A method of using sand culture to grow pasture to absorb biogas slurry in pig farms

A pig farm and biogas slurry technology, which is applied in the field of high-efficiency utilization of pig farming waste, can solve the problems of restricting the development of grass planting, excessive biogas slurry water and fertilizer loss, and difficulty in popularization and utilization, so as to reduce the land used for pasture production and improve biogas slurry consumption. The effect of capacity and labor cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

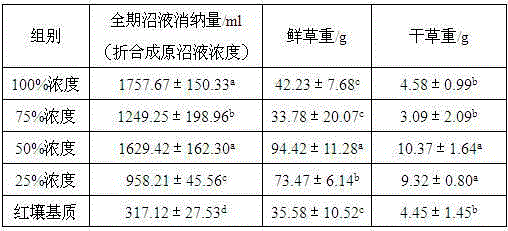

[0028] Example 1 (Experimental research on irrigating ryegrass multiflora with different concentrations of biogas slurry)

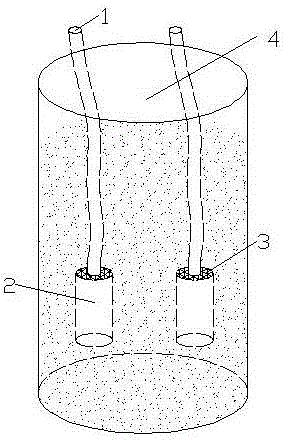

[0029] Use a wide-mouth plastic bottle with a capacity of 1L as the sand culture container, and the depth of the bottle is 20cm. The sand is filled with ordinary construction sand. After the sand is passed through a 22-mesh sieve, use a 45-mesh sieve to filter out fine gravel. Dry it in a constant temperature oven at 65°C for 48 hours, and use it as a test substrate after cooling. The saturated water content of Shashuo is 45.1%, and the bulk density is 1.71g / ml. Two 10ml disposable syringe shells (remove the piston and needle) are placed vertically in the Shashuo container as biogas slurry storage chambers, and the thin opening is connected with the external space through the hose (the outer opening of the hose is higher than the mouth of the plastic bottle). The wide mouth is slightly higher than the bottom of the plastic bottle, so as to prevent the san...

Embodiment 2

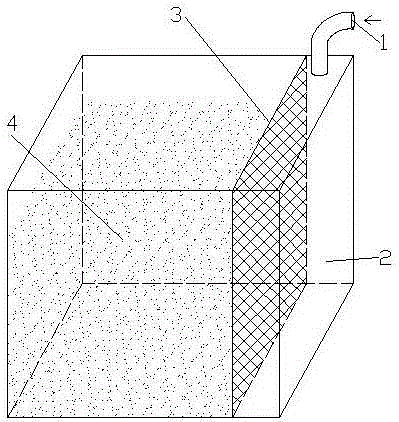

[0035] Taking biogas slurry from pig farms in Fuzhou, Fujian Province and producing gramineous forages throughout the year as an example, a sand culture pond with a depth of 50 cm was built, and a sand separation net was installed 5 cm from one side of the sand culture pond wall. Irrigate the sand in the net, and the outside of the sand separation net without sand is the biogas slurry storage room. The particle size of the sand is 0.5mm, and the livestock water in the sand culture pond is about 50%. Direct irrigation after sedimentation treatment, the average pH value of the irrigation biogas slurry is 7.3, the organic matter content is 1.75g / L, the total nitrogen is 302.1mg / L, the total phosphorus is 189.3mg / L, and the total potassium is 245.7mg / L. Plant sweet sorghum for “Hercules” in the sand culture pond in late March, with a sowing rate of 5-8g / m 2 During the germination period, it is necessary to ensure that the seeds are in the sand rich in biogas slurry, the mowing cyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com