Patents

Literature

145results about How to "Shorten hardening time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium phosphate cement composition and a method for the preparation thereof

ActiveUS6929692B2Good water solubilityIncreased formationOther chemical processesBone implantChemical synthesisCalcium biphosphate

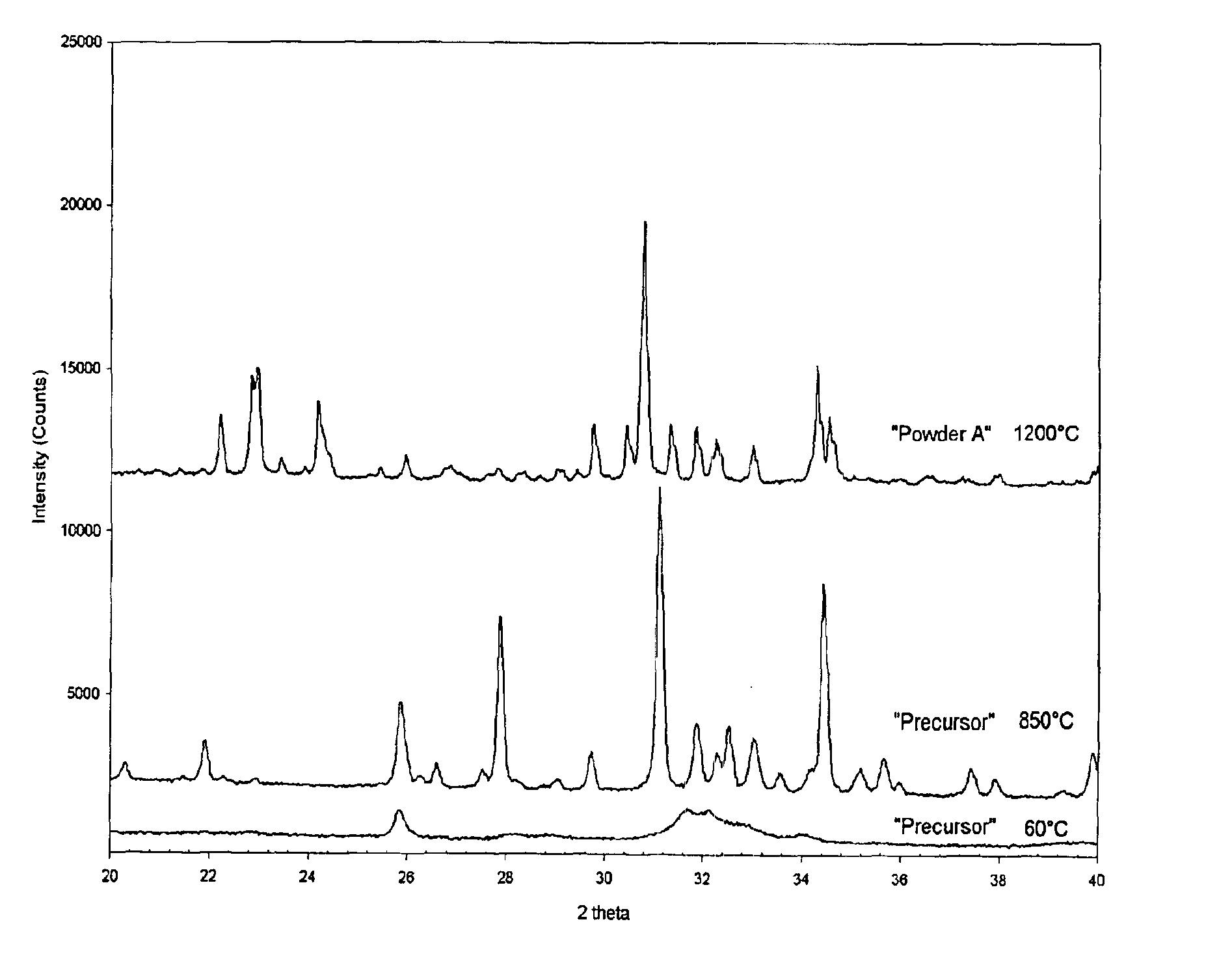

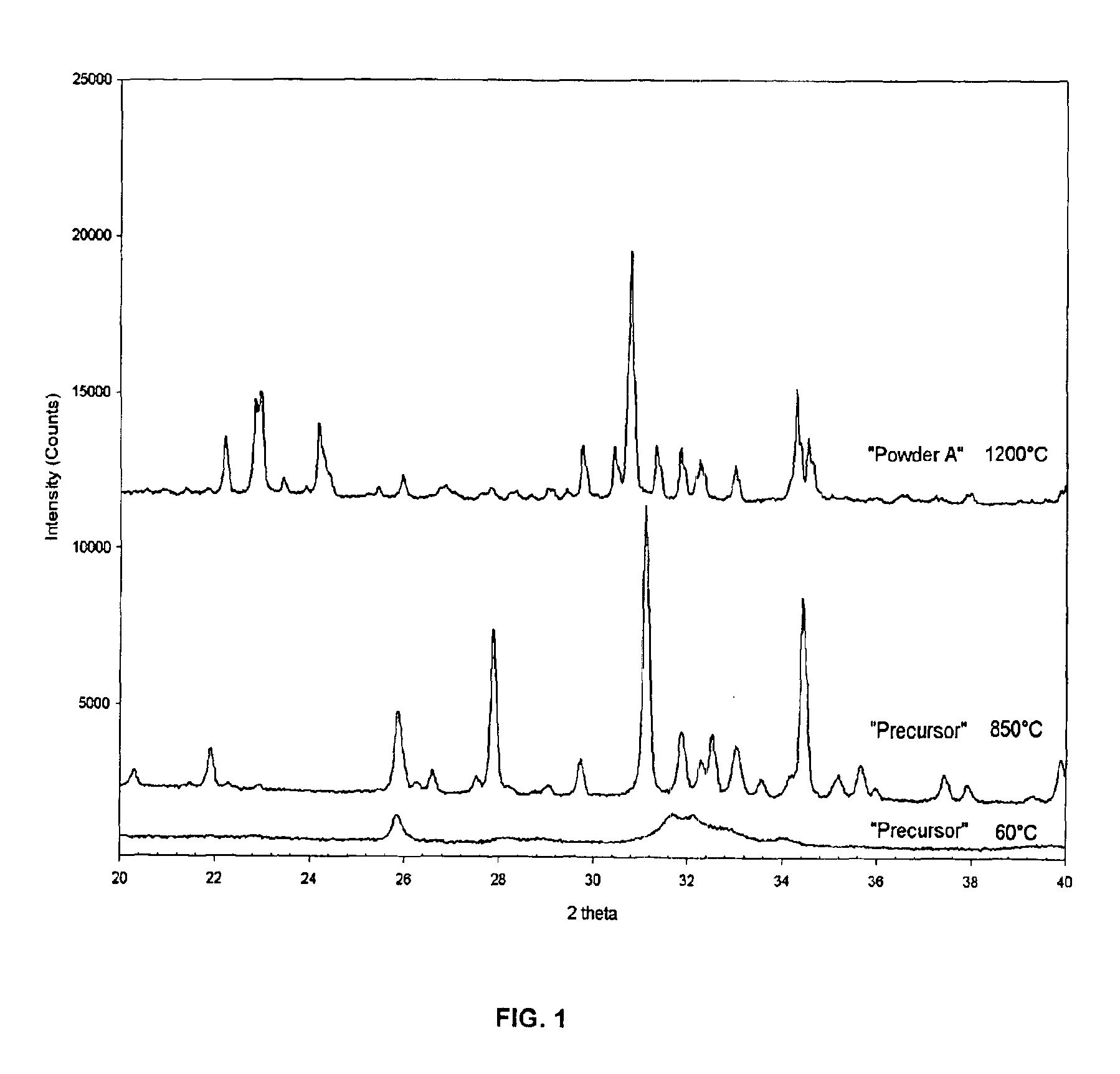

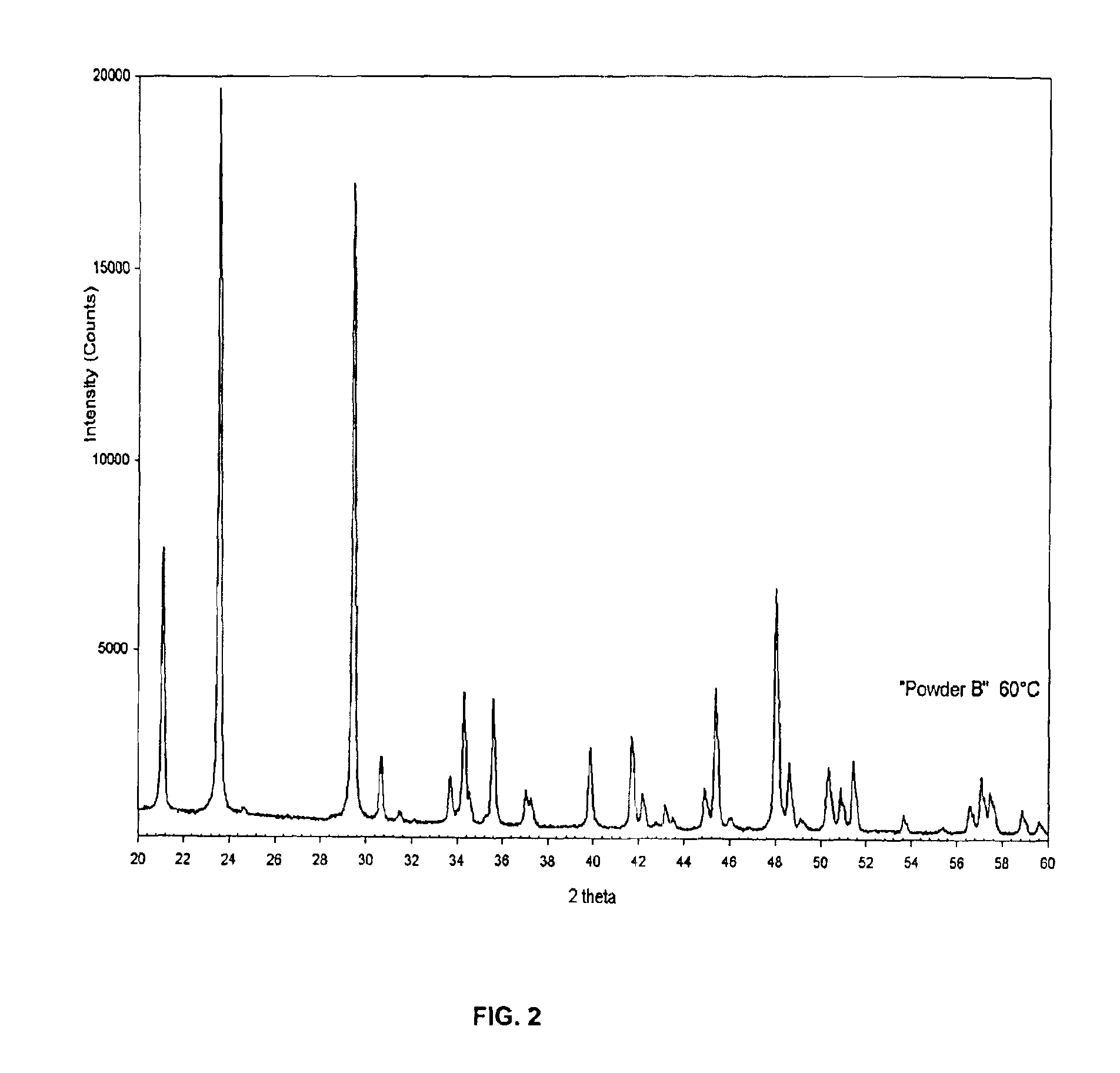

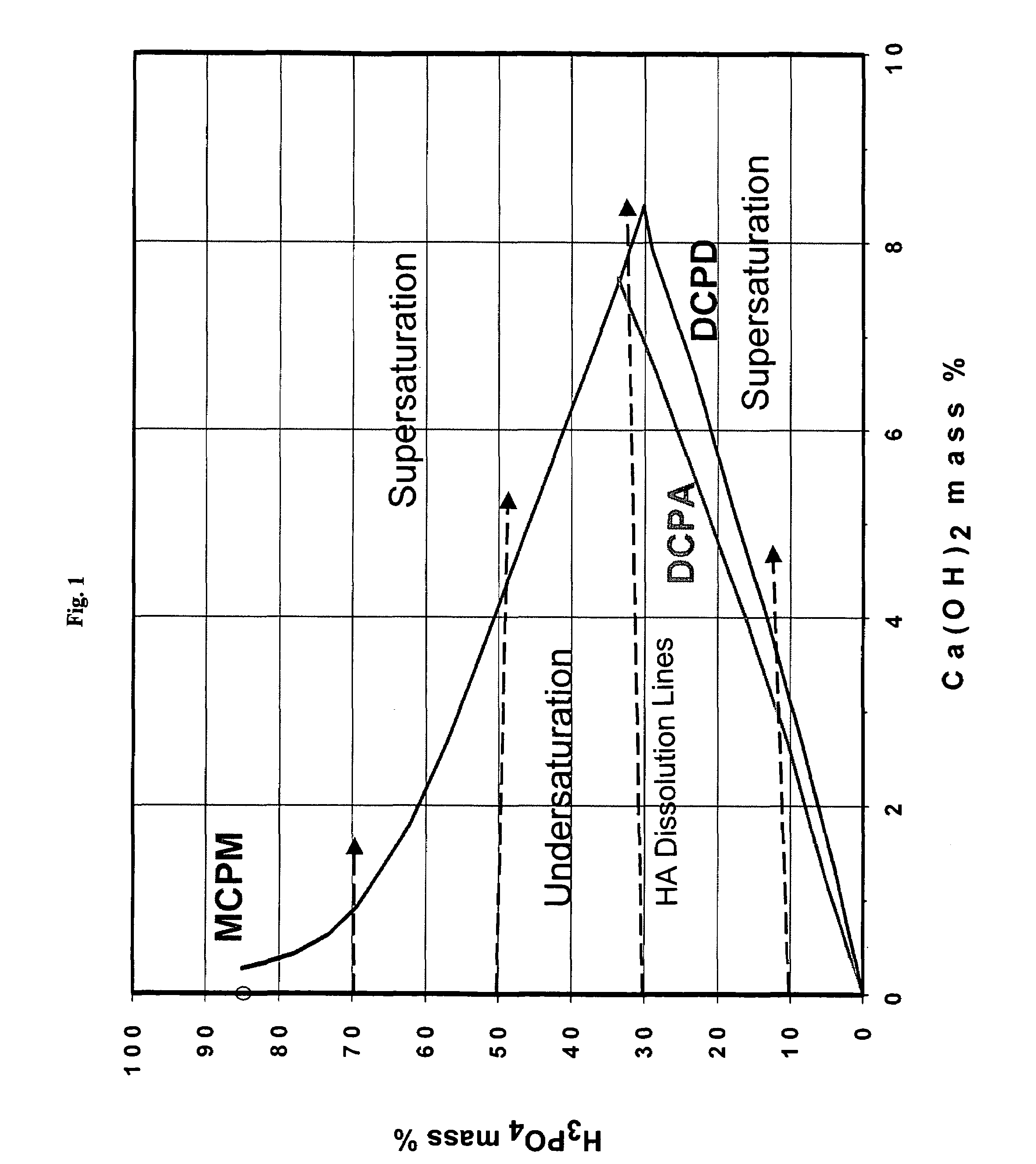

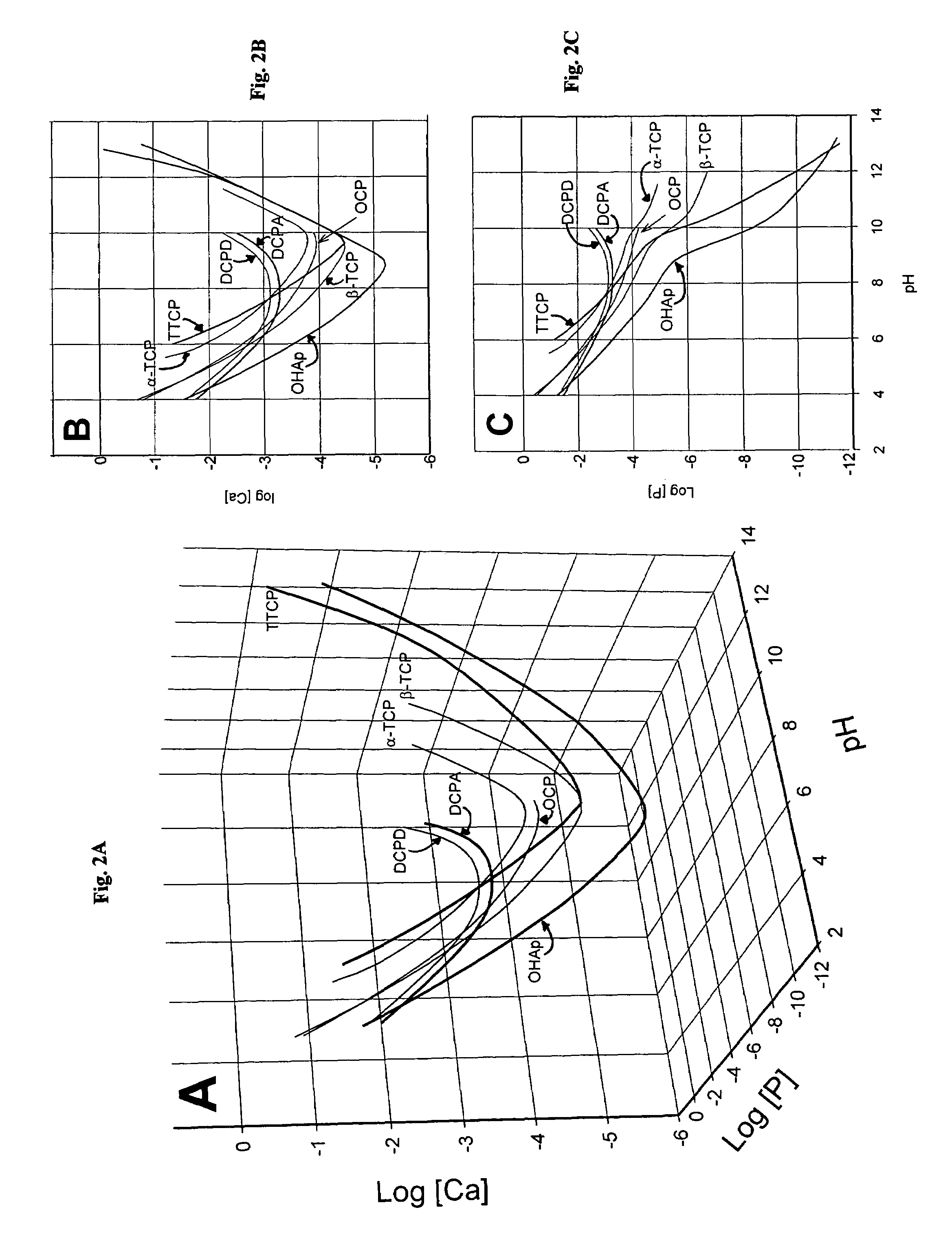

The invention describes a new calcium phosphate cement powder, whose composition can best be described over the Ca / P molar ratio range of 1.35 to 1.40, most preferably 1.39, and whose two components were prepared by wet chemical synthesis procedures. One component is chemically-synthesized, bi-phasic alpha-TCP (Ca3(PO4)2, 95 wt %)+HA (Ca10(PO4)6(OH)2, 5 wt %) powder, while the second component is again a chemically-synthesized, single-phase DCPD (CaHPO4·2H2O) powder. A setting solution (Na2HPO4·2H2O) is used to form a self-setting calcium phosphate cement from the powder mixture. This cement can be used as bone filler or bone substitute in applications, which require higher rates of resorption.

