Method and device for hardening frame glue of liquid-crystal display panel

一种液晶面板、框胶的技术,应用在非线性光学、仪器、光学等方向,能够解决框胶中光反应剂反应不完全、降低液晶面板显示质量、面板周边颜色分布不均等问题,达到减少硬化时间、改善碎亮点、增加面积的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Further details will be given below in conjunction with the preferred embodiments shown in the accompanying drawings.

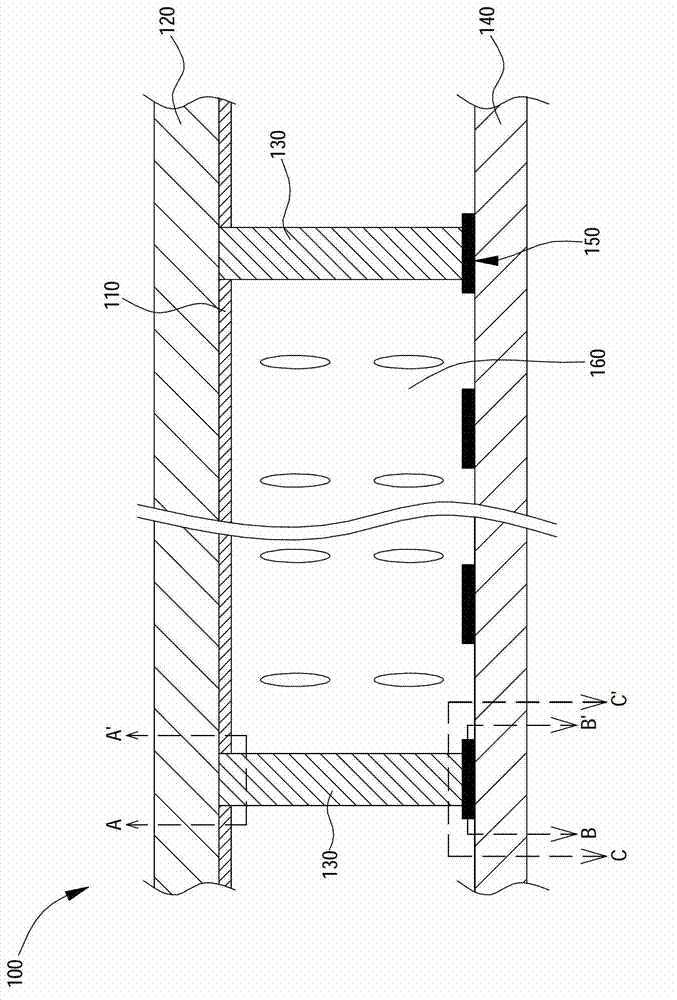

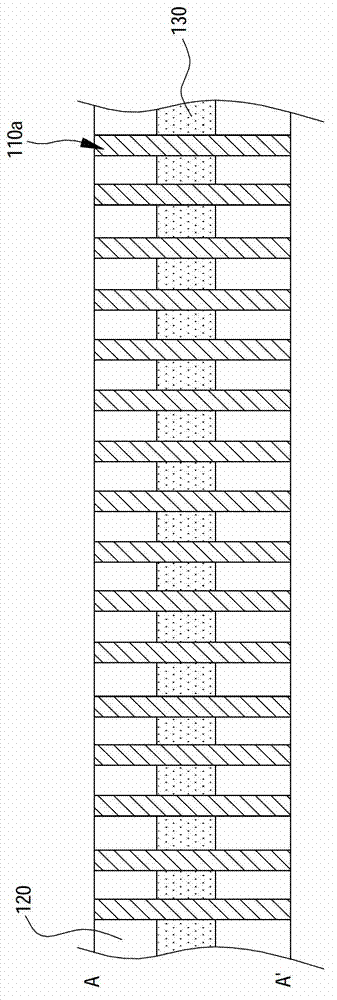

[0029] figure 2 It is a partial cross-sectional view of the LCD panel. Such as figure 2 As shown, a liquid crystal panel (LCD Panel) 100 includes a glass substrate 120, a circuit layer 110, a liquid crystal layer 160, a frame glue 130, a color filter substrate (colorfilter substrate) 140 and a black matrix (black matrix) 150.

[0030] The black matrix 150 is formed on the color filter substrate 140 . The circuit layer 110 and the sealant 130 are formed on the glass substrate 120 . Then, the liquid crystal molecules are evenly dropped into the space surrounded by the glass substrate 120 and the sealant 130 to form the liquid crystal layer 160, and immediately laminated with the color filter substrate 140, so that the liquid crystal layer 160 is located between the glass substrate 120 and the color filter substrate. Between the filter substrates 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com