Patents

Literature

50results about How to "Save production land" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

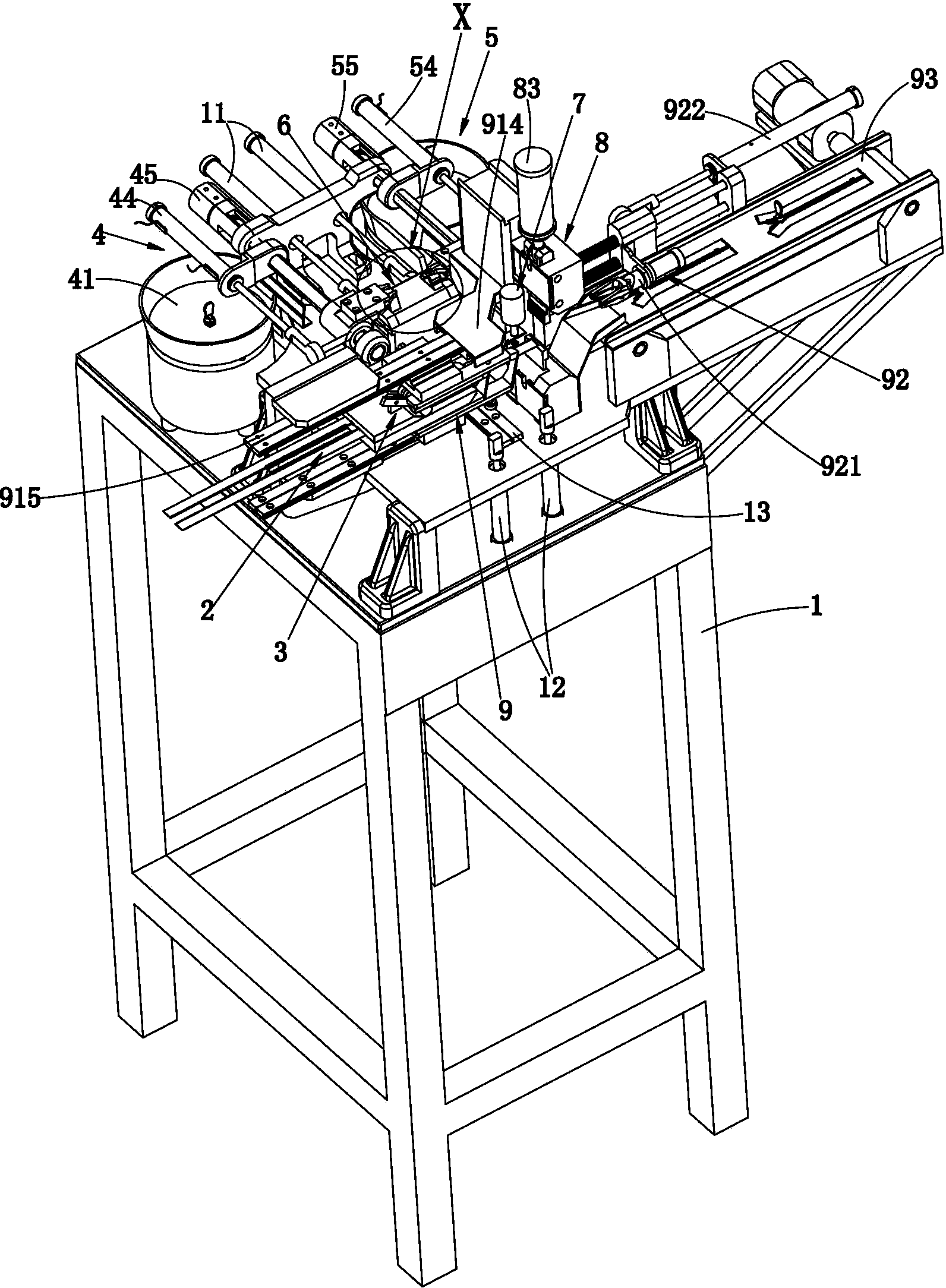

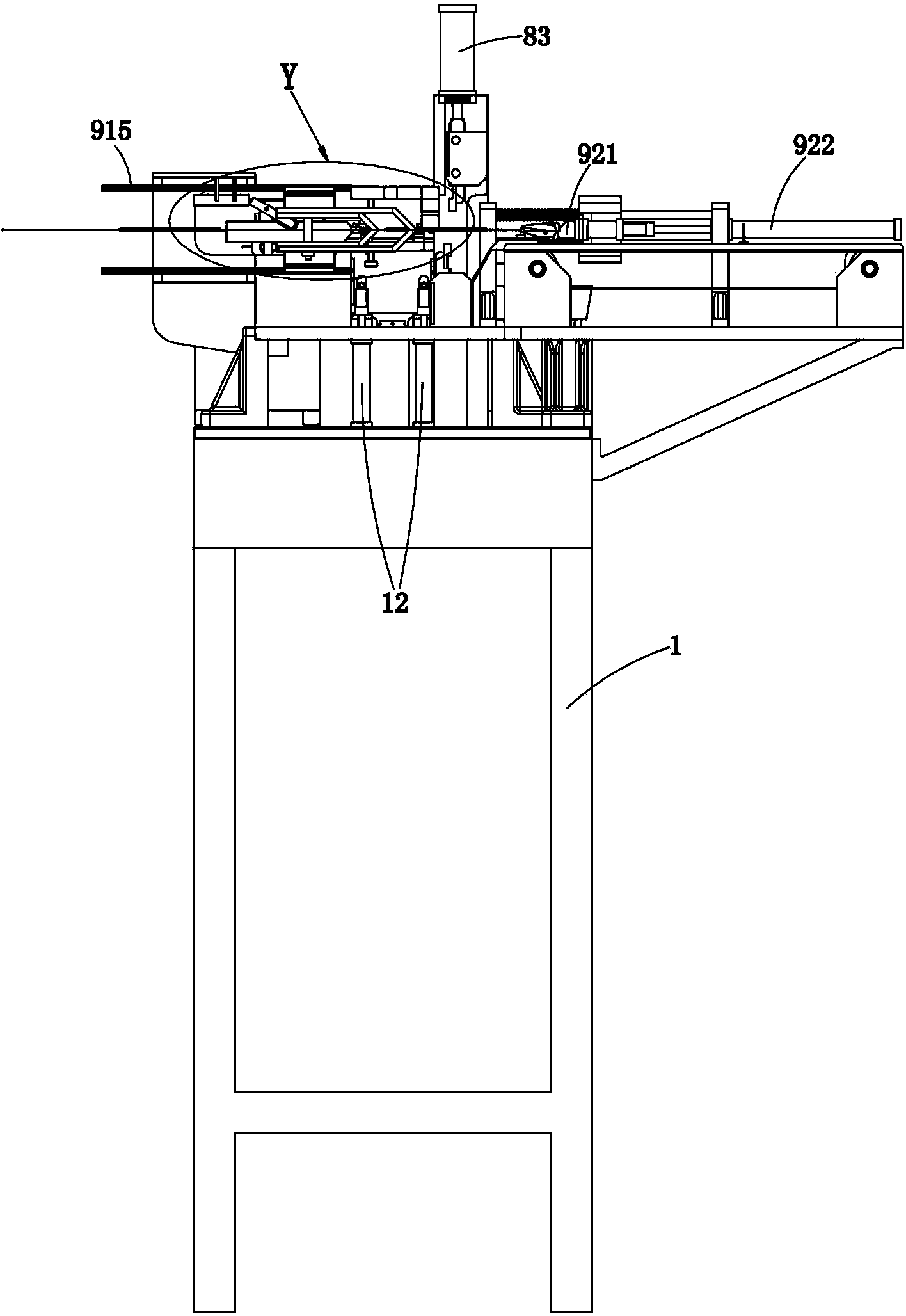

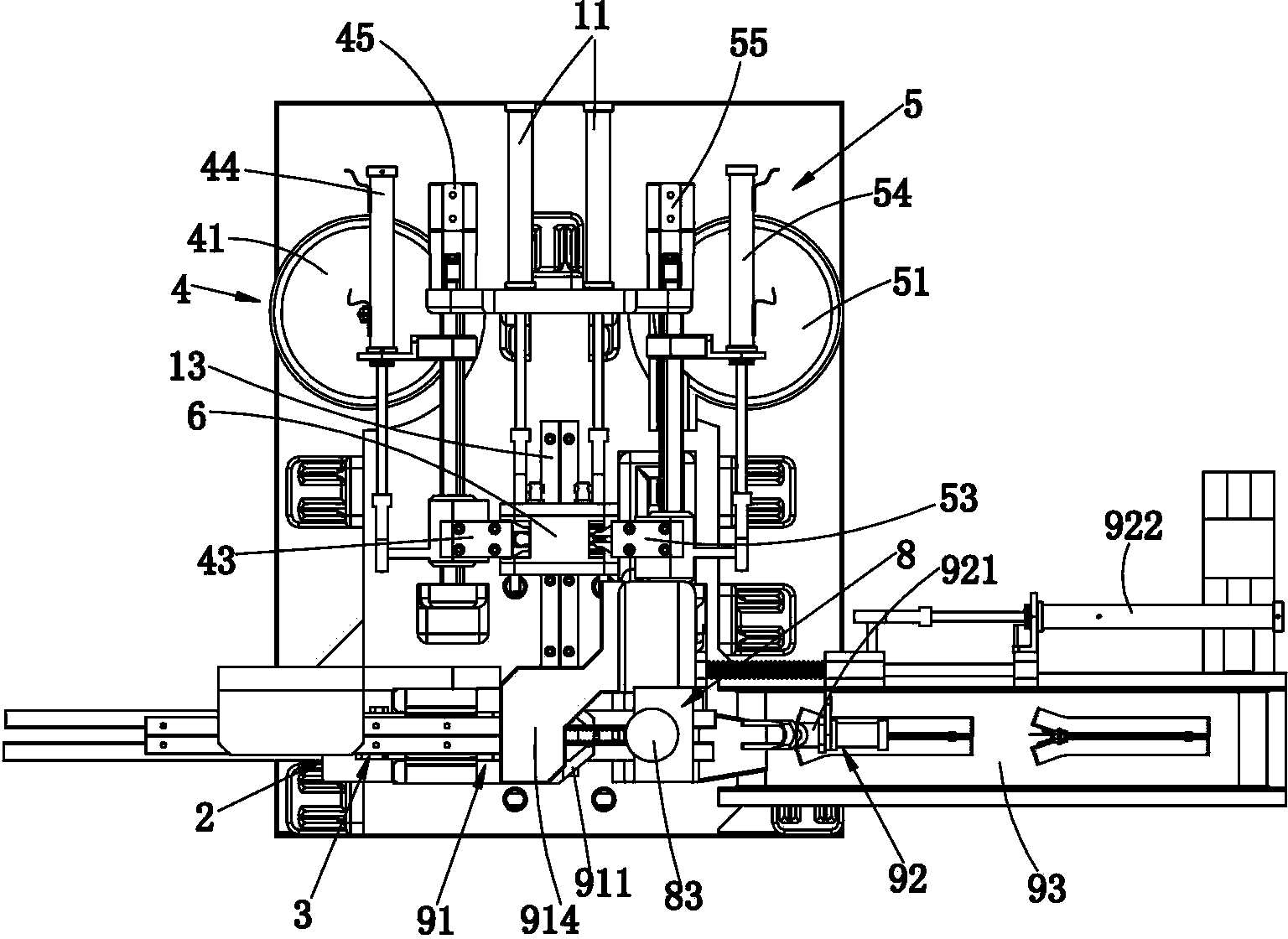

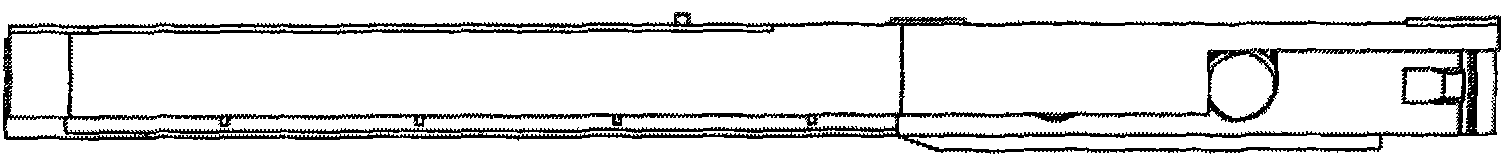

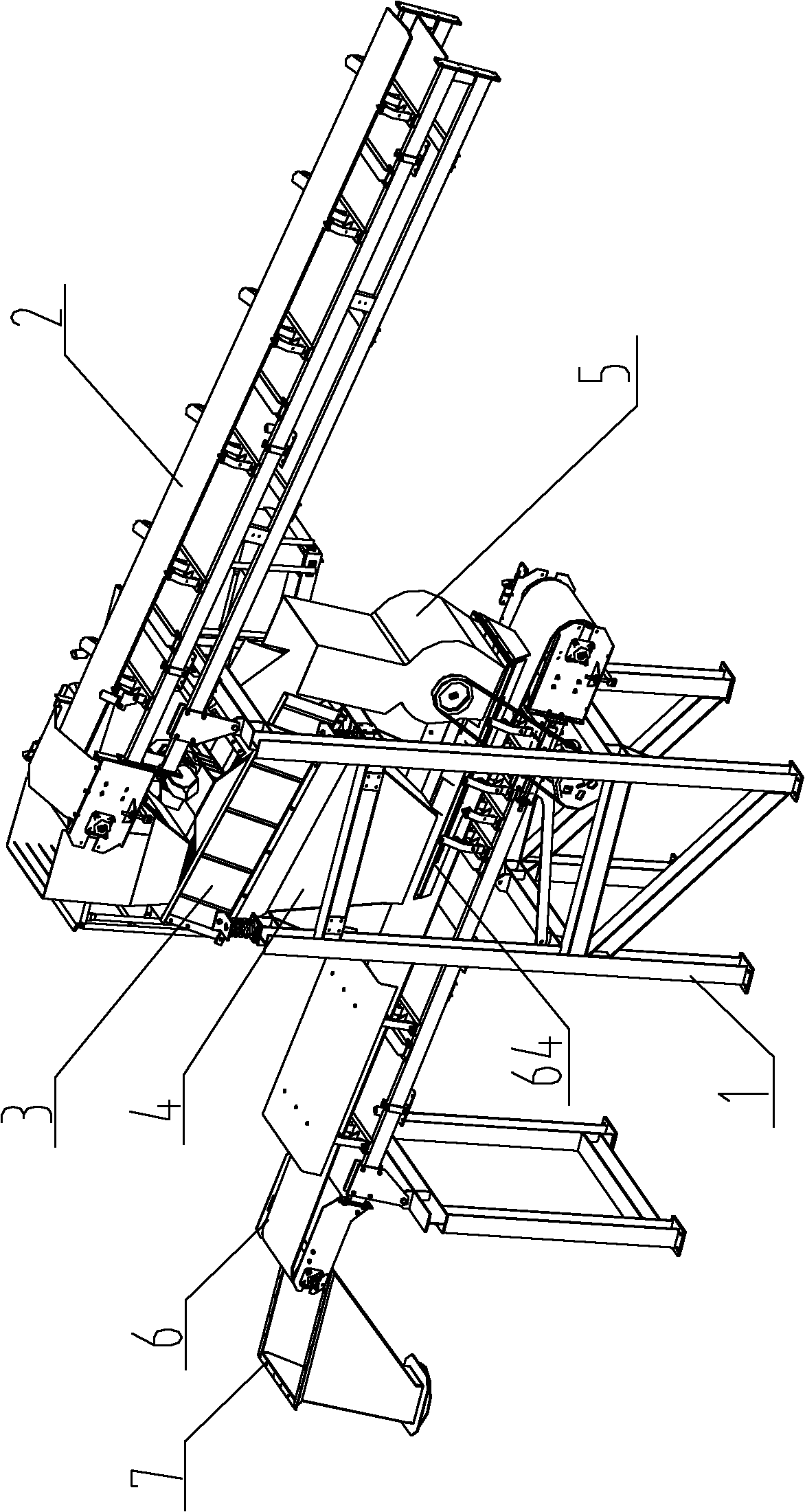

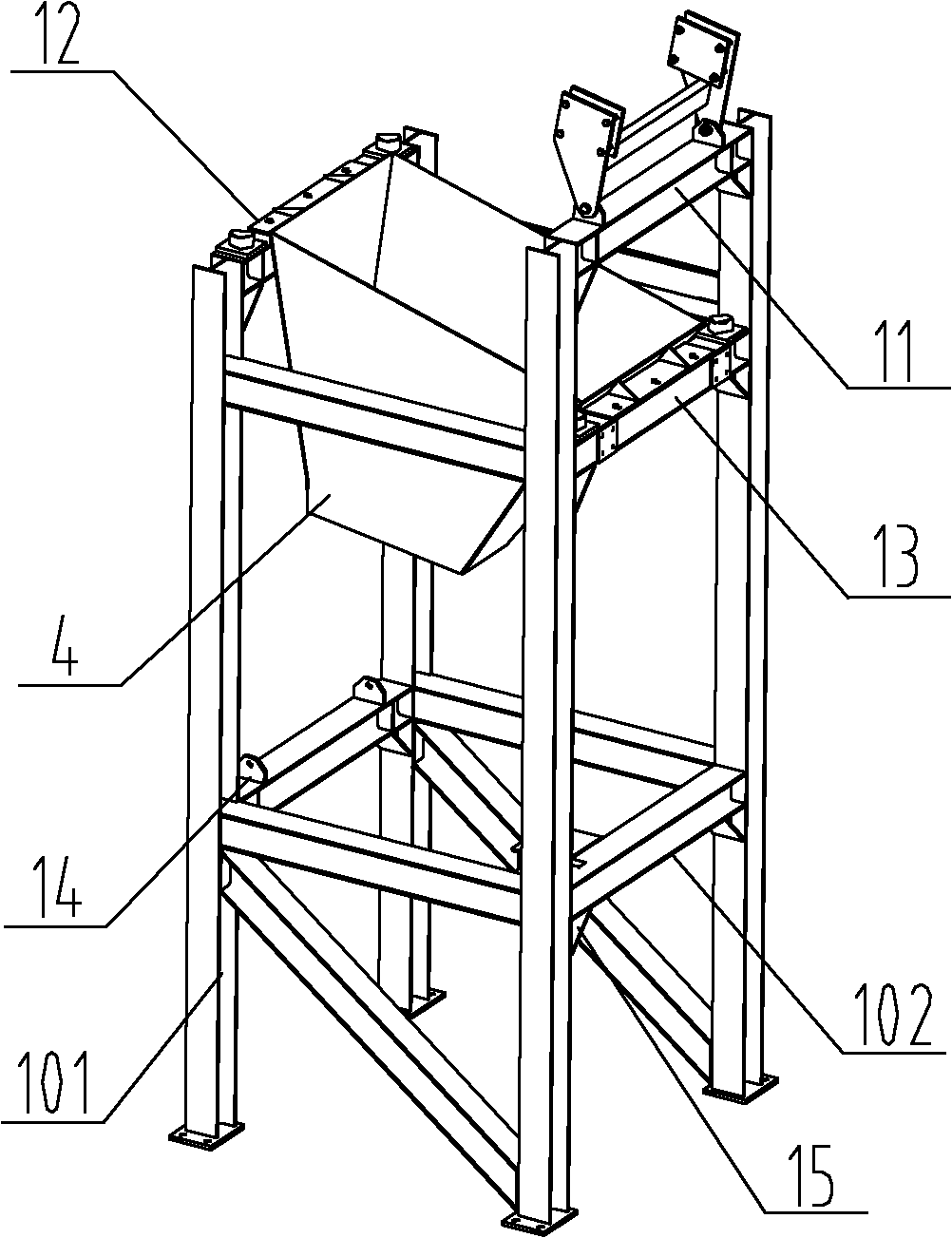

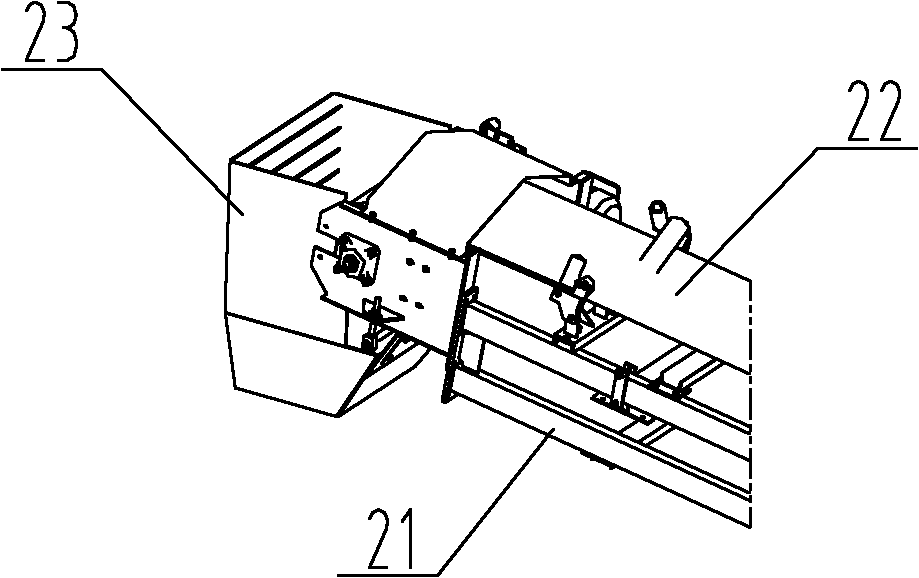

Production device for plastic steel closed zippers and zipper production method thereof

ActiveCN103504730ASimple production processKnead into smallSlide fastenersEngineeringInjection molding machine

The invention relates to a production device for plastic steel closed zippers and a zipper production method of the production device. The production device comprises a main frame body, and a zipper belt guide mechanism, a zipper tooth detection mechanism, a zipper head feeding mechanism, an I-shaped structure feeding mechanism, a material base, an I-shaped structure pressing mechanism, a cutter mechanism, a power mechanism and a control mechanism are assembled on the main frame body. Zipper belts produced in an injection molding through a injection molding machine directly enter the production device, and the finished zippers can be obtained after the processes of penetrating zipper heads, installing I-shaped structures and cutting off laces, the production processes of the zippers are simplified, investment of equipment and labor is small, production efficiency is effectively improved, the zippers produced by the production device are high in precision, and the rejection rate is effectively reduced; in addition, a novel zipper combining mode is adopted for the production device, namely, one zipper enters from the front end (provided with a guide post) of one zipper head, and a pulling piece is not needed to be pulled to lift a hook in the process, so that applicability to different pulling pieces of the device is greatly improved.

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

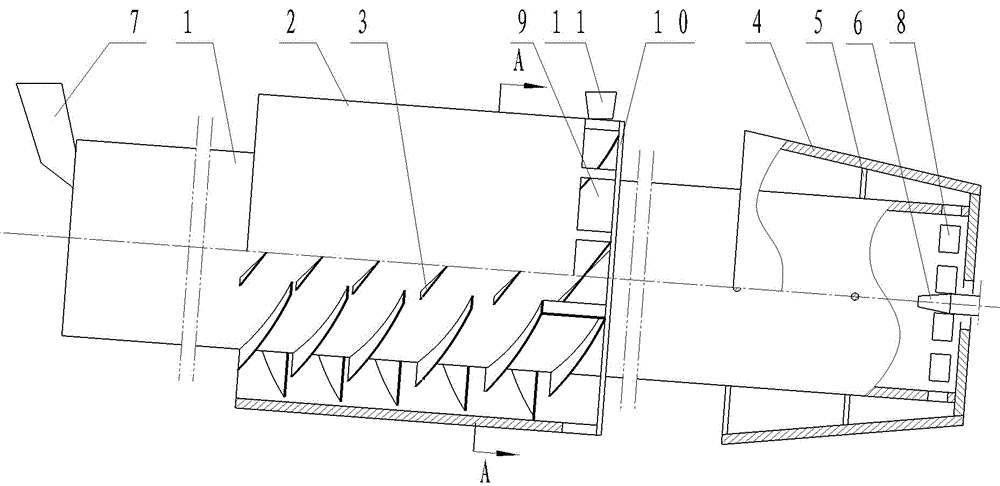

Method for preparing desulfurizing agent of thermal power plant by utilizing carbide slag and special equipment thereof

ActiveCN102886201ATake advantage ofAvoid pollutionSolid waste disposalDispersed particle separationPower stationSlag

The invention discloses a method for preparing a desulfurizing agent of a thermal power plant utilizing carbide slag and special equipment thereof. The method comprises the following steps of: taking the carbide slag as a raw material; and crushing, removing impurities, calcining, cooling and sieving to obtain the desulfurizing agent. Compared with the prior art, the method is simple in process, equipment used by the process is very simple and the machining cost is low; and the carbide slag is sufficiently utilized so that a resource is saved and the environmental pollution is prevented.

