Production device for plastic steel closed zippers and zipper production method thereof

A production device and zipper technology, applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the problems of high precision requirements, low production efficiency, high production cost, etc., to ensure firmness and stability, reduce scrap rate, The effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

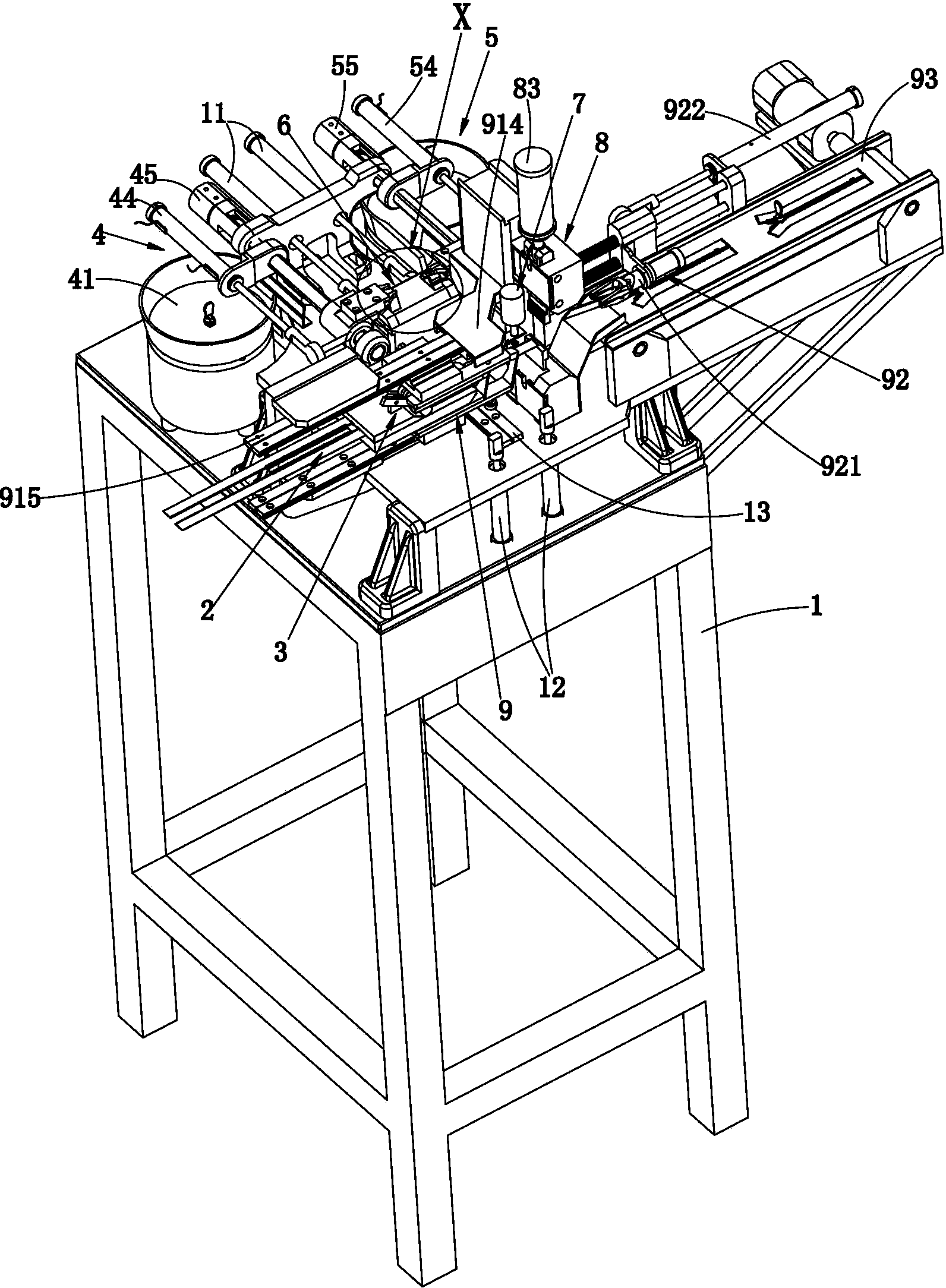

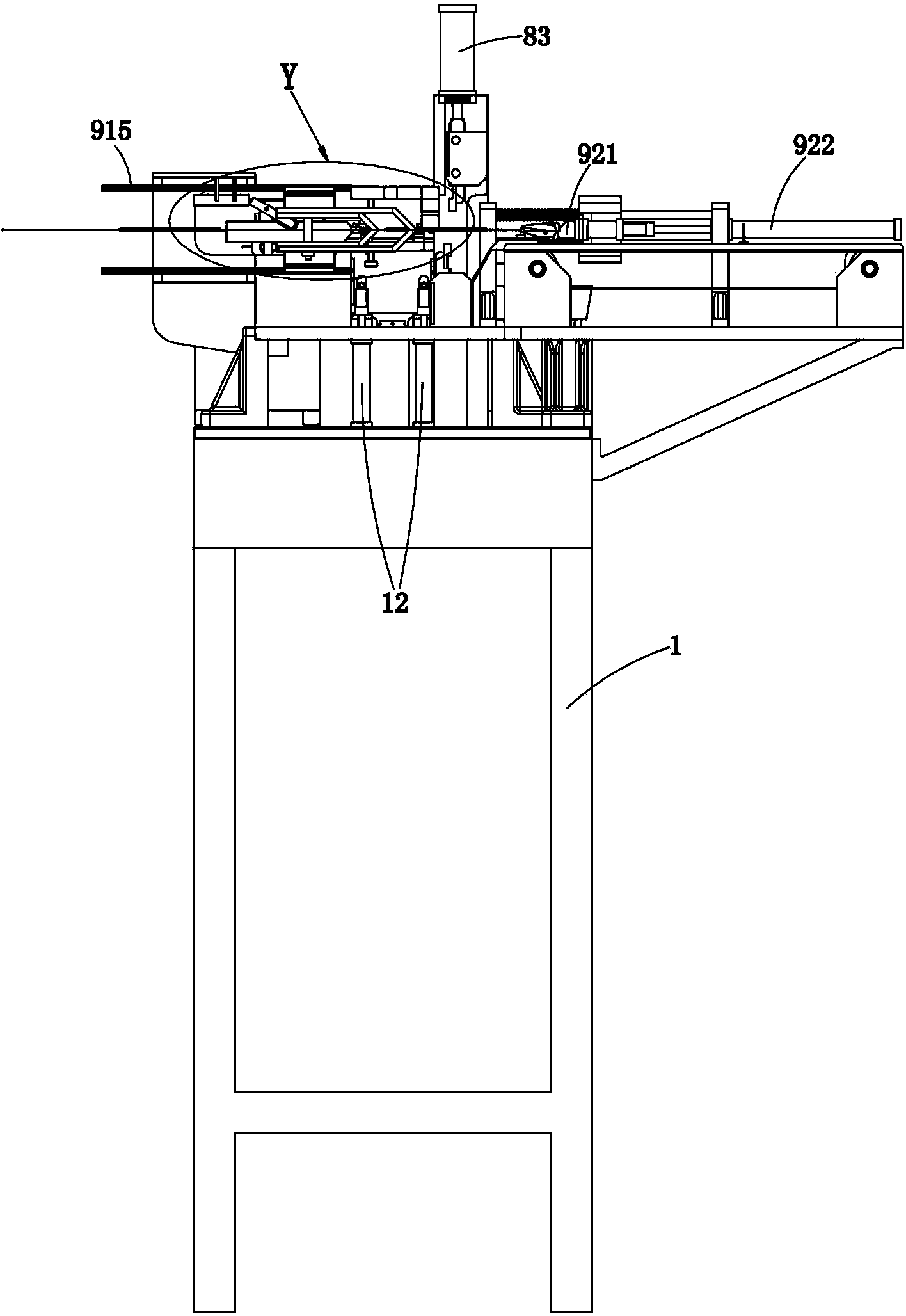

