Concrete building block continuous producing technology

A technology for concrete blocks and production processes, applied in manufacturing tools, ceramic molding workshops, ceramic molding machines, etc., can solve the problems of large storage space, long hardening time, low production efficiency, etc., to save production land and reduce transportation. The number of times, the effect of reducing the cost of transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Apply the process of the present invention to produce concrete blocks. The external dimensions of a single block are 240 × 115 × 90 millimeters, which are hollow blocks with a solid volume of about 1.5 cubic decimeters and a stacking height of 13 (i.e. 13 layers) blocks Height, the number of blocks per layer of a stack of blocks is 4 * 8 blocks.

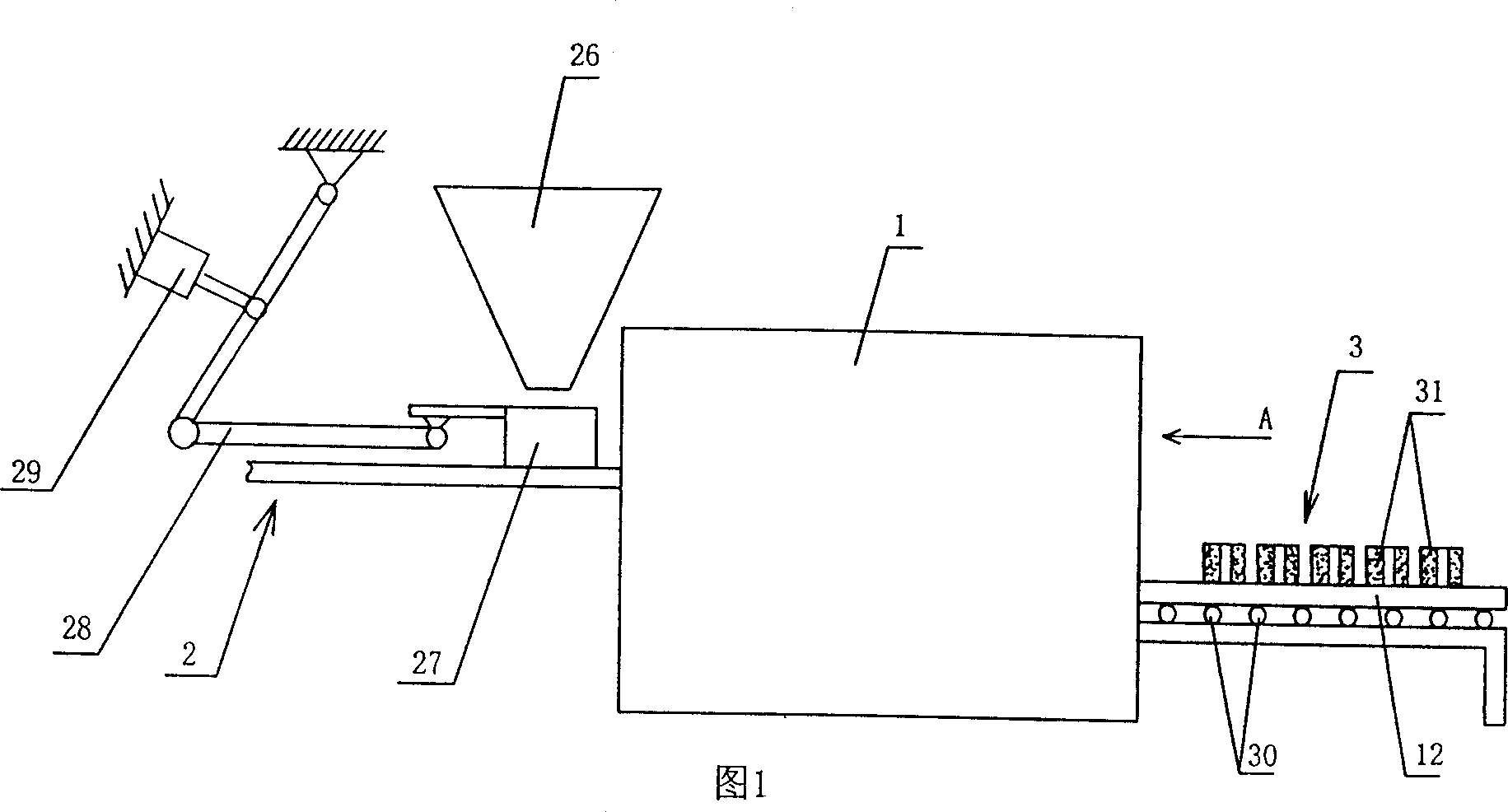

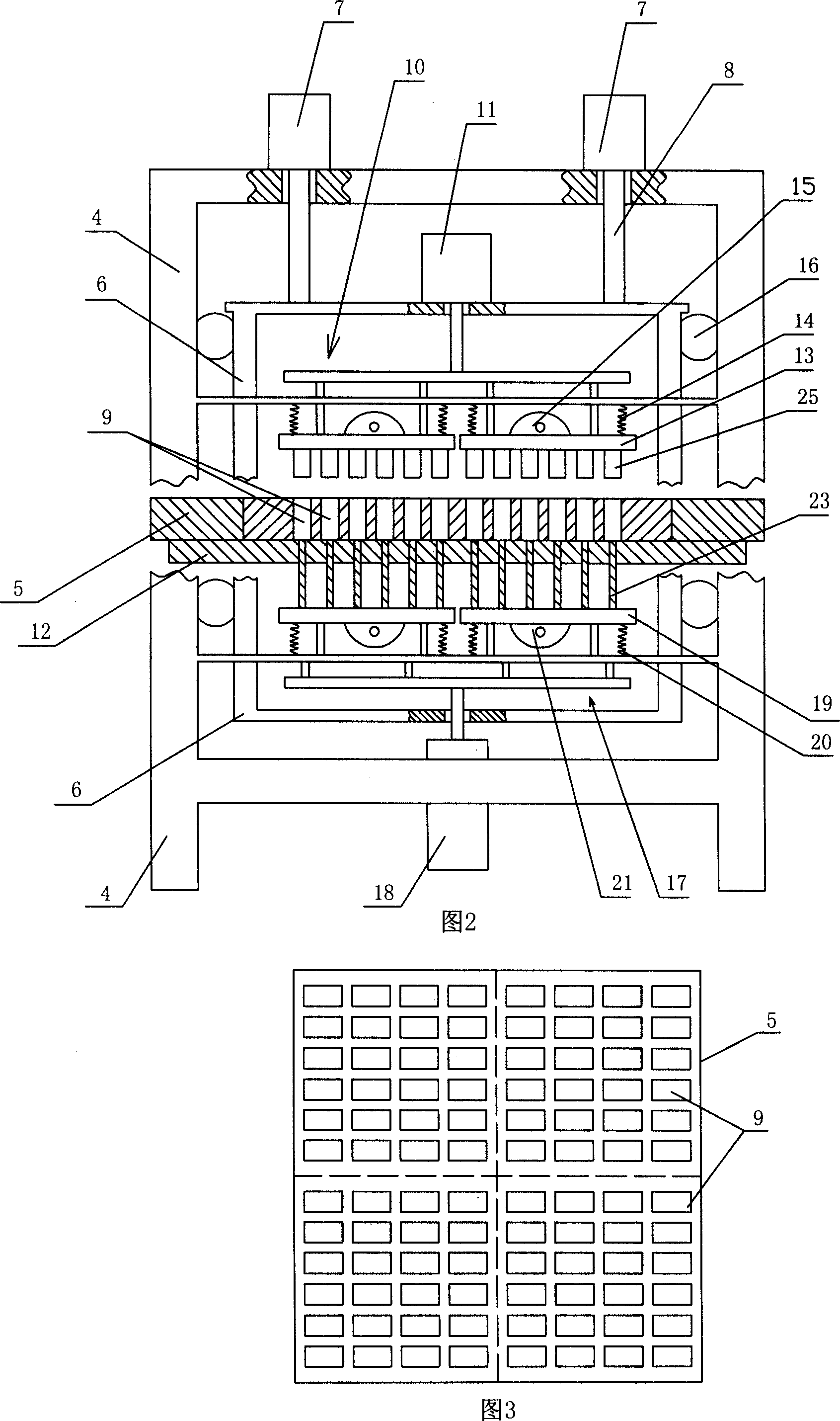

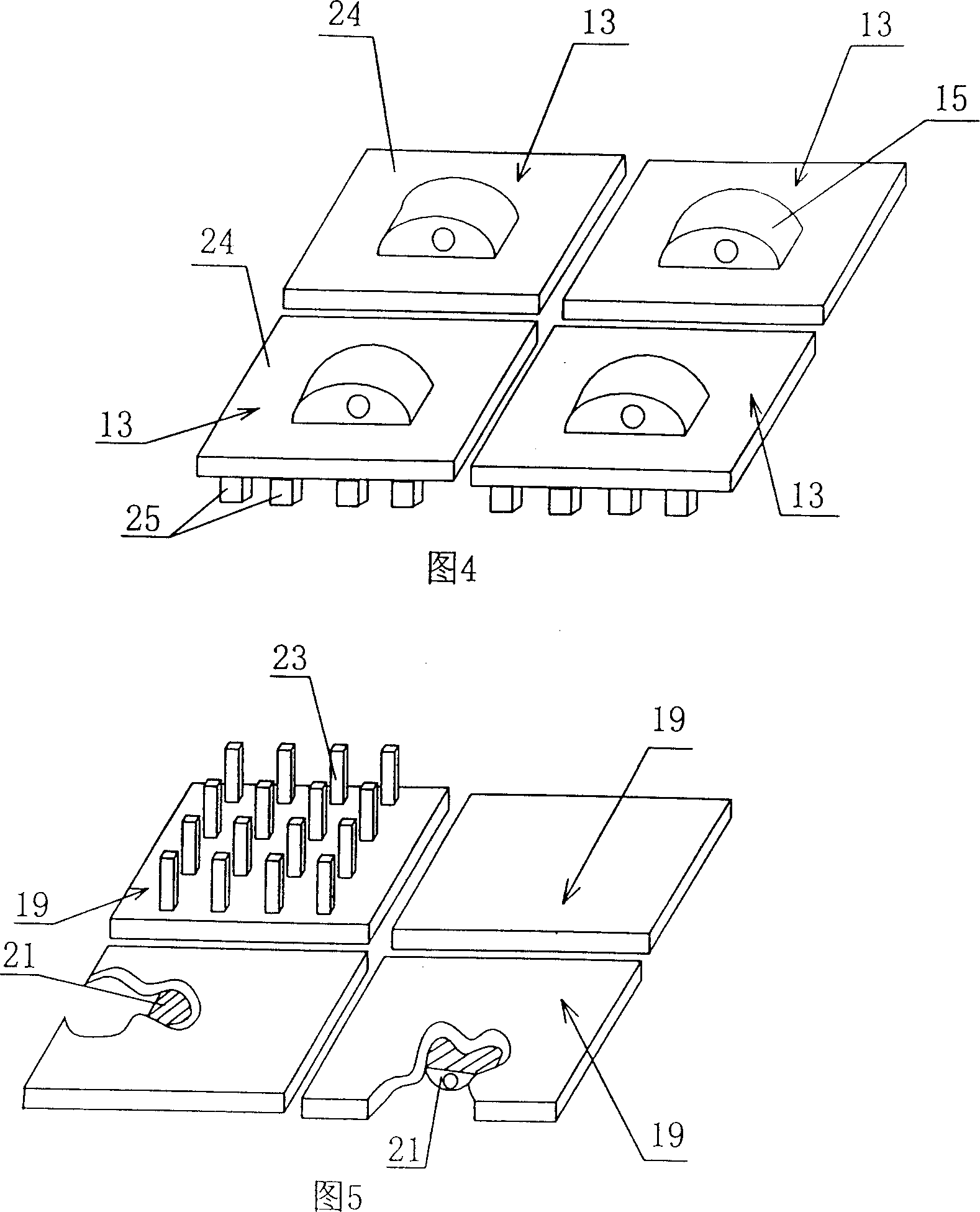

[0048] Fig. 1 to Fig. 5 are the structural schematic diagrams of a concrete block vibrating extrusion molding machine (another patent application) for realizing the process of the present invention.

[0049] Referring to Fig. 1, the molding includes a molding device 1 provided with a feeding mechanism 2 at the rear and a finished product transfer mechanism 3 positioned at the front of the molding device 1, as shown in Fig. 2, the molding device 1 has an outer frame 4 and a mold box 5. The top of the up and down moving frame 6 installed in the outer frame 4 is connected with the hydraulic column 8 of the hydraulic cylinder 7 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com