Owner:DR AHMET CUNEYT TAS

Rapid-hardening calcium phosphate cement compositions

InactiveUS7294187B2Easy and fast setupShorten hardening timeBiocideCosmetic preparationsCalcium biphosphateApatite

Owner:ADA FOUND

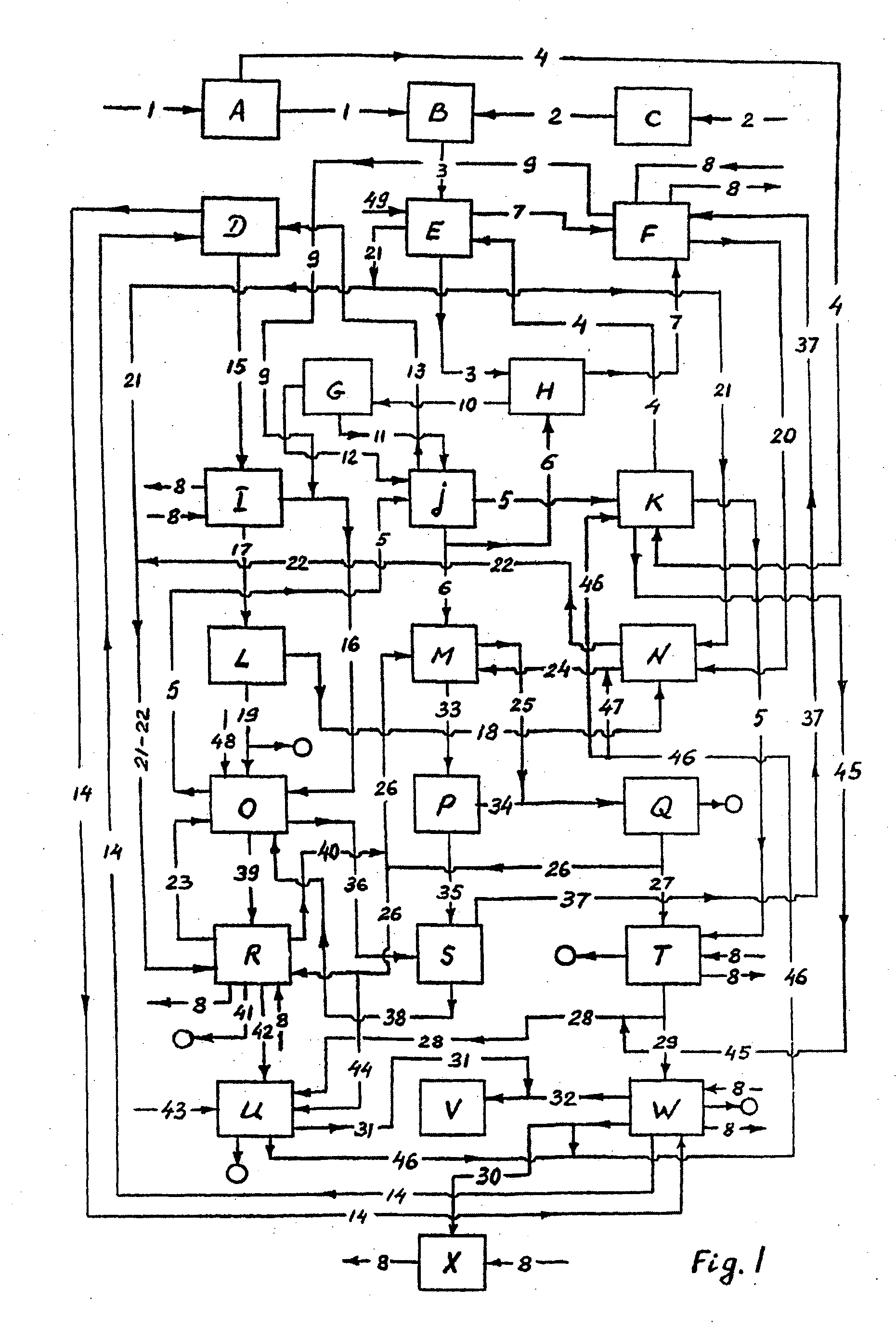

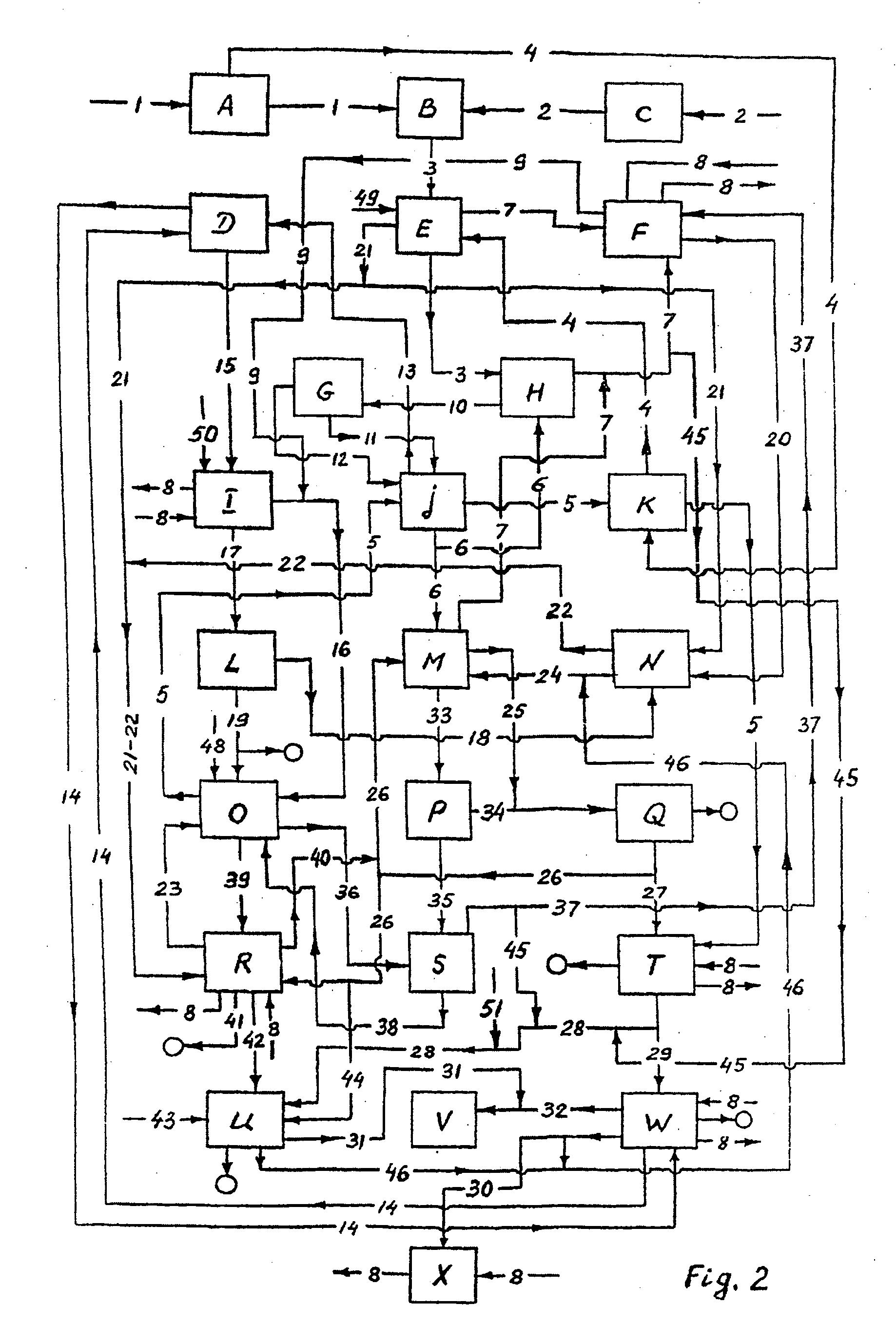

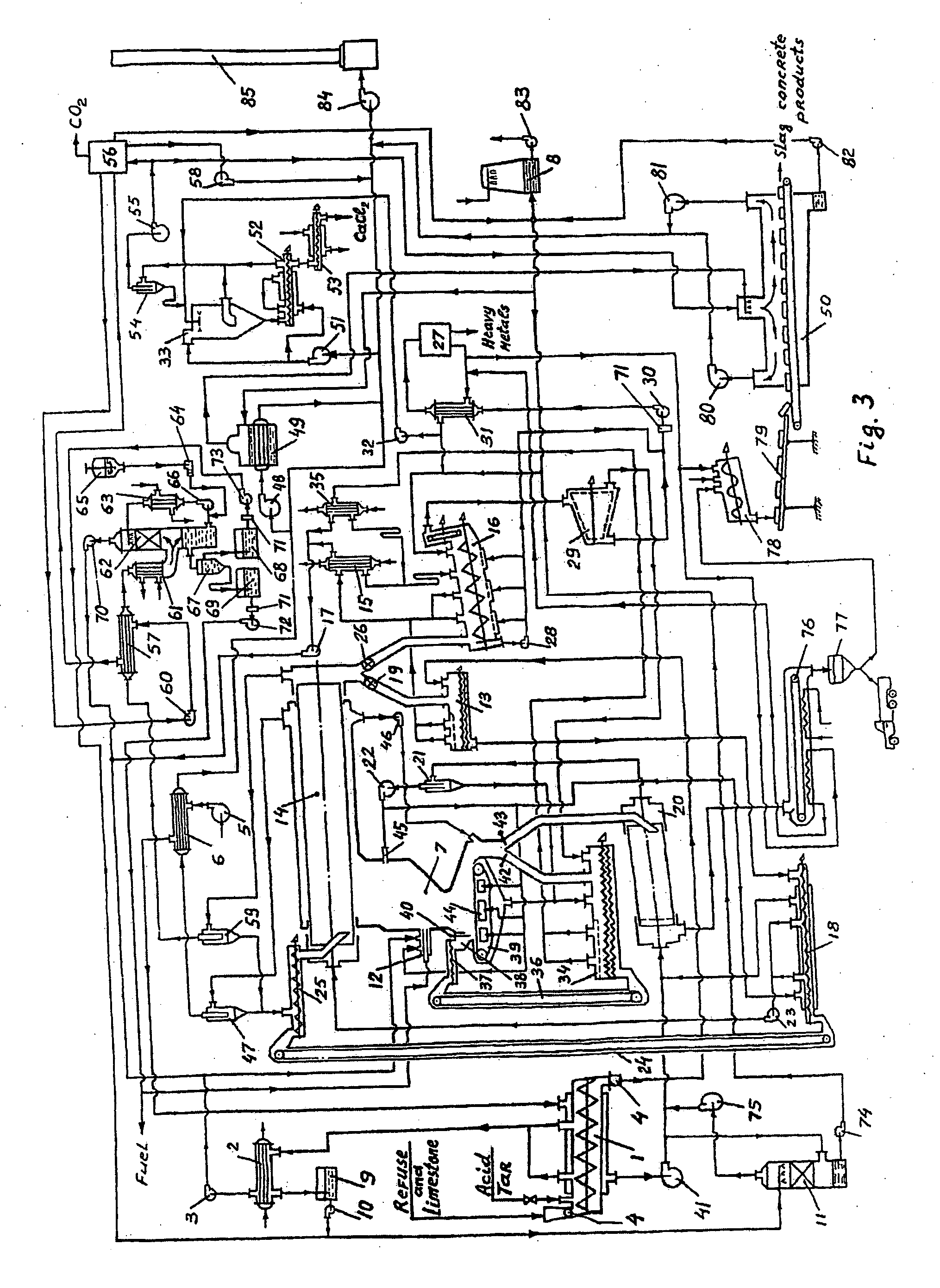

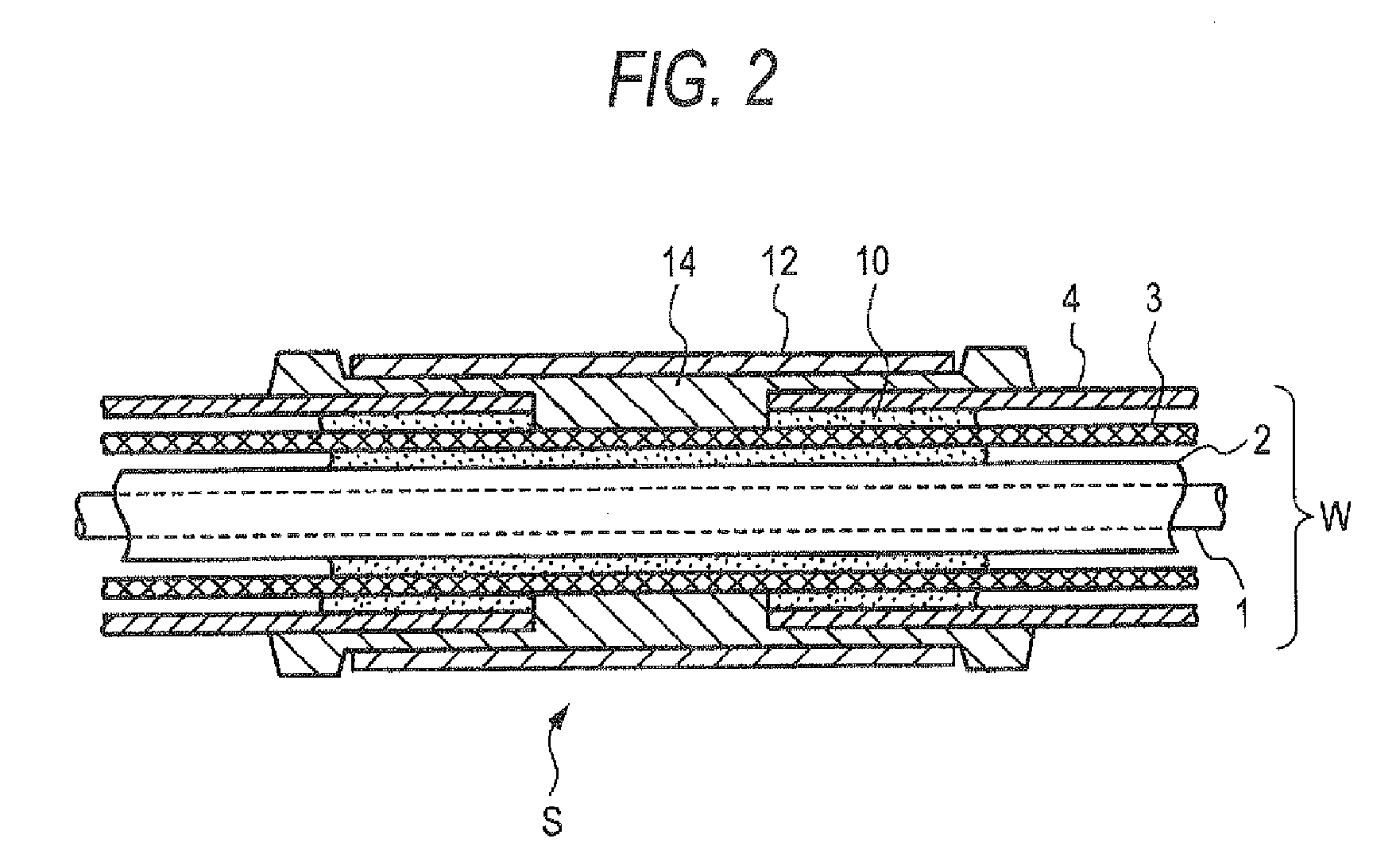

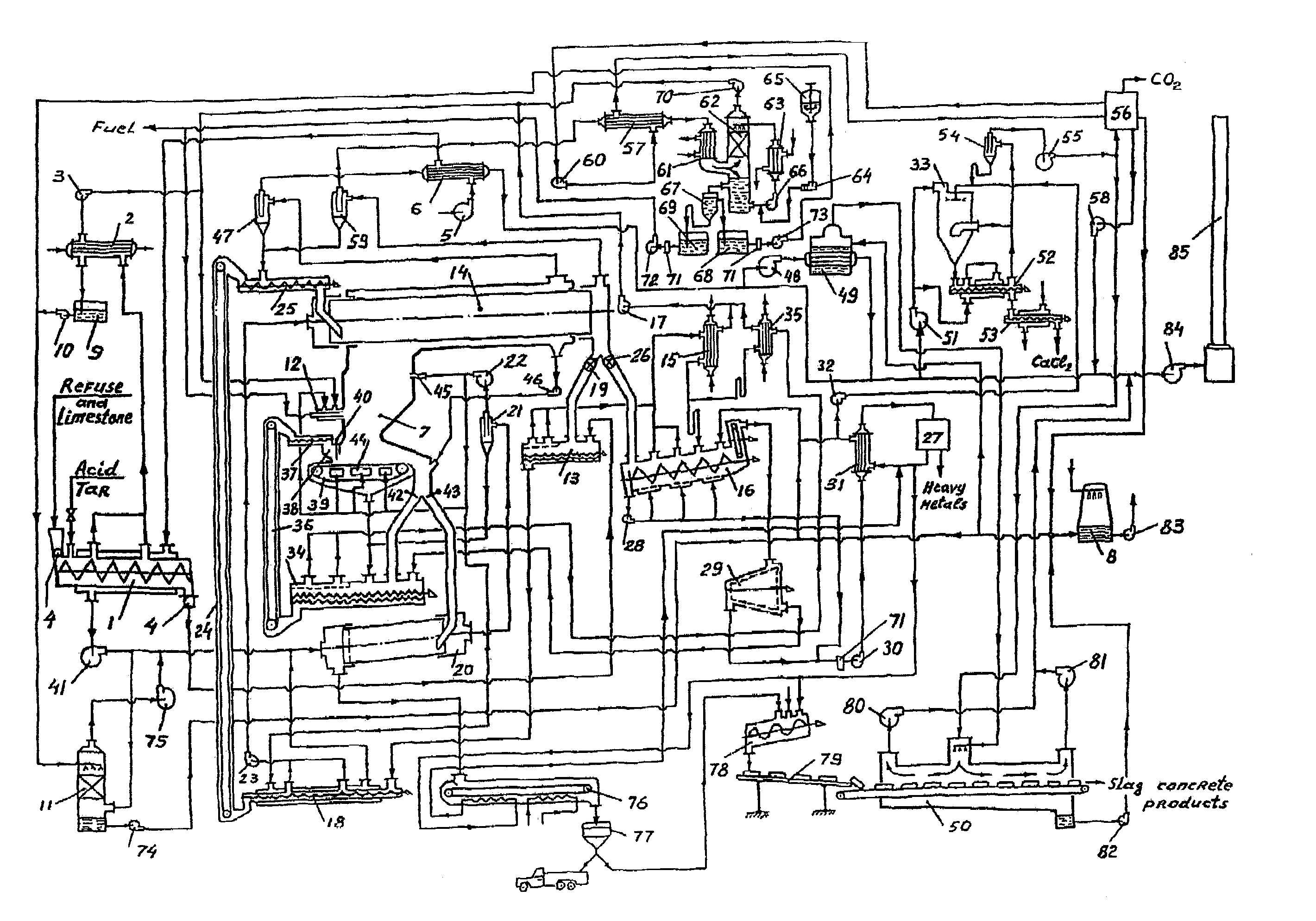

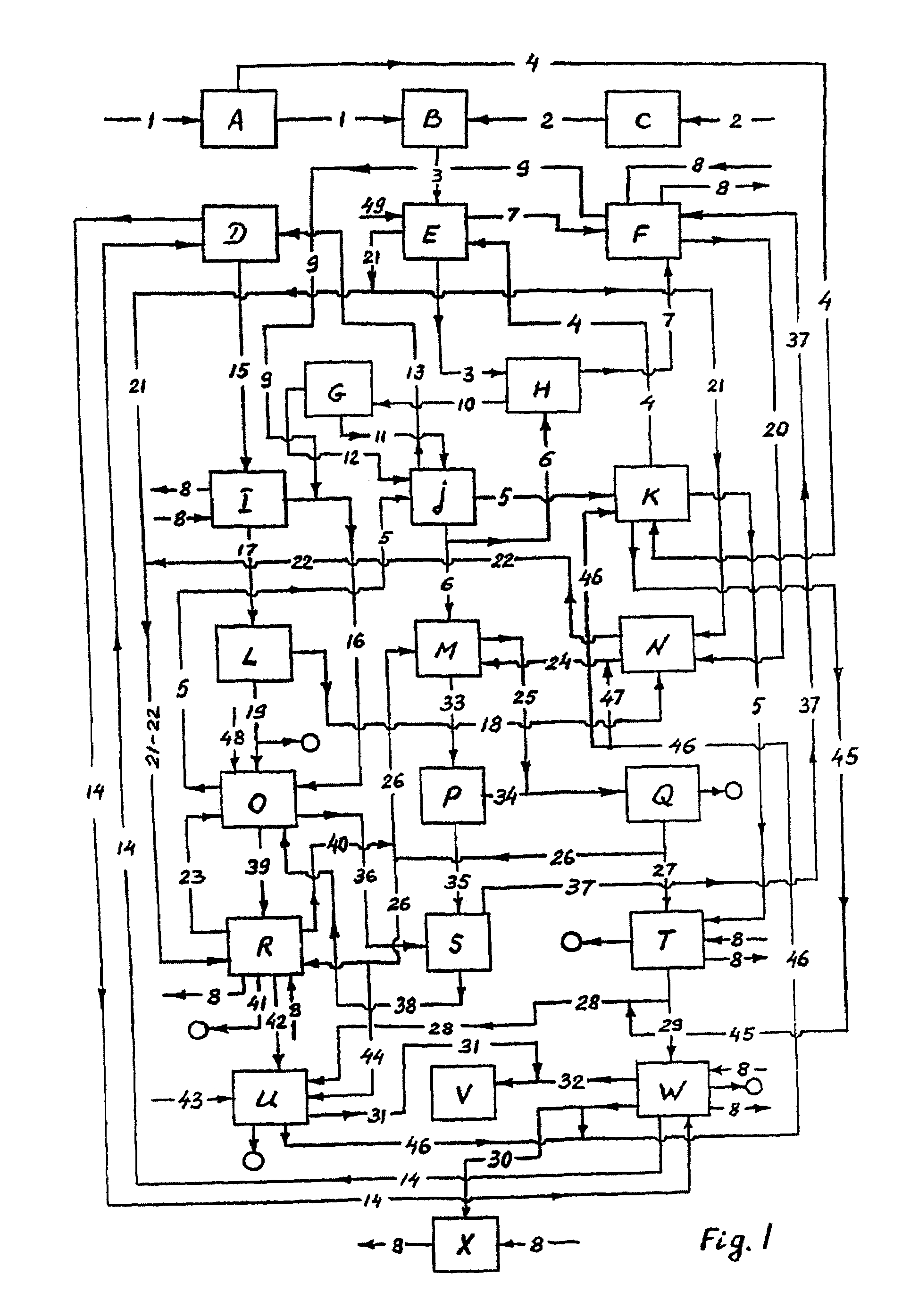

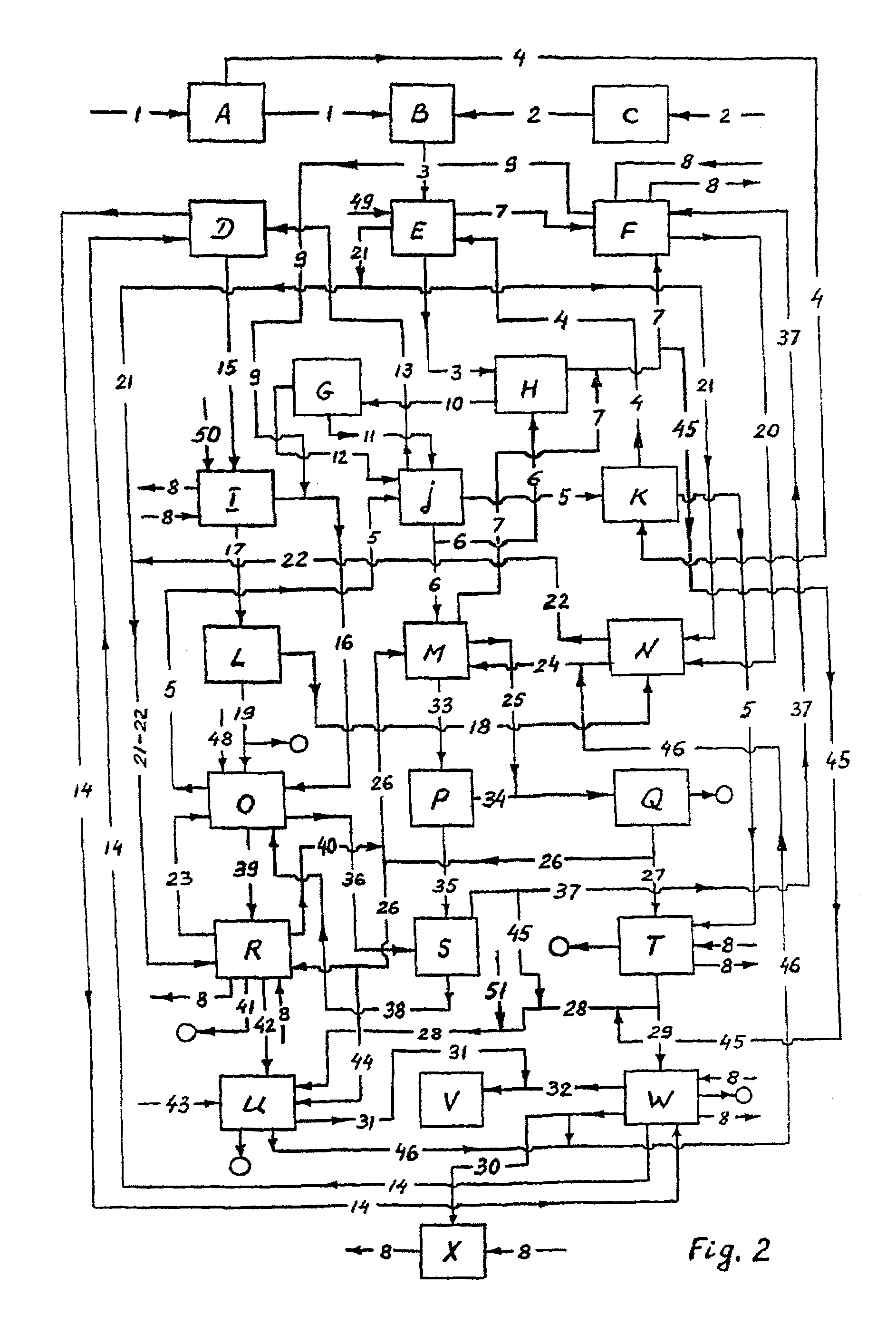

Method and plant for processing waste

ActiveUS20070251433A1Reduce water consumptionReduce the amount requiredSolid waste disposalEnergy inputCombustion chamberSlag

A municipal or like refuse is crushing, mixing with crushed limestone, dry up in two stages—by hot air and by part of solid products of pyrolysis which other part goes on washing out and filtration. Pyrolysis is carried out in two stages—due to heat of the specified part of solid products of pyrolysis and simultaneous neutralization of allocated hydrogen chloride by limestone with reception of calcium chloride, and then due to heat of final chimney gases of the combustion chamber, where in three stages the washed solid products of pyrolysis preliminary drained by a part of combustion chamber slag are burnt together with liquid and gaseous products of pyrolysis. Gas allocated at pyrolysis condense and divide on organic, which is liquid fuel and water phases. Air after a dryer moves to blowing away of light organic substances from the specified water phase, is heated up due to heat of slag and moves in combustion chamber. Washing water