Automatic production system for energy saving luminous tube

A technology for automatic production and energy-saving lamps, which is applied in the manufacture of electrode systems, the manufacture of discharge tubes/lamps, and electrical components, which can solve the problems of increasing labor intensity, inconvenient production and orderly management, and increasing production costs. Achieve the effect of reducing labor intensity, reducing damage, and saving production and labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

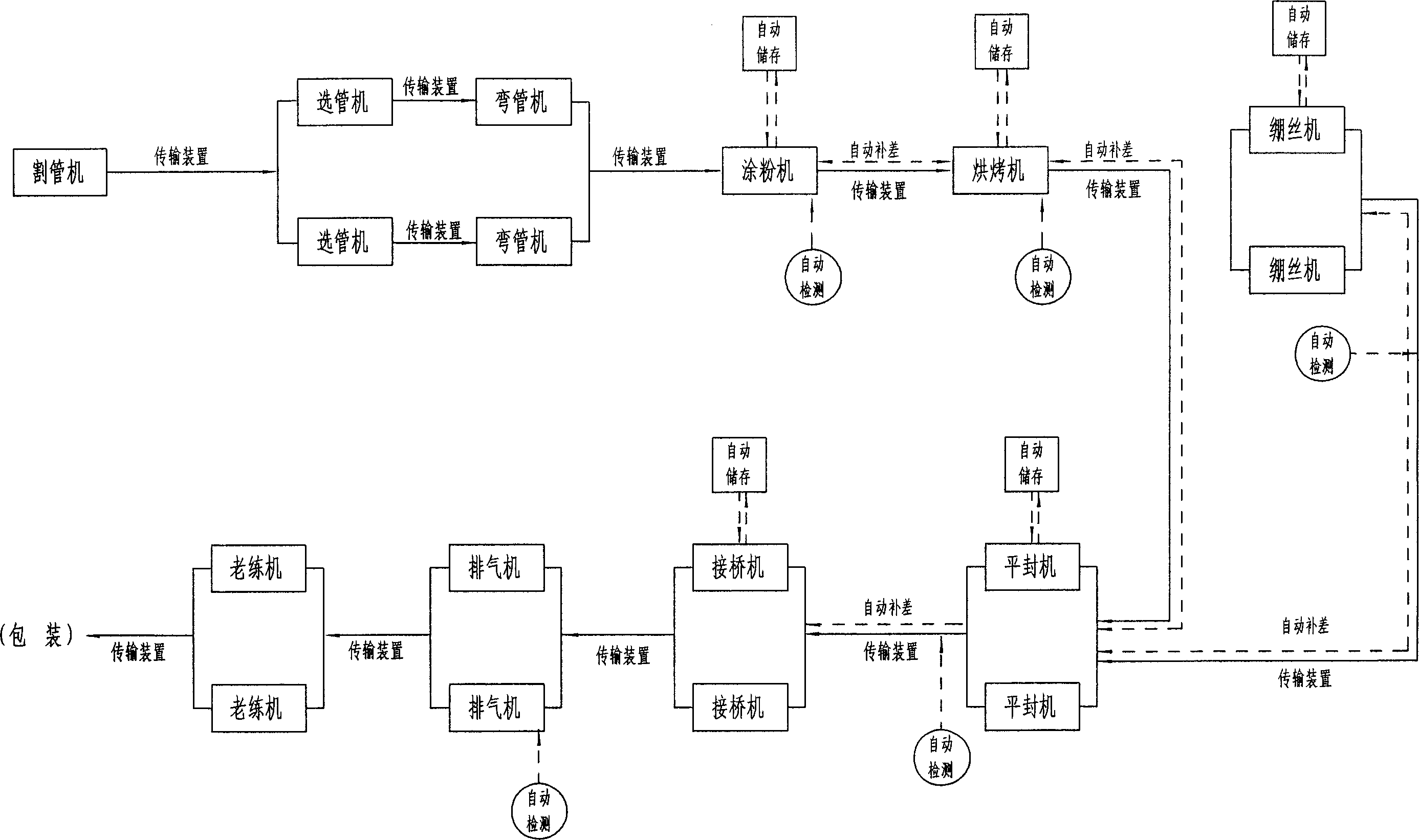

[0010] The invention mainly consists of ten single machines including a pipe cutting machine, a pipe selecting machine, a pipe bending machine, a powder coating machine, a baking machine, a wire stretching machine, a flat sealing machine, a bridge connecting machine, an exhaust machine and an aging machine. Arrange the pipe cutting machine, pipe selecting machine, pipe bending machine, powder coating machine, baking machine, stretching machine, flat sealing machine, bridge connecting machine, exhaust machine, aging machine in order, and set up between each single machine transmission device. The transmission device can have transmission forms such as mechanical intermittent transmission conveyor chain, flat belt transmission, chain transmission, and synchronous toothed belt transmission.

[0011] Install a powder coating detection device on the powder coating machine; install a baking detection device on the baking machine; install a wire stretching detection device on the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com