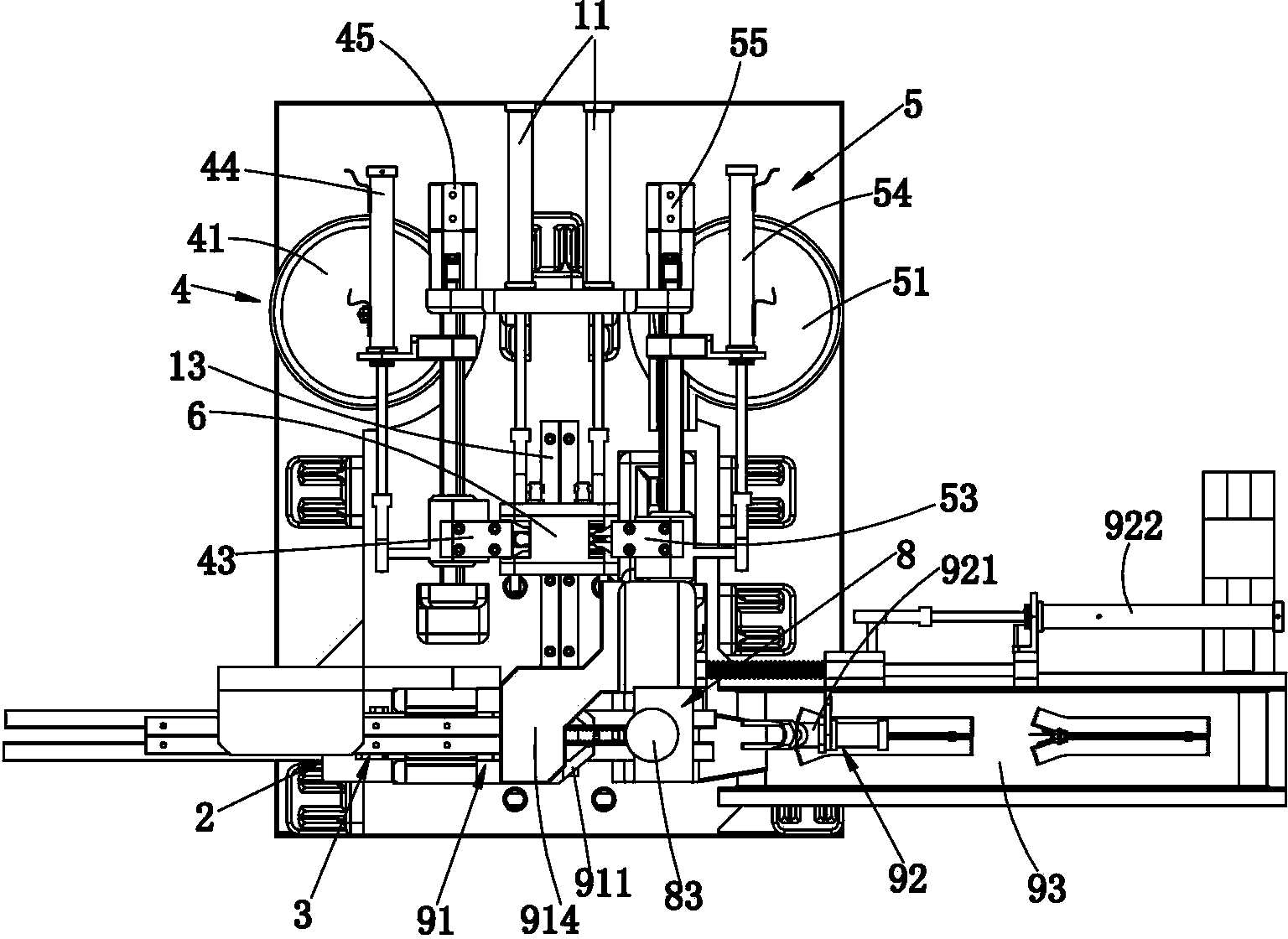

[0031] join figure 1 , figure 2 , image 3 , Figure 6 , the production device of the plastic-steel closed zipper, including the main frame body 1, the main frame body 1 is equipped with a chain belt guide mechanism 2, a chain tooth detection mechanism 3, a slider feeding mechanism 4, an I-shaped code feeding mechanism 5, and a material Seat 6, I-code pressing mechanism 7, cutter mechanism 8, power mechanism 9 and control mechanism. The chain element detecting mechanism 3 is used for detecting whether a chain element is set on the chain belt moving directionally along the chain belt guiding mechanism 2 . One end of the material seat 6 is provided with a slider placement groove 61, and the other end of the material seat 6 is provided with an I-code placement groove 62. The guide column of the head 10 is placed in the slider placement groove 61 adjace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com