goes on allocation of salts of heavy metals and calcium chloride, and slag after molding of a concrete mixture goes to the chamber of thermohumid processing of the slag concrete by a part of damp chimney gases after drying calcium chloride, other part of gases moves to manufacture of liquid carbon dioxide.

Owner:RABINER YURIY

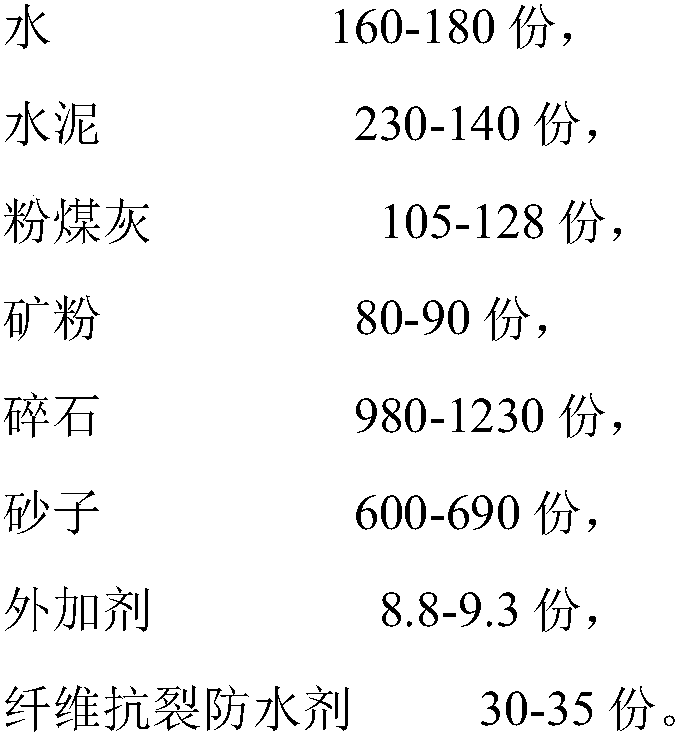

Anti-cracking mass concrete

InactiveCN107777956AMitigation of temperature cracksImprove crack resistanceCrack resistanceMaterials science

The invention discloses anti-cracking mass concrete which is characterized by comprising the following components in parts by weight: 160-180 parts of water, 140-230 parts of cement, 105-128 parts offly ash, 80-90 parts of mineral powder, 980-1230 parts of macadam, 600-690 parts of sand, 8.8-9.3 parts of an admixture and 30-34 parts of a fibrous anti-cracking water-proofing agent. The cracking resistance of the mass concrete is improved by improving the ratio of the components in the concrete.

Owner:天津顺德混凝土工程有限公司

Method for source modification treatment of fluoro-gypsum

The invention discloses a method for source modification treatment of fluoro-gypsum which comprises the steps of, (1) raw material selection, charging composite active triggering agent and alkaline material into the fluoro-gypsum, wherein the mass fraction of each components are, fluoro-gypsum 93-97, composite active triggering agent 1-2, alkaline material 2-5, (2) agitating and mixing, transferring to rainproof yard, stewing, (3) stacking, trickling and maintaining. The modified fluoro-gypsum is applied to cement production.

