Domestic laundry treating machine with a washing drum driven by an electric motor and mounting method

A technology for washing drums and electric motors, applied in washing devices, other washing machines, applications, etc., can solve problems such as costly manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

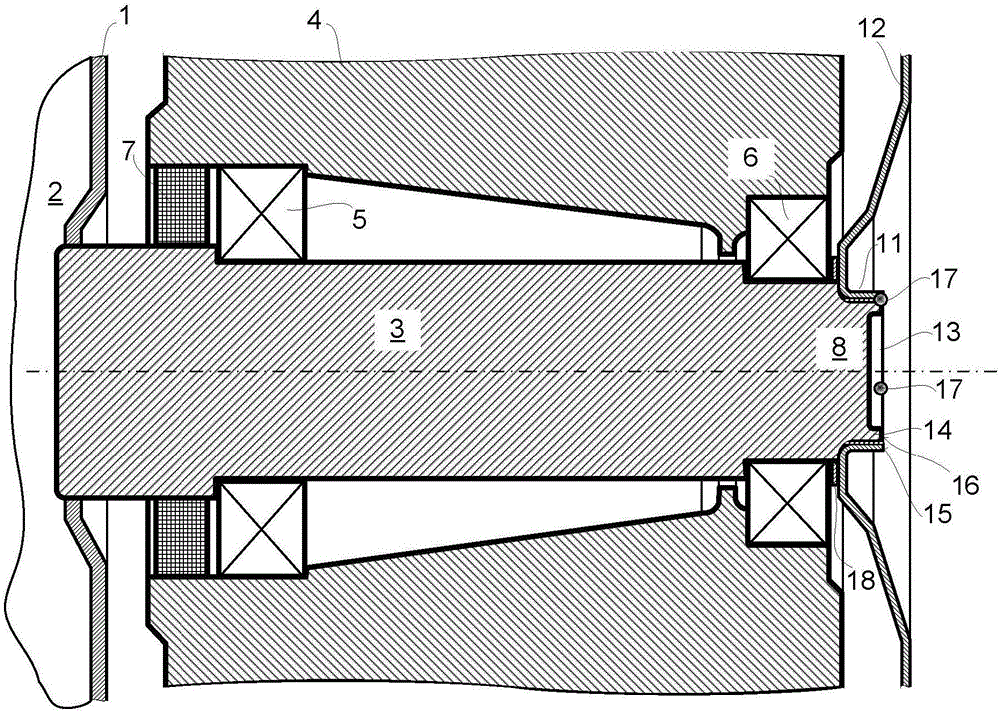

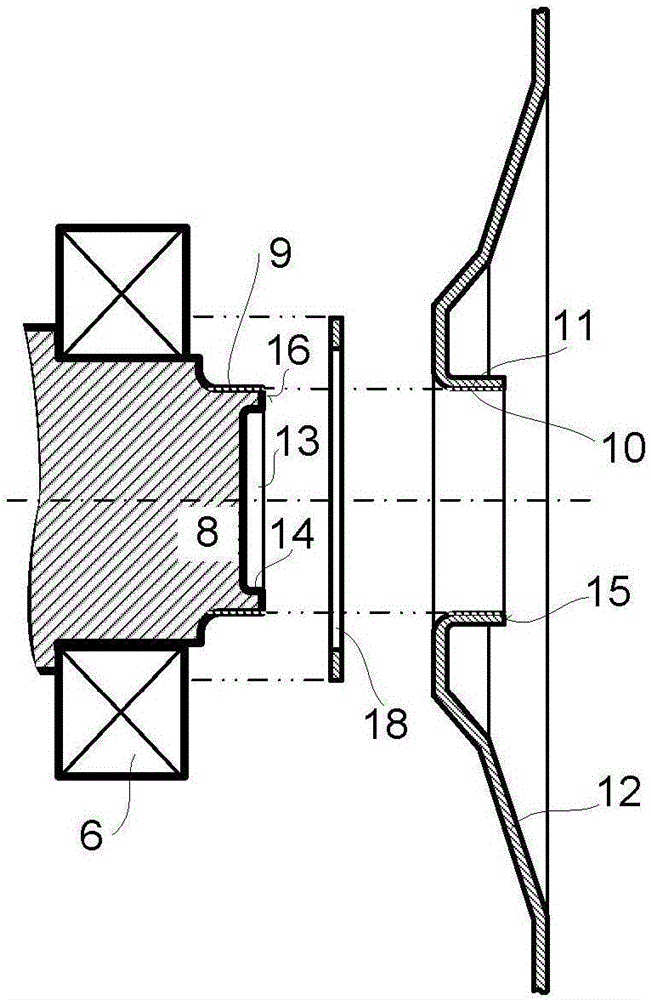

[0016] exist figure 1 In this case, the rear wall 1 of the washing drum 2 supported in the lye container (here made of plastic) is fixedly connected to the drive shaft 3 . Only a part of the lye container is shown here, in which part the bearing housing 4 is integrated on the rear wall of the lye container. In this case, the bearing housing 4 is bored for the drive shaft 3 , which, together with the washing drum 2 , is movably mounted in the bearing housing 4 on two roller bearings 5 and 6 . In this case, the inner rolling bearing 5 is protected from liquid from the lye container by a shaft seal 7 (shown only schematically here).

[0017] The drive shaft 3 has shoulders on the bearing points, which define the position of the rolling bearings 5 and 6 during press-fitting. The other shoulder on the outer end of the drive shaft 3 , ie the end 8 facing away from the washing drum 2 , contains an external thread 9 which fits into an internal thread 10 on the flange 11 of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com