Solenoid valves for jacquard

A technology of electromagnetic valve and jacquard machine, which is applied in the field of electromagnetic valve, can solve the problems of waste of resources, prone to deviation and malfunction, and increase of rejection rate of electronic jacquard machine, so as to reduce production cost and transportation cost, save raw materials, and reduce volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

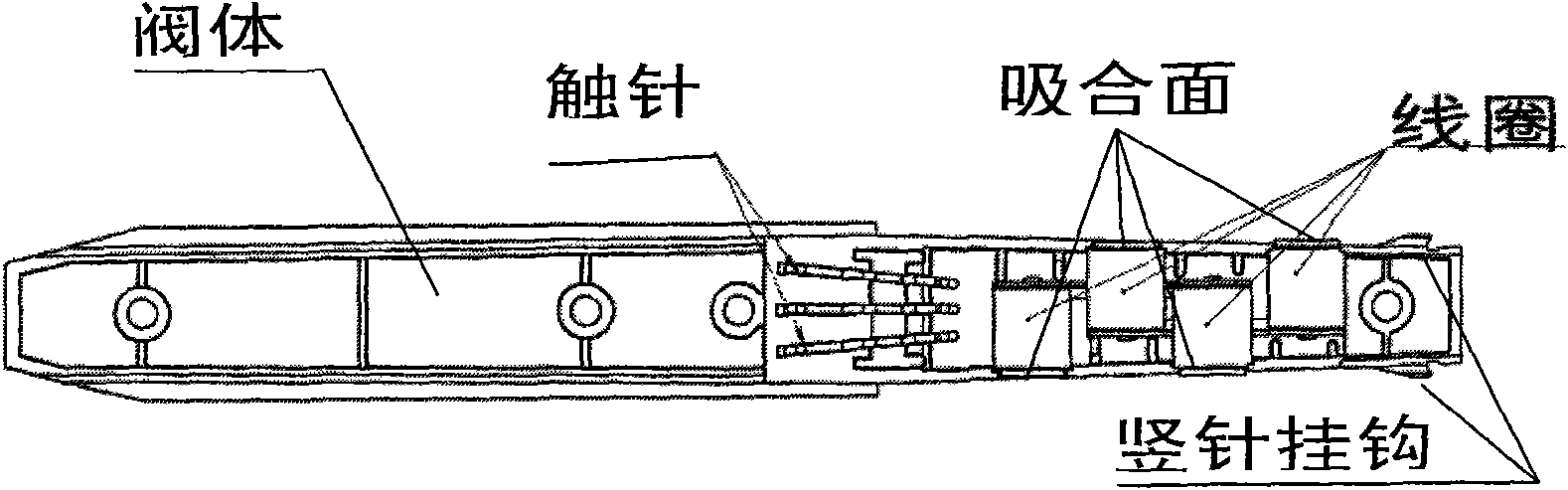

[0014] Example 1: Place the contact pin (2) and the electromagnetic coil (3) on the injection-molded valve body (1), connect two spaced electromagnetic coils (3) in series to form a group, and the two groups share one electrode. Solder to one of the contact pins (3), and the other end of each group of electromagnets is connected to the other two contact pins (3) by welding;

[0015] Each group of solenoid coils (3) connected in series form two suction surfaces (4) on one side (1) of the valve body;

[0016] There are two protruding vertical needle hooks (5) at the end of the valve body (1), which hook the vertical needles of the jacquard machine;

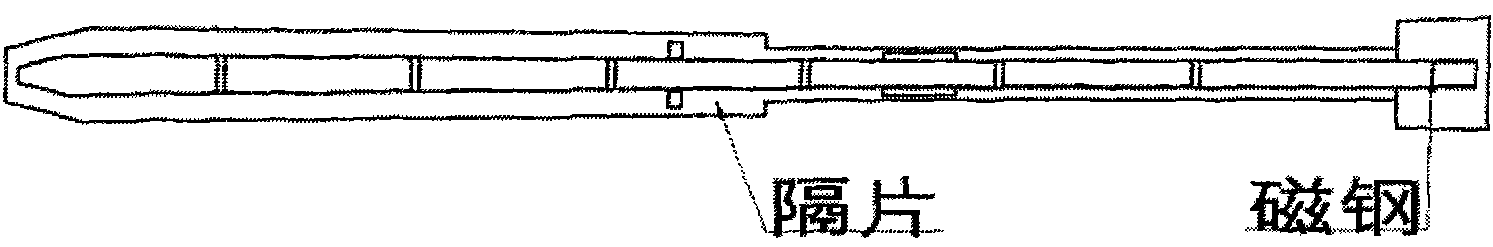

[0017] Place the magnetic steel (7) on the spacer (6) to correct and correct the movement of the vertical needle;

[0018] A cover plate (8) designed with a hook (9) is crimped on the valve body (1) to form a complete valve body.

[0019] The assembled valve body (1) cooperates with the spacer (6) to form a complete solenoid valve after a si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com