Owner:WUHAN UNIV OF TECH

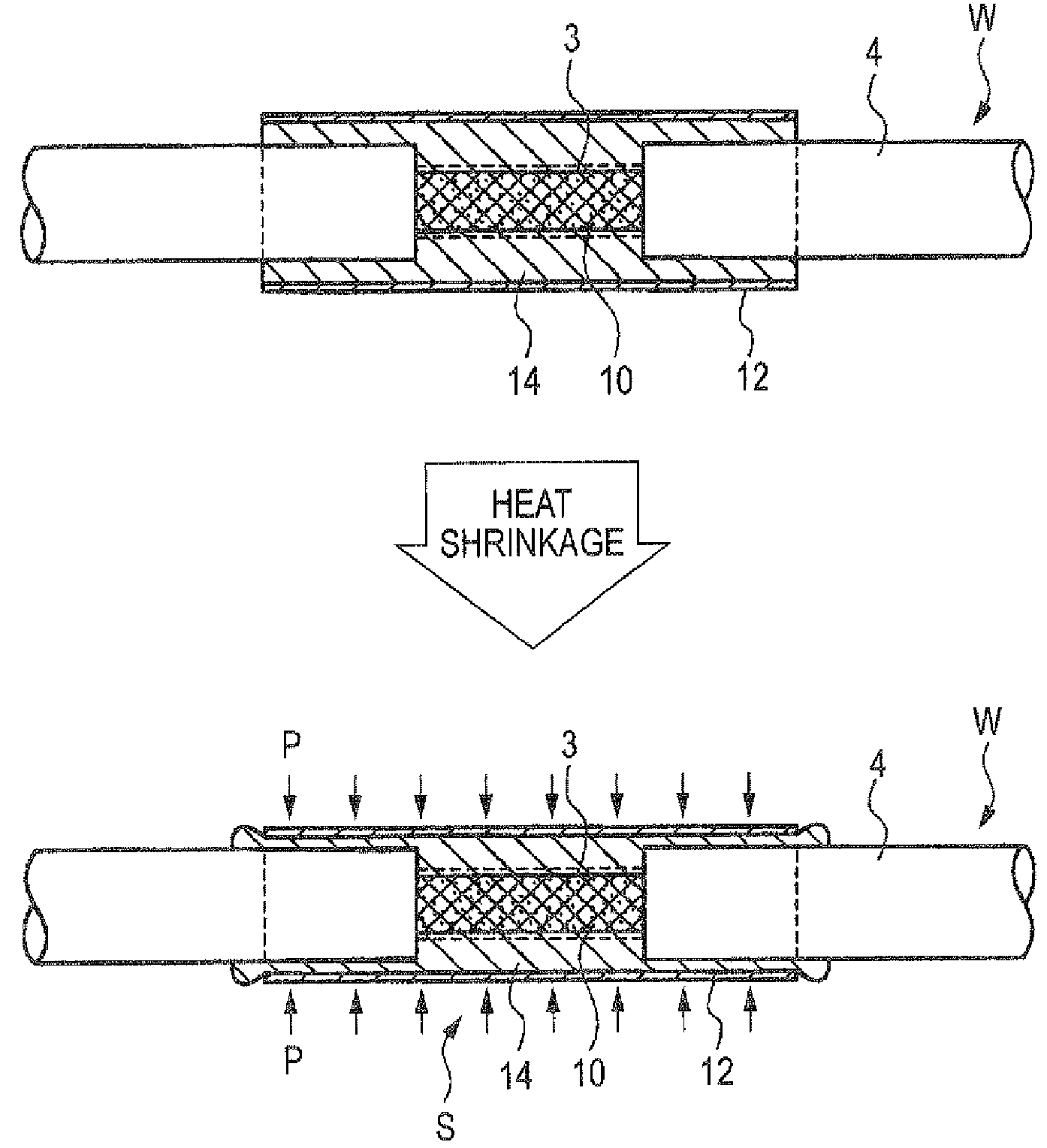

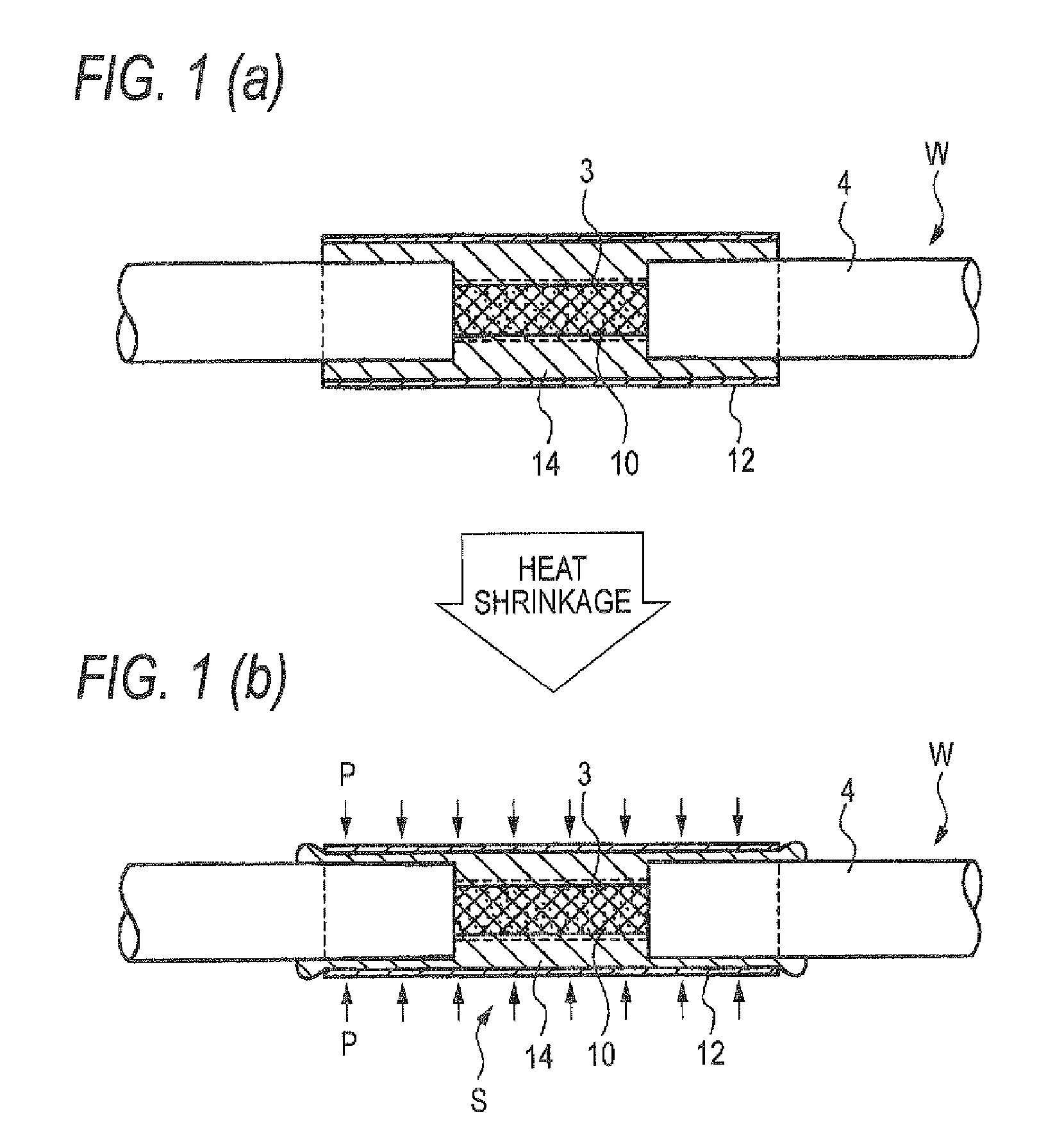

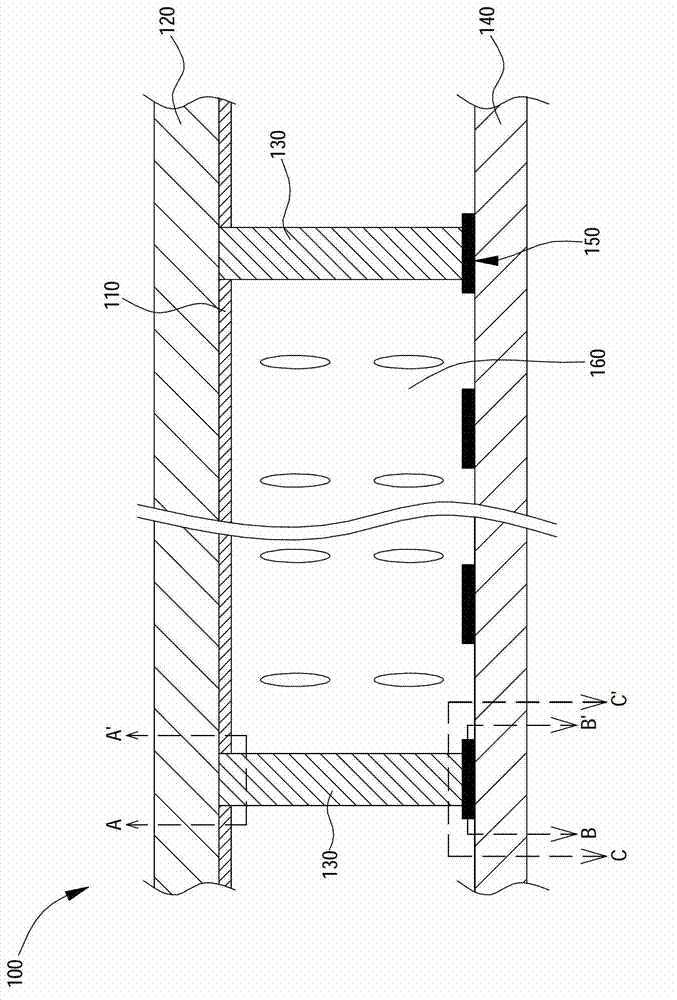

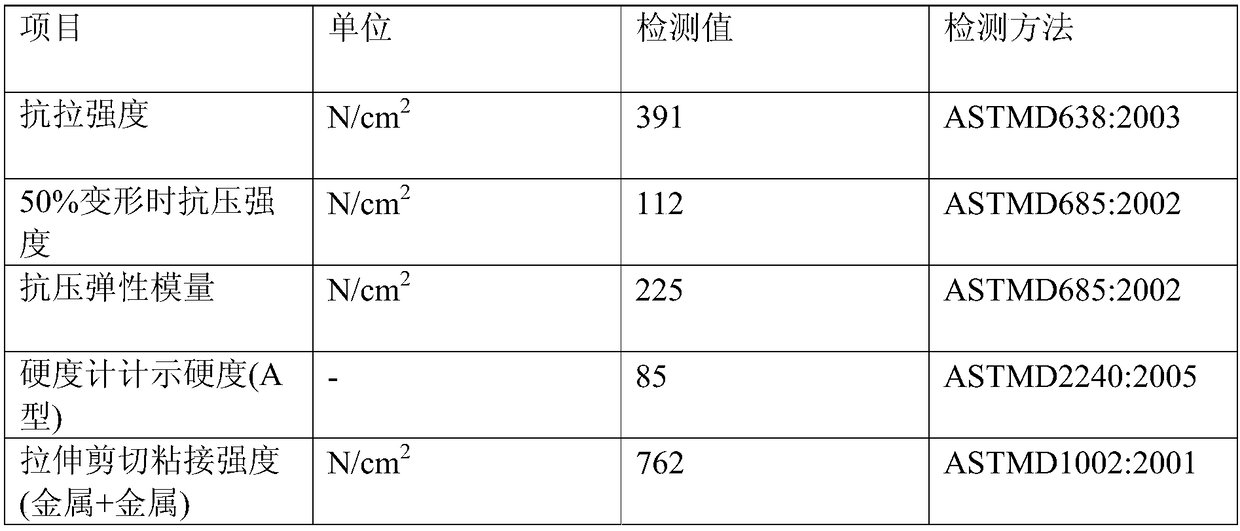

Structure and method for stopping water in shielded electric wire

ActiveUS7612287B2Low costBonding is surelyClimate change adaptationInsulated cablesHot meltElectric wire

To simply provide a water-stopping structures for shielded electric wire in the shielded portion of the wire at a low cost, a water stop structure in a shielded electric wire is comprised by stripping a sheath 4 of the shielded electric wire in the middle part thereof; permeating an adhesive into the exposed shield member 3; overlaying a heat shrinkable tube 12 over the shield member via hot melt 14; and heat shrinking the heat shrinkable tube 12 in a state where both ends of the heat shrinkable tube 12 are overlapped with the outer periphery of the sheath 4.

Owner:YAZAKI CORP

Method and plant for processing waste

ActiveUS7611576B2Reduce water consumptionAccelerate setting and hardeningSolid waste disposalEnergy inputCombustion chamberFiltration

A municipal or like refuse is crushing, mixing with crushed limestone, dry up in two stages—by hot air and by part of solid products of pyrolysis which other part goes on washing out and filtration. Pyrolysis is carried out in two stages—due to heat of the specified part of solid products of pyrolysis and simultaneous neutralization of allocated hydrogen chloride by limestone with reception of calcium chloride, and then due to heat of final chimney gases of the combustion chamber, where in three stages the washed solid products of pyrolysis preliminary drained by a part of combustion chamber slag are burnt together with liquid and gaseous products of pyrolysis. Gas allocated at pyrolysis condense and divide on organic, which is liquid fuel and water phases. Air after a dryer moves to blowing away of light organic substances from the specified water phase, is heated up due to heat of slag and moves in combustion chamber. Washing water goes on allocation of salts of heavy metals and calcium chloride, and slag after molding of a concrete mixture goes to the chamber of thermohumid processing of the slag concrete by a part of damp chimney gases after drying calcium chloride, other part of gases moves to manufacture of liquid carbon dioxide.

Owner:RABINER YURIY

Handicraft clay sculpture material and preparation method thereof

InactiveCN104261794AGuaranteed patch improvementsThe formula is scientific and reasonableOperabilityChloride

The invention discloses a handicraft clay sculpture material. The handicraft clay sculpture material is prepared from the following raw materials in parts by weight: 2-3 parts by weight of borax, 1-2 parts by weight of ammonium dihydrogen phosphate, 4-6 parts by weight of magnesium oxide, 0.5-1 part by weight of aluminum chloride, 0.5-1 part by weight of sodium humate, 50-60 parts by weight of kaolin, 10-20 parts by weight of calcium carbonate, 30-40 parts by weight of quartz powder, 10-20 parts by weight of white mica powder, 1-3 parts by weight of gypsum, 0.5-1 part by weight of hydroxyethyl cellulose and water, wherein the total amount of the water is the required amount for realizing a dough-like plastic state of a product. The handicraft clay sculpture material disclosed by the invention can be used under any conditions, has the advantages of reasonable and scientific formula, easiness in obtainment of the raw materials, low cost and easiness in dispersion and stirring, the surface of a work is less prone to cracking in a hardening process and is dense and smooth, and the handicraft clay sculpture material can be widely used in the fields of sculptures, clay sculptures, models and the like. The invention further discloses a preparation method of the handicraft clay sculpture material, and the preparation method has the advantages of simple process steps and strong operability.

Owner:HUANGHE S & T COLLEGE

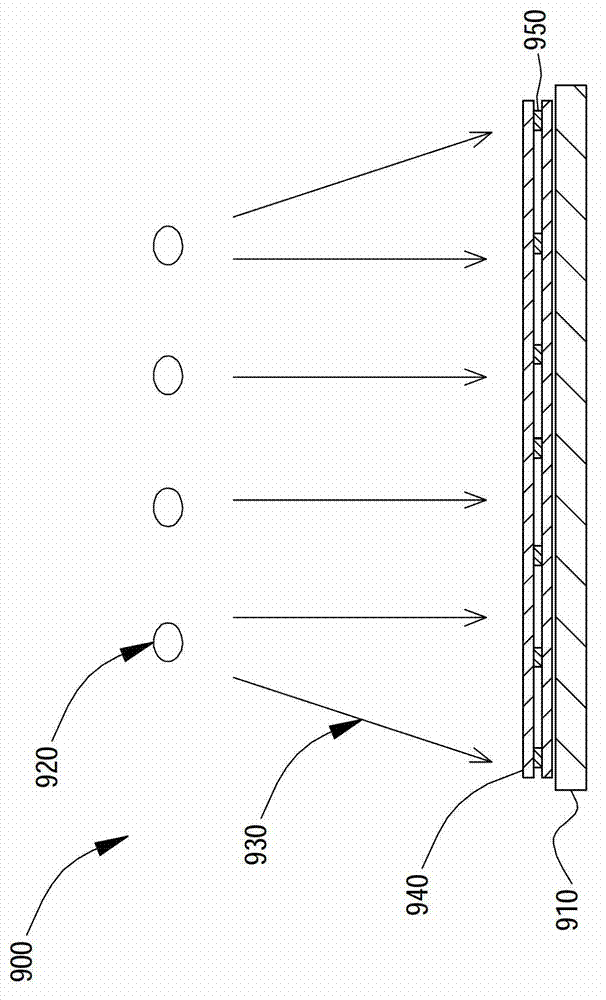

Method and device for hardening frame glue of liquid-crystal display panel

ActiveCN102830552AIncrease the areaIncrease reaction rateNon-linear opticsLiquid-crystal displayUltraviolet lights

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Tap hole reclaimed material recycled quick-dry anti-explosion castable

The invention discloses a tap hole reclaimed material recycled quick-dry anti-explosion castable which comprises the following components in parts by mass: 15-30 parts of electrically-fused dense corundum, 5-10 parts of brown fused alumina fresh material, 3-5 parts of brown fused alumina reclaimed material, 5-10 parts of mullite fresh material, 3-5 parts of mullite reclaimed material, 4-8 parts of silicon carbide, 4-6 parts of graphite, 2-5 parts of binding agent which is a mixture of pure calcium aluminate cement and nanometer silica-alumina gel powder, 3-8 parts of polycarboxylate superplasticizer, and 0.5-2 parts of compound anti-explosion agent. The tap hole reclaimed material recycled quick-dry anti-explosion castable has the beneficial effects that by adopting brown fused alumina reclaimed material and mullite reclaimed material, waste materials can be sufficiently utilized so as to reduce the cost of industrial products in the iron and steel industry, the condensation time can be effectively controlled by specially proportioning aggregate materials with different properties and particles and adding additional additives, the hardening time of the castable can be shortened, the quick-dry anti-explosion properties are good, the construction efficiency is improved, on-schedule tapping of a blast furnace can be guaranteed, and the service life of the castable can be prolonged.

Owner:CHANGXING MINGTIAN FURNACE CHARGE

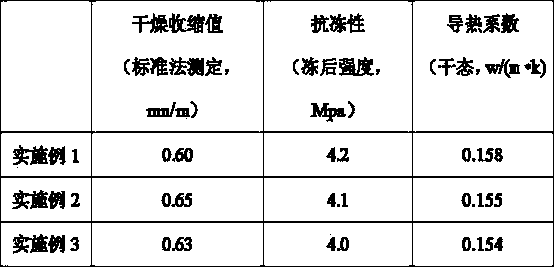

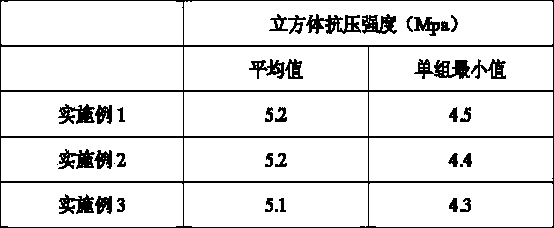

Molybdenum tailing aerated concrete block and manufacturing method thereof

ActiveCN103382124ARealize comprehensive utilizationReduce outputSolid waste managementCeramicwareCompressive resistanceThermal insulation

The invention belongs to the field of building materials and particularly relates to a molybdenum tailing aerated concrete block and a manufacturing method thereof. The molybdenum tailing aerated concrete block comprises, by weight, 65-78% of molybdenum tailings, 12-18% of quick lime, 5-18% of cement, 2.92-4.91% of gypsum and 0.08-0.09% of aluminum paste. The manufacturing method includes the following steps of (1) pre-processing raw materials; (b) crushing and grinding the quick lime to obtain quick lime powder; (c) preparing 8-10% aluminum paste suspension liquid by using the aluminum paste; (2) dosing and pouring; (3) precuring; (4) demolding and cutting; (5) steaming. The molybdenum tailing aerated concrete block is light in texture and good in thermal insulation property, has high compressive strength, overcomes the defect that a powder ash aerated concrete block is low in compressive strength, can replace clay bricks completely and is wide in use range. The method is simple in process and low in product energy consumption.

