Iron balancing technology in low-grade sulfide ore biological heap leaching-leachate purification-extraction and separation process

A biopile and leaching solution technology, applied in the direction of improving process efficiency, can solve the problems of affecting the extraction and separation process, affecting the extraction and separation efficiency, the recycling of extraction agents, and increasing the processing cost, so as to improve the leaching and extraction and separation efficiency of valuable metals , considerable economic and environmental benefits, and the effect of solving the entrainment of valuable metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

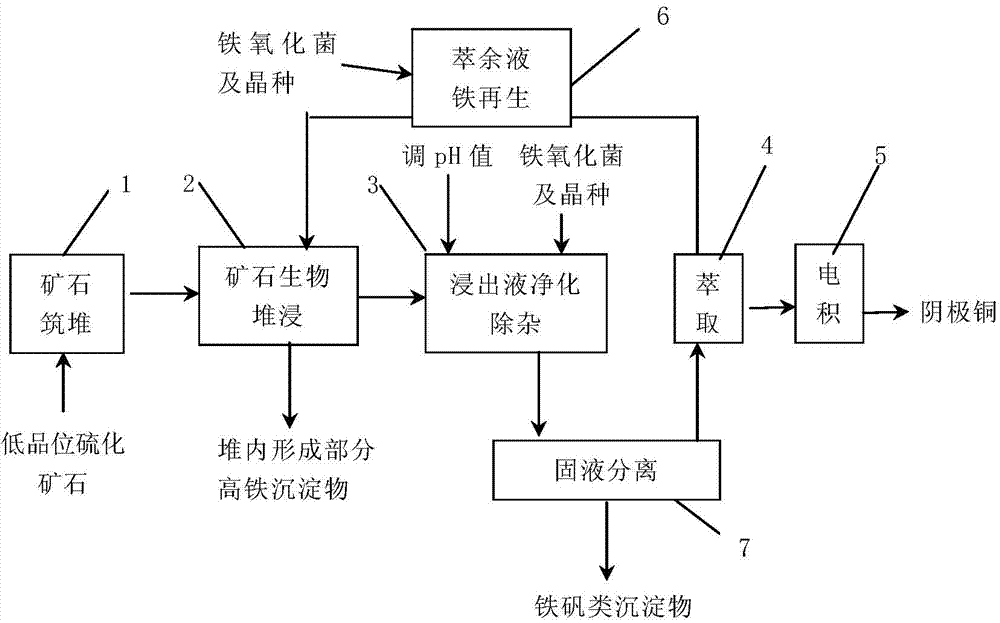

[0027] Such as figure 1 As shown, in the bioheap leaching of low-grade polymetallic copper-nickel-cobalt sulfide ore-leach solution purification and impurity removal process, the iron balance technology is divided into three steps, which are bioheap leaching process 2, bioleaching liquid purification and impurity removal process 3, and raffinate iron Regeneration process 6. In the ore bioheap leaching process, the monovalent cations such as potassium and sodium dissolved by the alunite and other minerals contained in the ore heap during the leaching process are easy to form part of the iron-like precipitates in the heap. During the process of purifying and removing impurities in the bioleach solution, by adjusting the pH value of the leach solution and adding iron-oxidizing bacteria and jarosite seeds, the iron ions in the leach solution are precipitated in the form of jarosite precipitates, and then enter the copper-nickel-cobalt solvent extraction and separation process 4. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com