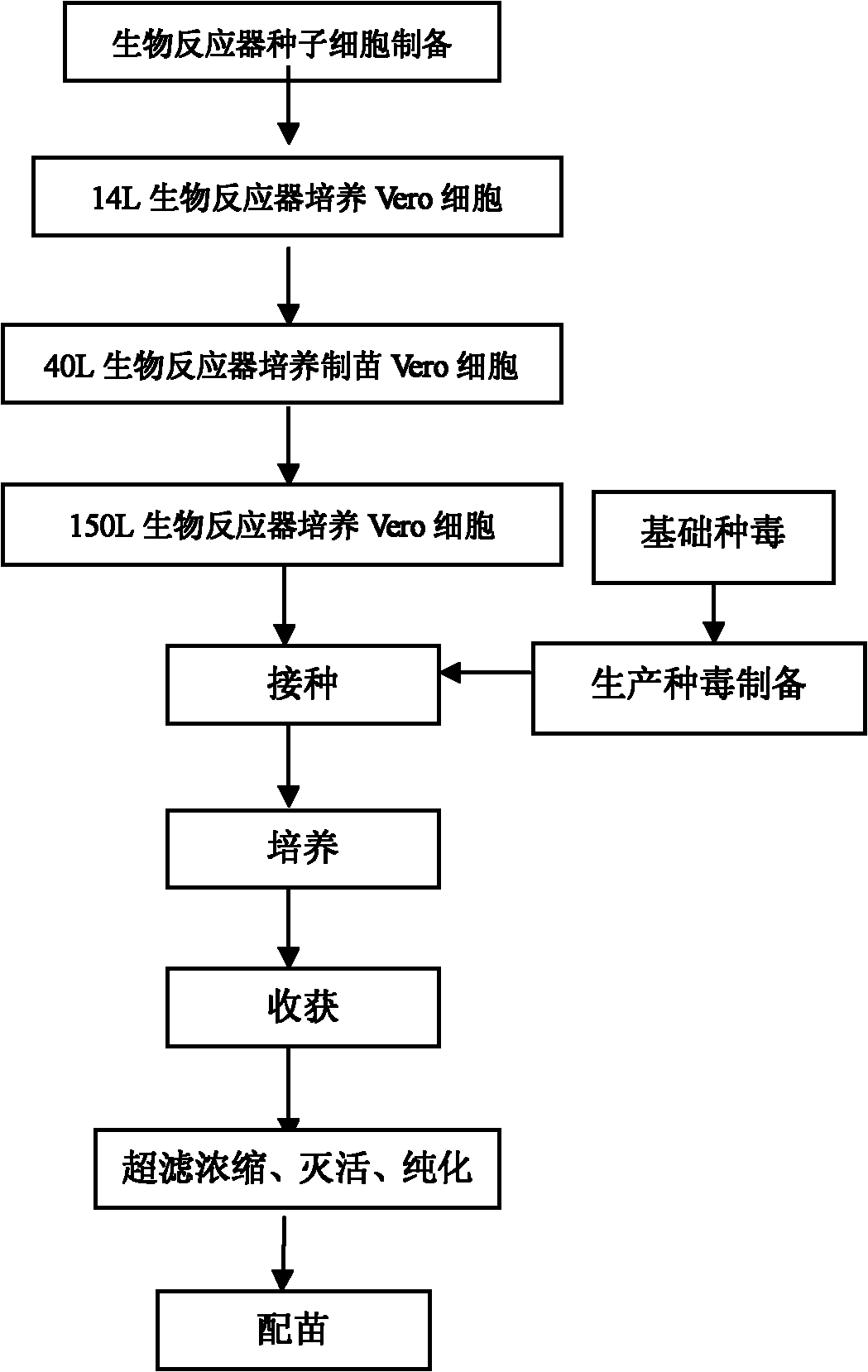

Method for industrially producing animal rabies vaccine by utilizing bioreactor

A technology of bioreactor and rabies vaccine, which is applied in the field of production of animal rabies vaccine, achieves the effects of cost reduction, easy expansion of scale, and small batch-to-batch difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Bioreactor: 14L and 40L bioreactors from NBS Company of the United States;

[0024] Microcarrier: Cytodex1 (General Electric Healthcare Life Sciences);

[0025] Rabies virus: the adapted virus 10aGV strain of aG strain domesticated by Vero cells;

[0026] Cell growth medium: M199 (Beijing Qingda Tianyi Biotechnology Co., Ltd.) containing 8% calf serum by volume;

[0027] Virus maintenance solution: M199 (Beijing Qingda Tianyi Biotechnology Co., Ltd.) containing 1% calf serum by volume;

[0028] Cell culture: In 14L bioreactors, add Cytodex-1 at a concentration of 10g / L. After hydration, wash with pH7.2 phosphate buffered saline PBS twice, sterilize, add cell growth medium, and inoculate Vero cells were cultured; the parameters of the culture method were: pH 7.2, temperature 37°C, dissolved oxygen 50%, stirring speed 30-100rpm; samples were regularly taken every day to observe the growth of the cells, and the cells were counted to determine the consumption of glucose. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com