Owner:ZHEJIANG TAIZHENG MOLYBDENUM IND DEVCO

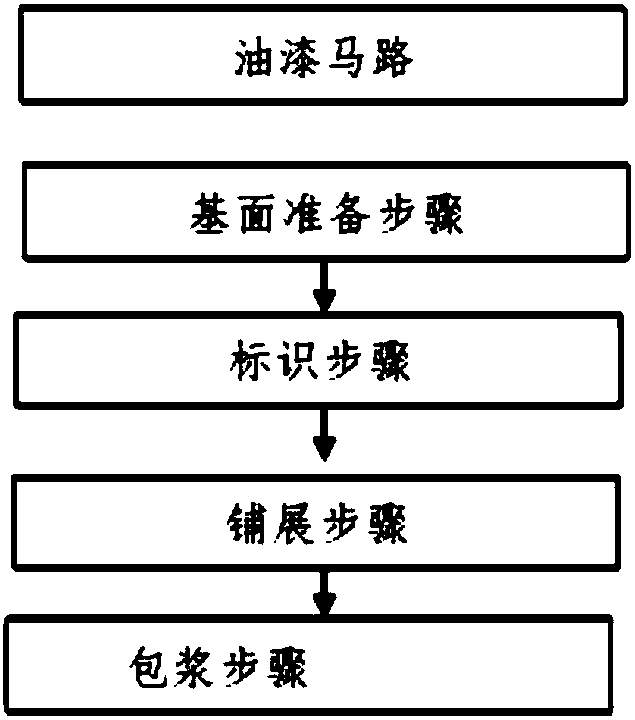

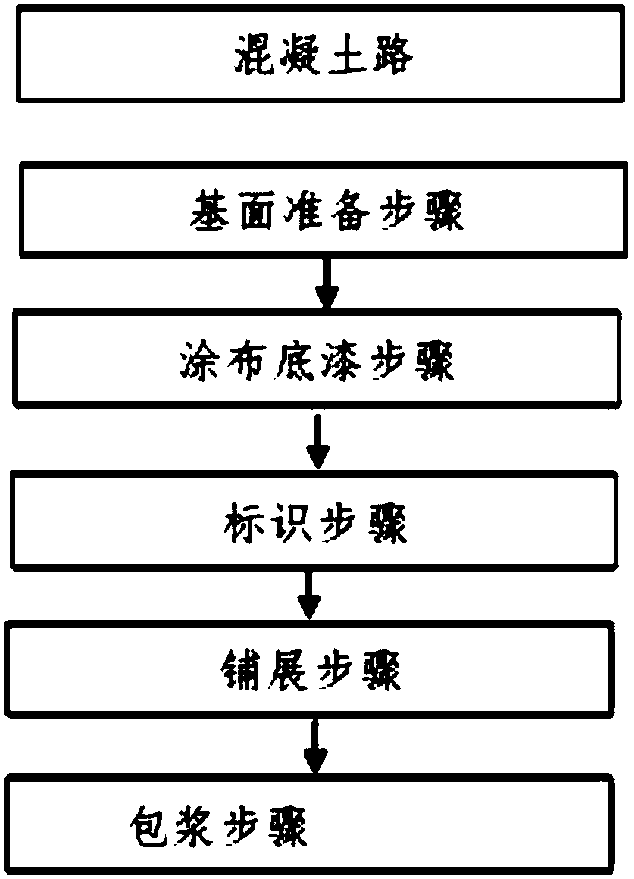

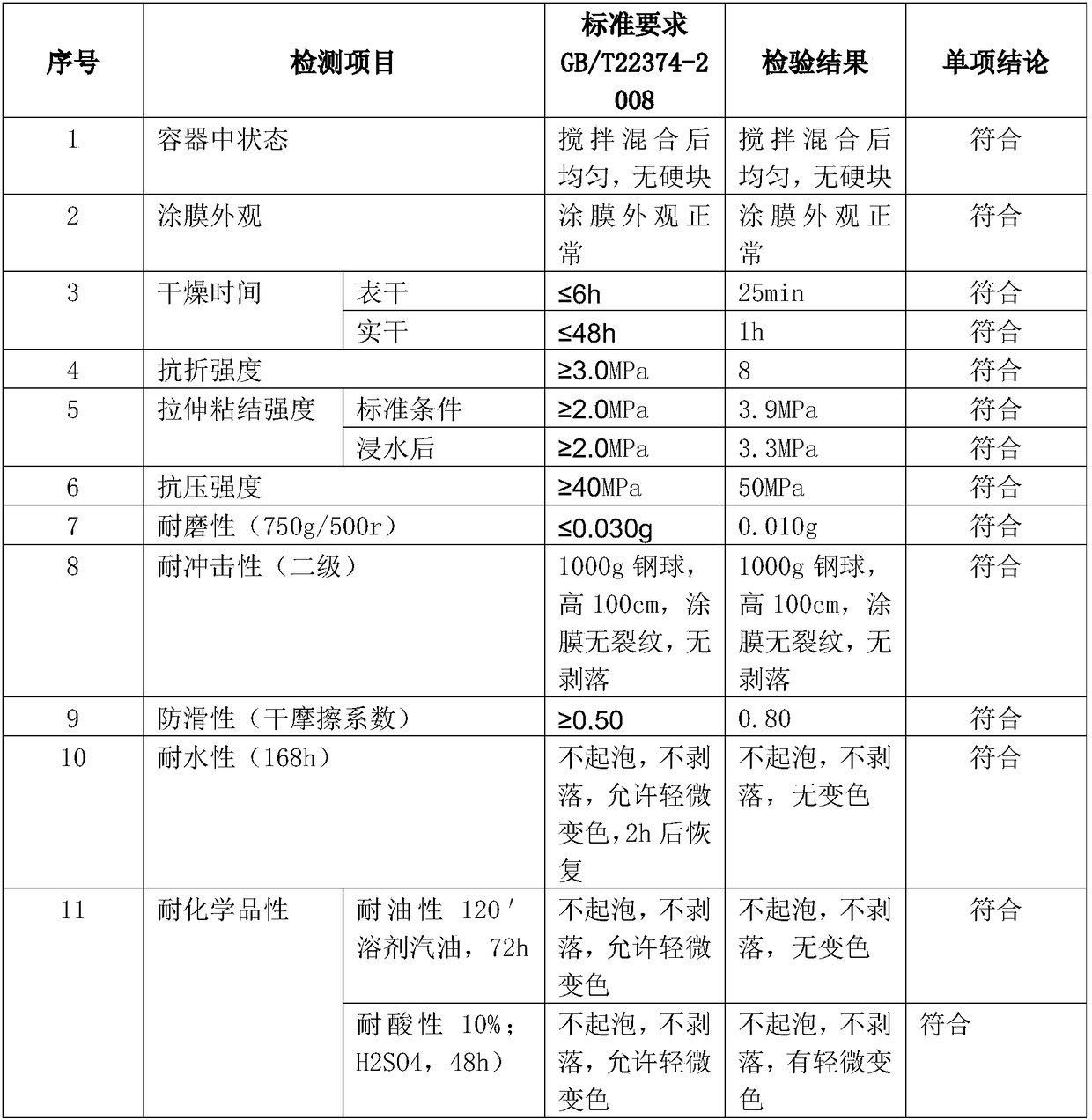

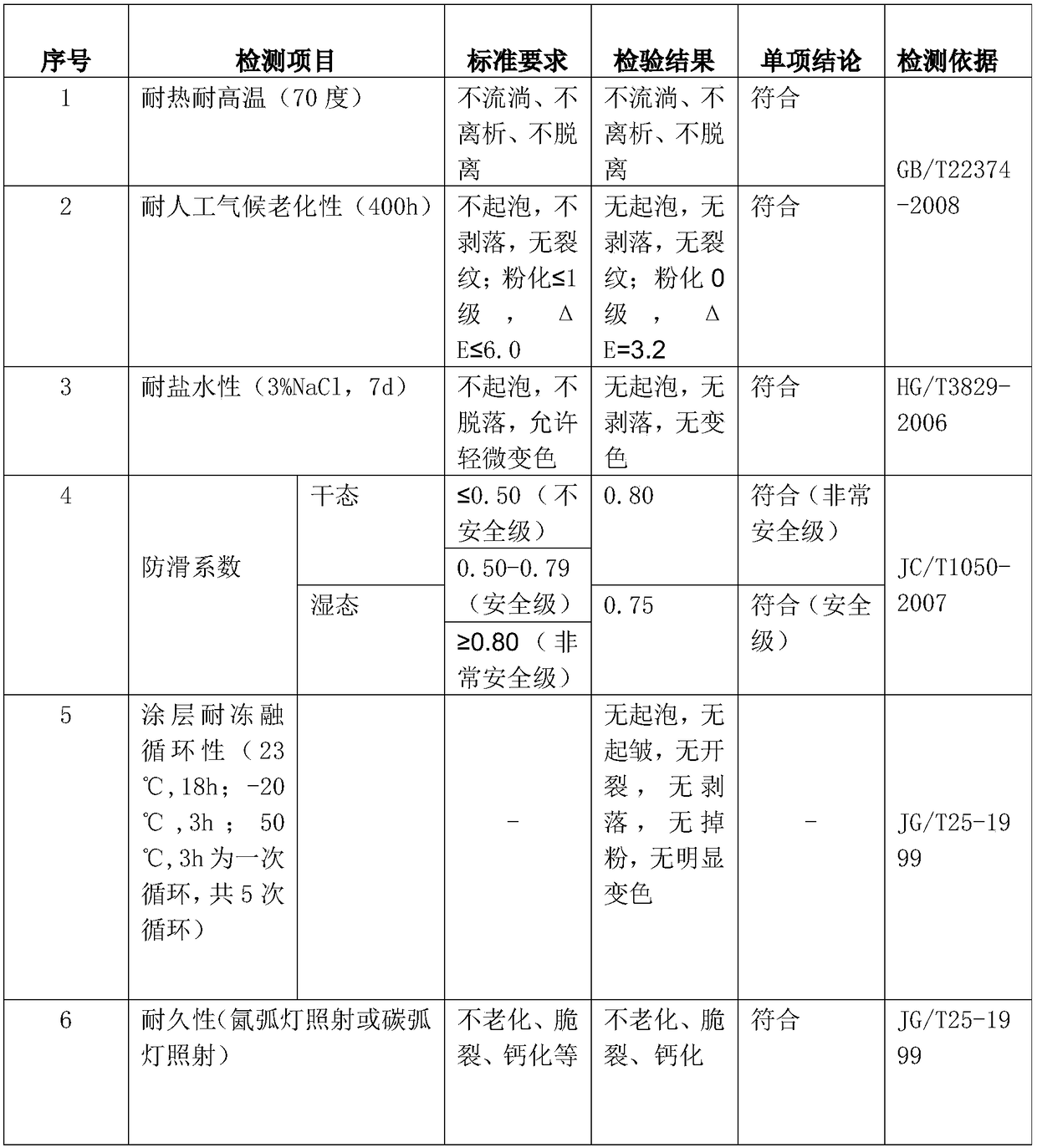

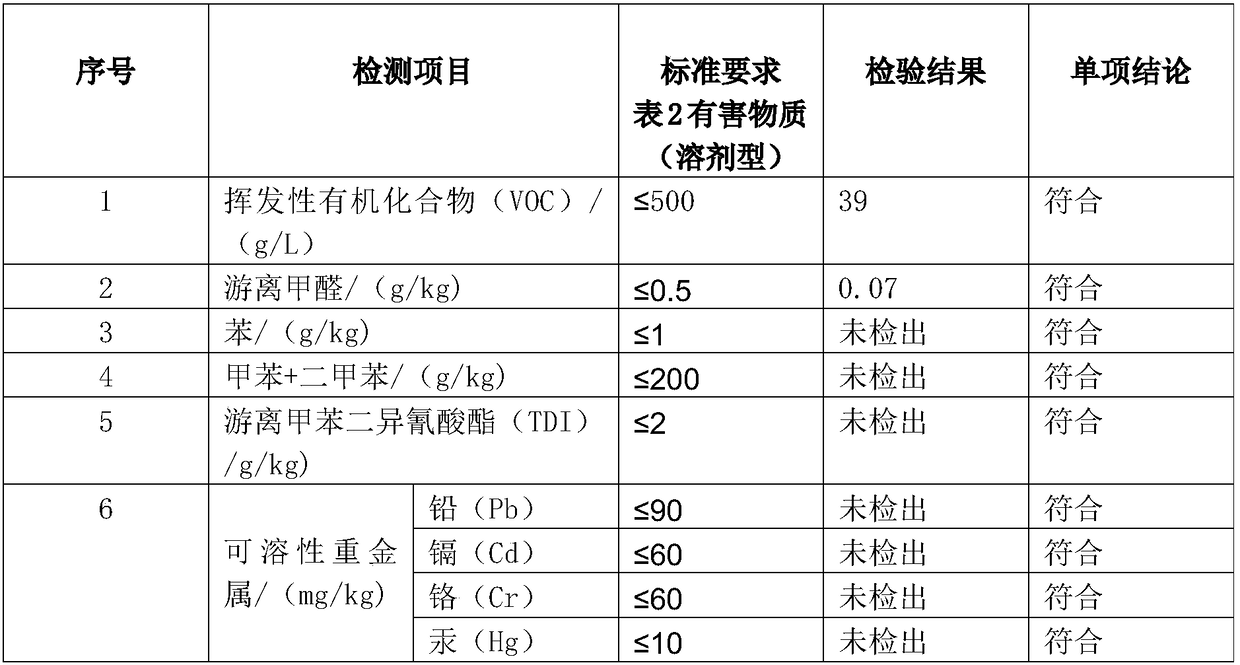

Anti-skid colored paving material for roads, and preparation method and construction process of paving material

InactiveCN108546383ALong construction periodAdvantage manufacturing methodSidewalk pavingsPaving detailsPolymethyl methacrylateDrying time

The invention provides an anti-skid colored paving material for roads, and a preparation method and a construction process of the paving materials. The anti-skid colored paving material for roads comprises the following components in parts by weight: 40-50 parts of polymethyl methacrylate resin, 10-20 parts of calcium carbonate, 1-5 parts of nano silicon dioxide, 2-5 parts of inorganic pigment, 5-15 parts of bauxite and 5-8 parts of quartz sand. The anti-skid colored paving material for roads provided by the invention has a shortened hardening time, and the bauxite with excellent acid resistance, alkali resistance and chemical resistance is used as the main material, so that an original working procedure of additional removal of anti-skid aggregates can be omitted, and the problems that the aggregate easily peels off from the paving material and uniform spreading is difficult due to uneven aggregate shape existed in the additional removal of the aggregates can be solved. Pre-mixing iscarried out for coating the aggregate with the quartz sand, the aggregate does not fall off easily, the drying time is faster, the traffic condition can be reached only in one hour, and the traffic pressure is greatly reduced.

Owner:TIANJIN BAISITE NEW MATERIAL TECH

Concrete early strength agent and preparation method thereof

The invention discloses a concrete early strength agent and a preparation method thereof. The concrete early strength agent is prepared from the following components in parts by weight: 1-3 parts of sodium chloride, 1-3 parts of sodium nitrite, 10-20 parts of sodium sulfate, 3-6 parts of calcium chloride, 2-6 parts of urea, 5-15 parts of methacrylic acid, 1-3 parts of silane, 1-5 parts of calcium gluconate, 1-5 parts of triisopropanolamine, 5-10 parts of fatty glyceride, 50-80 parts of polycarboxylate superplasticizer and 2-4 parts of finely grinded cement stone. The concrete early strength agent has the beneficial effects of rapidly drying concrete even in a low-temperature environment.

Owner:温州市环美建筑工程有限公司

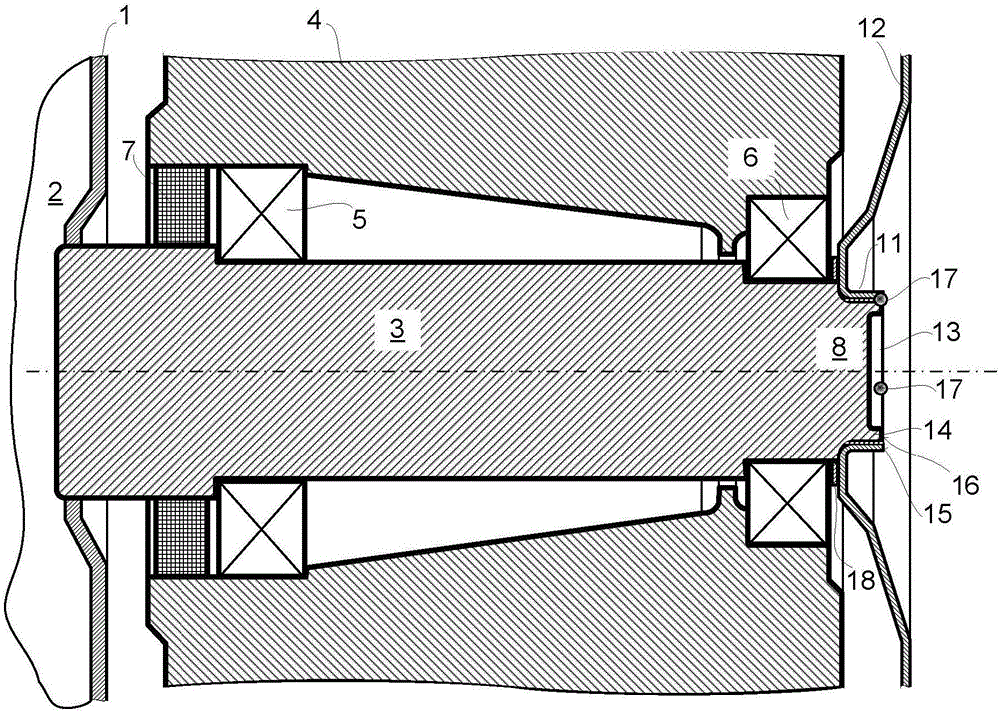

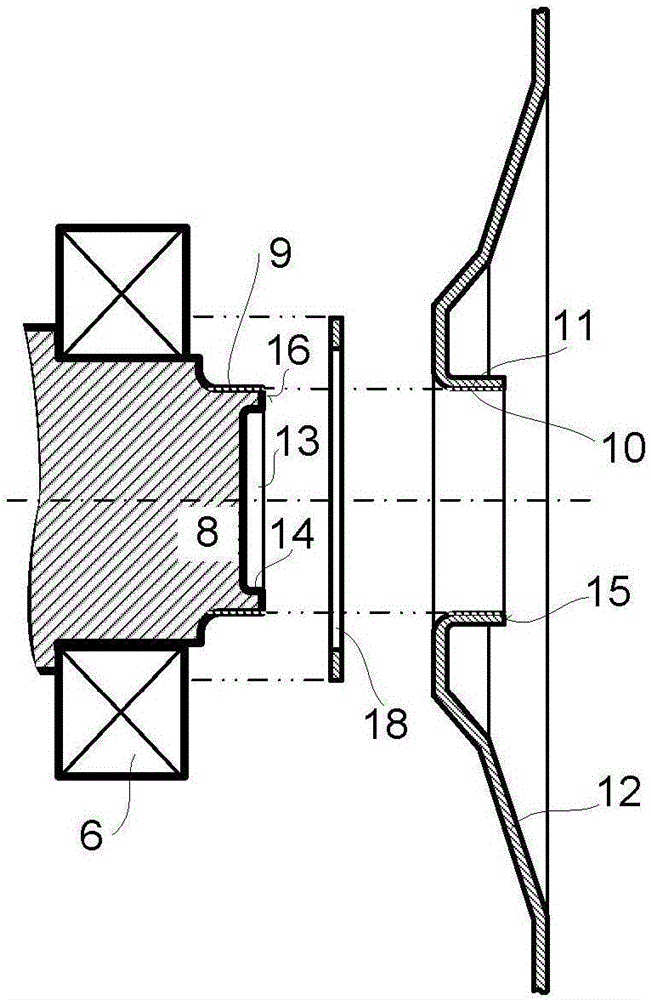

Domestic laundry treating machine with a washing drum driven by an electric motor and mounting method

ActiveCN106414833AFirmly connectedProtected from high heat inputOther washing machinesTextiles and paperDrive shaftEngineering

The domestic laundry treating machine according to the invention is preferentially a front-loading washing machine. Said machine has a washing drum (2) driven by an electric motor and a belt drive between the washing drum (2) and the electric motor, in which the washing drum (2) is firmly connected to a drive shaft (3), and the drive shaft (3) is connected to a pulley (12) of the belt drive, wherein the pulley (12) is provided with a flange (11) having an internal thread (10) in the region of the connection to the drive shaft (3). In addition, the end (8) of the drive shaft (3) facing away from the washing drum (2) is preferentially provided with a shallow pot-like depression (13) and has an external thread (9) engaging in the internal thread (10). Moreover, both threads (9, 10) are connected non-detachably, in particular bonded, to one another.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

Building material and preparation method thereof

The invention provides a building material and a preparation method thereof, and relates to the field of materials. The building material comprises the following raw materials in parts by weight: 11 parts of asphalt, 15 parts of bauxite, 10 parts of tricalcium silicate, 6 parts of polypropylene resin, 8 parts of quartzite, 7 parts of calcium acetate, 12 parts of abandoned polyethylene foam plastic, 10 parts of abandoned polyurethane foam plastic, 13 parts of vermiculite, 8 parts of coal ash, 14 parts of activated carbon, 13 parts of bamboo carbon, 7 parts of expanded and vitrified microspheres, 15 parts of glass wool, 7 parts of ceramic fiber, 8 parts of polyarmide fiber, 14 parts of a light stabilizer, 0.4 parts of a heat stabilizer, 0.5 parts of a foaming agent, 0.4 parts of a retarder, 0.7 parts of a water reducer and 9 parts of water. The preparation method comprises the following preparation steps: (1) weighting of raw materials; (2) grinding of the raw materials into powder; (3) heating; (4) calcinating; (5) smashing; (6) stirring; (7) pressure forming; (8) drying. According to the building material, the problem of defects of the existing building material when the existing building material is applied to a building with high requirements for fracture resistance and compression resistance strength, heat insulation, environmental protection and energy saving is solved.