Owner:SHIHEZI DALU IND & TRADE

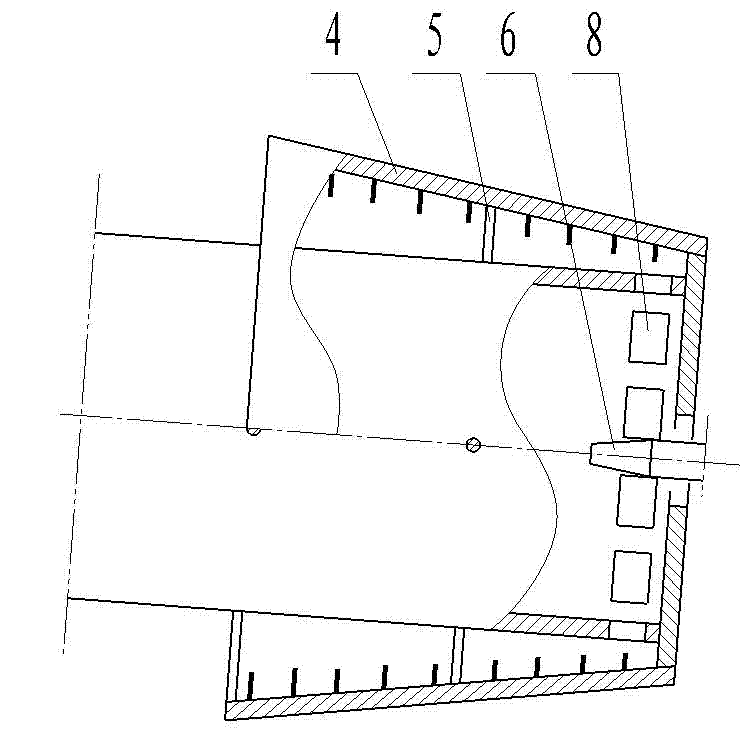

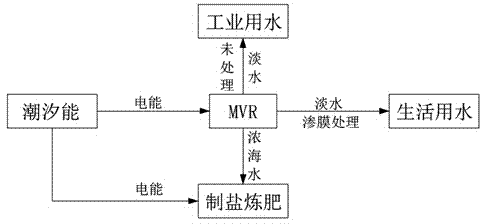

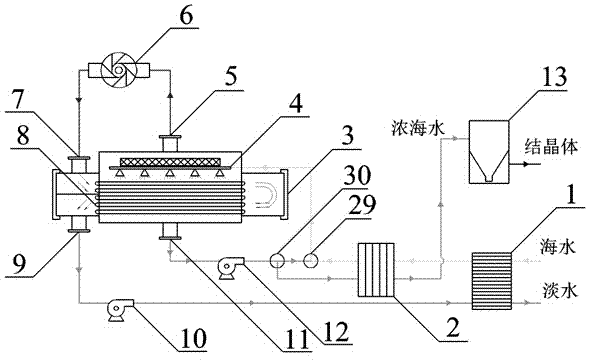

Tidal energy, solar energy, and mechanical vapor recompression integrated seawater desalination system

InactiveCN104773779AReduce electricity consumptionIncrease costGeneral water supply conservationSeawater treatmentThermal energyPower station

The invention belongs to the technical field of seawater desalination, and especially relates to an integrated seawater desalination system, which utilizes the tidal energy and solar energy to generate power to drive a mechanical vapor recompression seawater desalination comprehensive utilization device to produce fresh water and refine salt-containing minerals. The system comprises a tidal energy power generation system, a solar energy power generation system, and an MVR evaporation system. The tidal energy power generation system is a tidal energy power station, which supply power to the system. The solar energy power generation system is a solar plate-type pre-heater, which can absorb the optical energy and convert the optical energy into electric energy and thermal energy, supplies power to the system, and preheats seawater in the pipes of the preheater. The MVR evaporation system is used to condense and desalinate the seawater.

Owner:SHENYANG AEROSPACE UNIVERSITY

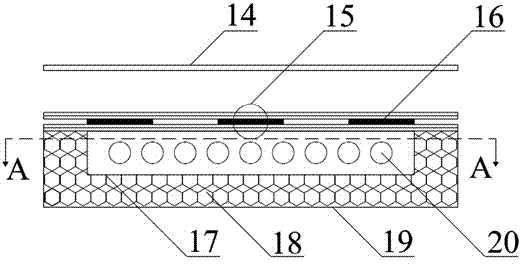

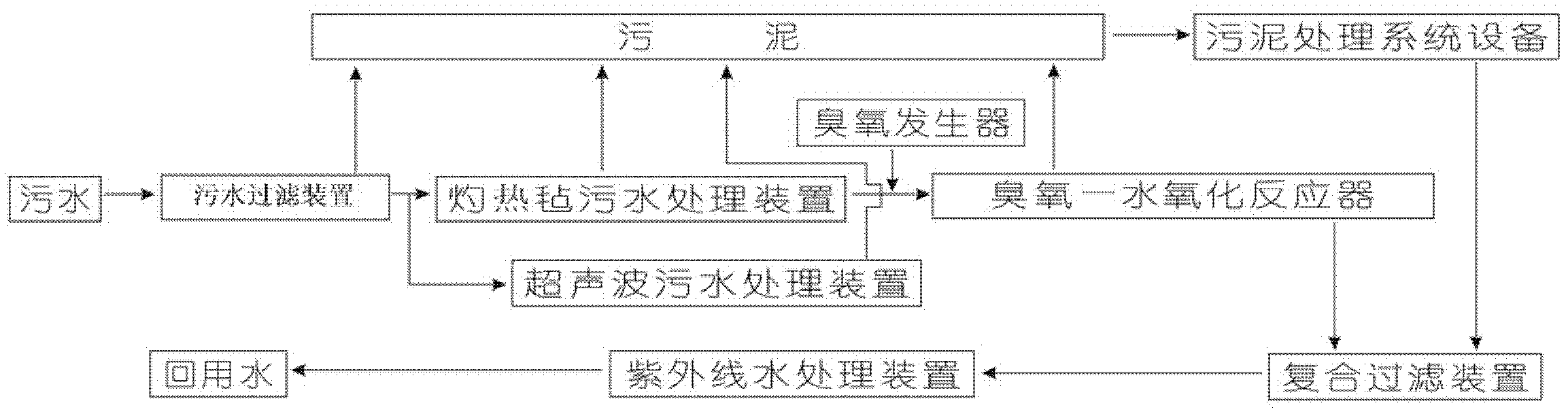

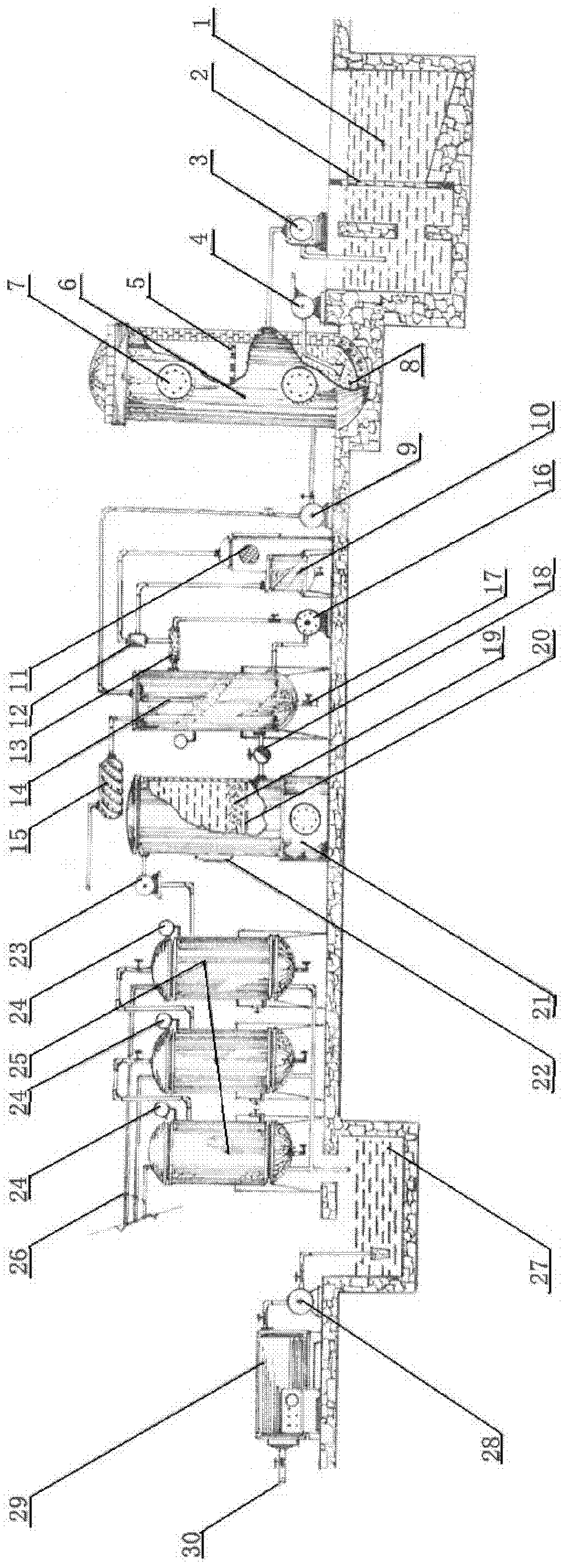

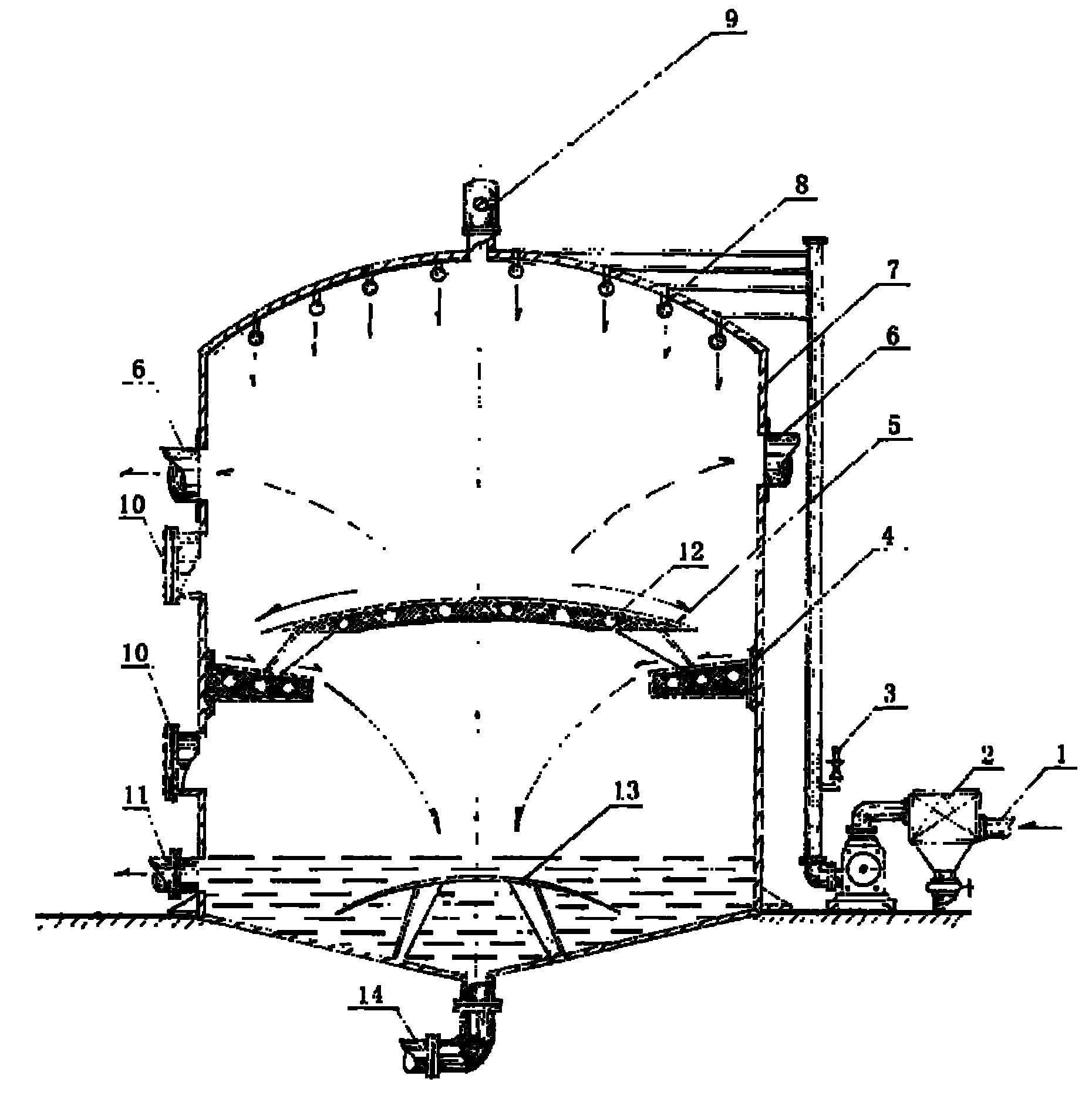

Sewage treatment system equipment for absolute quantification of sludge and method for recycling sewage

InactiveCN102531250AAvoid secondary pollutionSave production landWater/sewage treatment by irradiationWater/sewage treatment with mechanical oscillationsReclaimed waterWater collection

The invention provides sewage treatment system equipment for absolute quantification of sludge and a method for recycling sewage. The equipment comprises a sewage filtration device, a solid-liquid separation device, an ozone generator, a gas-water mixer, an ozone-water reactor, a composite filtration device, an ultraviolet water treatment device, and sewage treatment system equipment for converting the sludge into an adsorbent and a hybrid charge adsorbent, wherein the sewage filtration device is connected and communicated with the solid-liquid separation device. The method for recycling the sewage comprises the following steps that: the sludge in the sewage and the sewage are separated in the solid-liquid separation device; the sewage is collected by using a fog water collection device and then flows into the gas-water mixer; meanwhile, ozone gas produced by the ozone generator also flows into the gas-water mixer and then is mixed with the input sewage, and is conveyed to the ozone-water reactor; the sewage treated by using the ozone-water reactor flows into the composite filtration device; and water obtained after the treatment of the composite filtration device flows into a reservoir, then is fed to the ultraviolet water treatment device through a water pump and treated to form reclaimed water.

Owner:SOUTH CHINA REBORN RESOURCES ZHONGSHAN

Vertical type reeled paper glazing device and the printing system thereof

ActiveCN101032881AFully automatedImprove printing qualityOffice printingPrinting press partsGear driveRolling paper

The vertical coil paper glazing machine includes one glazing head, a coil paper conveying and supporting roller and a stoving unit. The glazing head includes a frequency variable speed regulating motor with synchronous rotation with the printing unit during glazing operation and slowed rotation in no glazing operation, one driving gear driven with the motor, one glazing roller and one slurry roller driven with the driving gear, and one roller clutch driving unit. The present invention also discloses one kind of printing system with the vertical coil paper glazing machine. The present invention has raised printing quality, lowered production cost and other advantages.

