Sewage treatment system equipment for absolute quantification of sludge and method for recycling sewage

A technology of sewage treatment system and system equipment, applied in water/sludge/sewage treatment, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of secondary pollution and pollution diffusion, and save production Land use, good treatment conditions, and the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

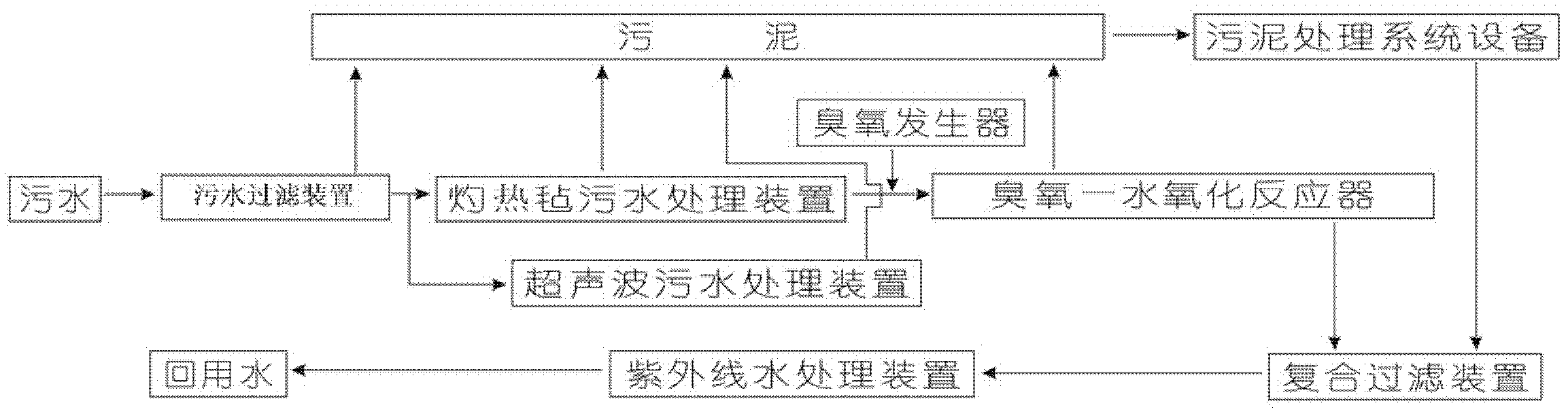

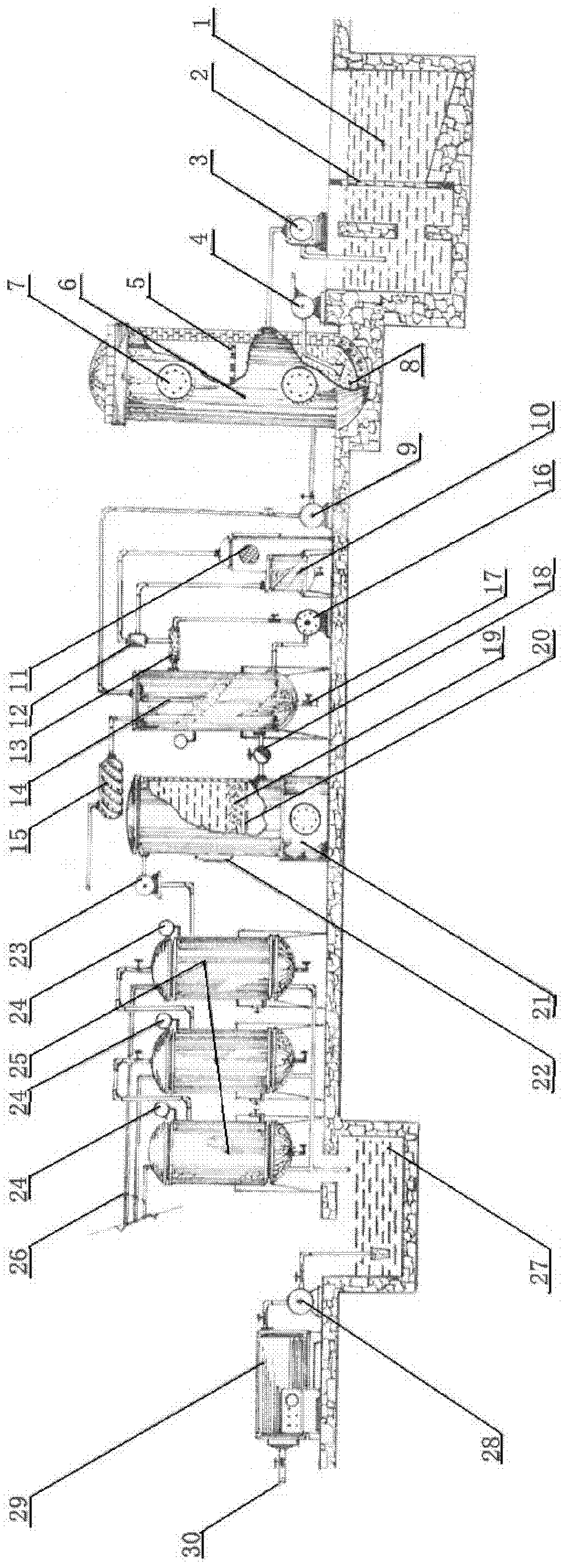

[0085] Embodiment 1 Sewage treatment system equipment using glowing felt water treatment device and its treatment method and process flow

[0086] like figure 2 , the method and equipment include the following:

