherein the transparent conductive substrate is glass, and the conductive film is indium tin oxide.

[0061]Step S2, treat the transparent conductive substrate processed in step S1 with ultraviolet ozone for 6 minutes; spin-coat the PH1000 solution on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com