Owner:浙江武义华东实业有限公司

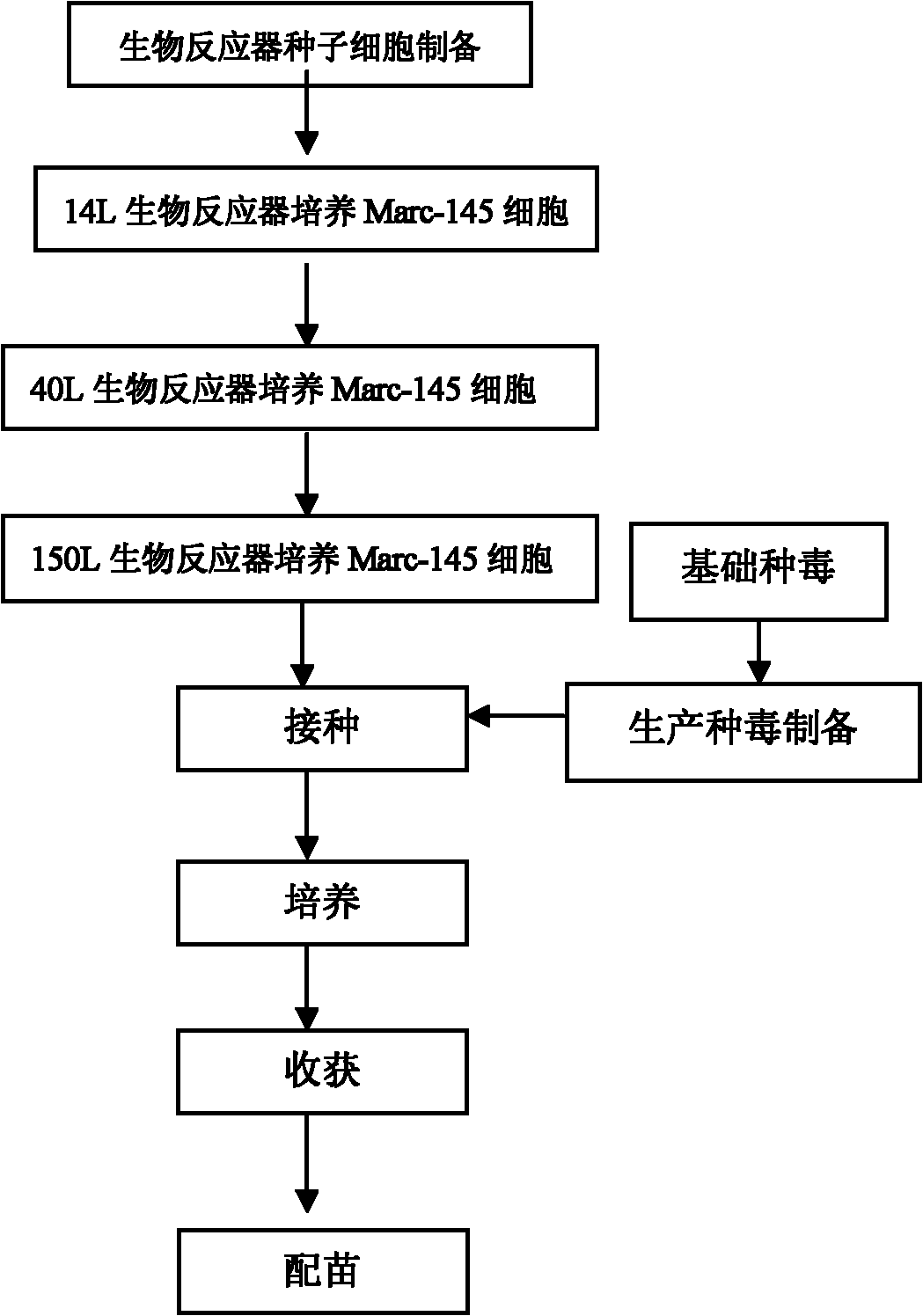

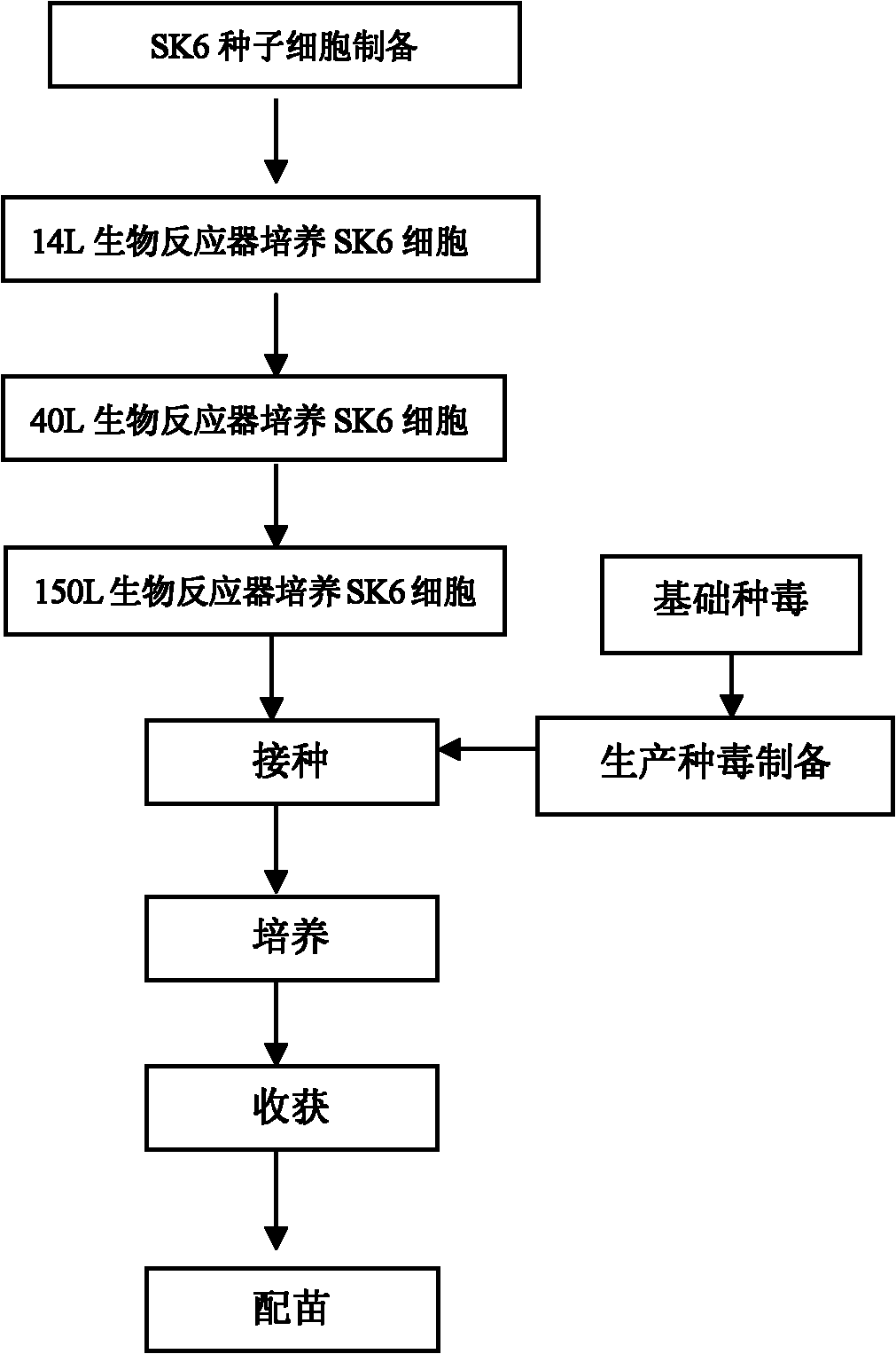

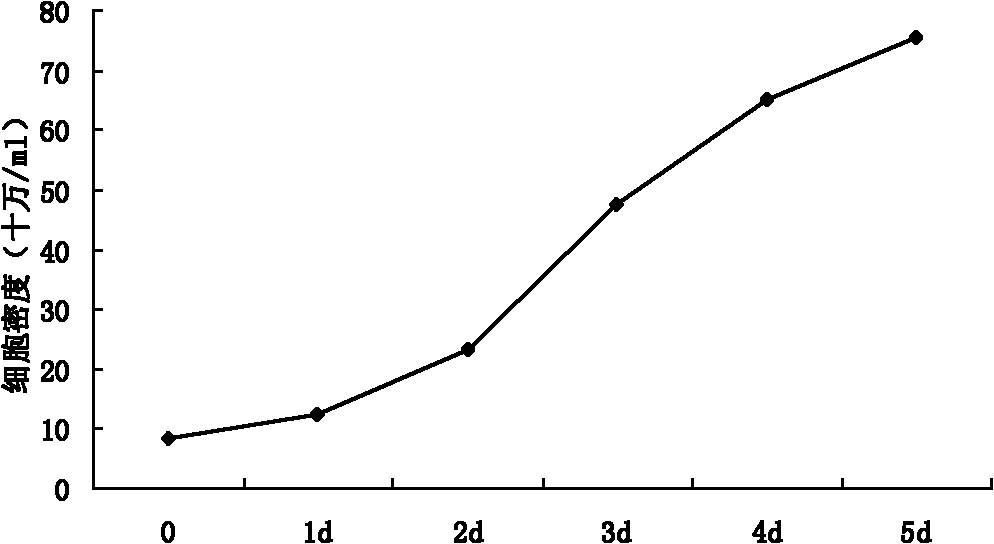

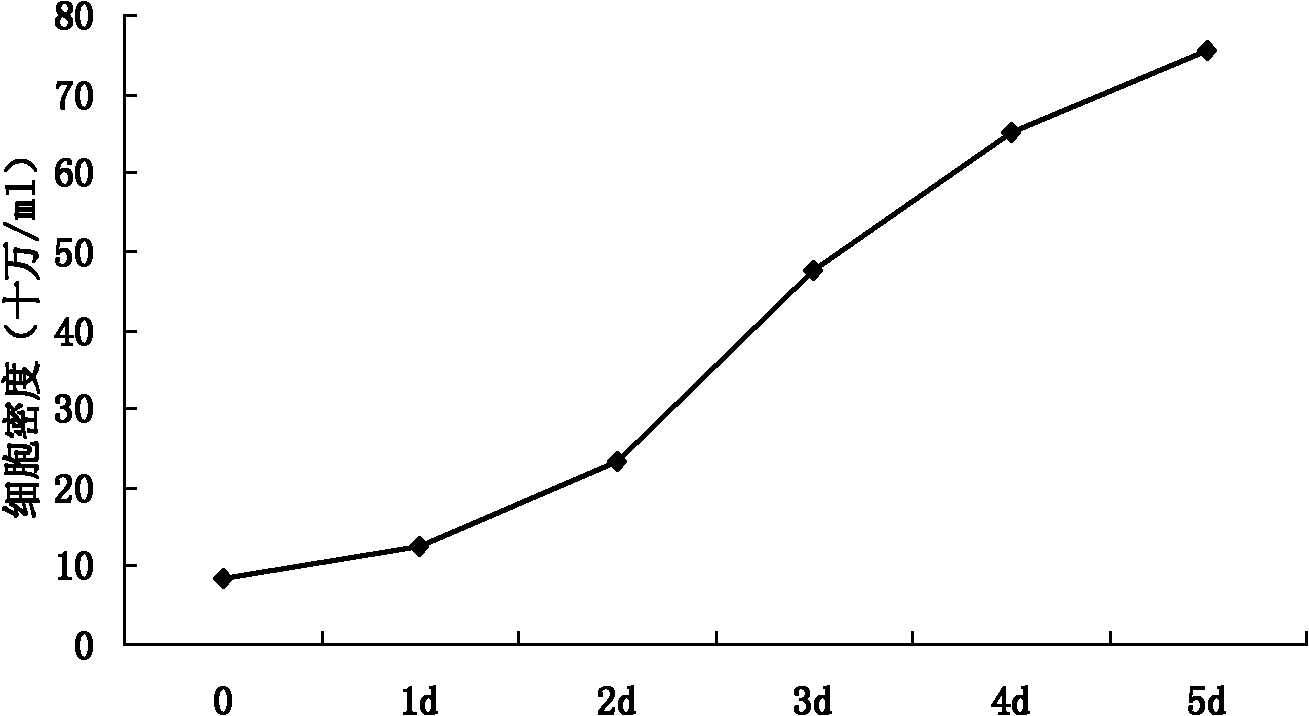

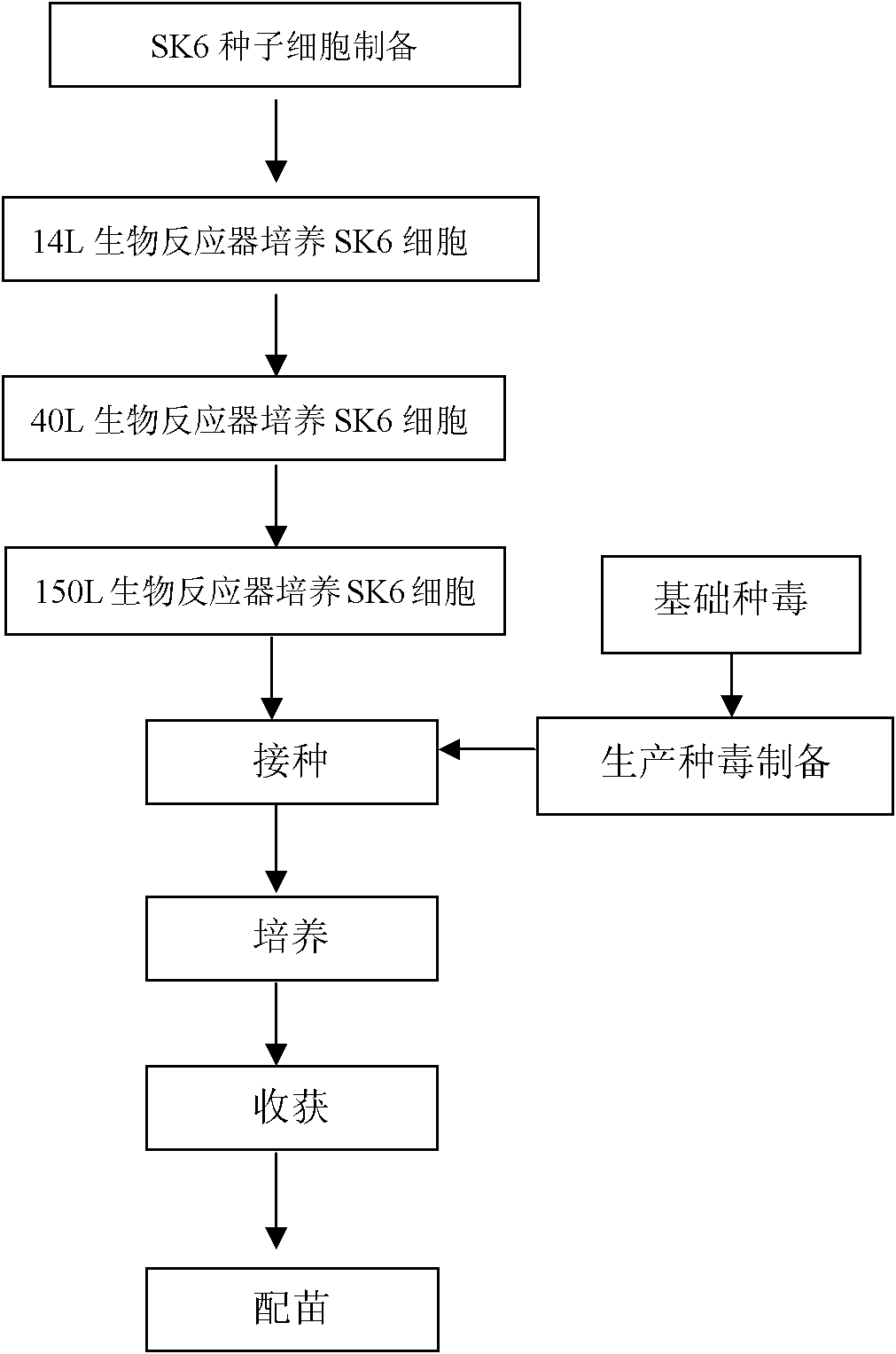

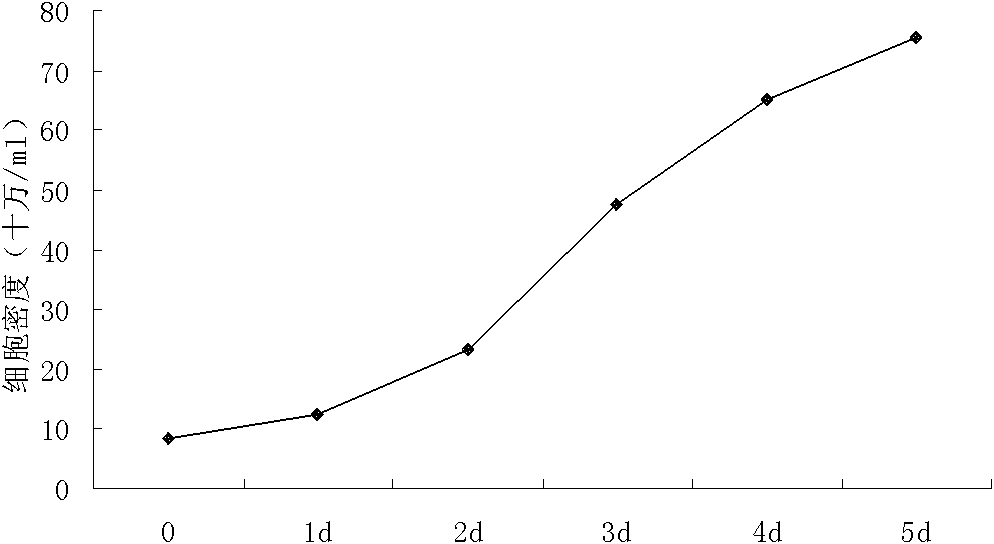

Method for industrially producing porcine reproductive and respiratory syndrome (PRRS) vaccines by utilizing bioreactor

ActiveCN102038942AHigh titerHigh degree of automation controlViral antigen ingredientsMicroorganism based processesAdjuvantFreeze-drying

The invention relates to a method for industrially producing porcine reproductive and respiratory syndrome (PRRS) vaccines by utilizing a bioreactor. The method comprises the following steps: (1) sterilizing a microcarrier and the bioreactor, then adding cell growth liquid, inoculating cells for vaccine preparation for culturing, inoculating PRRS viruses when dense monolayers are formed on the cells on the microcarrier and continuing culturing to reproduce the viruses; (2) stopping culturing and harvesting virus suspension when cytopathy reaches more than 80%; and (3) adding a freeze-drying protective agent to the harvested virus suspension to prepare freeze-dried attenuated live vaccines or carrying out ultrafilter concentration as well as virus inactivation on the harvested virus suspension, purifying the inactivated viruses by adopting column chromatography, and adding adjuvants to prepare inactivated vaccines. Compared with the traditional spinner bottle production process, the method has the following advantages: the automation control degree is high, so production can be monitored in real time; the labour is saved, thus reducing the cost; the land for production is few, thus being easy to enlarge the scale of production; and the produced viruses have high titer, so the batch-to-batch variation is small, the product quality is stable and the side reaction is low.

Owner:WUHAN CHOPPER BIOLOGY

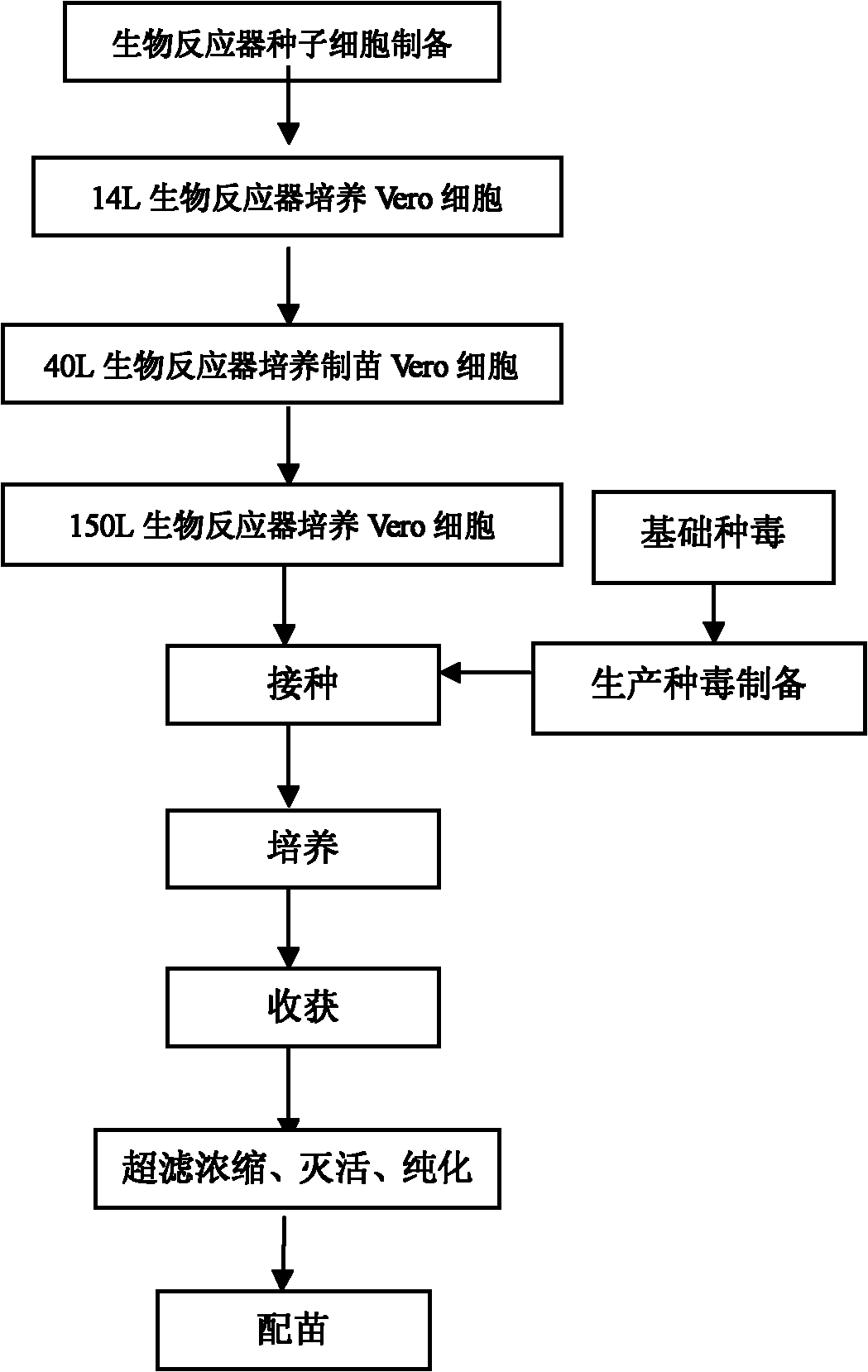

Method for industrially producing animal rabies vaccine by utilizing bioreactor

InactiveCN102038947AHigh titerHigh degree of automation controlMicroorganism based processesAntiviralsUltrafiltrationBottle

The invention provides a method for industrially producing an animal rabies vaccine by utilizing a bioreactor, comprising the following steps of: (1) sterilizing a micro-carrier and the bioreactor, adding a cell growth solution, inoculating Vero cells for culturing, inoculating rabies viruses after the cell on the micro-carrier forms a compact single layer, and continuously culturing to propagate the viruses; (2) inoculating for 18h and then continuously harvesting a virus solution; (3) carrying out ultrafiltration concentration and virus inactivation on the harvested virus solution; and (4) purifying and inactivating the viruses through a column chromatography method to prepare the vaccine. In the invention, the high density culturing of the cells is carried out by utilizing a bioreactor micro-carrier culturing technology to produce the animal rabies vaccine. Compared with the traditional rotating bottle production method, the automation control degree is high, the production can be monitored in real time, the labor power and the cost are reduced, the production land is less, the scale is easy to expand, the produced virus titer is high, the difference among batches is less, the product quality is stable, and the side reaction is less.

Owner:WUHAN CHOPPER BIOLOGY

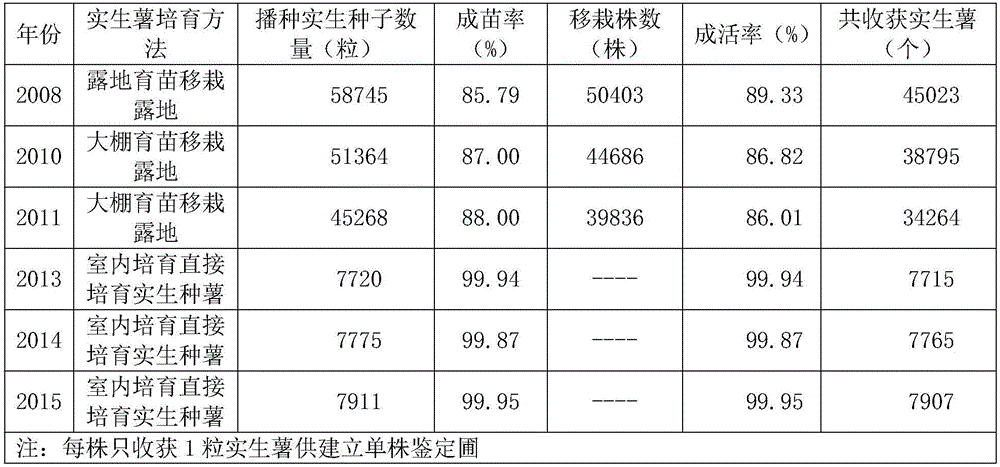

Indoor culture method of seedling seed potatoes

InactiveCN106818162ASave production landReduce labor for transplantingSeed and root treatmentHorticultureSowingGenotype

The invention discloses an indoor culture method of seedling seed potatoes. The method is characterized in that seedling seeds harvested in the current year are subjected to dormancy processing and germination acceleration, and seedling seed sowing culture is performed in a culture room to produce the seedling seed potatoes. The method mainly includes: preparing substrates, preparing seedling culture plates, breaking the dormancy period of the seedling seeds, and performing germination acceleration, sowing, management and harvesting. The method has the advantages that the seedling seeds harvested in the current year are used to produce the seedling seed potatoes in the current year, the seed culture time is shortened by more than one year as compared with the existing seed culture technology, and seed culture efficiency is increased; the seedling seed potatoes are directly produced in the seedling culture plates, transplanting labor is reduced, and seed potato production land is saved; the seed potatoes are directly cultured in the seedling culture plates, and a seedling culture effect is prevented from being affected by seedling culture genotype loss caused by seedling deaths during transplantation; soil diseases and pests caused by a convention culture manner are avoided; the substrates are local natural-resource pine needle humus soil, the rich nutrition of the humus soil is provided for the growth of plants, fertilizing is not needed, and the substrates are easy in material obtaining and low in cost.

Owner:GUIZHOU HENGFENG TECH DEV

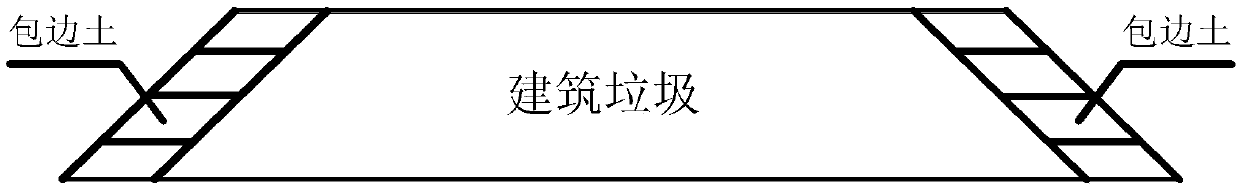

Highway roadbed filling method based on construction waste

InactiveCN108677638ASolve the accumulationSave natural resourcesRoadwaysArchitectural engineeringPre treatment

The invention discloses a highway roadbed filling method based on construction waste. The highway roadbed filling method comprises the steps of pre-processing on a construction site, survey and setting out, basal layer treatment, pre-treatment of the construction waste, water insulation treatment of surrounding soil, laying and leveling of the construction waste, crushing of the construction wasteand quality inspection. The highway roadbed filling method based on the construction waste realizes high-quality filling of highway roadbed by utilizing the construction waste, largely solves the problem of excess construction waste, provides a reliable choice for materials and methods of roadbed filling, and achieves the concept of sustainable development by saving resources and protecting the environment to a certain extent.