Owner:河南颇文商贸有限公司

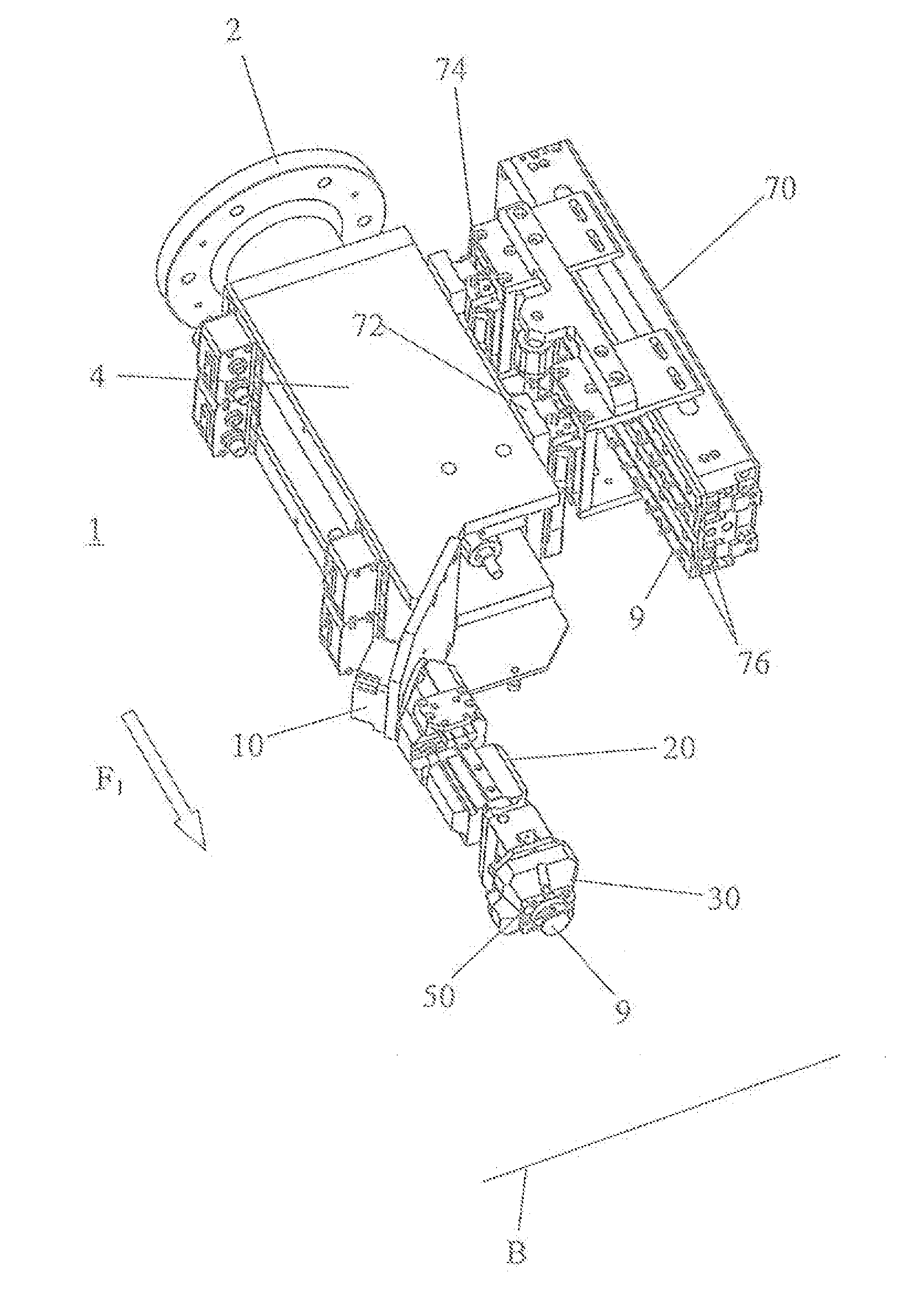

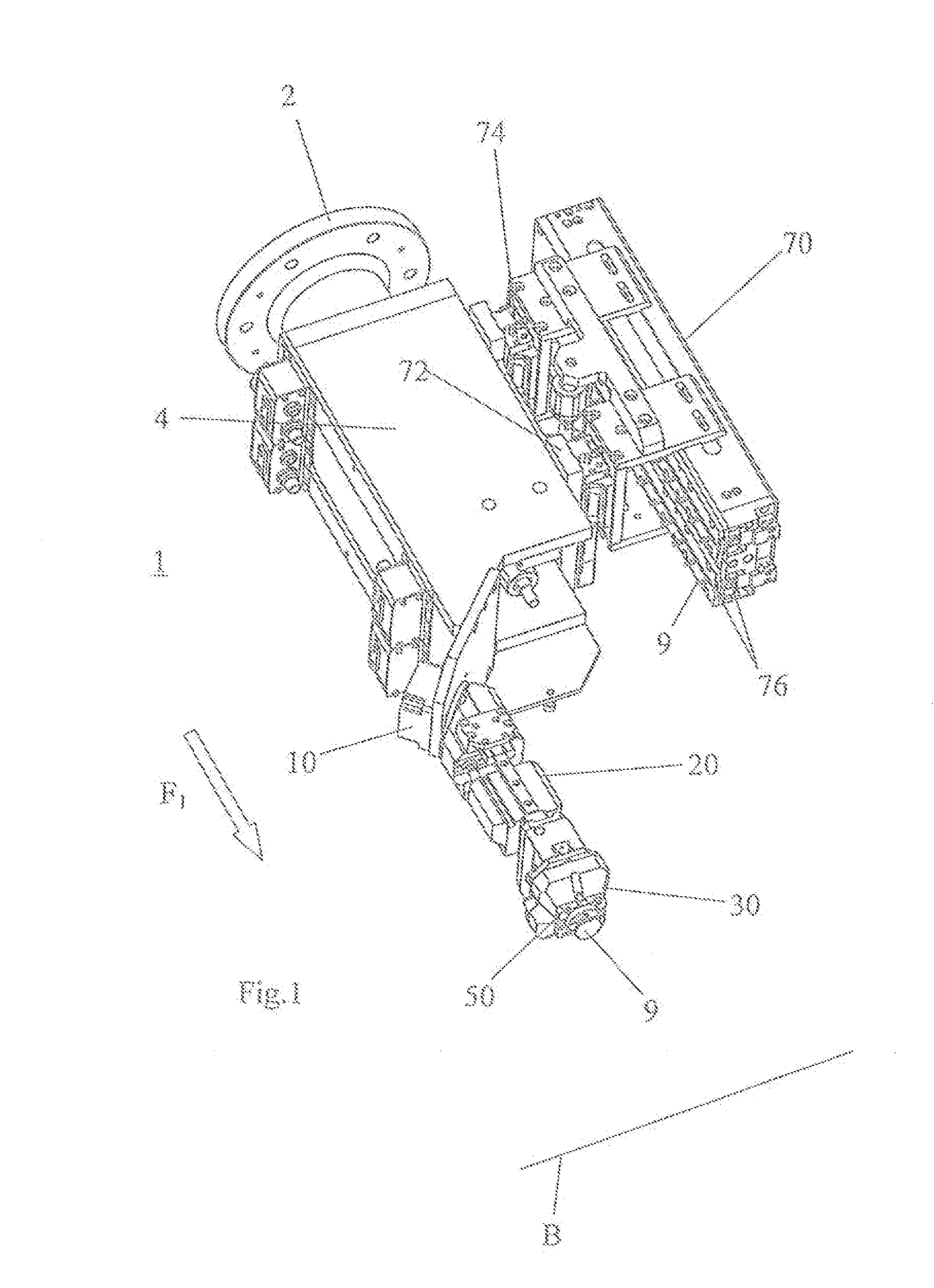

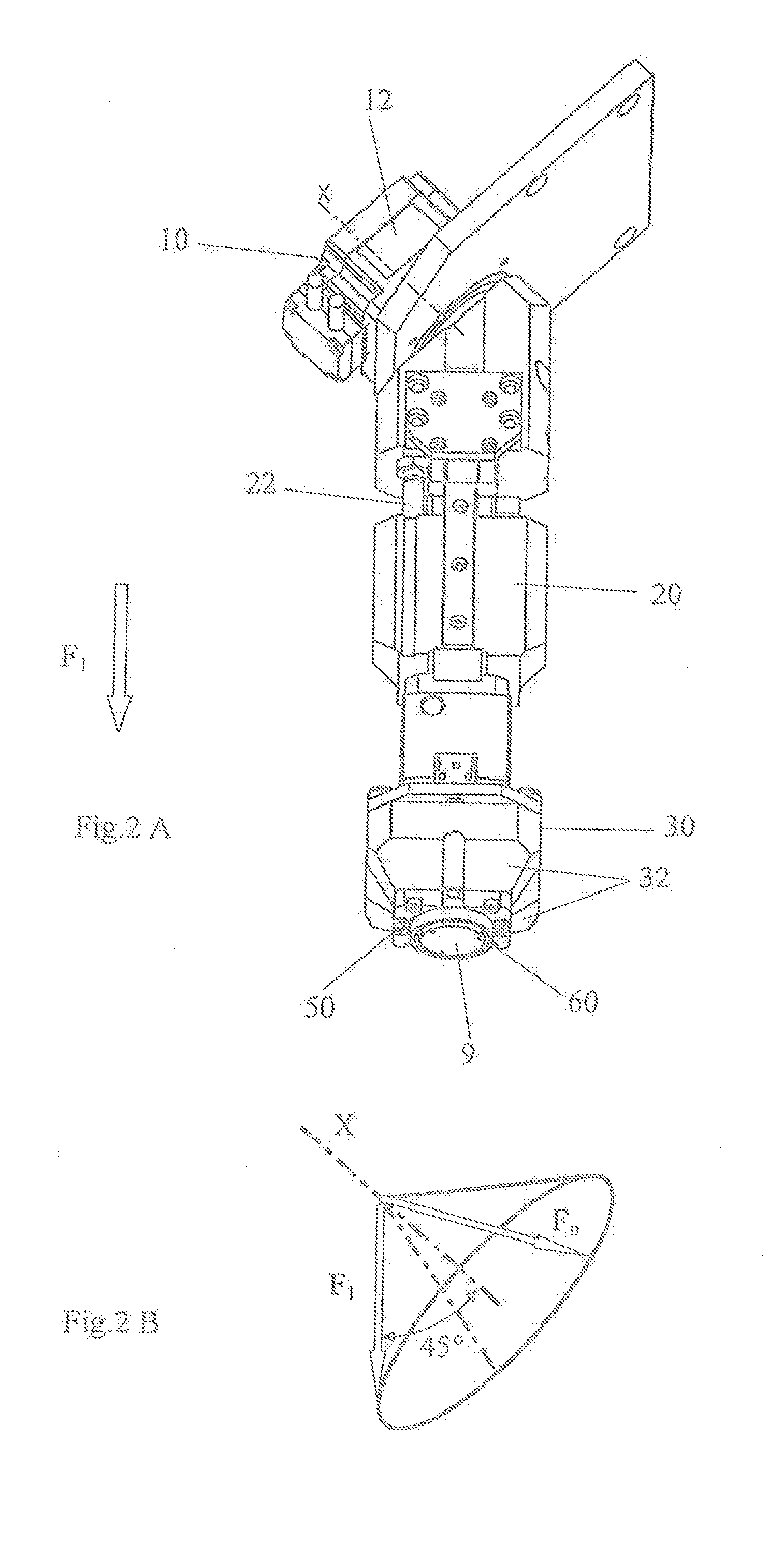

Jointing head for fastening element, and a fastening method

InactiveUS20140020814A1Dampens mechanicalLess vulnerableMechanical working/deformationSlide fastenersMechanical engineeringLight source

The present invention comprises a jointing head 1, a robot with this jointing head 1, and a fastening method for affixing fastening elements 9 to a component surface B. The jointing head 1 comprises a gripper 30 that removes fastening elements 9 from a removal position E of a cartridge 70 by means of a pivoting movement. In addition, the jointing head 1 comprises a compensation mechanism 40 of the gripper 30 so that, when the fastening element 9 is mounted on a component surface B, the fastening element 9 is optimally arranged adjacent to a hardening source 60 such as a light source.

Owner:BOLLHOFF VERBINDUNGSTECHNIK GMBH

Weather-resistant high-strength environment-friendly antique-imitation brick and preparation method thereof

The invention discloses a weather-resistant high-strength environment-friendly antique-imitation brick. The weather-resistant high-strength environment-friendly antique-imitation brick is prepared from the following raw materials in parts by weight: 10-20 parts of blue stone powder, 3-7 parts of antique-imitation auxiliaries, 7-9 parts of blast-furnace slag, 5-7 parts of steel slag, 4-8 parts of coal gangue, 10-14 parts of purified landfill, 8-12 parts of waterproof latex, 6-8 parts of tackifying additives, 13-15 parts of ore powder, 10-14 parts of fine sand and 7-11 parts of silicate cement. The environment-friendly antique-imitation brick disclosed by the invention has excellent performance in imperviousness, corrosion resistance and freeze-thaw resistance, the compression strength is relatively high, the appearance is pure in color and full in antique tone, and the environment-friendly antique-imitation brick has a realistic effect when the environment-friendly antique-imitation brick is applied to the repair or imitation of antique buildings; meanwhile, by adopting a large amount of industrial and agricultural wastes, the resources are saved, the cost is reduced, the raw materials are readily available, the process is simple, and the environmental hazards are effectively reduced, so that the preparation method disclosed by the invention has a relatively high practical value and a good application prospect.

Owner:HEFEI SHANGHAN DECORATION ENG CO LTD

Method for planting cedrela sinensis

InactiveCN107125078AImprove physiological activityImprove germination rateCultivating equipmentsSoilless cultivationNutrient solutionBud

The invention relates to the field of cedrela sinensis planting, and discloses a method for planting the cedrela sinensis. The method includes the following steps of (1) seed treating, wherein seeds are screened and then soaked with sprouting liquid, and the physiological activity of the seeds is improved; (2) sowing and seedling culturing, wherein the seedling culturing mode is that seedlings are cultured into bud seedlings with seedling substrates, then the bud seedlings are shifted into a water-cultured nutrient solution, and the seedling culturing speed can be increased; meanwhile, the seedling exercising time is saved, and the resistance of the seedlings is high; (3) tree seedling culturing, wherein the seedlings obtained from water-cultured seedlings grow to 10 cm to 12 cm, and then can be transplanted to a field for tree seedling culturing, and main points of fertilization are that the proportion of nitrogen and phosphorus fertilizer is modulated, tree seedlings are subjected to timely top removing, which helps cedrela sinensis trees to grow luxuriantly. The method for planting the cedrela sinensis is suitable for large-scale planting, the germination rate of the seeds can be increased, and the growth speed and the branch quantity of the cedrela sinensis are increased.

Owner:ANHUI WEIXIAN FOOD

High-strength erosion-resistant ladle self-flow castable and preparation method thereof

ActiveCN112500139AHigh strengthImprove erosion resistanceMelt-holding vesselsFiberUltimate tensile strength

The invention provides a high-strength erosion-resistant ladle self-flow castable and a preparation method thereof. And steel ladle self-flowing castable is calculated according to parts by mass. Thepreparation raw materials comprise the following components in parts by weight: 5-40 parts of chromium corundum aggregate, 20-70 parts of washed corundum aggregate, 5-40 parts of white corundum fine powder, 1-15 parts of fused magnesite fine powder, 1-25 parts of low-sodium alpha alumina micro powder, 110 parts of pure calcium aluminate cement, 0.1-5 part of zirconium composite silicon micro powder, 0.1-5 part of a delayed coagulation type water reducing agent and 0.01-0.5 part of organic fibers. The self-flow castable has high strength, good erosion resistance and slag erosion resistance, andcan solve the problems of poor fluidity, segregation, no erosion resistance, no erosion resistance and the like of corundum self-flow castables in the use process.

Owner:北京利尔高温材料股份有限公司

Soilless cutting seedling culture method of grapes

InactiveCN107318616AShorten rooting timeNutrient-rich substrateBiocideBio-organic fraction processingShootCallus formation

The invention mainly relates to the technical field of grape planting, and discloses a soilless cutting seedling culture method of grapes. The method includes the steps of clipping cutting slips, soaking the cutting slips, conducting cutting of the cutting slips, conducting post-cutting management, and exercising seedlings for cultivation. The method is simple and facilitates mass operation, the rooting time of the grape cutting slips is shortened to be 9-10 days, the rooting rate reaches 92%, the survival rate reaches 100%, the planting efficiency is obviously improved, and the economic income is increased by 9.6%; two-three-year-old grape shoots are clipped to serve as the cutting slips, many nutrients are accumulated in the cutting slips and can be supplied to callus formation of the cutting slips when external nutrients are not accumulated in the cutting slips yet, and the treating time and the rooting time are shortened.

