A high-efficiency busbar production device

A technology for production devices and busbars, which is applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve the problems of unsuitable production efficiency, cumbersome drying process, and reduced production efficiency, etc. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

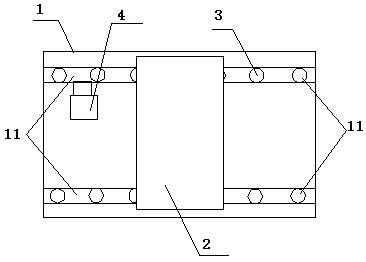

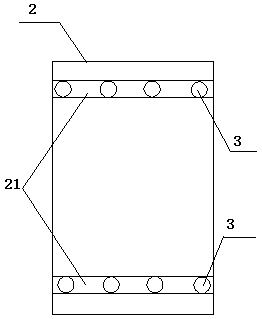

[0012] As shown in the figure, a high-efficiency busbar production device includes a body 1 and a first roller set 11 inside the body. The first roller set 11 includes several pairs of rollers arranged evenly in the body 1 and arranged up and down. 3. Wherein, the drying box body 1 is provided with a paint box 2; the paint box 2 is located in the middle of the drying box 1, and the paint box 2 is provided with a second roller set 21. The second roller set 21 includes several pairs of rollers 3 that are evenly arranged in the paint box 2 and arranged up and down; the rollers in the first roller set 11 and the second roller set 21 3. The chain and sprocket are mutually driven by the reduction motor 4. The busbar passes through the first roller set 11 for drying and then enters the paint box 2. The busbar passes through the second roller set 12 for paint and then exits the paint box 2. Continue Carry out drying until the busbar is sent out of the drying box.

[0013] Beneficial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com