Owner:SHANGHAI JIAO TONG UNIV

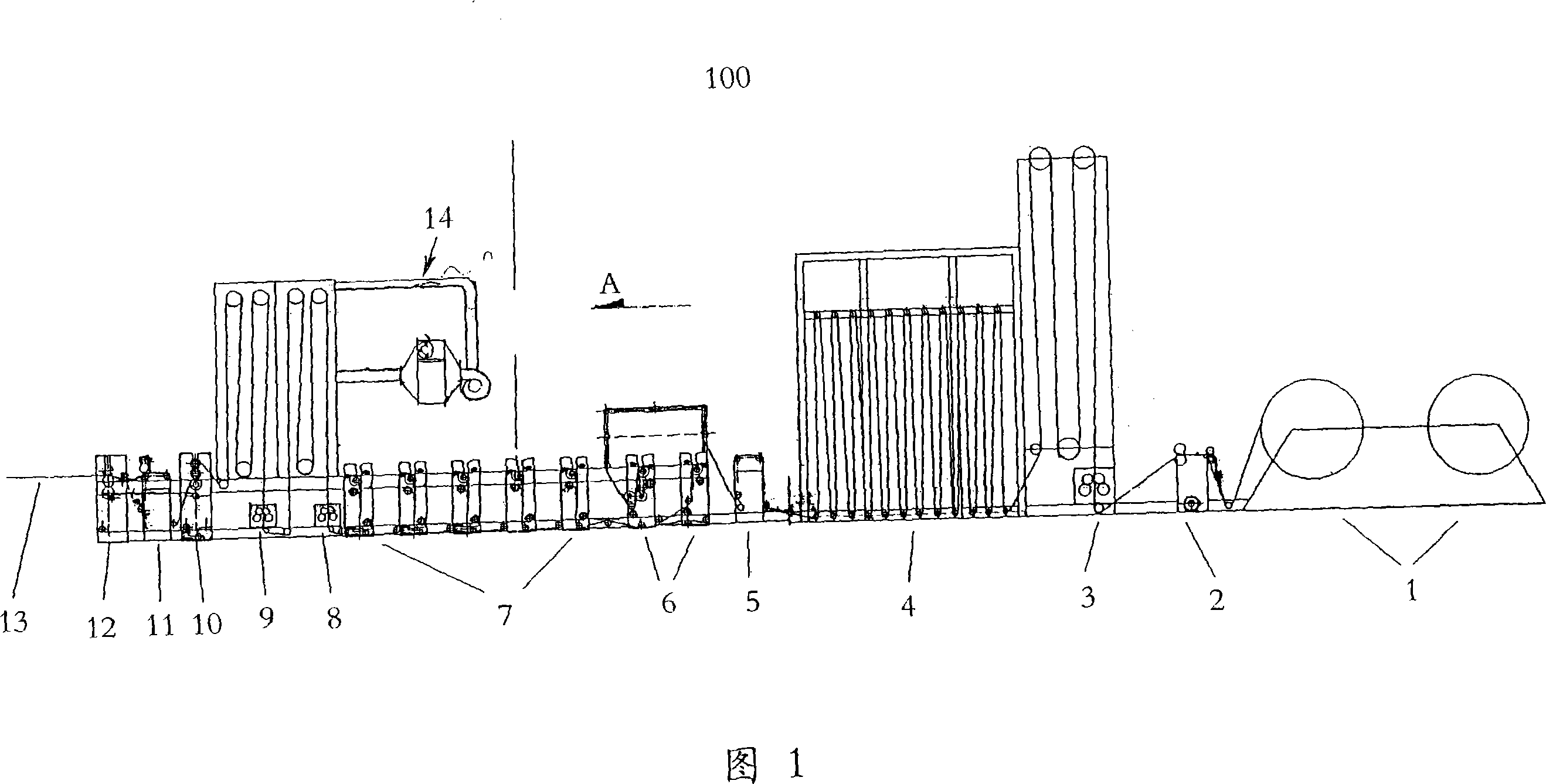

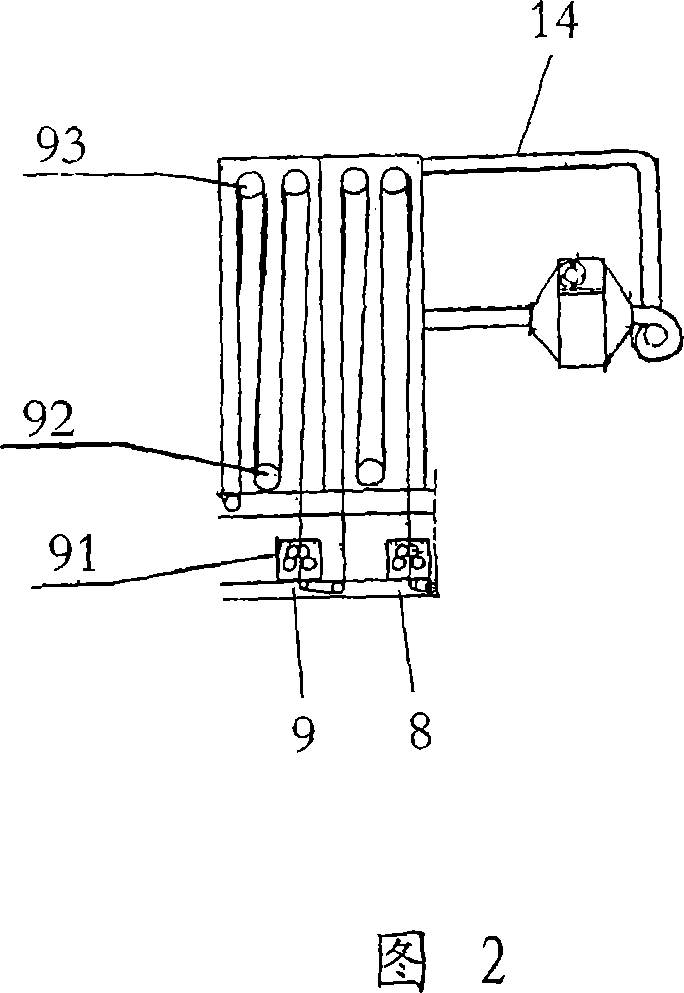

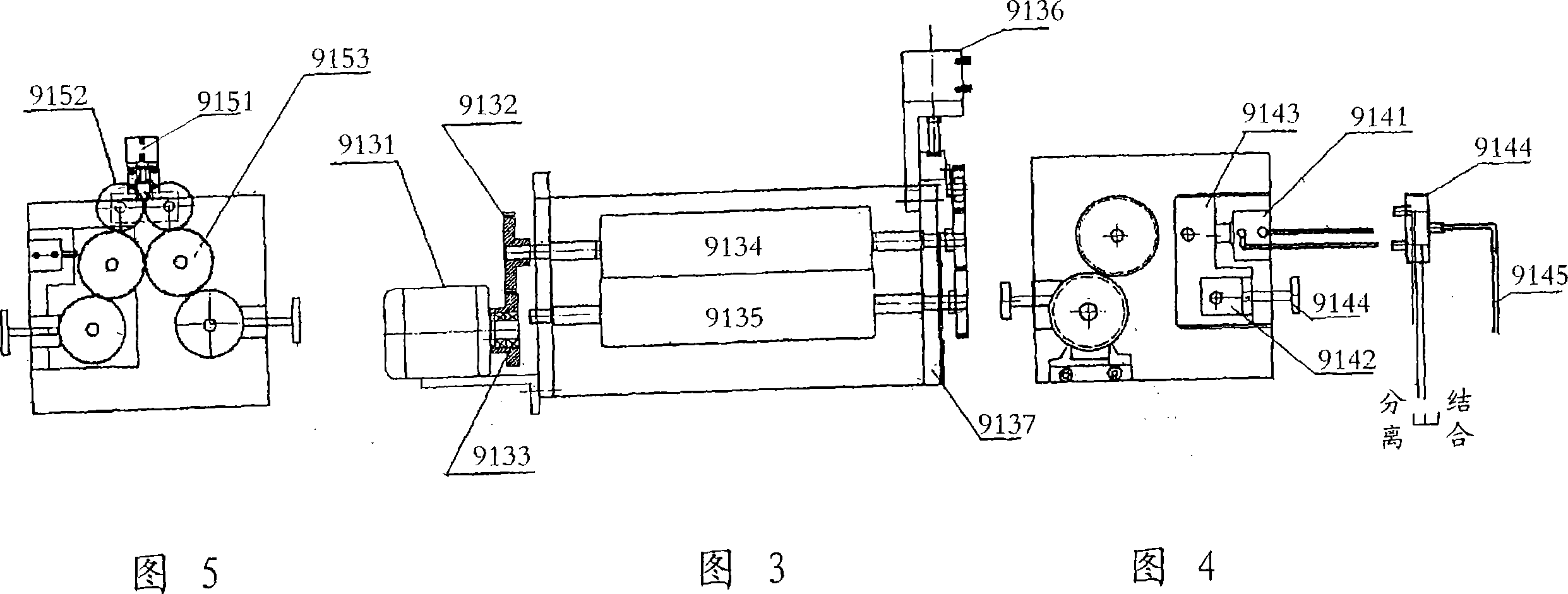

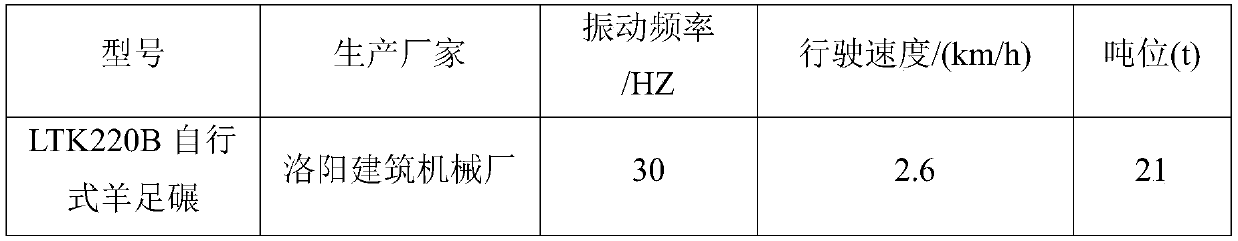

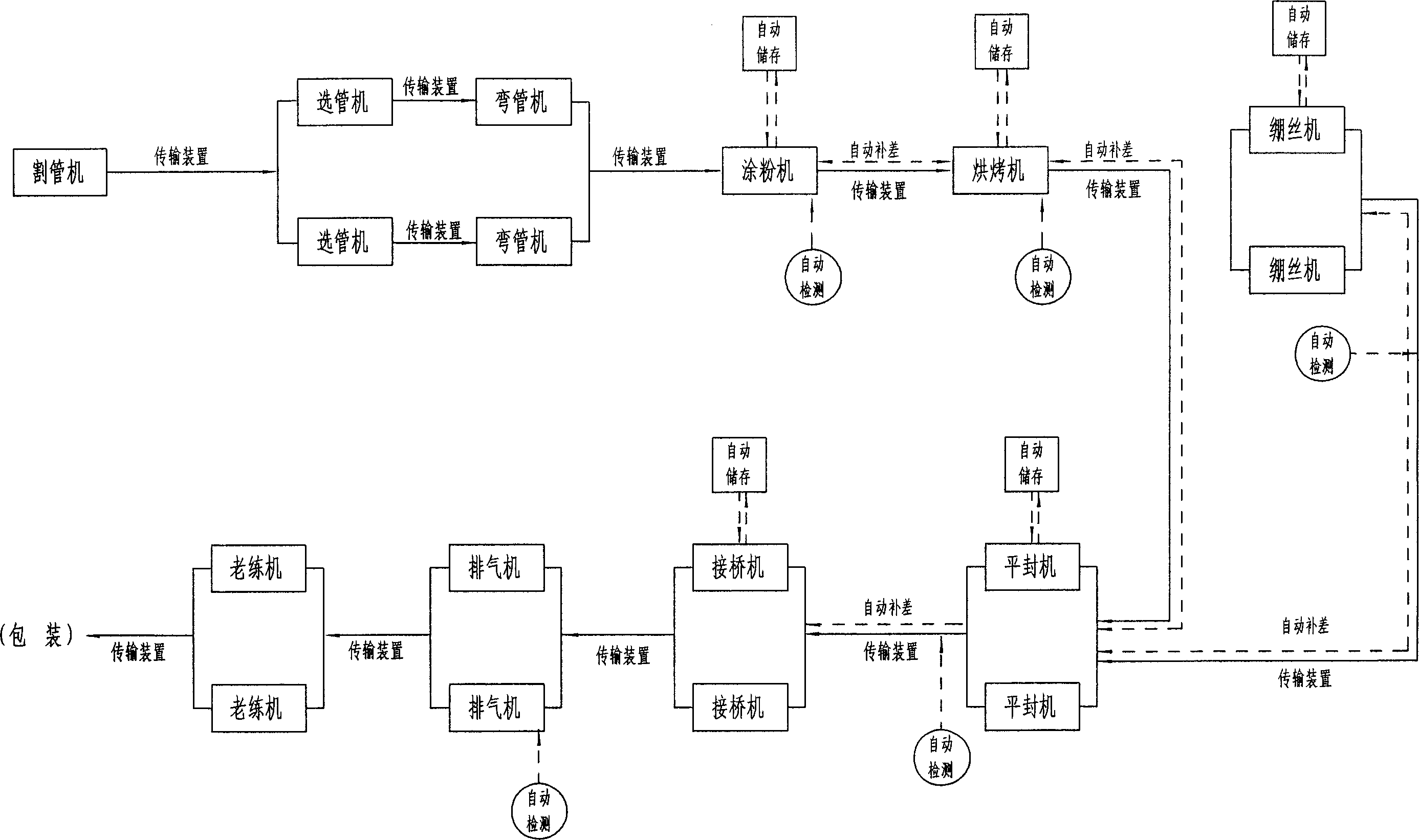

Automatic production system for energy saving luminous tube

InactiveCN1873883AMinus the phenomenon of multi-employmentReduce clutterVessels or leading-in conductors manufactureCold cathode manufactureProcess engineeringWork in process

The disclosed automatic system for fabricating energy-saving luminous tube arranges following facilities in order: tube cutter, tube selection unit, tube bender, powder coating machine, roasting unit, capper, air exhauster and aging machine etc. Transmission equipment is set up between each unit of machine. Through transmission equipment, each unit of machine is cascaded. Thus, half-finished product from previous working procedure enters to unit of machine at next working procedure automatically. Advantages are: reducing manual work and number of worker, reducing breakage of half-finished or finished products in each working procedure so as to save ground area needed for production.

Owner:JIANGSU HAOMING PHOTOELECTRIC TECH

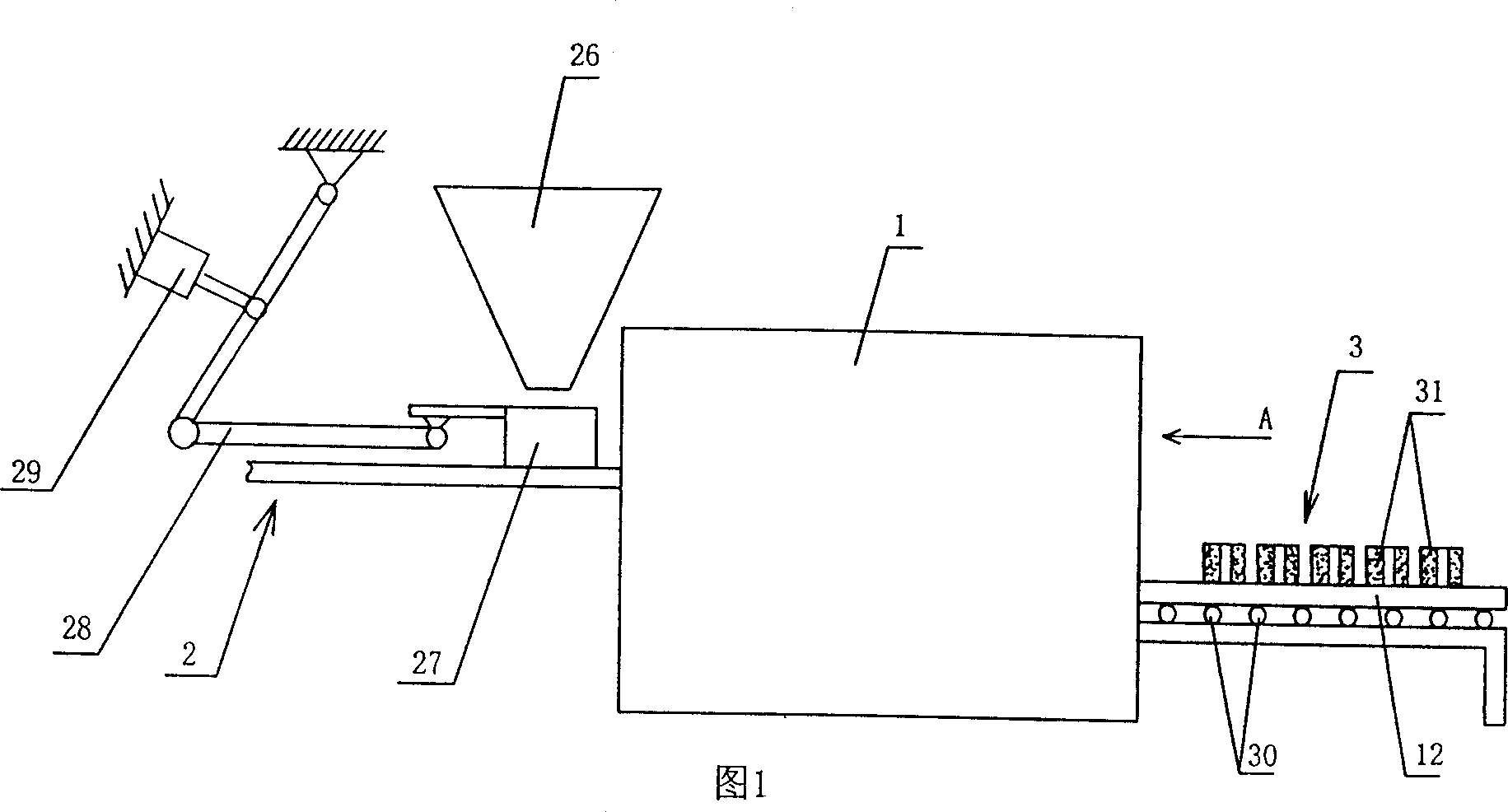

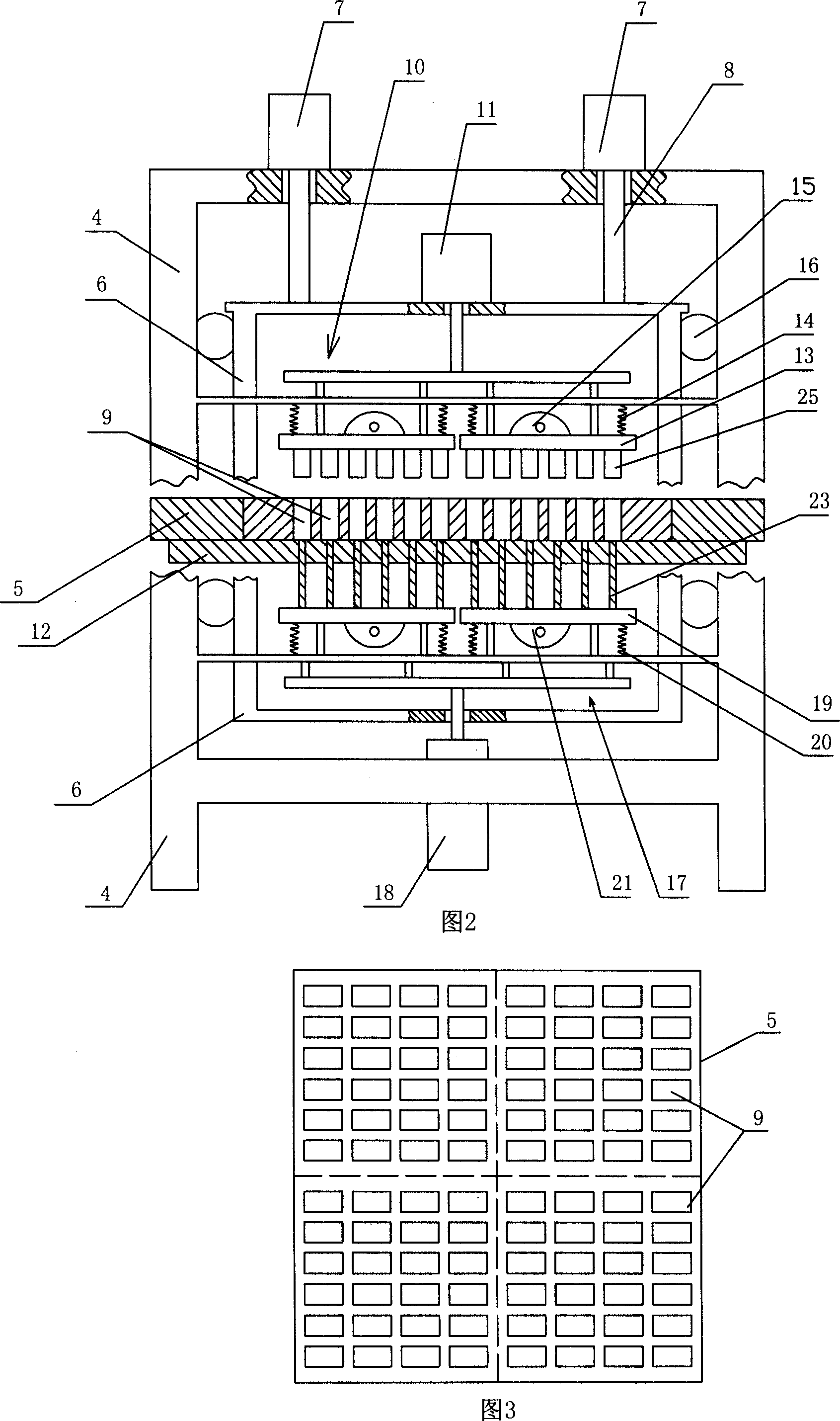

Concrete building block continuous producing technology

InactiveCN101143463ASave production landReduce the number of transshipmentsCeramic shaping plantsMolding machineUltimate tensile strength

A continuous production technology for a concrete block comprises a quantitative hopper feed into a die box of a concrete block molding machine. The adoption of a vibration extrusion molding leads to a direct palletizing and a transshipment strength for the molded block. The direct palletizing is done after block-molding and mold-stripping. The palletized block is transshipped into the hardening process. A top product is produced out after the hardening process. The technology saves a plurality of wooden carriers and carrier storage racks as well as storage space, saves the production site, reduces the number of transit and lowers transit cost. The heat of hydration in the hardening process of the concrete block is fully utilized. When the blocking process is done at a lowered temperature, the hardening time is shortened more than one and a half times than that at a natural temperature environment. The invention greatly saves production cost and improves production efficiency.

Owner:王海清

Processing method of pinellia rhizome fermented mass

ActiveCN101912545AShorten production timeSave production landDigestive systemRespiratory disorderPinelliaRed bean

The invention relates to a processing method of pinellia rhizome fermented mass. The processing method comprises the following steps of: taking 11-13kg of flour, 32-36kg of wheat bran, 1-3kg of bitter almonds, 1-3kg of small red beans and 0.1-0.4kg of dry polygonum according to each 10kg of rhizoma pinellinae praeparata; grinding and sieving the dry polygonum, the bitter almonds and the rhizoma pinellinae praeparata; grinding the small red beans, adding water and boiling the small red beans into porridge, and fermenting and foaming; pouring rhizoma pinellinae praeparata powder, the flour, the wheat bran, the crude powder of the bitter almonds and the crude powder of the dry polygonum into a mixer for stirring; adding the fermented small red bean porridge to the mixer for stirring together; taking the mixture out of the mixer to form a pile, tamping, and covering the mixture with plastic cloth to ferment for later use; molding the broken pinellia rhizome fermented mass, drying the molded pinellia rhizome fermented mass in a drying oven, and cooling to obtain the finished product. The invention has the advantages of advanced technique, scientific and reasonable process design, specific technological parameters, easy operation control and increased production efficiency. The invention is applicable to scale production and automatic production, and has a demonstration effect on the optimization of an industrial structure and the technological upgrading in the production of traditional Chinese oral tablets.

Owner:北京同仁堂(亳州)饮片有限责任公司

Method for industrially producing swine fever live vaccine by using bioreactor

ActiveCN102038944AHigh titerHigh degree of automation controlMicroorganism based processesAntiviralsHigh cellVaccine Production

The invention relates to a method for industrially producing a swine fever live vaccine by using a bioreactor. The method comprises the following steps of: (1) sterilizing a microcarrier and the bioreactor, adding cell growth solution, inoculating cells for vaccine production, culturing the cells, and after the cells on the microcarrier form a compact monolayer, discarding the cell growth solution, adding virus maintenance solution and inoculating swine fever virus, and continuously culturing to allow the virus to reproduce; and (2) after the virus is inoculated for 18 hours, continuously obtaining virus culture solution, storing the virus culture solution at the temperature of below -15 DEG C, mixing the virus culture solution, and adding a cryoprotectant to prepare the swine fever live vaccine. The method has the advantages of high controllability of process parameters, high cell culture density, high virus titer, high vaccine safety, stable and reliable quality, high production efficiency and the like.

