Method for preparing desulfurizing agent of thermal power plant by utilizing carbide slag and special equipment thereof

A technology for thermal power plants and special equipment, which is applied in the field of preparing desulfurizers for thermal power plants, which can solve the problems of large production equipment, high requirements for process methods, and high requirements for equipment, so as to shorten the length of equipment and prevent environmental pollution , the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

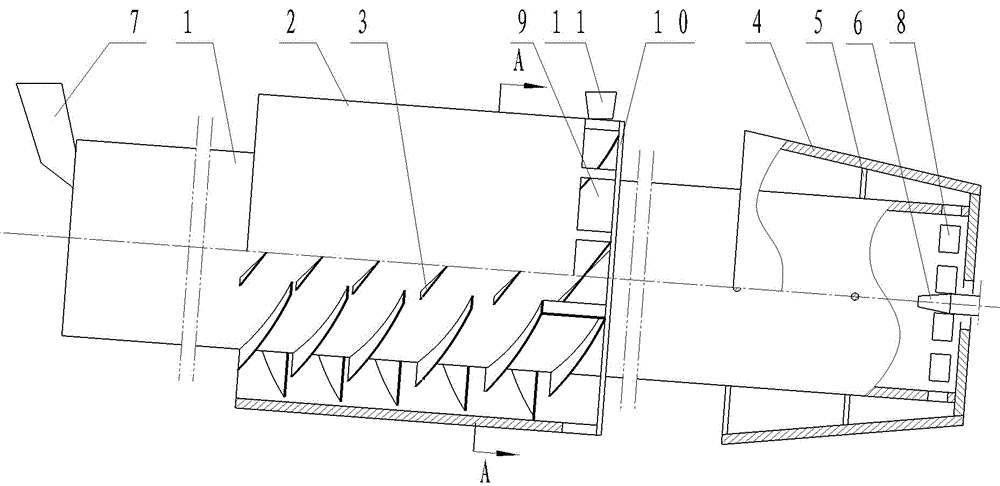

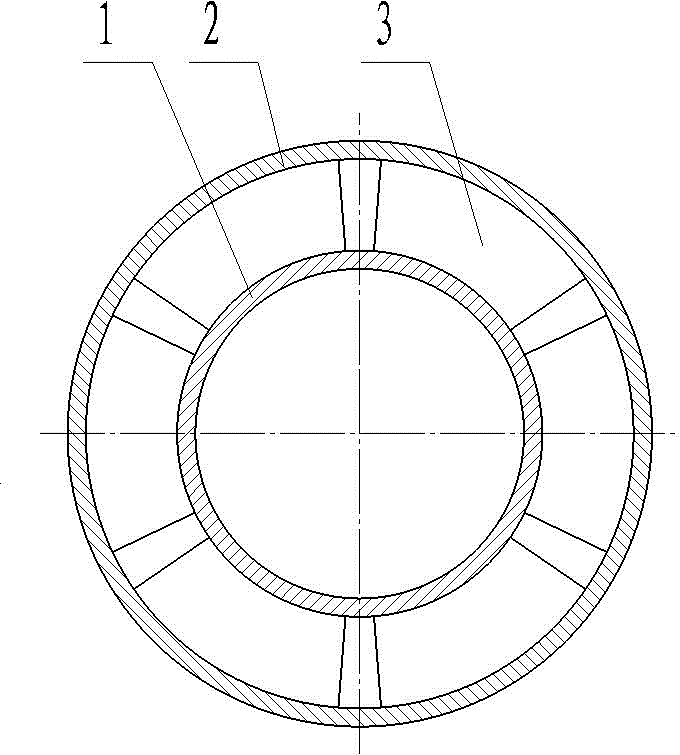

[0026] Example 1: refer to Figure 1~2 , is a schematic structural diagram of the calcining equipment used in Example 1 of the present invention. The calcining equipment used in the present invention includes a rotatable cylindrical barrel 1 inclined to the horizontal. The high end of the cylindrical barrel 1 is provided with a raw material inlet 7, and the low end is provided with a burner 6. The entire cylindrical barrel 1 is arranged from front to back It is divided into a preheating zone, a heating zone and a roasting zone, and the end of the cylindrical cylinder 1 is provided with a finished product outlet 8 on a circumference around the cylinder wall, and a trumpet-shaped cooling cylinder is provided on the outside of the finished material outlet 8. 4. The cylindrical tube 1 and the trumpet-shaped cooling tube 4 are provided with cooling tube pillars 5, and the burner 6 is a jet-type coal-fired burner. A drying device is provided on the outer wall of the middle part o...

Embodiment 2

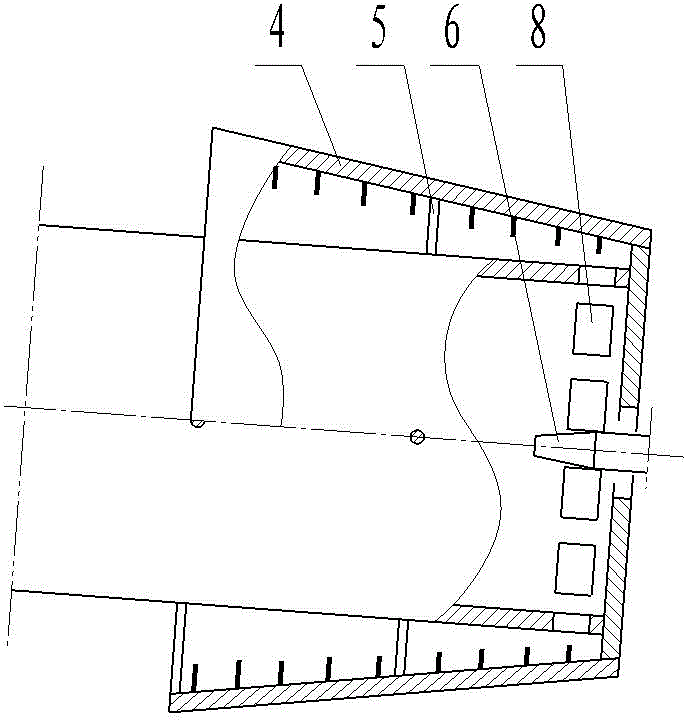

[0033] Example 2: refer to image 3 , is a schematic structural diagram of the calcining equipment used in Example 2 of the present invention. Compared with Embodiment 1, the difference of this embodiment is that: the inner wall of the trumpet-shaped cooling cylinder 4 is also provided with a helical pusher plate.

Embodiment 3

[0034] Example 3: Compared with Embodiment 1, the difference of this embodiment is that the burner 6 is a gas burner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com