Owner:JINZHAI XINTIANDI MODERN AGRI

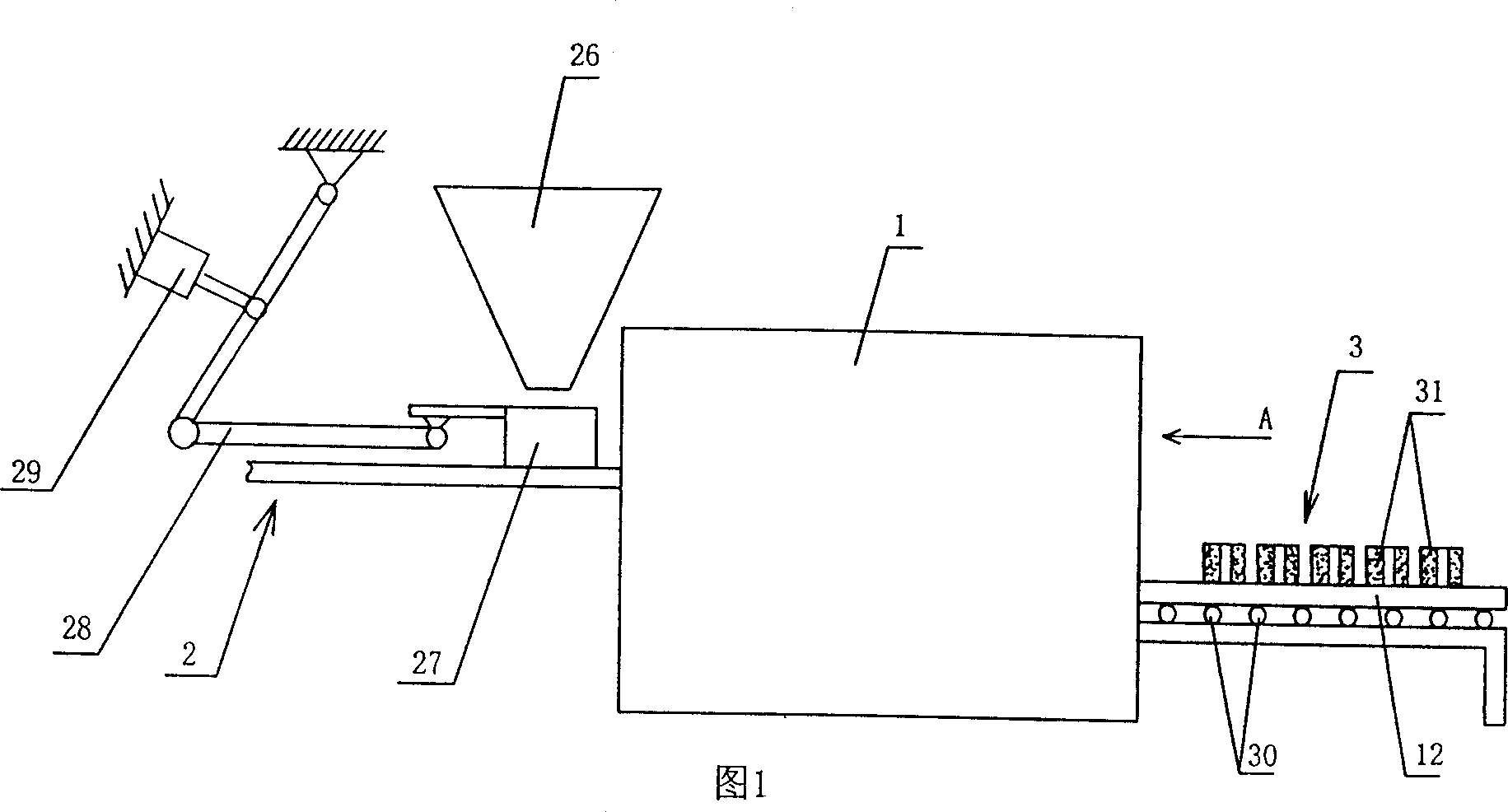

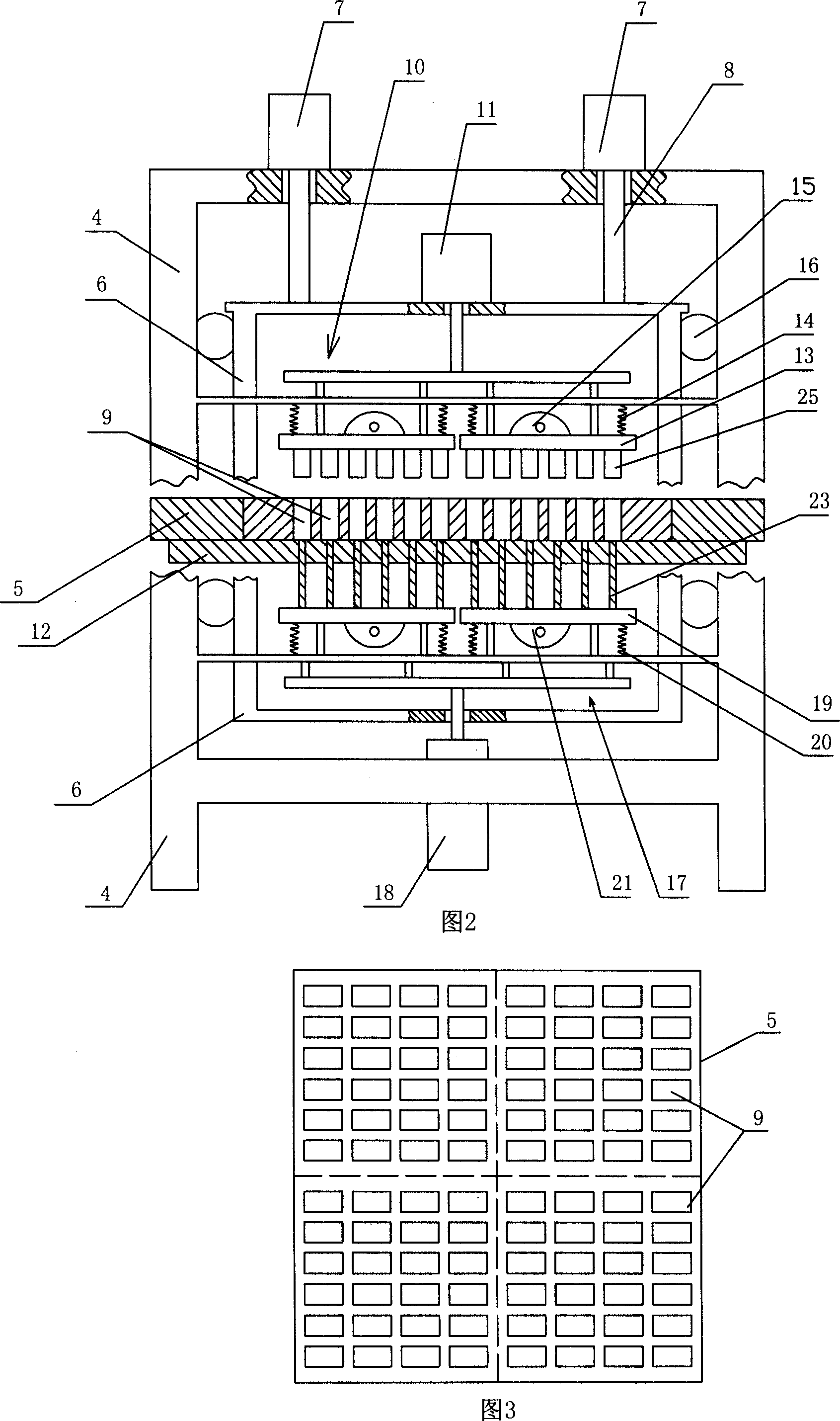

Concrete building block continuous producing technology

InactiveCN101143463ASave production landReduce the number of transshipmentsCeramic shaping plantsMolding machineUltimate tensile strength

A continuous production technology for a concrete block comprises a quantitative hopper feed into a die box of a concrete block molding machine. The adoption of a vibration extrusion molding leads to a direct palletizing and a transshipment strength for the molded block. The direct palletizing is done after block-molding and mold-stripping. The palletized block is transshipped into the hardening process. A top product is produced out after the hardening process. The technology saves a plurality of wooden carriers and carrier storage racks as well as storage space, saves the production site, reduces the number of transit and lowers transit cost. The heat of hydration in the hardening process of the concrete block is fully utilized. When the blocking process is done at a lowered temperature, the hardening time is shortened more than one and a half times than that at a natural temperature environment. The invention greatly saves production cost and improves production efficiency.

Owner:王海清

Preparation method of polymer composite water-proof mortar

The invention relates to the technical field of building mortar preparations, and concretely relates to a preparation method of a polymer composite water-proof mortar. The preparation method of the polymer composite water-proof mortar comprises the following steps: firstly, natural river sand and glass fiber are used as filling materials to improve the mechanical properties of the mortar, orange peel juice and rose essential oil are decomposed to produce a large number of lipophilic ester groups and aromatic hydrocarbon groups under the function of microbes, and the lipophilic groups are introduced onto the surface of a mixed powder through microbes, so that the compatibility of an inorganic mixed powder with a polymer is improved, and the anti-permeable strength of the mortar is improved.According to the polymer composite water-proof mortar, the excellent water-resistant properties of silica sol and organic siloxane are fully used to improve the water-proof property of the mortar, besides the polymeric matrix contains abundant silicon hydroxyl groups, and the silicon hydroxyl groups and silicon hydroxyl groups on the surface of the modified mixed powder undergo a reaction under the effect of a heating power to form Si-O-Si bonds with extreme big bond energy, so as to improve the internal bonding strength of the mortar, and further improve the mechanical properties of the water-proof mortar, thereby, the polymer composite water-proof mortar has a broad application prospect.

Owner:常州市绿意管道有限公司

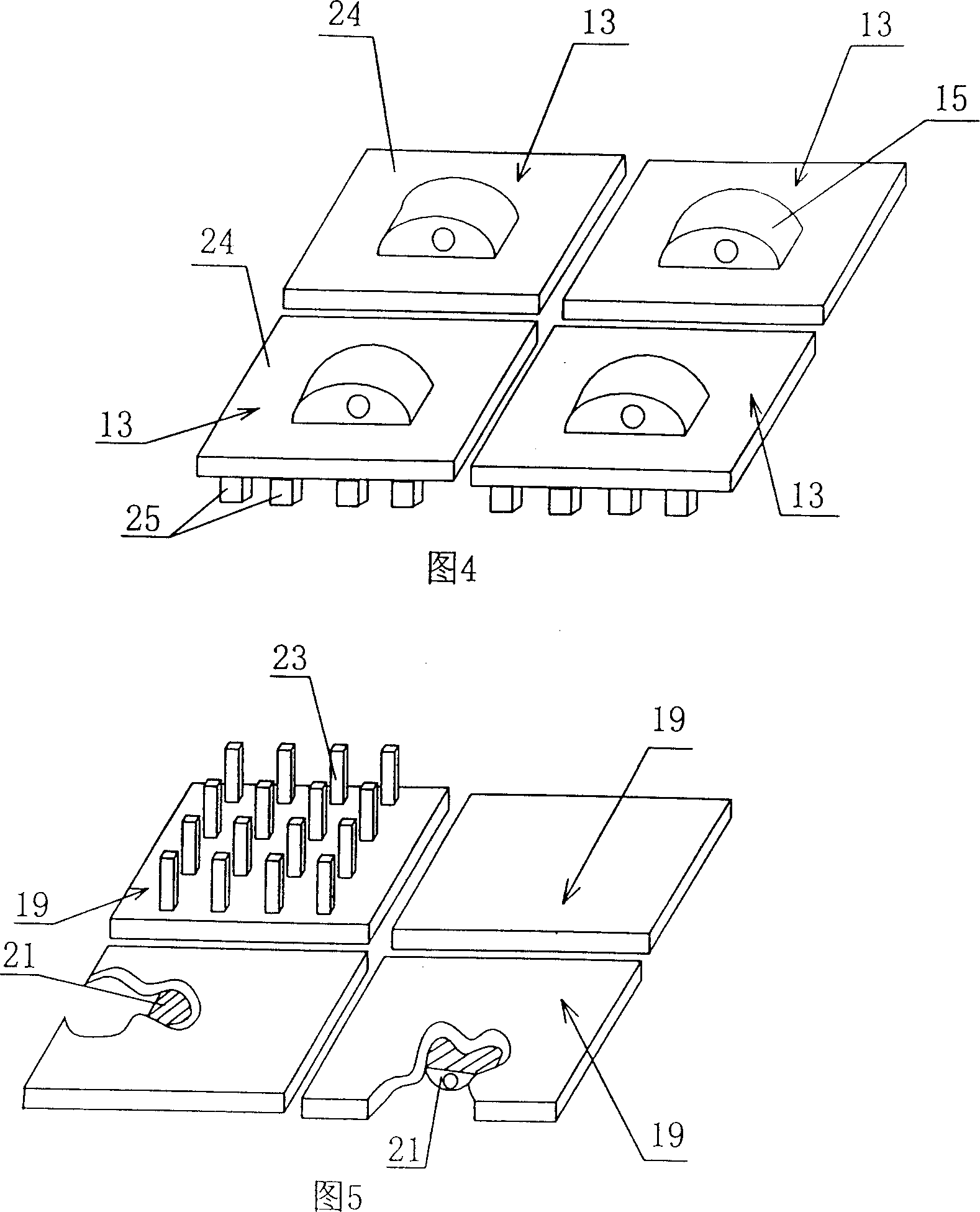

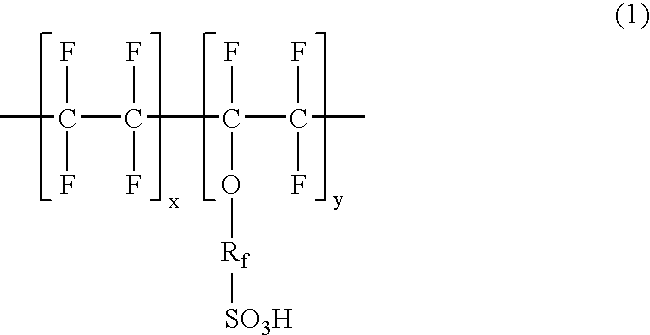

Photocatalytic coating and steel plate and canvas coated with the same

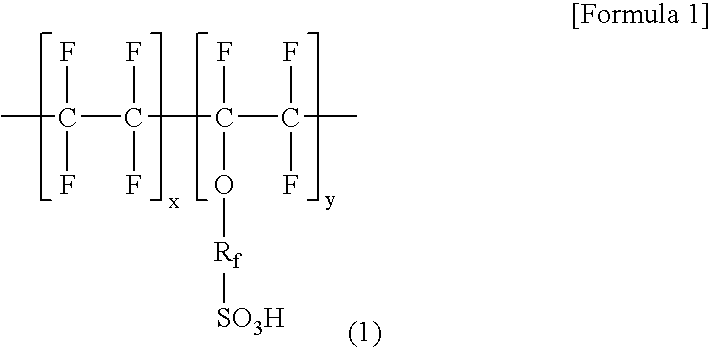

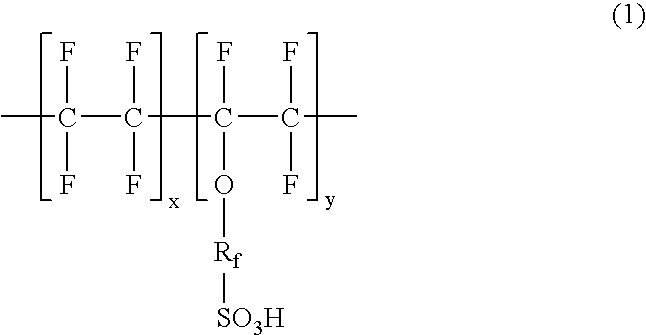

InactiveUS20080118744A1Inhibit deteriorationKeep for a long timeOrganic-compounds/hydrides/coordination-complexes catalystsSynthetic resin layered productsSheet steelPhotocatalytic reaction

The present invention provides a photocatalytic coating which has a predetermined photocatalytic function and reduces hardening time after coating, and the hardened coated film is not dissolved due to photocatalytic function and has flexibility. The present invention also provides a photocatalytic coating in which NAFION® (registered trademark of DuPont) is used as an organic resin binder which is not dissolved due to a photocatalytic reaction and has flexibility after dry hardening, and provides steel plates and canvases are coated with said photocatalytic coating, wherein the coatings are not removed when the coated film is bent after coating.

Owner:PIALEX TECH CORP

Fireproof and heat-insulating building material and preparation method thereof

InactiveCN108821648AImprove thermal insulation performanceImprove fire performanceCeramic shaping apparatusCeramicwareFiberCalcium silicate

The invention provides a fireproof and heat-insulating building material and a preparation method thereof, and relates to the field of building materials. The fireproof and heat-insulating building material comprises nanometer silicon carbide, stearyl alcohol, sepiolite powder, asbestos, calcium silicate powder, polyurethane, silk fibroin fibers, 1,4-butylene glycol, waste polyethylene plastics, phosphate slag, diatomaceous earth, activated carbon particles, glass wool, a cementing material, a set retarder, a thickener, a foaming agent, a water reducer and water. The preparation method comprises the following steps: (1) weighing of above raw materials; (2) crushing; (3) stirring; and (4) casting molding, demolding, piling and curing. The fireproof and heat-insulating building material prepared in the invention has the advantages of good heat insulation property, good fireproof property, environmental protection, energy saving and high compressive strength.

Owner:张建

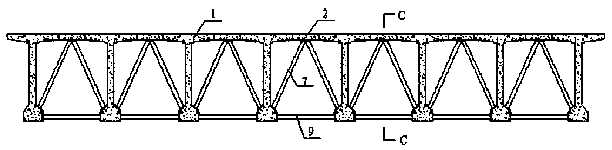

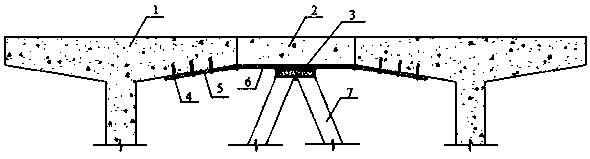

Combination T beam bridge assembly type cross connection reinforced structure and reinforcing method thereof

ActiveCN108517793AShorten hardening timeShorten maintenance timeBridge erection/assemblyBridge strengtheningCross connectionT-beam

The invention discloses a combination T beam bridge assembly type cross connection reinforced structure and a reinforcing method thereof. A top plate is fixedly connected to joint seams and the lowersurfaces of two adjacent T-shaped girders, a steel concrete combination base plate is fixedly connected to the lower surface of the top plate, the bottoms of two inclined supports are fixedly connected to T-shaped horseshoe parts of the two T-shaped girders, the tops of the two inclined supports are fixedly connected to the steel concrete combination base plate, and the two ends of a horizontal support are fixedly connected with the T-shaped horseshoe parts of the two T-shaped girders; the two inclined supports and the horizontal support form a triangular support structure. Accordingly, the defects that for a traditional cross connection reinforcing method, the construction period is long, the effect is poor, many limiting factors exist, and the construction condition requirements are highare overcome, the technical problem that combination T beam bridge cross connection urgently needs to be improved is solved. The structure can be widely applied to cross connection reinforcing of a combination T beam bridge and a concrete box beam bridge, and meanwhile the structure can also serve as a diaphragm plate of a new bridge for use.

Owner:江苏梦联桥科技有限公司

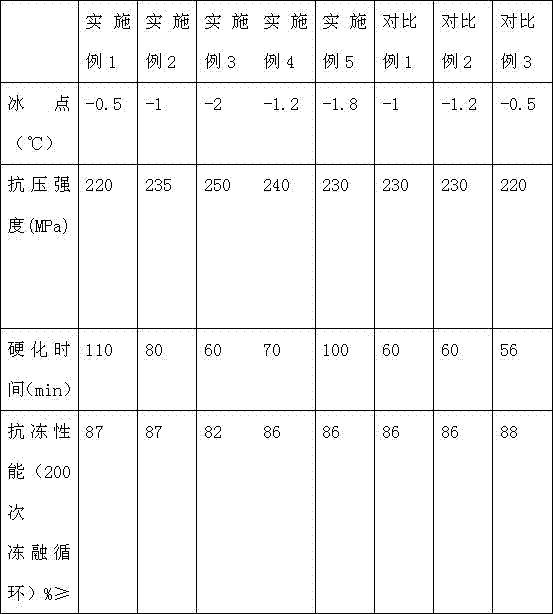

Quick repairing material of airfield pavement and road, and preparation method and construction method of quick repairing material

PendingCN109384418AExcellent mix ratioGuarantee the construction qualityIn situ pavingsTemporary pavingsSodium BentoniteCrack resistance

The invention provides a quick repairing material of an airfield pavement and a road, and a preparation method and a construction method of the quick repairing material. The quick repairing material comprises the following ingredients in parts by weight: 30-35 parts of polymethyl methacrylate resin, 10-15 parts of calcium carbonate, 5-10 parts of bentonite, 1-5 parts of nano silicon oxide, 10-20 parts of quartz sand, 2-5 parts of inorganic pigment, 0.5-1 part of an anti-settling agent, 0.5-1 part of a thickening agent, 5-10 parts of bauxite and 5-10 parts of carborundum. The material takes thepolymethyl methacrylate resin, the bauxite, the bentonite, the thickening agent, the anti-settling agent, the quartz sand and the carborundum as main materials, has excellent performance of fast curing within 1h at -30 DEG C, ultra-high cohesion, excellent crack resistance, acid resistance, alkali resistance and chemical resistance; emission of VOCs (volatile organic compounds), heavy metals andthe like is lower; the environmental pollution is reduced; the problems of defects such as cracks, dusting and damage of a maintenance surface are avoided; and the traffic efficiency of the road is greatly improved.