Owner:WUHAN CHOPPER BIOLOGY

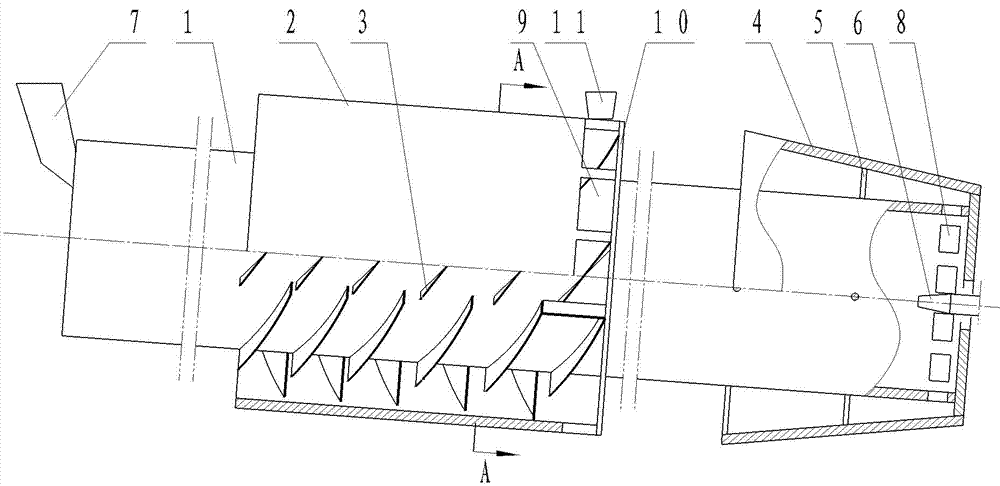

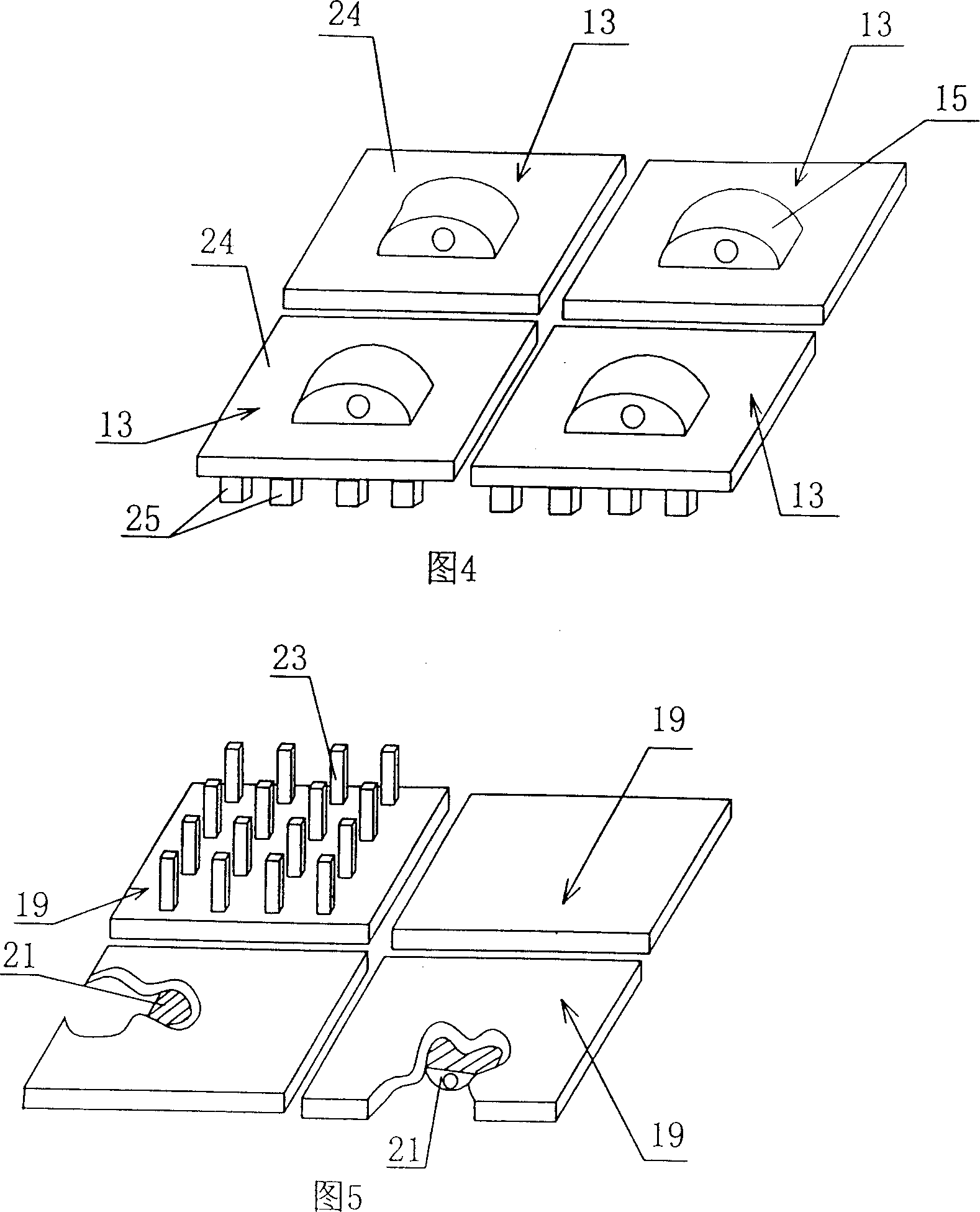

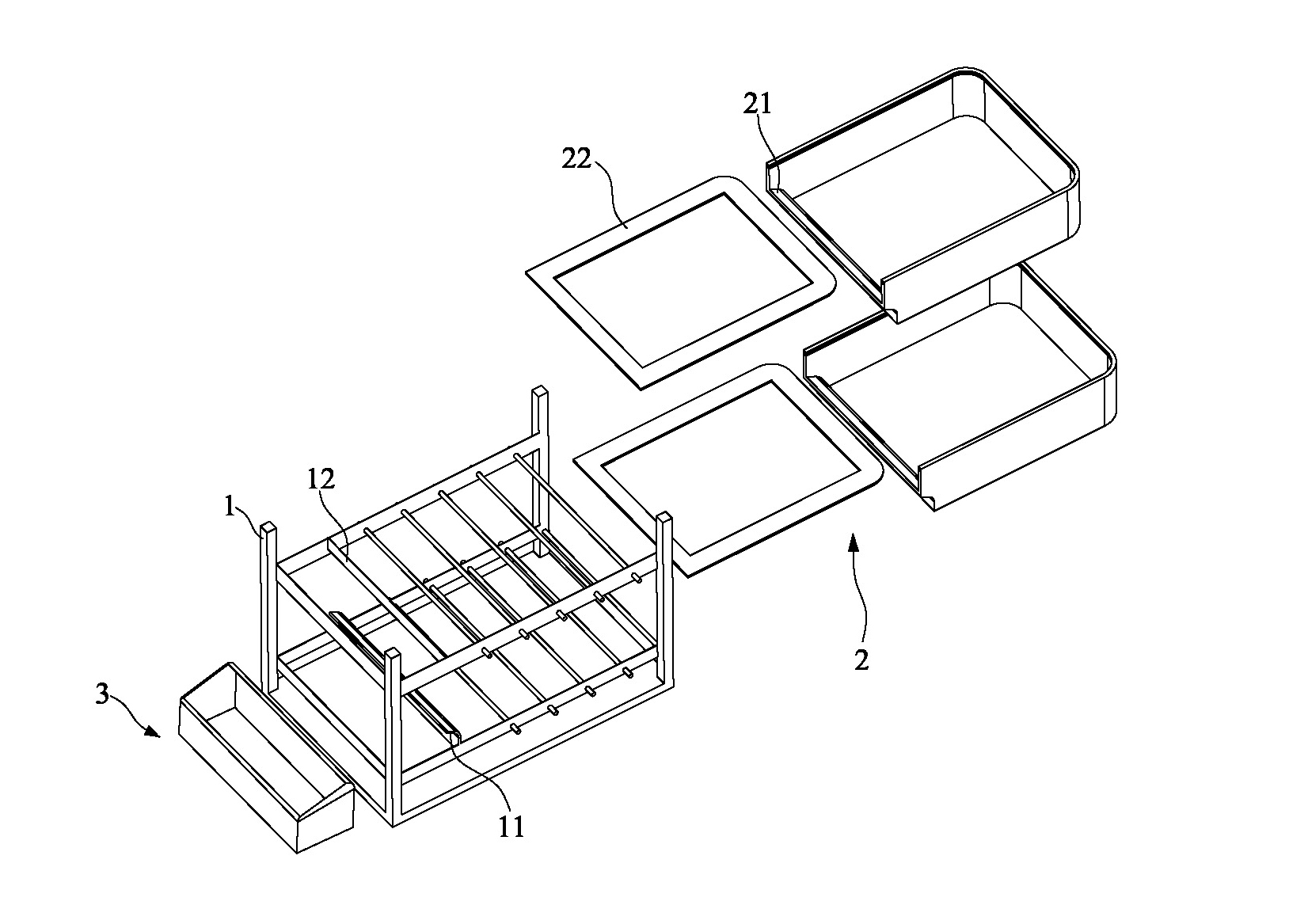

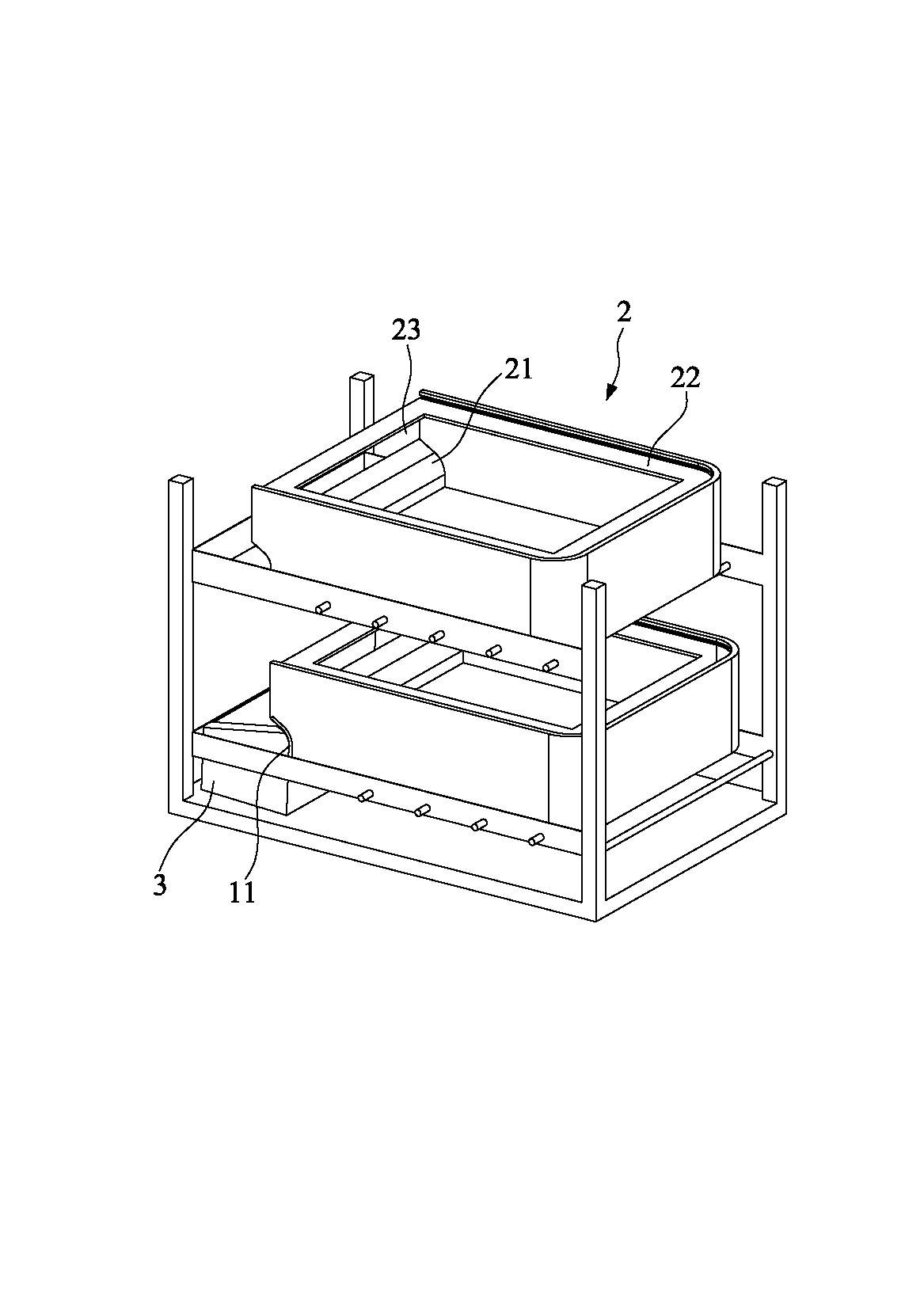

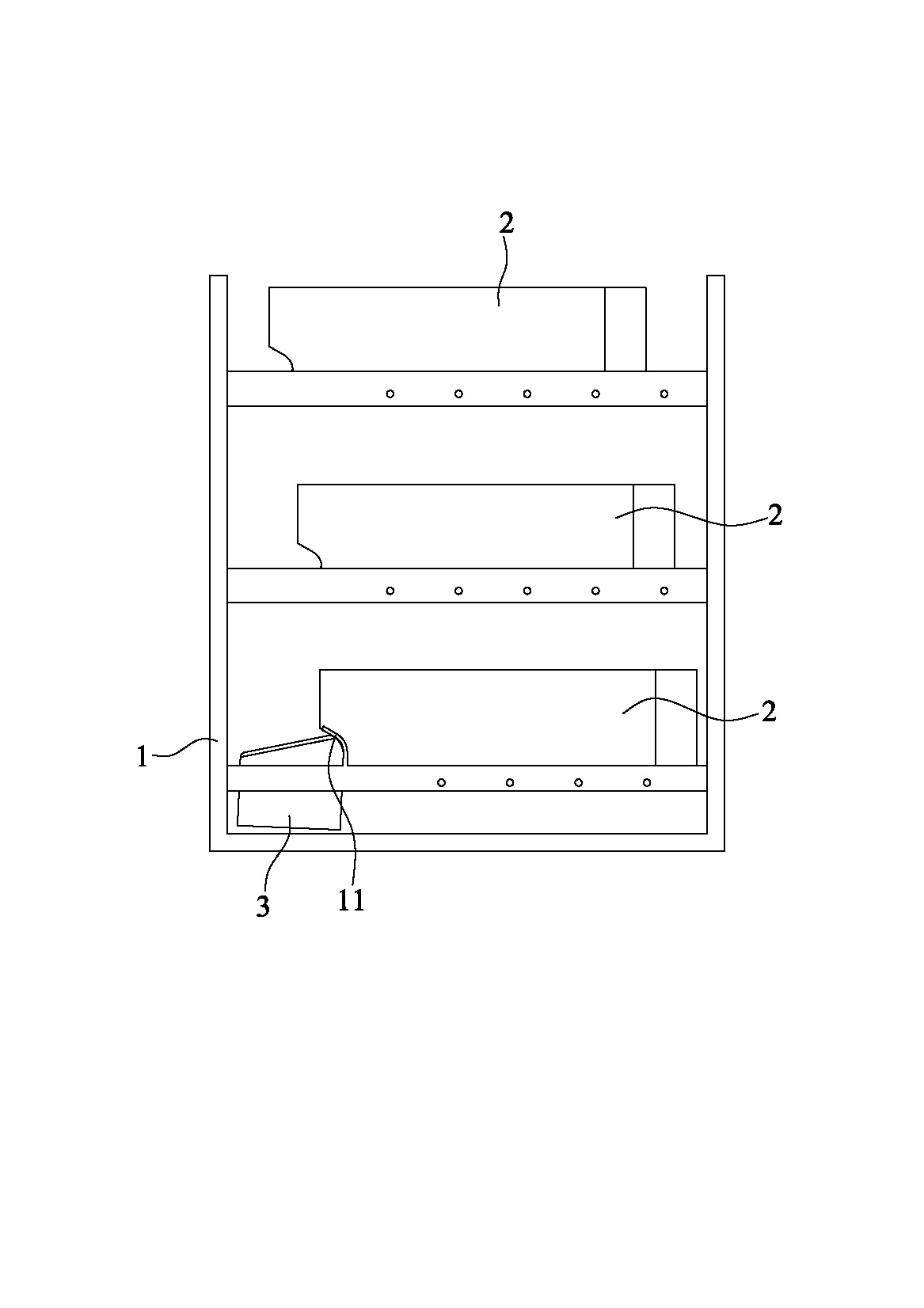

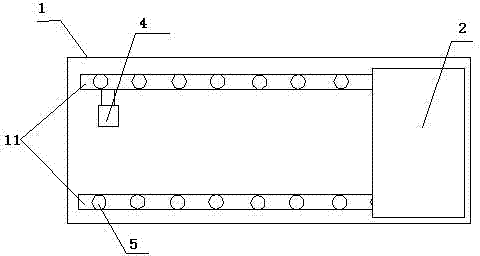

Maggot culture apparatus and large-scale maggot culture system

The invention discloses a maggot culture apparatus, which consists of a culture rack, a culture box and a collecting box. The top of the culture box is open, three sides of the culture box are provided with side plates, one side of the culture box is provided with an oblique outer guide plate, a blocking frame is covered on the opening of the top, and a maggot is formed between the oblique outer guide plate and one corresponding edge of the blocking frame; the top of the collecting box is open, and four sides of the collecting box are provided with side plates; and the culture rack is provided with at least one bottom layer, the culture box and the collecting box are placed on the bottom layer, the oblique outer guide plate of the culture box on the bottom layer is tightly attached to the side plates of the collecting box, and the top of the oblique outer guide plate of the culture box on the bottom layer is higher than the top of the corresponding side plate of the collecting box. The maggot culture apparatus, a fermentation tower, a quantitative feeder, a conveying line and a stacking mechanism form a large-scale maggot culture system. By the maggot culture apparatus, the culture density can be improved, the problem of air pollution is solved, and large-scale automatic production is facilitated.

Owner:程粮

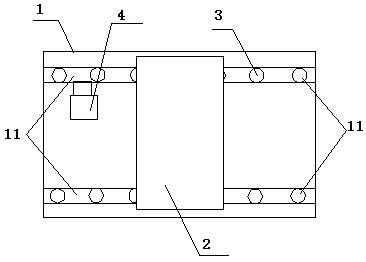

Bus production device

ActiveCN104269222AReduce manufacturing costReduce energy consumptionCable/conductor manufactureFuel tankEngineering

The invention discloses a bus production device which comprises a body and a first roller set in the body. The body is an oil pumping box. A drying box is arranged at the tail end inside the oil pumping box and fixed to the side wall inside the oil pumping box. A coating box is arranged in the drying box and located in the middle inside the drying box. The original oil pumping box, a drying oil box, the coating box and a coating drying box are simplified into one device, the space occupied by enterprise production is saved, the operation procedures are greatly simplified, only one drying box is needed, no coating drying box is arranged, the energy consumption is saved, secondary drying is not needed, and the enterprise production cost is reduced.

Owner:江苏华威线路设备集团有限公司

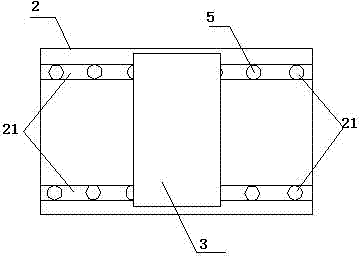

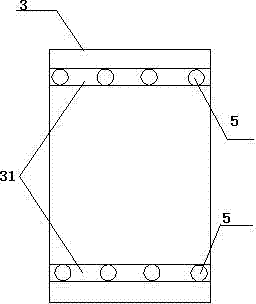

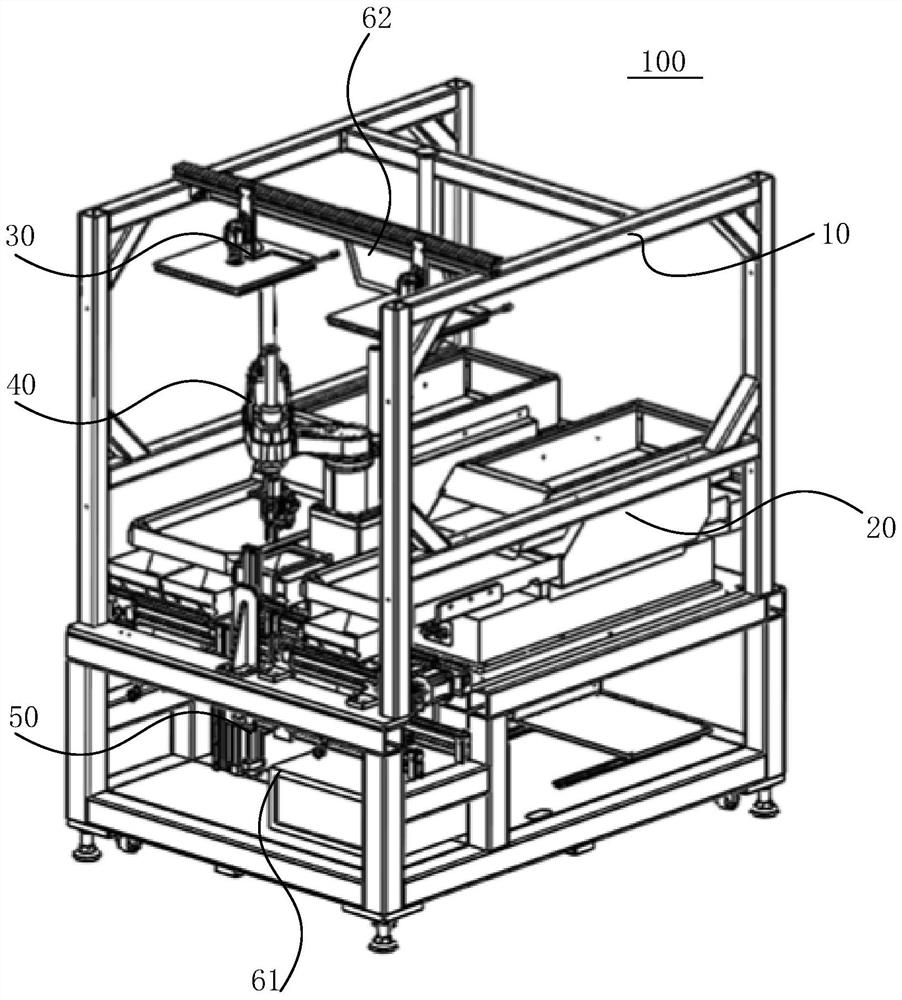

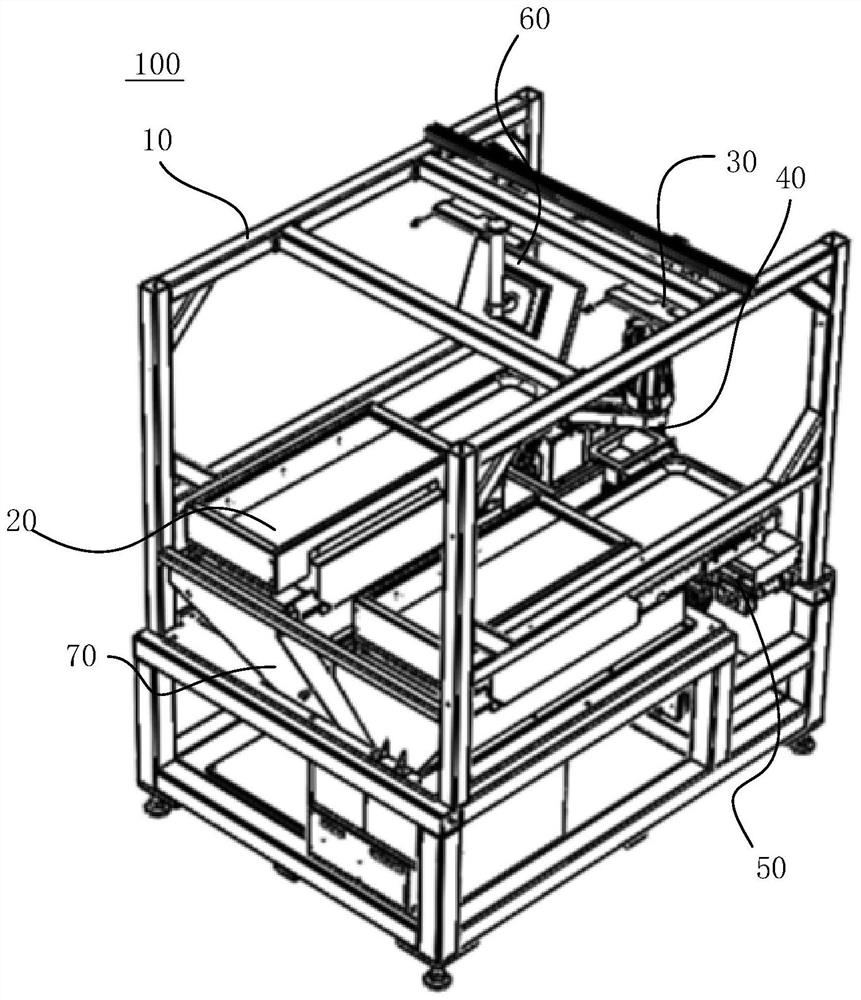

Sorting device and sorting method

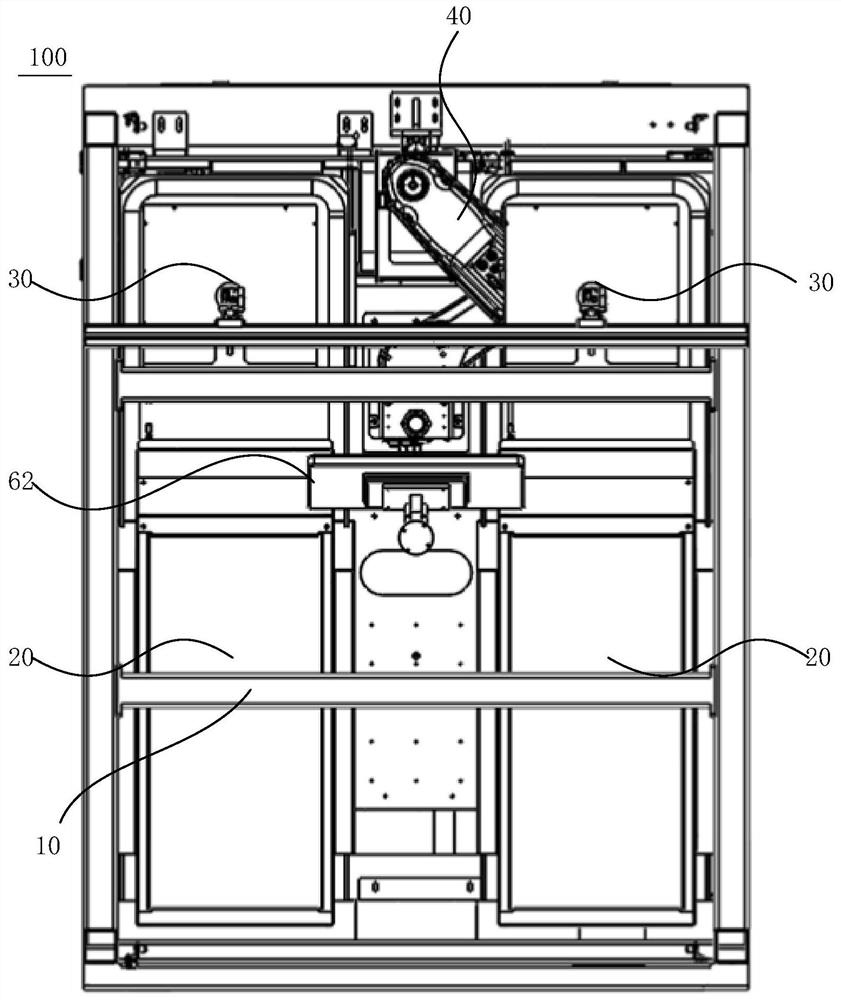

PendingCN113262989ARealize sortingRealize the supplySortingProcess engineeringIndustrial engineering