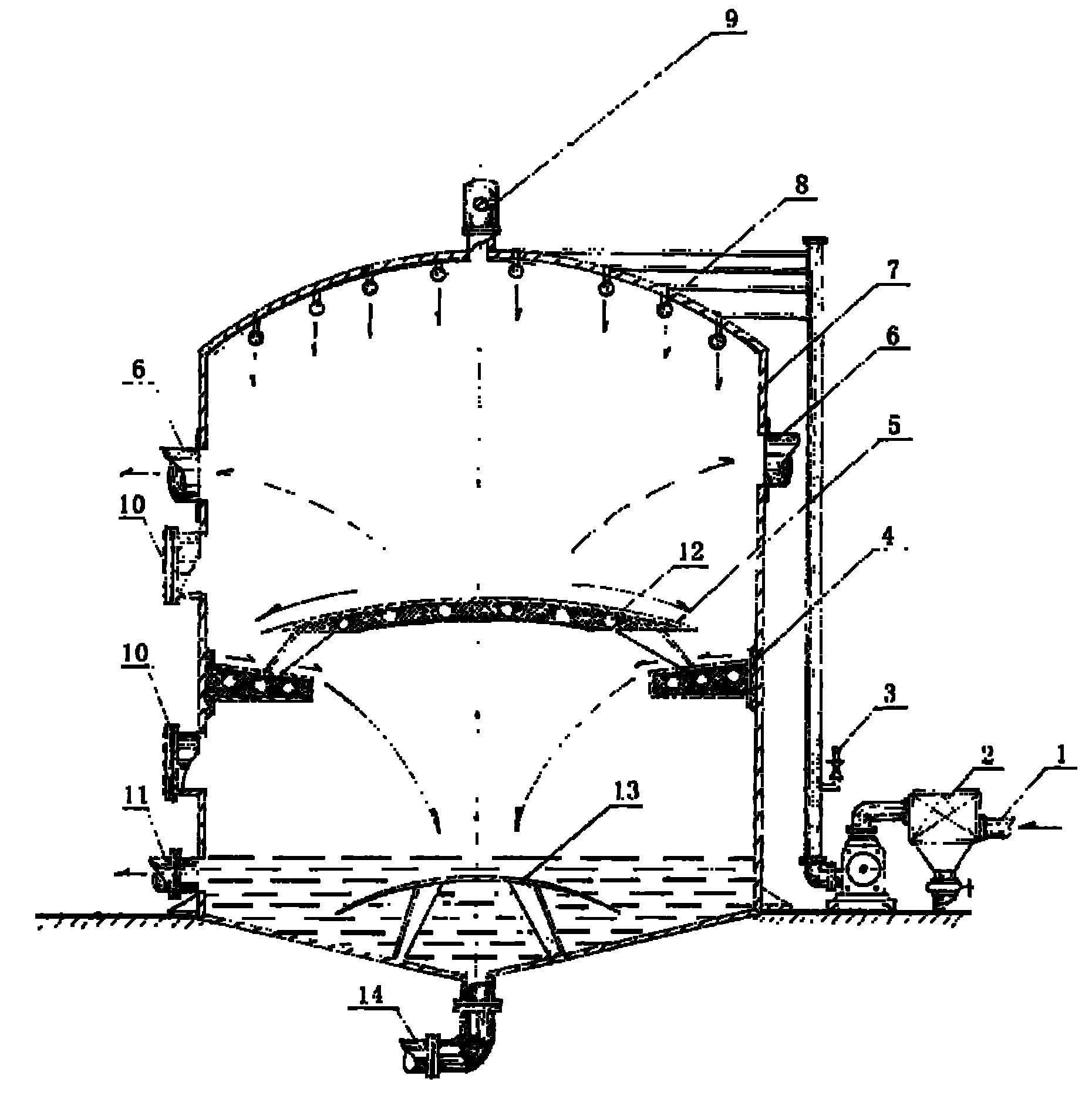

[0087] 1. 100 tons of sewage is preliminarily filtered from the primary sedimentation tank 1 through the solid-liquid separation gate 2 in the sundries column, and then is fed into the glowing felt water treatment device in the equipment system by the water inlet pump 3 at a delivery rate of 4.8 tons per hour for solid-liquid treatment. Separation, the sewage is sprayed on the glowing felt 5 in the middle of the tank through the injection port on the top of the tank, after solid-liquid separation, the liquid enters the water storage 6 at the bottom of the tank, and there are several manholes for repairs on the tank 7. After the sludge in the sewage settles at the bottom of the tank, it is pumped out by the sludge pump 4 to be used in the subsequent process and made ...

Embodiment 2

[0096] Embodiment 2 Sewage treatment system equipment using a vertical ultrasonic sewage treatment device and its treatment method and process flow

[0097] like Figure 4 Shown:

[0098] 1. The mixed sewage of 50 tons of domestic sewage and industrial sewage is initially filtered by the primary sedimentation tank 1 through the solid-liquid separation gate 2 of the debris column, and then input into the water storage tank 5 in the equipment system through the water inlet pump 3, The sludge is discharged through the sludge pump 4 at the bottom of the water storage tank 5, and is used in the production of subsequent adsorbents; after the sewage passes through the water storage tank 5, it enters the vertical ultrasonic atomization device for solid-liquid separation, and the vertical ultrasonic atomization device It includes a plurality of ultrasonic atomizers 8 with downward spraying heads, and a mist dropper 9 is arranged below it. After the sewage is collected by the mist drop...

Embodiment 3

[0103] Embodiment 3 Sewage treatment system equipment using a horizontal ultrasonic sewage treatment device and its treatment method and process flow

[0104] like Image 6 Shown:

[0105] 1. The mixed sewage of 100 tons of domestic sewage and industrial sewage is initially filtered from the primary sedimentation tank 1 through the solid-liquid separation gate 2 of the sundries column, and then enters the sewage pool 5 through the water inlet pipe 3, and the sewage at the bottom of the sewage pool 5 The pool sediment 9 is discharged through the sludge pump 4, and is used in the production of subsequent adsorbents; in this embodiment, the solid-liquid separation device is a horizontal horizontal ultrasonic sewage treatment device 6, and the top of the device is provided with a rotating scraper for cleaning. arm 6, the device is located above the liquid level of the sewage pool 5, and an automatic suction valve 8 is provided on the top shell, and the atomized sewage is sucked i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com