Owner:TIANJIN BAISITE NEW MATERIAL TECH

Energy-saving environment-friendly wall body material and preparation method thereof

The invention provides an energy-saving environment-friendly wall body material and a preparation method thereof, and relates to the field of building materials. The energy-saving environment-friendly wall body material is prepared from the following raw materials in parts by weight: 15 to 19 parts of fine sand, 30 to 40 parts of crushed stone, 18 to 30 parts of cement, 10 to 15 parts of waste polyurethane foam plastic, 9 to 17 parts of waste extruded sheet, 15 to 20 parts of bamboo charcoal, 5 to 9 parts of ceramic fiber, 8 to 14 parts of polyamide fiber, 3 to 5 parts of attapulgite, 12 to 16 parts of phenolic foam, 11 to 17 parts of vermiculite, 0.2 to 0.4 part of bonding agent, 0.7 to 1.1 parts of thermal stabilizer, 0.3 to 0.5 part of air entraining agent, 0.2 to 0.6 part of retarder, 0.3 to 0.7 part of water reducing agent, and 3 to 7 parts of water. The preparation method comprises the following steps: (1) weighting the raw materials; (2) calcining the vermiculite; (3) smashing the mixed materials; (4) preparing a mixture; (5) preparing mixed slurry; (6) casing, demolding and curing. The energy-saving environment-friendly wall body material prepared by the method provided by the invention has the advantages of high compressive strength, high tensile strength, high heat preservation and insulation performance, energy saving and high environmental friendliness.

Owner:HEFEI FENGTENG ENERGY SAVING TECH CO LTD

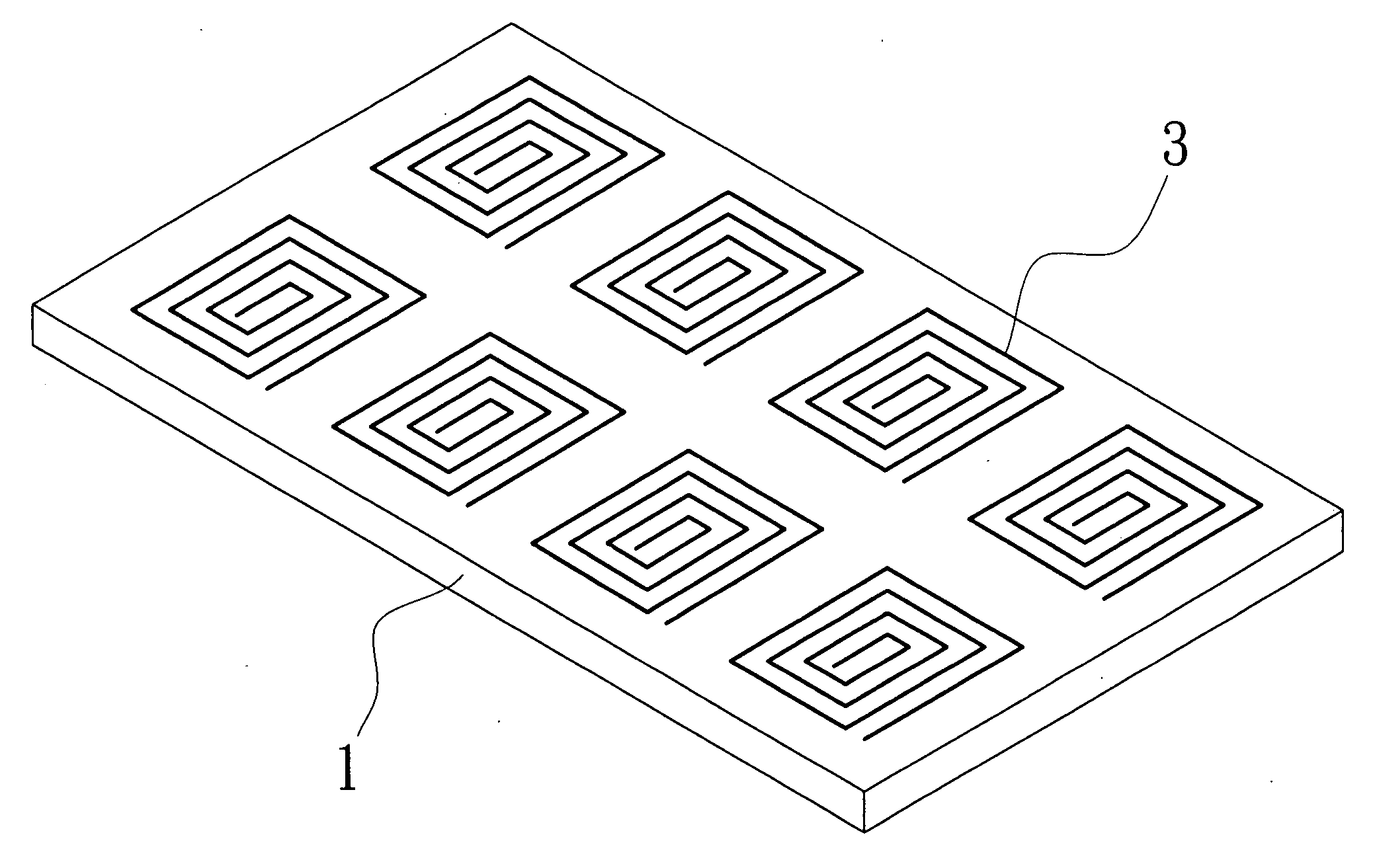

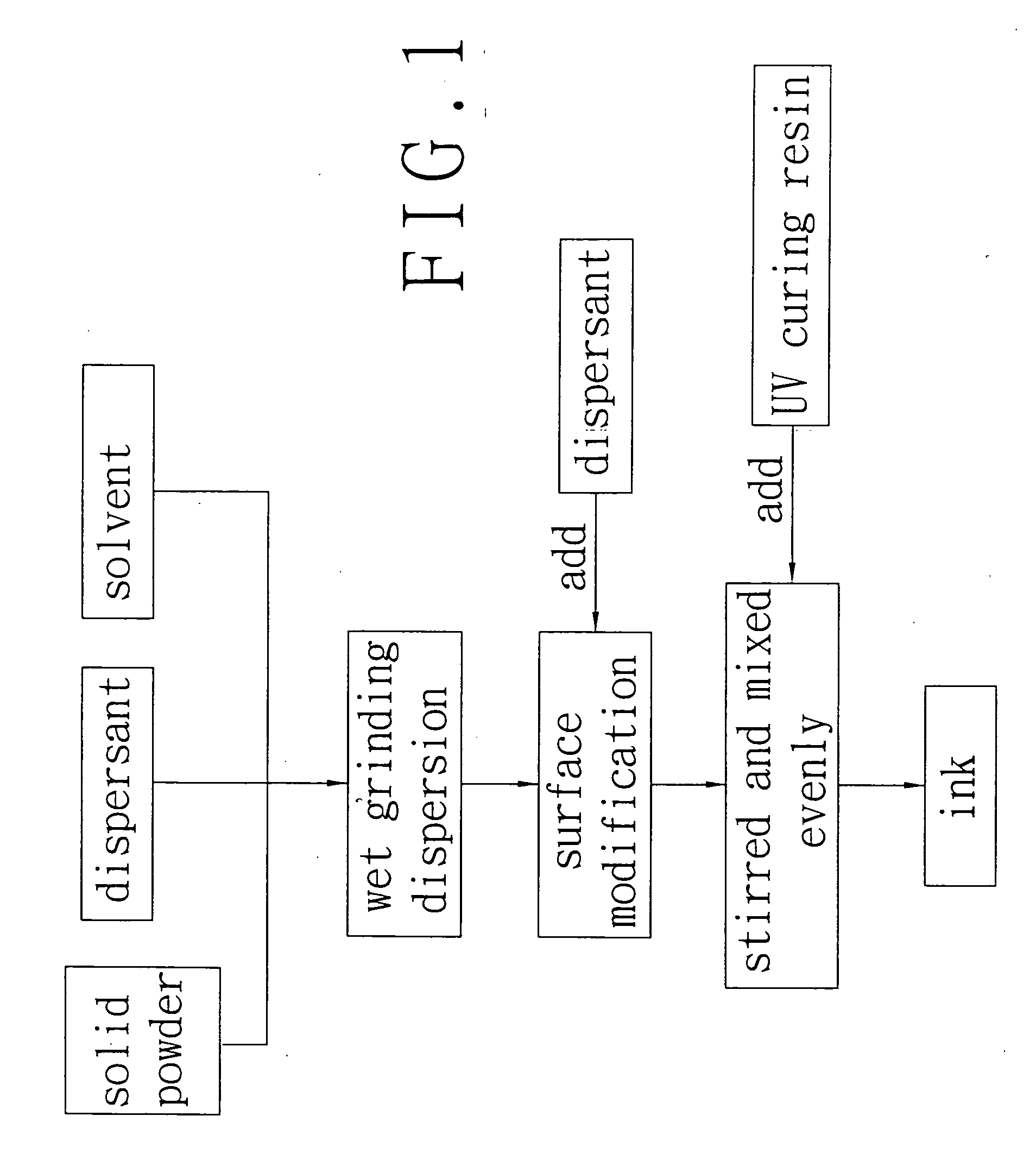

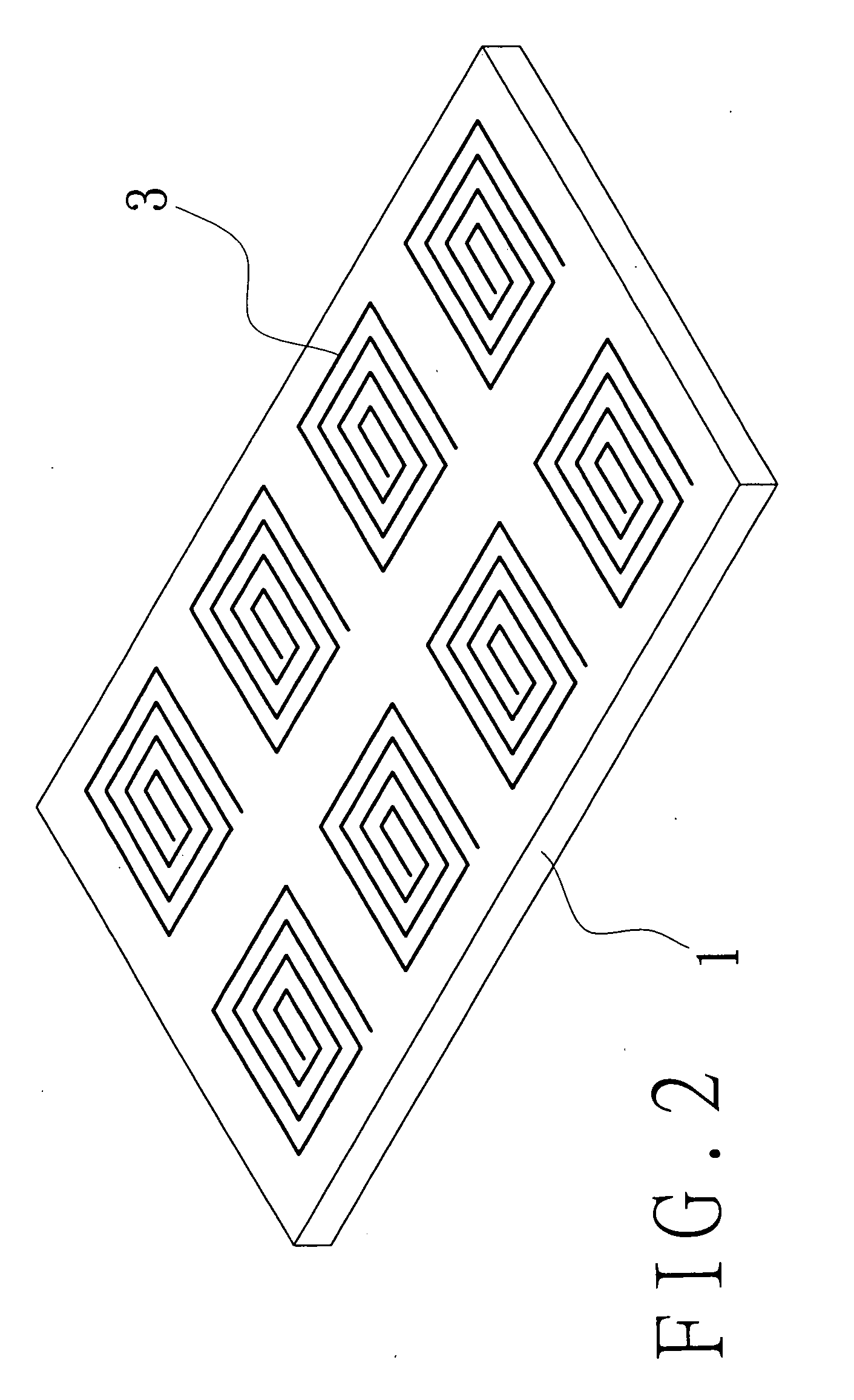

Ink and manufacturing method thereof

InactiveUS20100249301A1Low costShorten hardening timePhotomechanical apparatusInksScreen printingChemical plating

An ink and a manufacturing method thereof are revealed. The ink includes nanoparticles treated by wet-grinding and surface modification and ultraviolet curing resin, mixed with each other evenly. The ink is applied to manufacturing processes of ink patterns formed by screen printing and followed by chemical plating and horizontal thickening process to add up a conductive layer, especially suitable for manufacturing processes of antennas of RFID systems.

Owner:UNIVACCO TECH

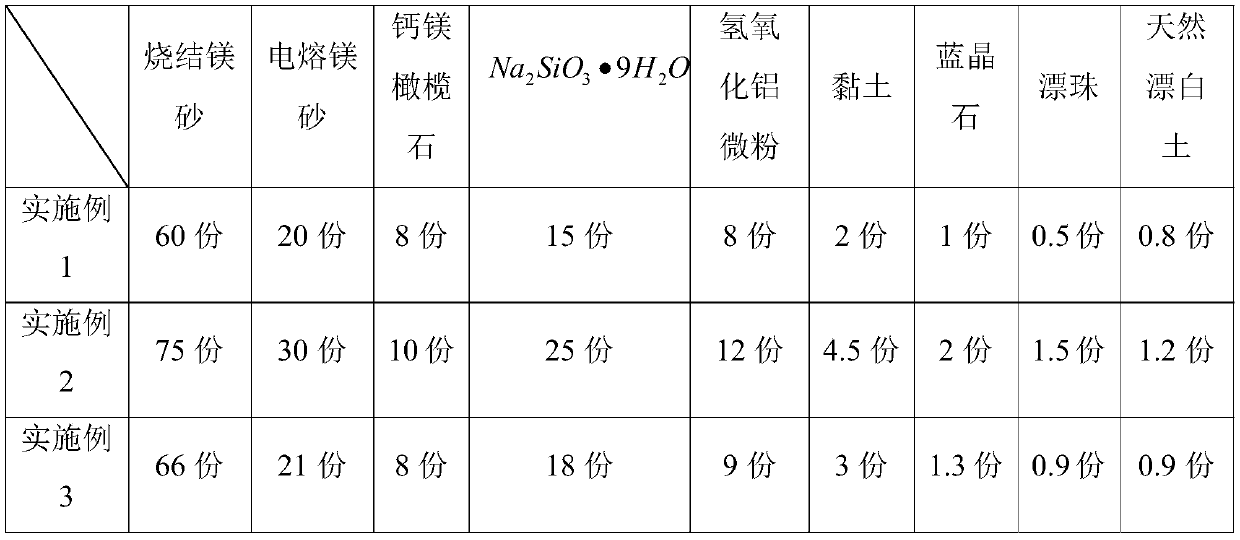

Environment-friendly magnesian dry material and preparation process thereof

An environment-friendly magnesian dry material comprises sintered magnesia, fused magnesia, calcium forsterite, a binding agent, aluminum hydroxide micro powder, a high-temperature sintering agent, anexpanding agent, floating beads and bentonite in a mass ratio of (60-75): (20-30): (8-10): (15-25): (8-12): (2-4.5): (1-2): (0.5-1.5): (0.8-1.2). According to the invention, the proportion of each component of the dry material is optimized; by adopting the environment-friendly binding agent, the problem that the binding agent is decomposed into toxic and harmful substances under a high-temperature condition can be effectively solved, the dry material is more energy-saving and environment-friendly, the hardness requirement of the dry material in the using process can be ensured on the premisethat the dry material has no pungent smell in the using process and is more beneficial to the production environment, and the scouring resistance of the dry material is ensured.

Owner:浙江欣辉耐火材料股份有限公司

Waterproof closed-cell expanded perlite

InactiveCN101781098AHighlight the effect of closed poresImprove thermal insulationHeat proofingCompressive strengthUltimate tensile strength

The invention provides a waterproof closed-cell expanded perlite which is prepared by the following steps of: matching silica sol, water glass, a waterproof agent, cement powder, a curing agent and water in parts by weight, and uniformly mixing to prepare a waterproof closed-cell sizing agent; then uniformly spraying the waterproof closed-cell sizing agent to the surface of an expanded perlite, and then drying or airing the expanded perlite to obtain the waterproof closed-cell expanded perlite, wherein 215.1-262.9 kilograms of the waterproof closed-cell sizing agent is sprayed to the expanded perlite per cubic metre. The waterproof closed-cell expanded perlite has the outstanding advantages of light capacity, good heat insulation property, waterproofness, good affinity, high compression strength, extensive usage temperature, high chemical stability, innocuity, odourless, incorruption and non-inflammation, acid-alkali resistance, simple preparation process and low cost, thereby being an ideal building heat insulation material.

Owner:韩志同

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com