The invention provides a sorting device and a sorting method, and relates to the field of feeding and sorting. The sorting device comprises a feeding mechanism, a recognition mechanism, a picking mechanism, an output mechanism and a control mechanism. The feeding mechanism is used for bearing materials and dispersing the materials, the recognition end of the recognition mechanism faces the feeding mechanism, and the recognition mechanism is used for photographing the materials borne on the feeding mechanism and transmitting photographed image information to the control mechanism. The control mechanism can confirm material information of materials and position information of the materials on the feeding mechanism according to the photographed image information, the picking mechanism is used for picking the materials on the feeding mechanism and placing the materials on the output mechanism, and the output mechanism is used for outputting the materials placed on the output mechanism. According to the sorting device, sorting is carried out without depending on the boundary dimensions of the materials, various different materials can be sorted at the same time, the types of the sorted materials can be rapidly switched according to needs, the production utilization rate is increased, and meanwhile the production land is saved.

Owner:UBTECH ROBOTICS CORP LTD

Seal coating process and manufacturing method of wood furniture

The invention relates to a seal coating process and a manufacturing method of wood furniture. The seal coating process includes the steps of 1), using, by weight, 10-35% of air-drying resin, 60-85% o plastics and 5-30% of a thinner to blend brushing plastics; 2), coating the brushing plastics on a work piece with the coating weight controlled within 80-120g / m<2>; 3), starting a movable-type UV (ultraviolet) drier, and drying the plastics through motion of the movable-type UV drier; 4), diluting the sealing plastics to coat the same on the work piece; 5), starting the movable-type UV drier, and drying the plastics through motion of the movable-type UV drier. The coating process has the advantages of operation easiness; environment pollution, production space, polishing manpower, paint consumption, damages to human health, time on the coating process can all be reduced and the like.

Owner:JIANGMEN GUOMEI CHEM

Method for industrially producing swine fever live vaccine by using bioreactor

ActiveCN102038944BHigh titerHigh degree of automation controlMicroorganism based processesAntiviralsVaccine ProductionSwine Fever Virus

The invention relates to a method for industrially producing a swine fever live vaccine by using a bioreactor. The method comprises the following steps of: (1) sterilizing a microcarrier and the bioreactor, adding cell growth solution, inoculating cells for vaccine production, culturing the cells, and after the cells on the microcarrier form a compact monolayer, discarding the cell growth solution, adding virus maintenance solution and inoculating swine fever virus, and continuously culturing to allow the virus to reproduce; and (2) after the virus is inoculated for 18 hours, continuously obtaining virus culture solution, storing the virus culture solution at the temperature of below -15 DEG C, mixing the virus culture solution, and adding a cryoprotectant to prepare the swine fever live vaccine. The method has the advantages of high controllability of process parameters, high cell culture density, high virus titer, high vaccine safety, stable and reliable quality, high production efficiency and the like.

Owner:WUHAN CHOPPER BIOLOGY

Method for preparing desulfurizing agent of thermal power plant by utilizing carbide slag and special equipment thereof

ActiveCN102886201BTake advantage ofAvoid pollutionSolid waste disposalDispersed particle separationPower stationSlag

The invention discloses a method for preparing a desulfurizing agent of a thermal power plant utilizing carbide slag and special equipment thereof. The method comprises the following steps of: taking the carbide slag as a raw material; and crushing, removing impurities, calcining, cooling and sieving to obtain the desulfurizing agent. Compared with the prior art, the method is simple in process, equipment used by the process is very simple and the machining cost is low; and the carbide slag is sufficiently utilized so that a resource is saved and the environmental pollution is prevented.

Owner:SHIHEZI DALU IND & TRADE

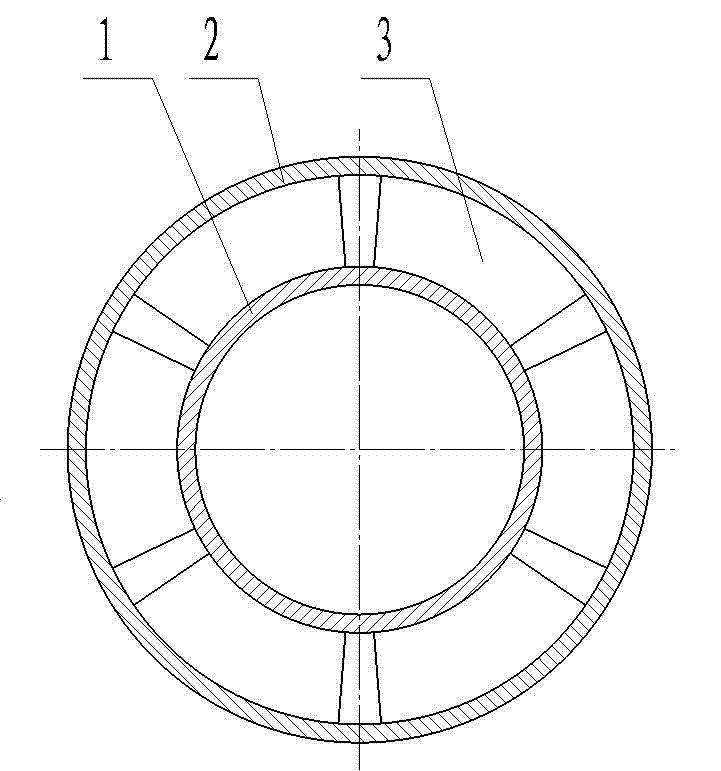

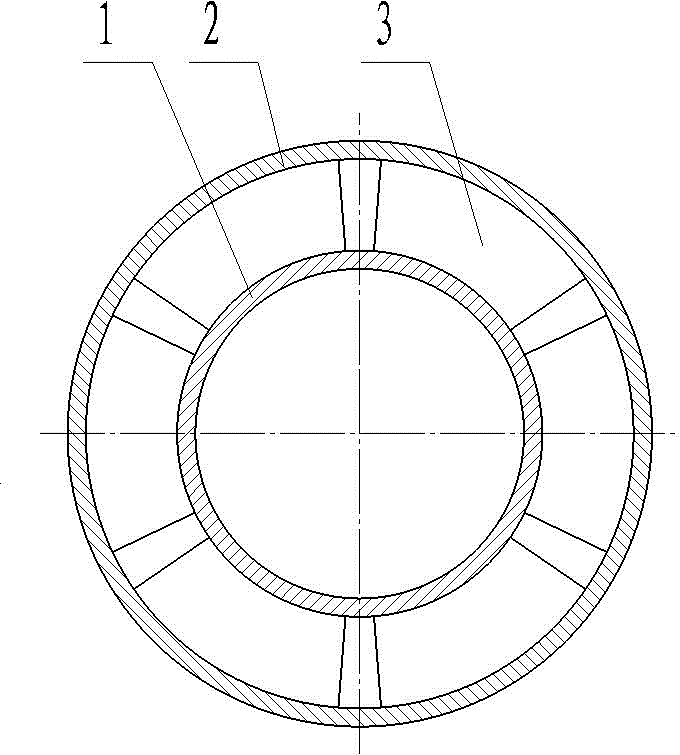

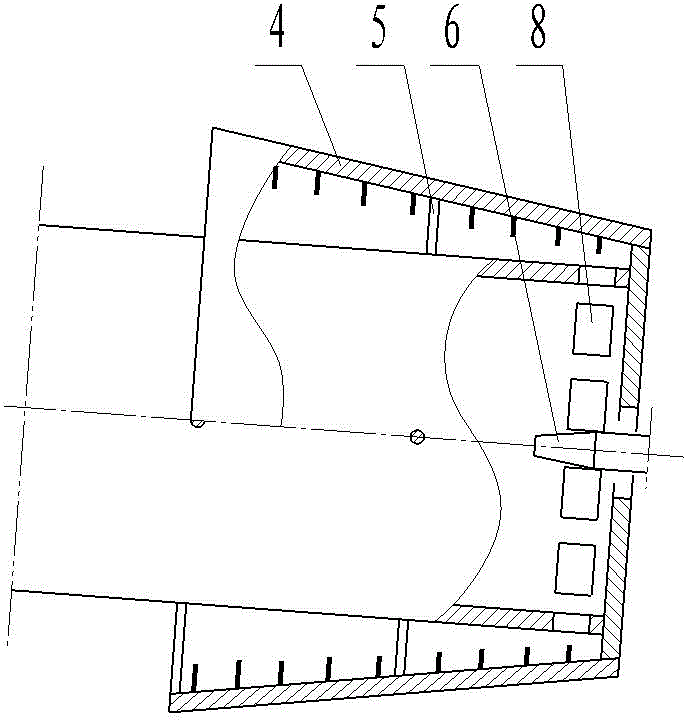

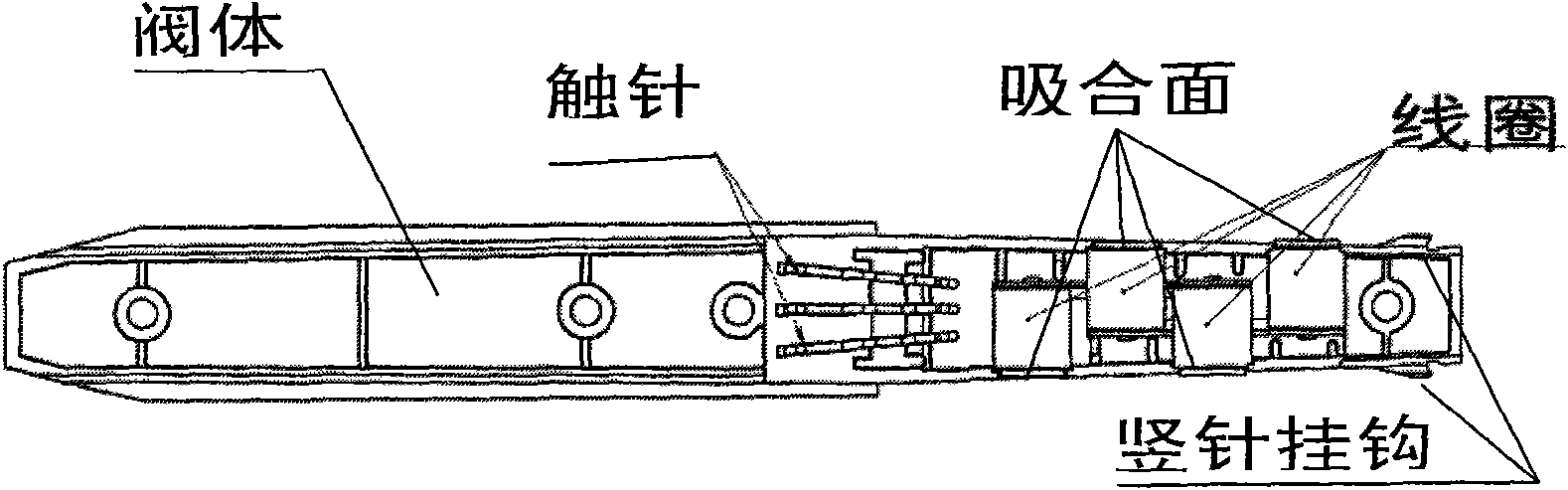

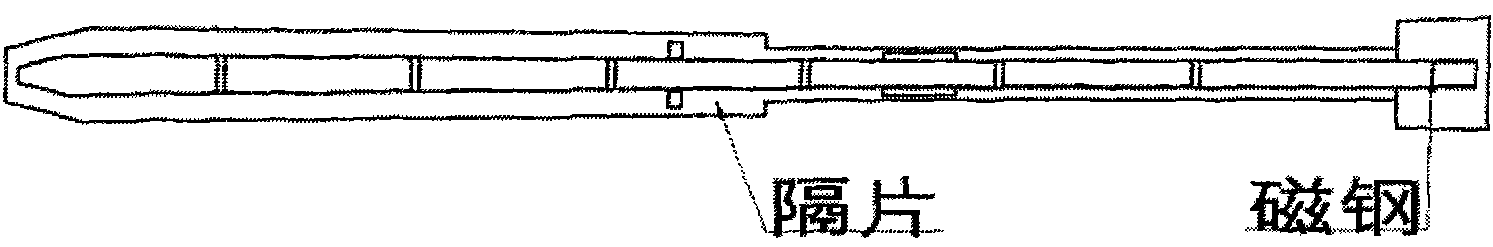

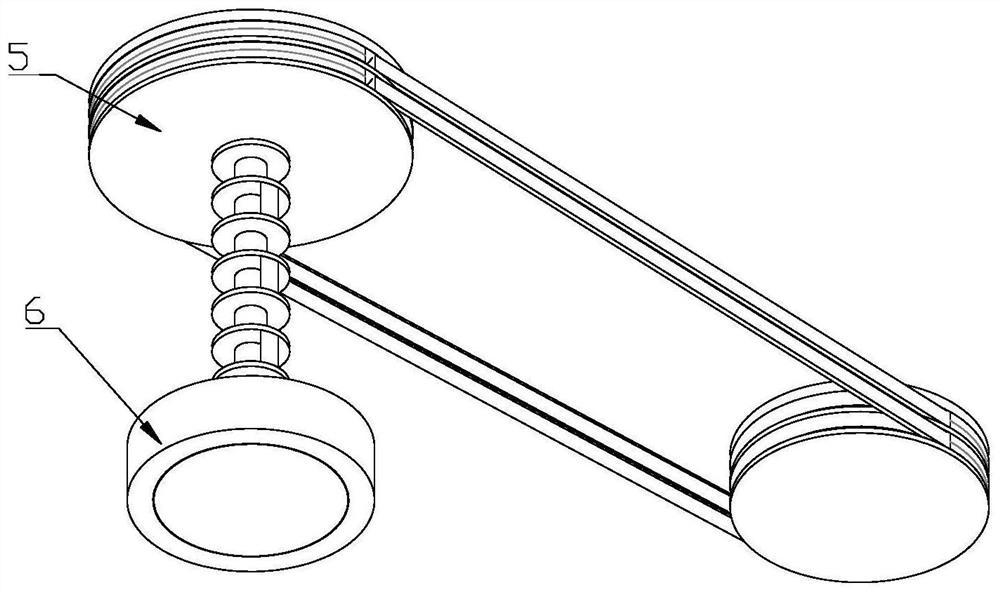

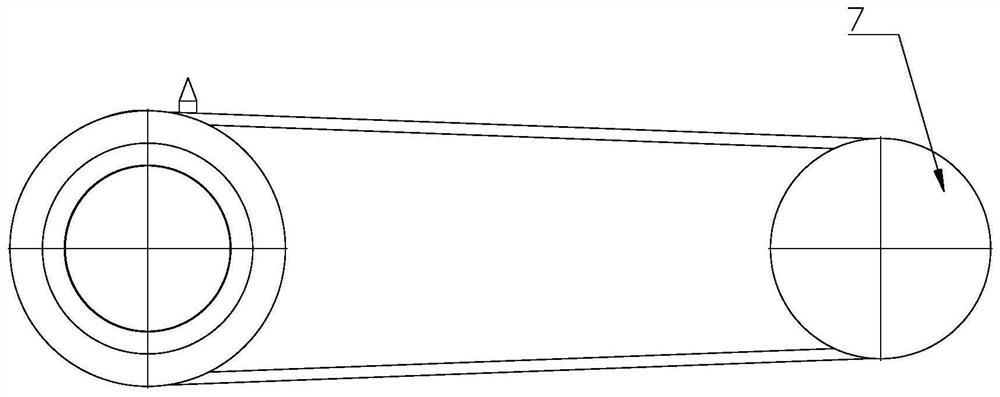

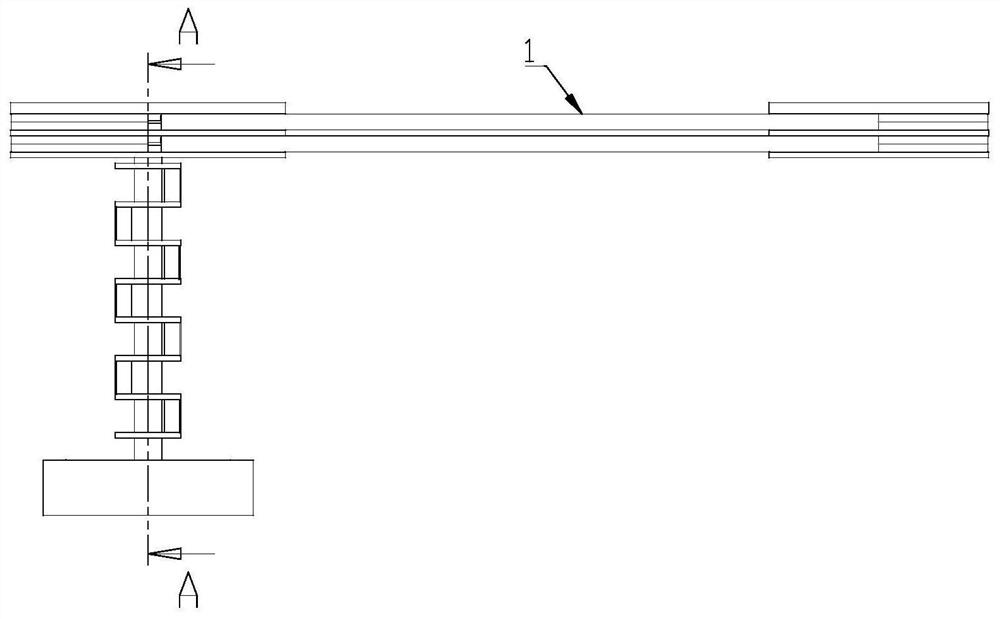

Solenoid valves for jacquard

InactiveCN101787600ASave production landSave raw materialsJacquardsOperating means/releasing devices for valvesSolenoid valveElectrical connection

The invention relates to solenoid valves for a jacquard, which are improved revolutionarily. Two groups of solenoid coils (3) are arranged in the same valve body (1); the two groups of solenoid coils (3) share an electrode and are in electrical connection with exterior through three contact pins (2) arranged in a neck of the valve body (1) in parallel; each group of solenoid coils (3) are respectively provided with two pick-up surfaces (4) on both sides of the valve body (1); the two pick-up surfaces (4) on the same side are used as a working surface; two vertical needle hooks (5) are arranged at the tail of the valve body (1), so that vertical needles lifted by the jacquard are hooked, and each solenoid valve can control the motion of the two vertical needles simultaneously and independently; magnetic steel (7) is arranged at the tail end of a distance piece, and the vertical needles picked up with the pick-up surfaces (4) can reduce deviation and malfunction under the action of the magnetic steel (7); hooks (9) capable of being in close fit to each other are designed on a cover plate (8), and the cover plate (8) is pressed on the valve body (1) tightly through the hooks (9), so that the cover plate fixes the contact pins (2) and the solenoid coils (3) and prevents dust; and simultaneously, the design method of quick connection can also improve the assembling efficiency of the solenoid valves.

Owner:SHANGHAI CHAOCHENG ELECTRON SCI & TECH

Reclaimed material screening and breaking device and method for screening and breaking reclaimed materials

InactiveCN102600935ASimplify the work processReduce manufacturing costSievingScreeningEngineeringMechanical engineering

Owner:SANY HEAVY IND CO LTD (CN)

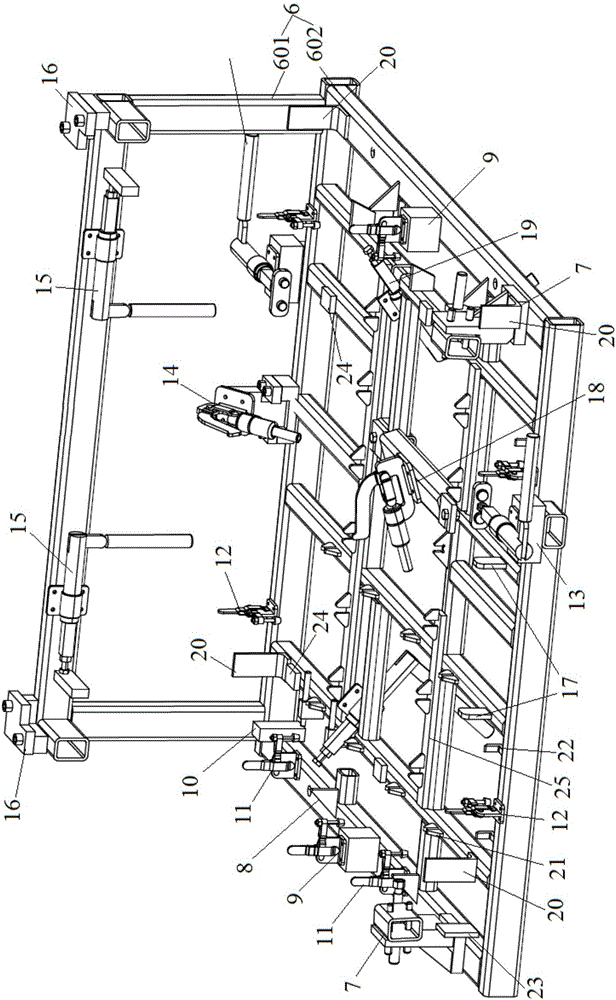

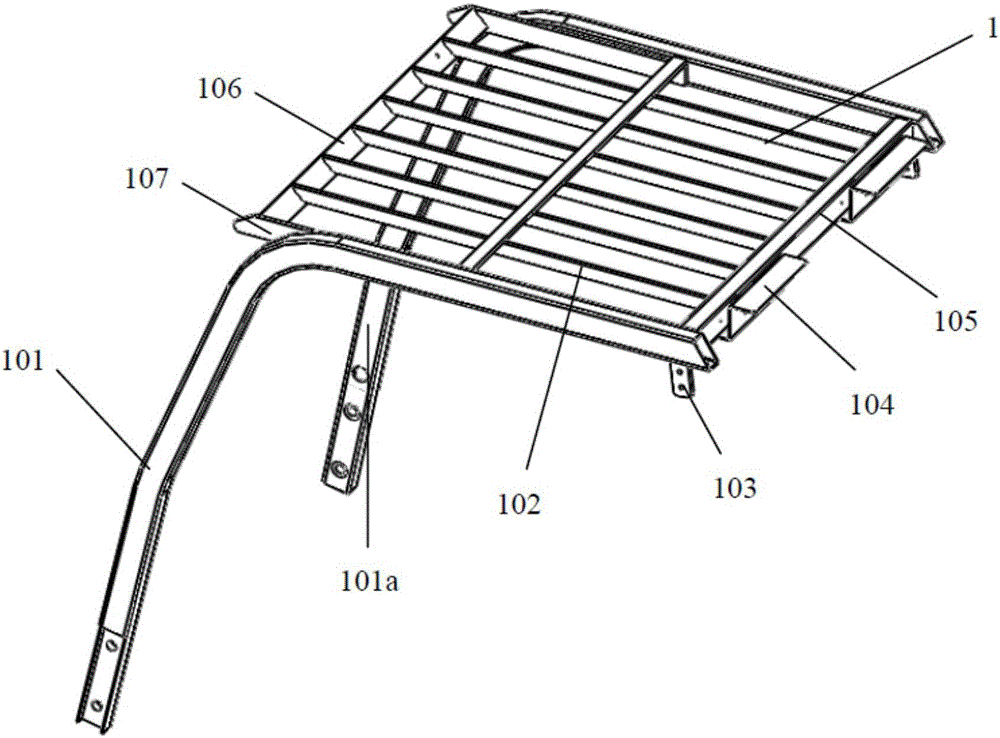

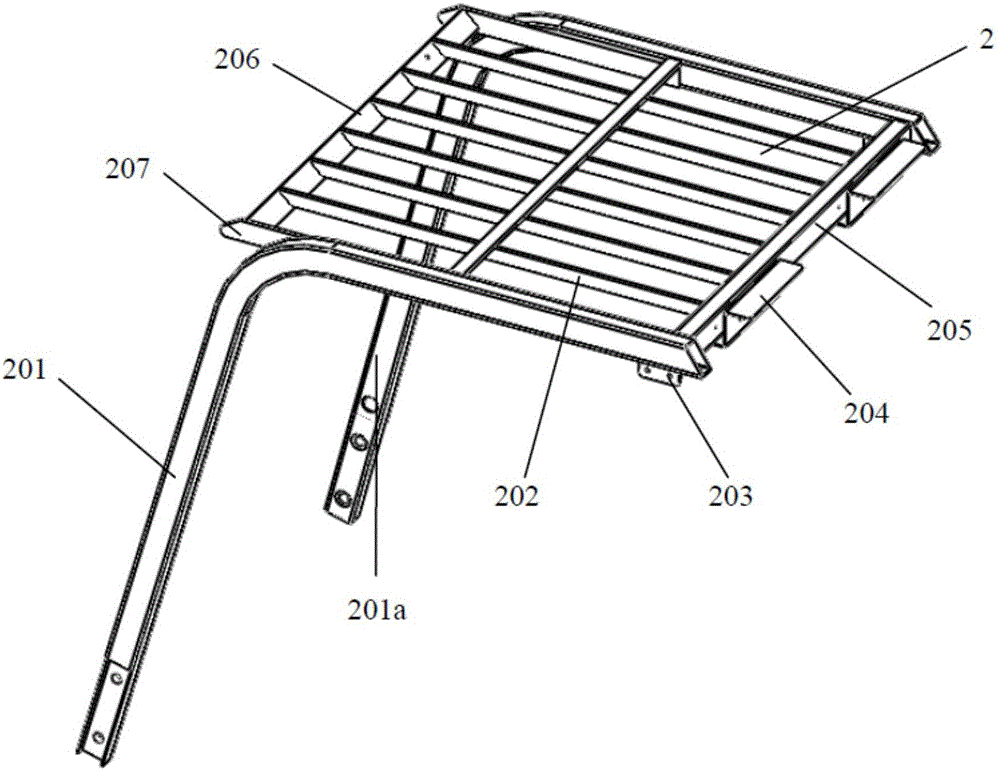

Welding tool, welding processing equipment having same and welding method

ActiveCN104759822BEasy to makeEasy to useWelding/cutting auxillary devicesAuxillary welding devicesWeld seamIndustrial engineering

The invention discloses a welding tool, welding equipment provided with the welding tool and a welding method. The welding tool comprises a carrying frame and a positioning and clamping device. The positioning and clamping device is arranged on the carrying frame and used for positioning and clamping a canopy guard frame and / or a load backrest of a forklift. The positioning and clamping device is provided with a horizontal bottom frame and a vertical bottom frame which is vertically connected with the horizontal bottom frame. The welding tool can be used for assembly welding of the canopy guard frame and the load backrest of the forklift at the same time, is high in universality, easy to manufacture and convenient to use, can effectively reduce cost input, shortens the preparation period, reduces production land, substantially improves production efficiency and guarantees welding seam quality and product uniformity. The welding tool can further weld the canopy guard frame and the load backrest of the forklift in cooperation with a welding robot, omits the rivet welding procedure, achieves automatic welding of the robot, avoids the interference caused by human factors and saves the feeding time for workers. Besides, the welded product uniformity is good.

Owner:WUHU RUICHUANG FORKELEVATOR

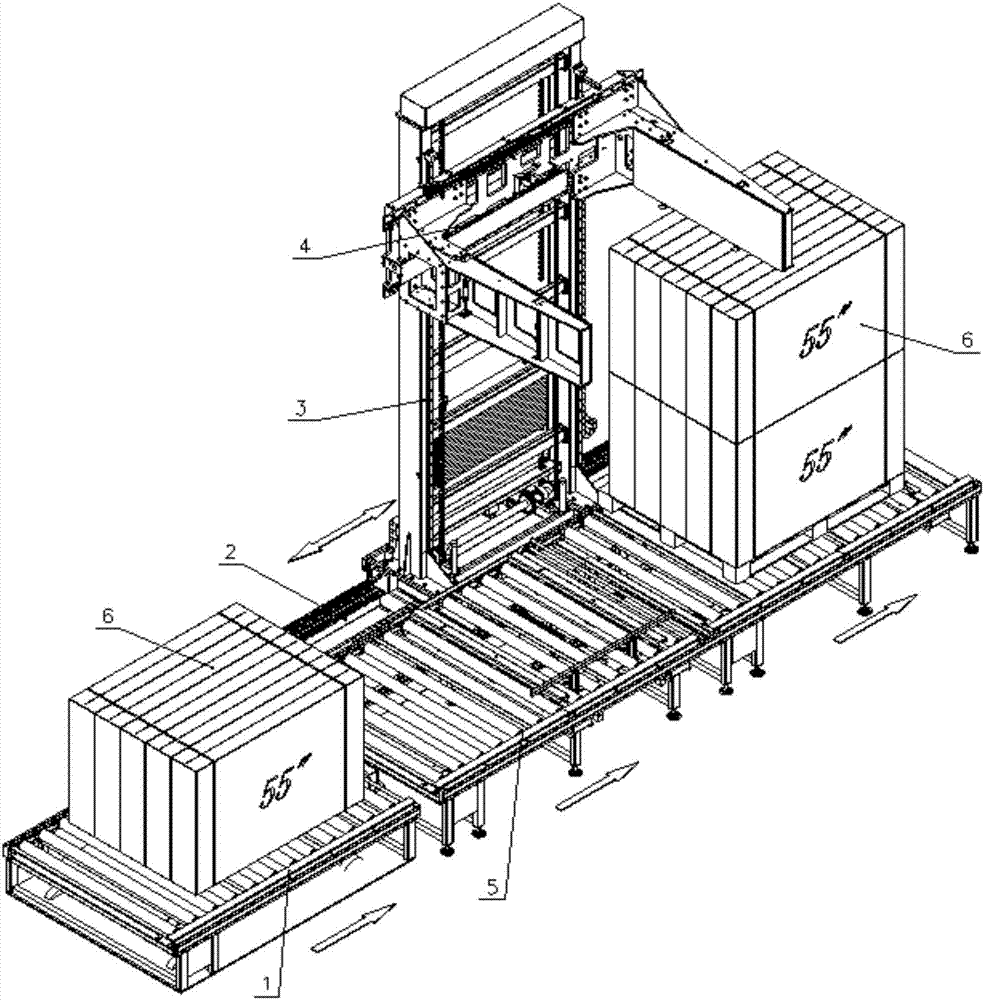

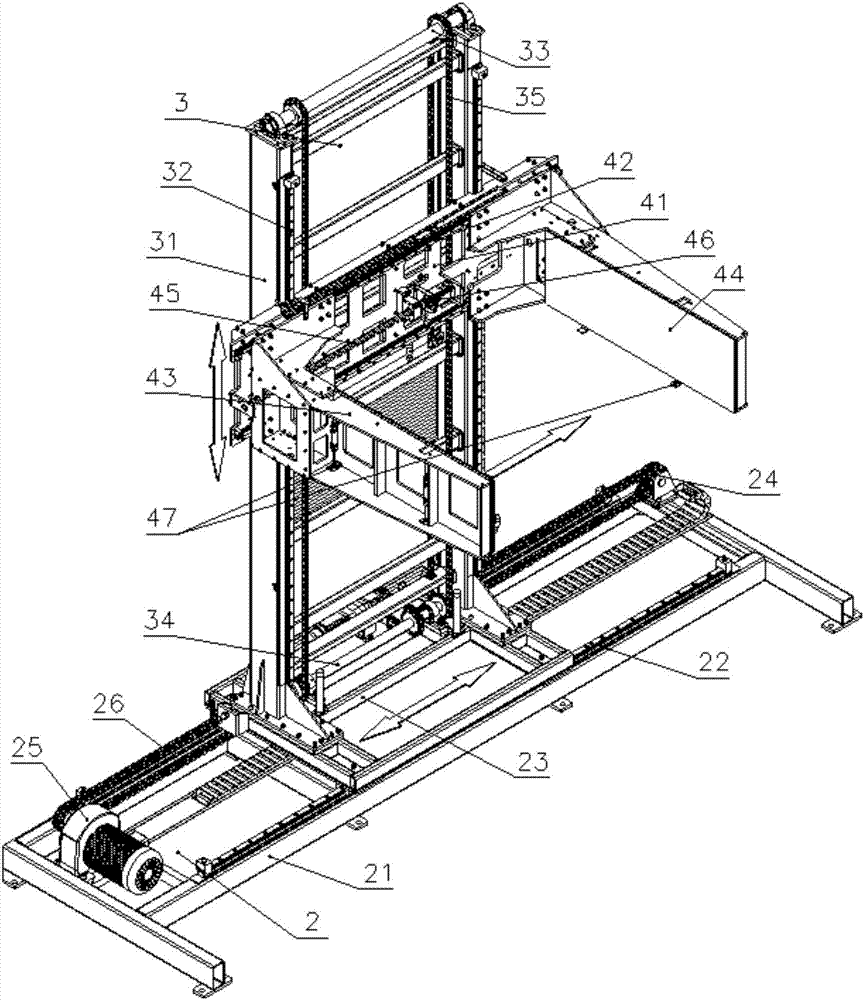

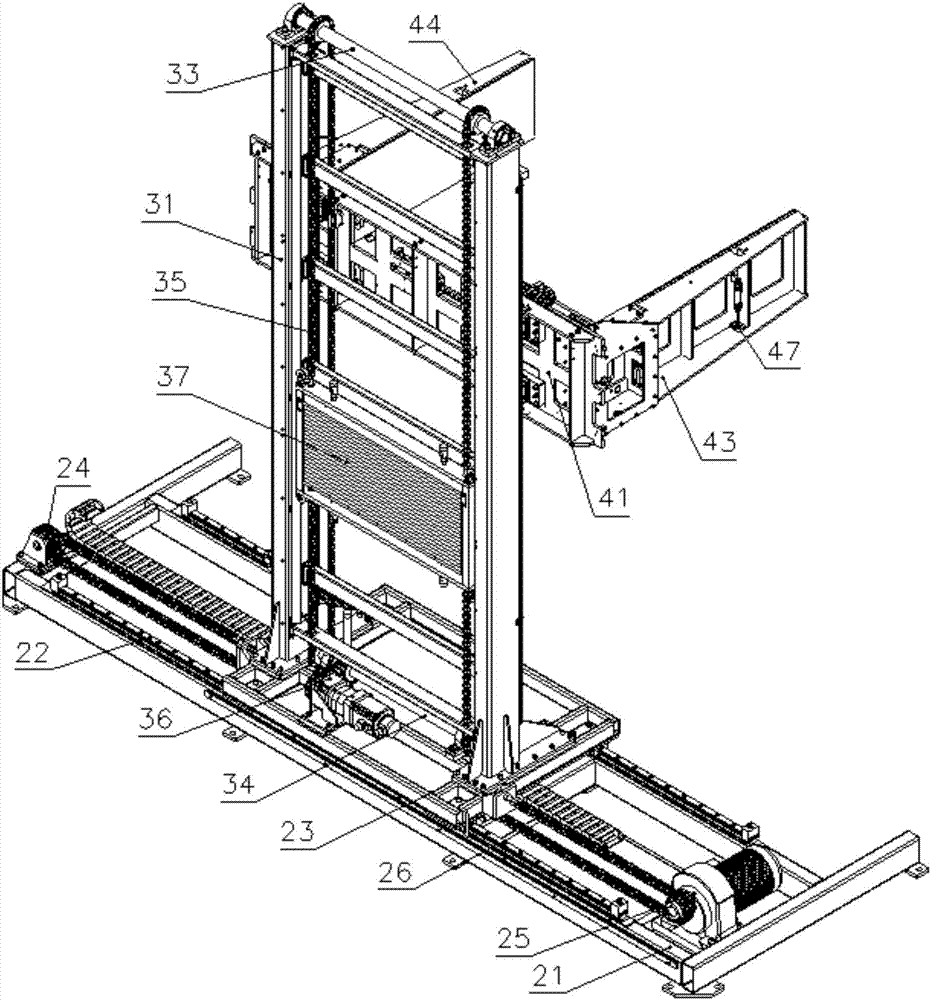

Cantilever clamping type stacking machine for flat television

InactiveCN107150908ASimple structureLow costStacking articlesDe-stacking articlesStack machineMovement control

The invention discloses a cantilever clamping type palletizer for a flat-panel TV, which is mainly composed of an AGV trolley, a transfer mechanism, a lifting mechanism, a clamping mechanism, and a roller transmission line. The AGV trolley transports the single-layer bundled products to the front end of the roller transmission line and realizes the functions of holding, transferring and stacking through the transfer mechanism, lifting mechanism, clamping mechanism and roller transmission line. The invention is not only simple in structure, but also low in cost. It is optimized and integrated by several mechanisms with different functions. The information uploaded by the detection switch, the MES information system, and the motion control system issue motion commands, so that several mechanisms can run in parallel in an orderly manner without affecting each other. , so that the equipment can perform operations such as turnover, transfer, and multi-layer palletizing for products of various specifications. The invention can not only guarantee the quality of the product, but also meet the production requirement, thereby saving the cost and improving the production efficiency.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

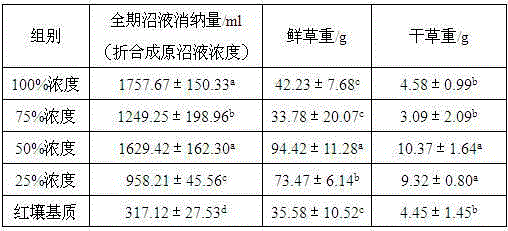

A method of using sand culture to grow pasture to absorb biogas slurry in pig farms

The invention discloses a method for utilizing a sand culture mode to plant forage grass to consume biogas slurry of a pig farm. The method includes that high-efficiency sewage consumption and fresh grass supply of the forage grass is realized by constructing a waterproof and rainproof sand culture container, laying and pouring sand girt, controlling concentration of the biogas slurry, irrigating the biogas slurry, planting the forage grass and harvesting the forage grass. According to the method, biogas slurry consumption quantity of the forage grass per unit area can be remarkably increased. The forage grass produced by the method has the advantages of high yield, good quality and the like. Land for forage grass production can be greatly reduced by fully utilizing space advantage; by further transforming equipment, controllable and intensive production of high-quality forage grass can be realized, and large-scale production of plant-eating animals is benefitted.

Owner:INST OF ANIMAL HUSBANDRY & VETERINARY FUJIAN ACADEMY OF AGRI SCI

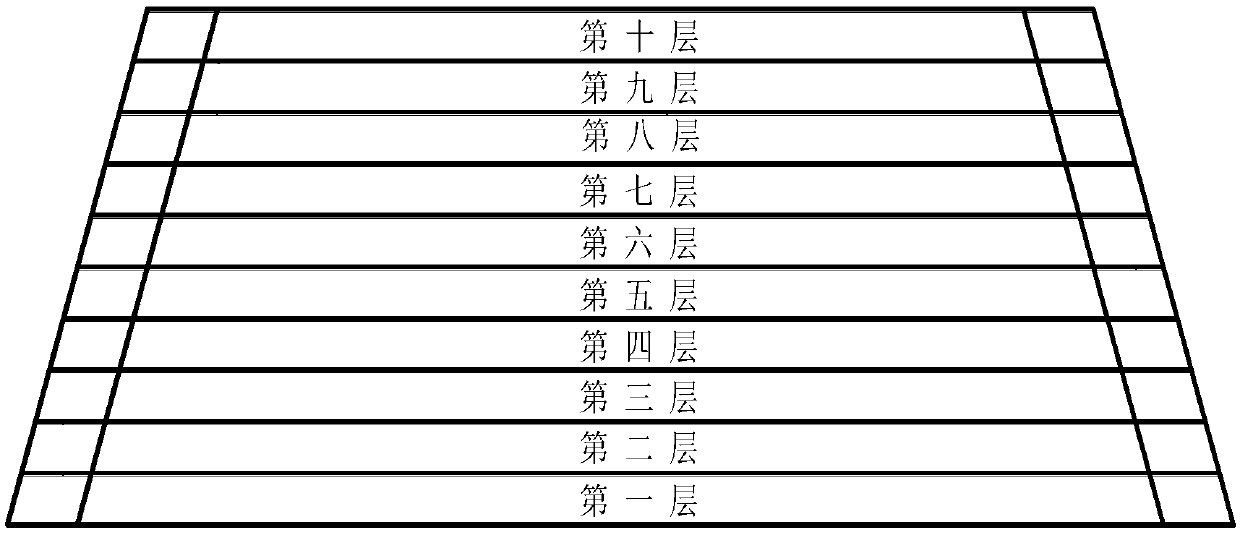

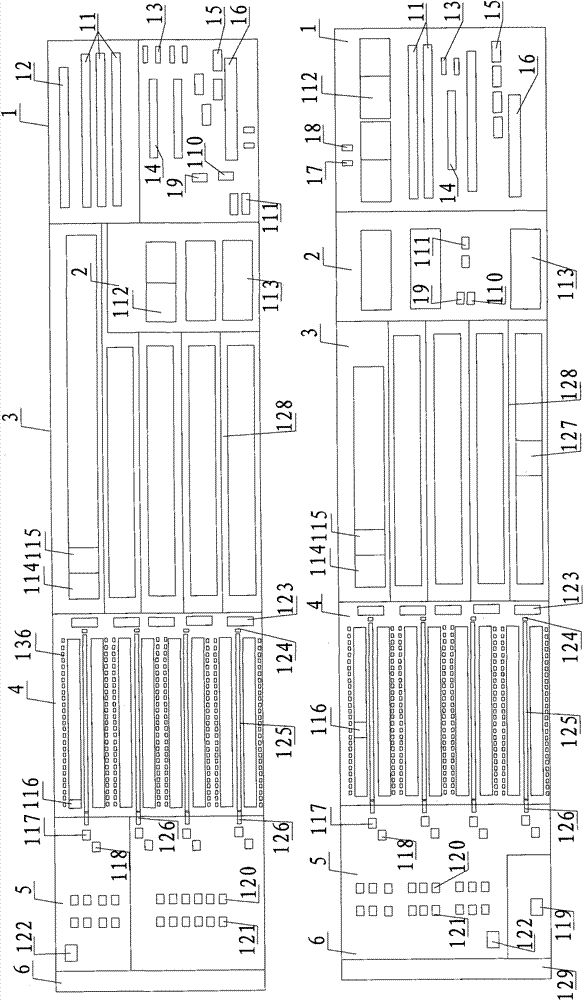

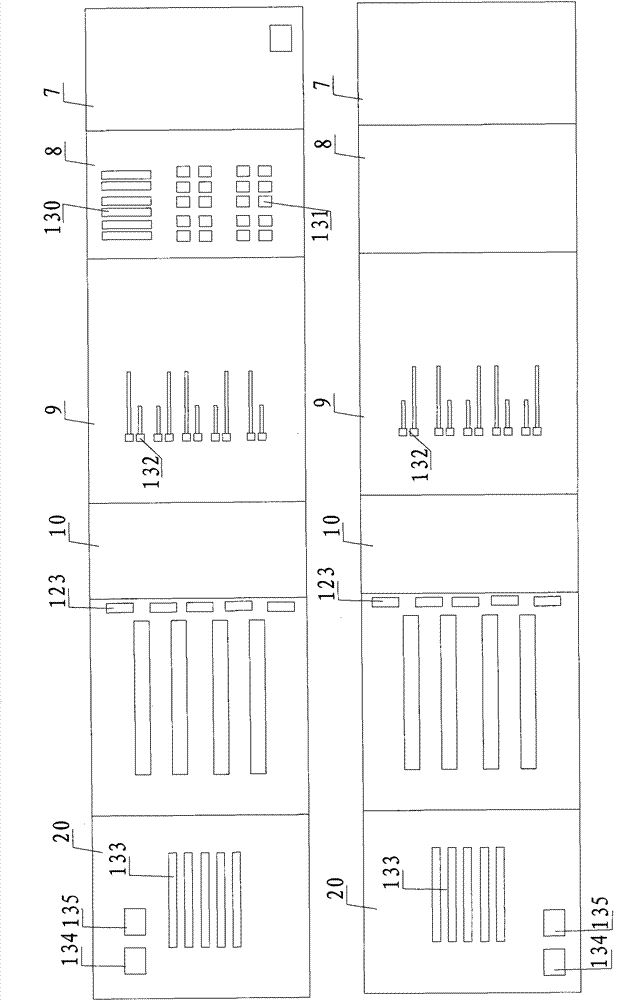

Intensive ultra-large-scale radial tire production system of high-performance car

ActiveCN102152484BEasy to arrangeConducive to automated continuous productionTyresProduction lineProduct inspection

The invention relates to a radial tire production system, in particular to an intensive ultra-large-scale radial tire production system of a high-performance car. The intensive ultra-large scale radial tire production system of the high-performance car provided by the invention comprises three layers of building plant, wherein the first layer is sequentially provided with a semi-finished product extrusion calendaring region, a cutting region, a molding region, a vulcanizing region, a finished product inspection region and a storage and transportation shipping region; the second layer sequentially comprises a mixing rubber storage region, a semi-finished product production region, a green tire spraying region, a green tire storage region and a finished tire storage region; the semi-finished product production region is provided with multiple triangular rubber pasting machines and multiple steel ring extrusion and rolling production lines; the third layer comprises a tire edge polishingregion, a tire inflation region and a tire maintenance region; the total area of the production system is larger than or equal to 250,000 m<2>, the total height is larger than or equal to 23.5m, the length is larger than or equal to 450m and the width is larger than or equal to 190m; and the temperature of the molding region is controlled to be 23+ / -5 DEG C and the humidity is controlled to be less than or equal to 70%. The tire production system provided by the invention has the intensive and ultra-large-scale characteristics.

Owner:ZHONGCE RUBBER GRP CO LTD

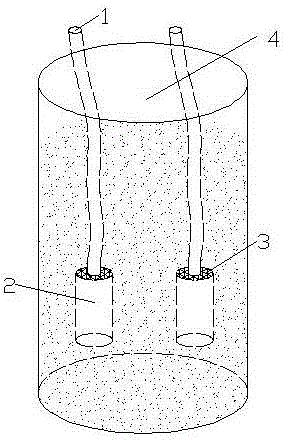

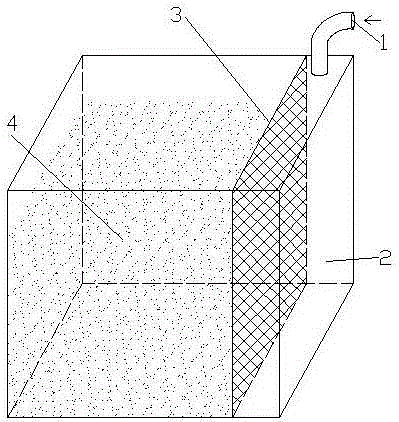

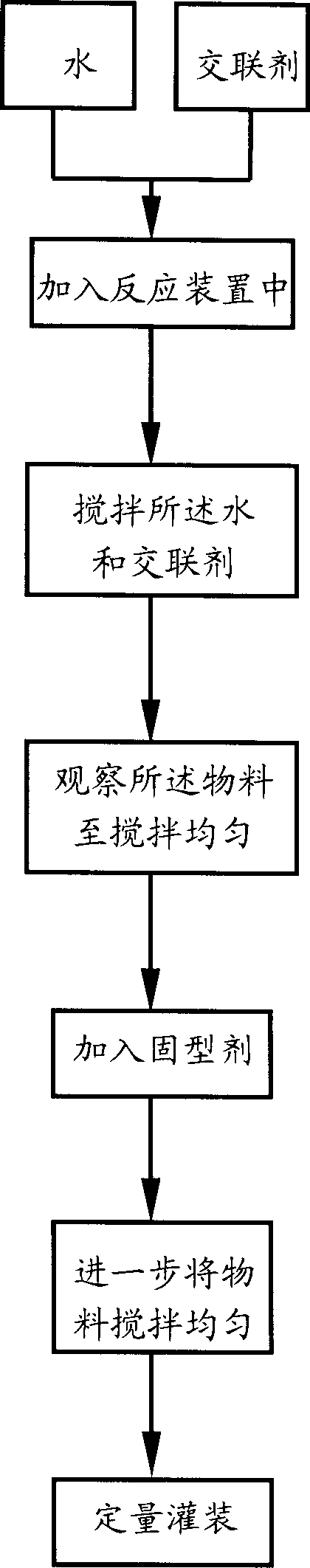

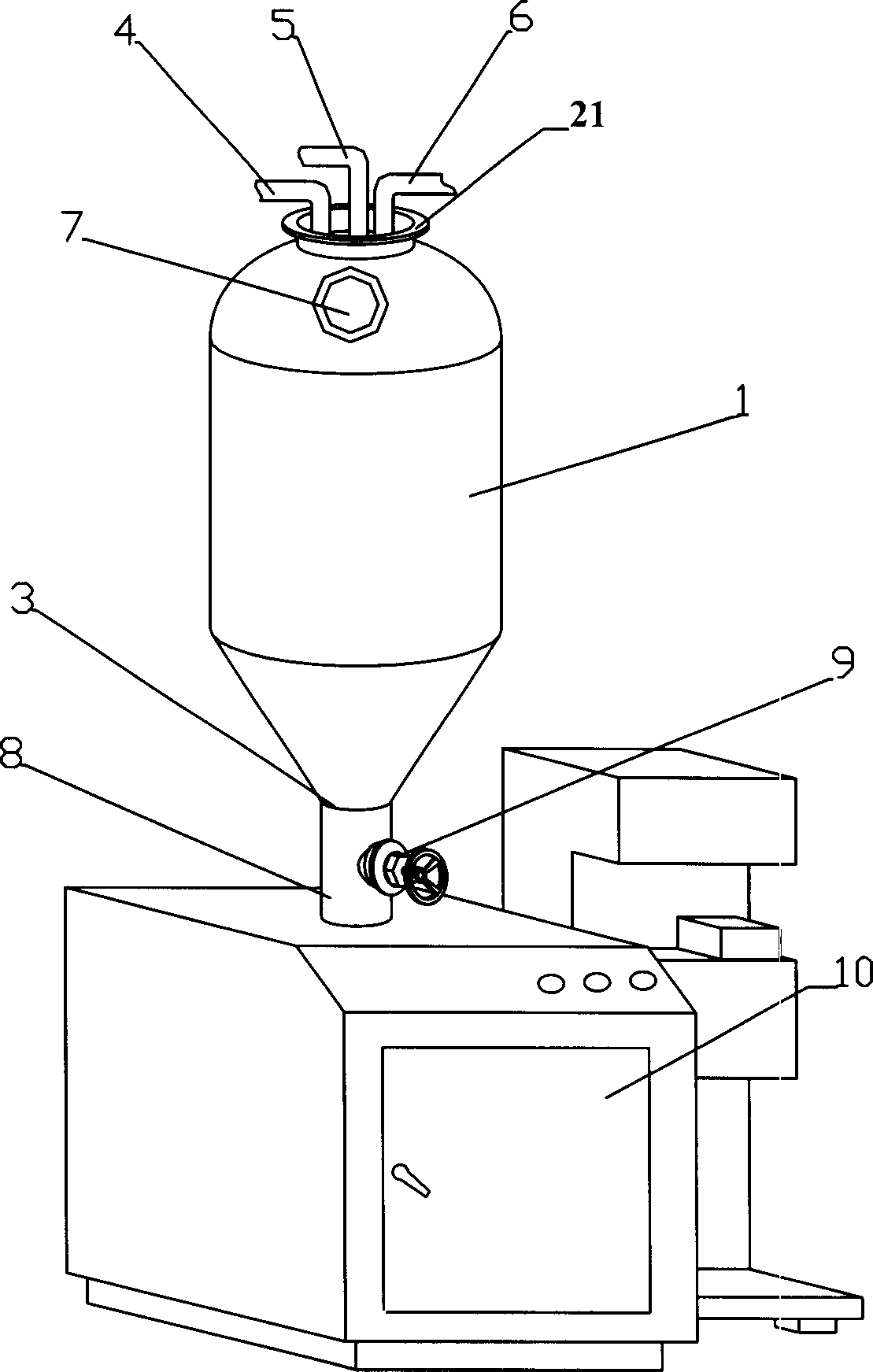

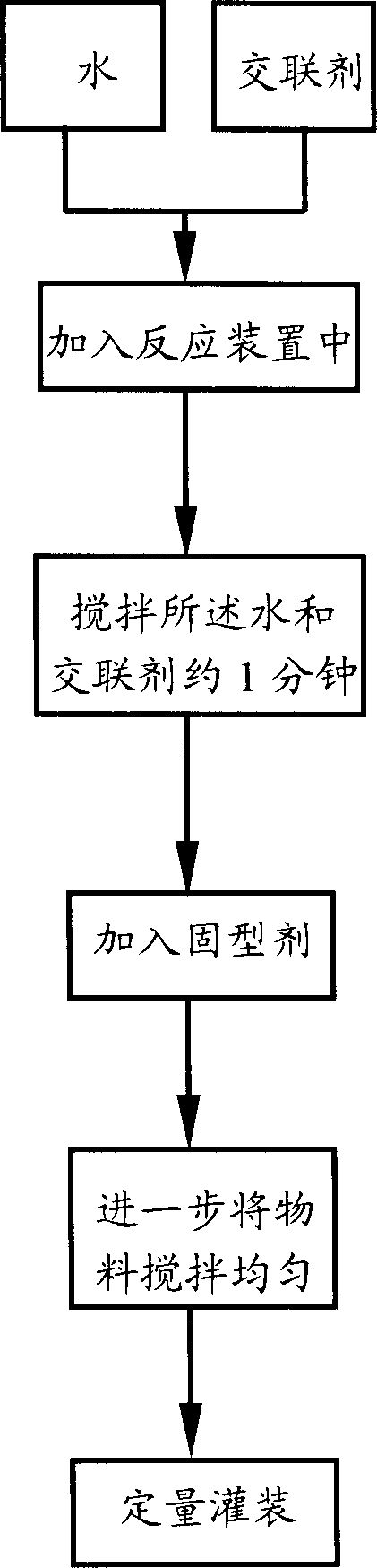

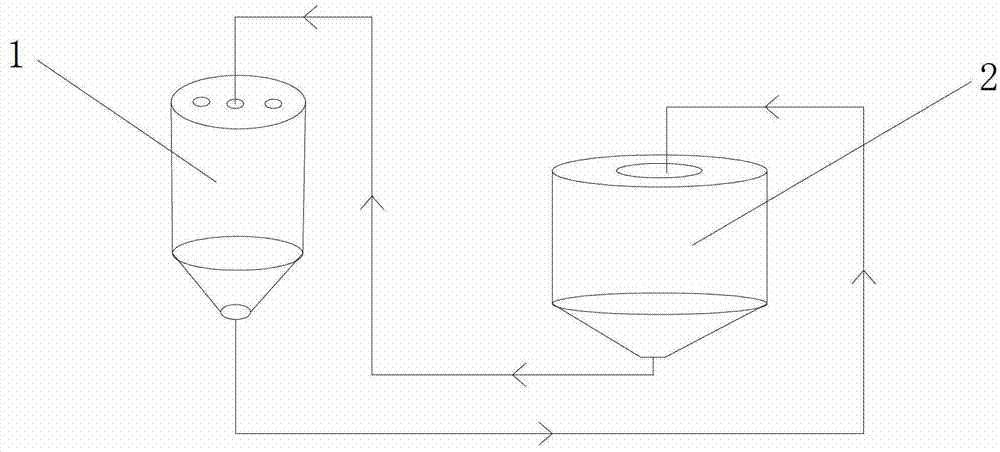

Slow releasing water producing method and apparatus

InactiveCN1416690AReduce energy consumptionEasy to set upRoot feedersWater/sewage treatmentEnvironmental engineeringPower consumption

The present invention aims to produce slow releasing water in short production time, low power consumption and less apparatus. The production process of delayed releasing water includes the steps of stirring water and crosslinking agent in some reactor; adding some shaping agent; and further stirring to produce delayed releasing water. The delayed releasing water is especially suitable for irrigation in farm and forest.

Owner:王钰

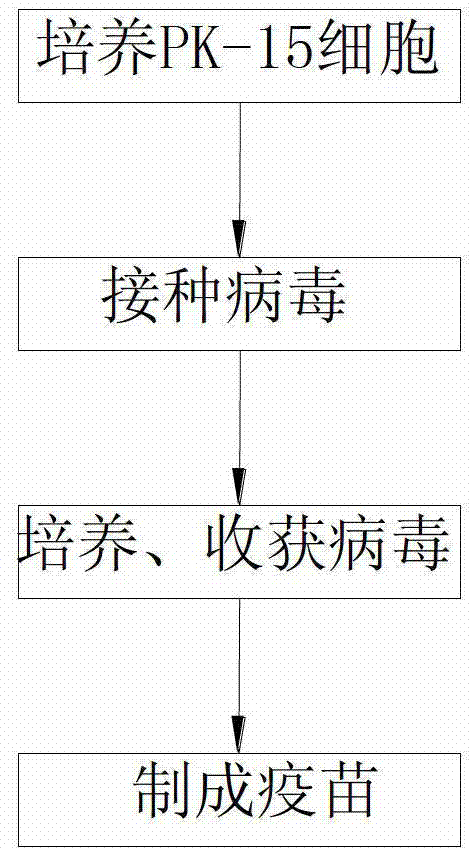

A kind of method utilizing bioreactor to prepare porcine circovirus type 2 inactivated vaccine

ActiveCN103100082BSave production landImprove securityViral antigen ingredientsMicroorganism based processesSide effectCircovirus

The invention relates to a method for preparing porcine circovirus type 2 inactivated vaccine by utilizing a bioreactor, wherein the bioreactor is a riptide type bioreactor; a circulatory system is composed of a perfusion bag and a riptide bag; a cell culture bag is built in the perfusion bag; a paper carrier is in the cell culture bag; and the method comprises the following steps of: culturing PK-15 cells; inoculating porcine circovirus type 2; culturing the porcine circovirus type 2, measuring sugar consumption by taking a virus maintenance solution, and obtaining a virus solution when the sugar consumption is decreased; and preparing the porcine circovirus type 2 inactivated vaccine. The method for preparing the porcine circovirus type 2 inactivated vaccine by utilizing the riptide type bioreactor disclosed by the invention is small in production site, low in labour intensity, relatively lower in production cost, simple in operation, low in inter-batch difference, and high and steady in product quality; full-automatic micro-computer control can be achieved; and the prepared porcine circovirus type 2 inactivated vaccine is good in safety, high in immune efficacy and low in side effect and has the better immune protective effect on virulent attack of porcine circovirus type 2.

Owner:兆丰华生物科技(南京)有限公司 +1

Cod skin frozen block crushing and melting device and crushing and melting method

PendingCN112841289AAchieve uninterrupted productionQuick thawMeat/fish preservation by freezing/coolingGrain treatmentsMechanical engineeringRaw material

The invention relates to a cod skin frozen block crushing and melting device and crushing and melting method. The crushing and melting device comprises a cutting table and a lead screw cutting device, cutting discs with the thickness being 10 mm are welded to a rotating shaft of a lead screw cutting rod of the lead screw cutting device at a certain interval, an iron block is welded between every two adjacent cutting discs, the two adjacent iron blocks are arranged on the two sides of the rotating shaft respectively, and the cutting disc and the iron blocks are combined to quickly unfreeze the frozen cod skin blocks through mechanical cutting, vibration and extrusion. Moreover, the process does not need to consume water, the cod skin blocks can be continuously crushed, the production land is reduced, and the continuous production of the cod skin is realized. The phenomenon of production halt caused by the fact that the raw materials are not unfrozen is avoided, the production time can be greatly shortened, and the water consumption is reduced.

Owner:QINGDAO LANGYATAI GRP

A high-efficiency busbar production device

ActiveCN104240846BReduce manufacturing costReduce energy consumptionCable/conductor manufactureBusbarEngineering

The invention discloses an efficient busbar production device which comprises a body and a first roller wheel set in the body. The first roller wheel set comprises a plurality of pairs of roller wheels uniformly arranged in the body and vertically distributed. The efficient busbar production device is characterized in that a paint box is arranged in the drying box body and located in the middle in the drying box body, a second roller wheel set is arranged in the paint box and comprises a plurality of pairs of roller wheels uniformly arranged in the paint box and vertically distributed, a busbar is painted when the busbar is in a half-wet and half-dried state after a half of the busbar enters an inlet, and water in paint of the painted busbar continues to be dried in the drying box body. An original paint drying box is omitted, energy consumption is reduced, secondary drying is not needed, only one drying box body is provided, the structure is simple, operation is easy and convenient, production efficiency is improved, and the production cost of enterprises is reduced.

Owner:江苏华威线路设备集团有限公司

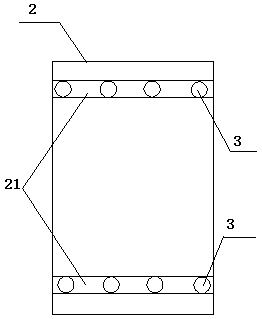

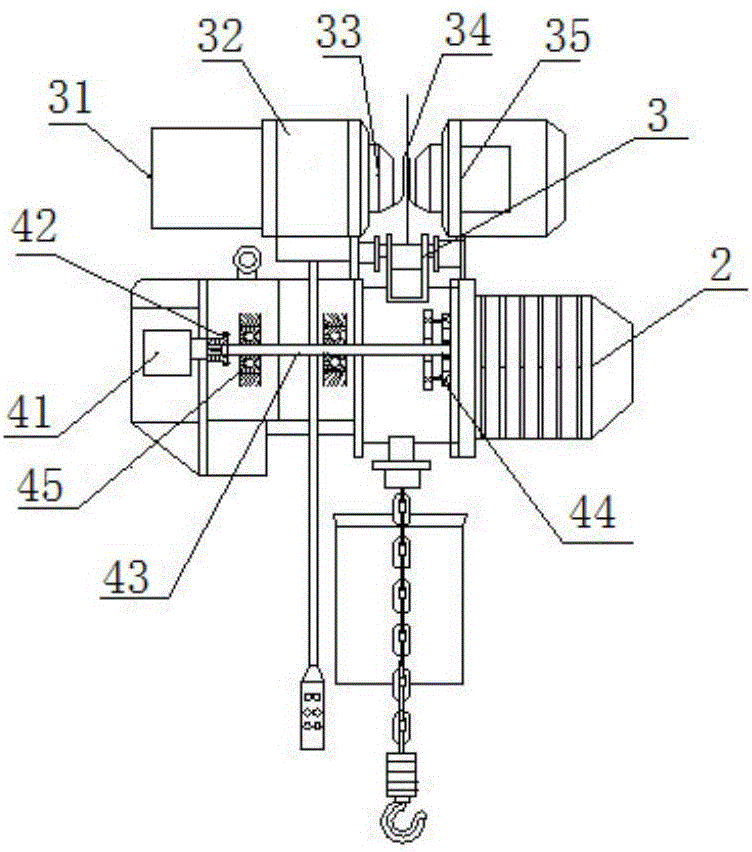

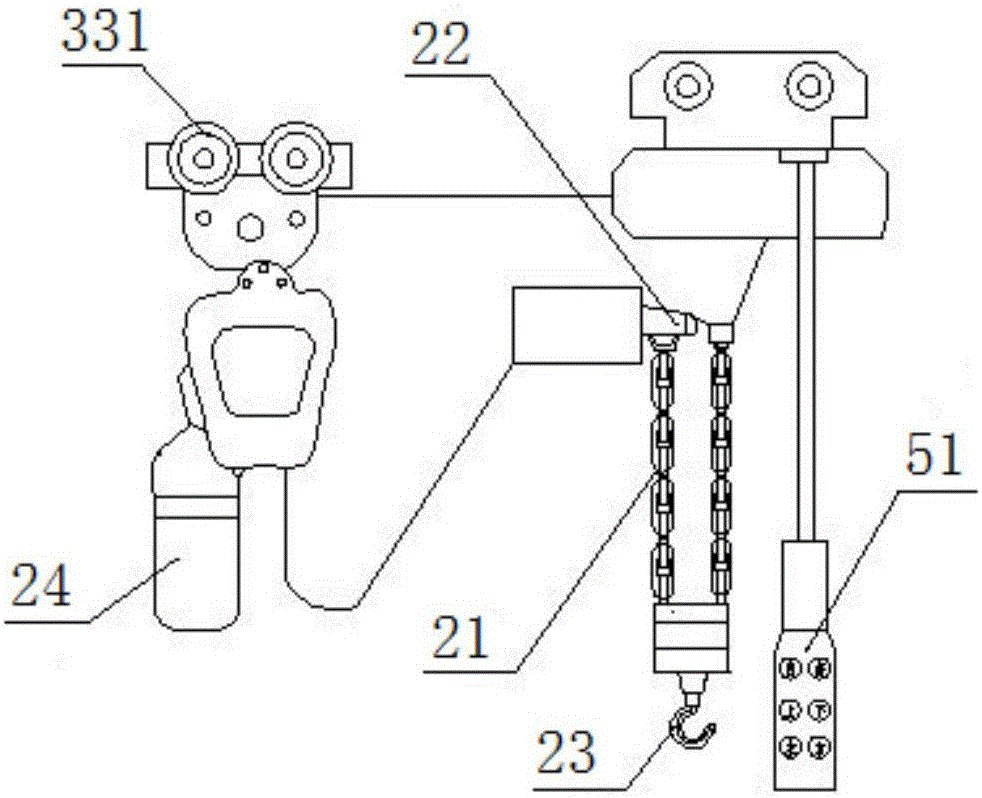

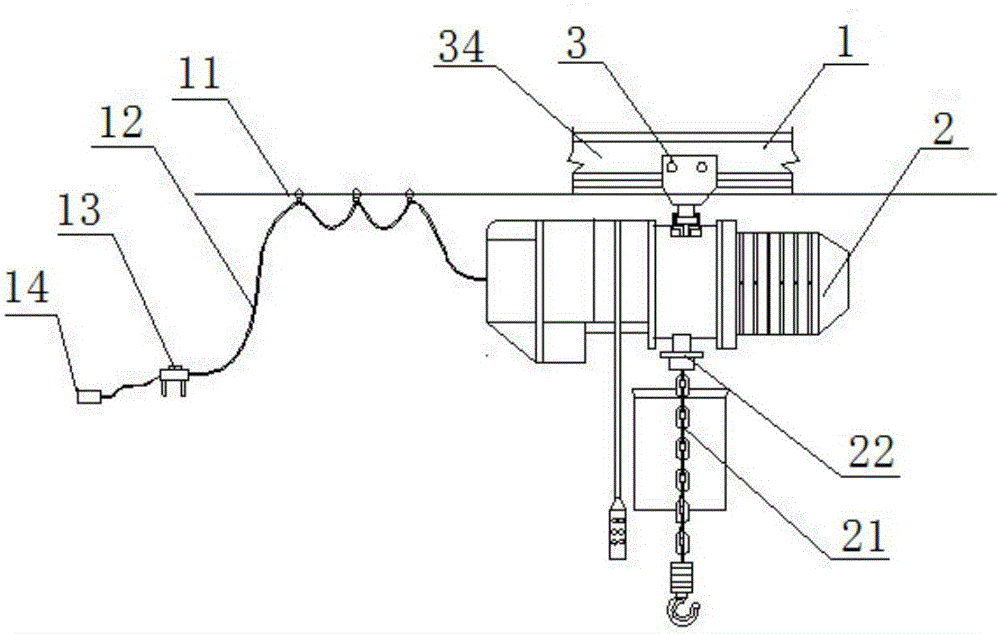

Low-clearance air hoist

The invention relates to a low-clean air dynamic hoist, which belongs to the field of hoisting equipment. It includes a slide rail running device, an air hoist and a hanger. The air hoist is fixed on the slide rail running device through the hanger. There is a wire under the slide rail running device. The air pipe is connected with the air hoist through the wire, and the other end of the air pipe passes through The pneumatic triple unit is connected to the air compressor, and the lifting chain of the air hoist is provided with a limiter; the invention has good safety, high reliability, and low failure rate, and breaks through the bottleneck that the air hoist cannot be used due to limited space , making the scope of application more extensive.

Owner:安徽三雕起重机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com