Anti-cracking mass concrete

A technology of large-volume concrete and anti-cracking waterproofing agent, which is applied in the field of building materials, can solve the problems of increasing construction difficulty and affecting the effect of concrete cracking, and achieves the effect of uniform internal strength, uniform internal and sufficient filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

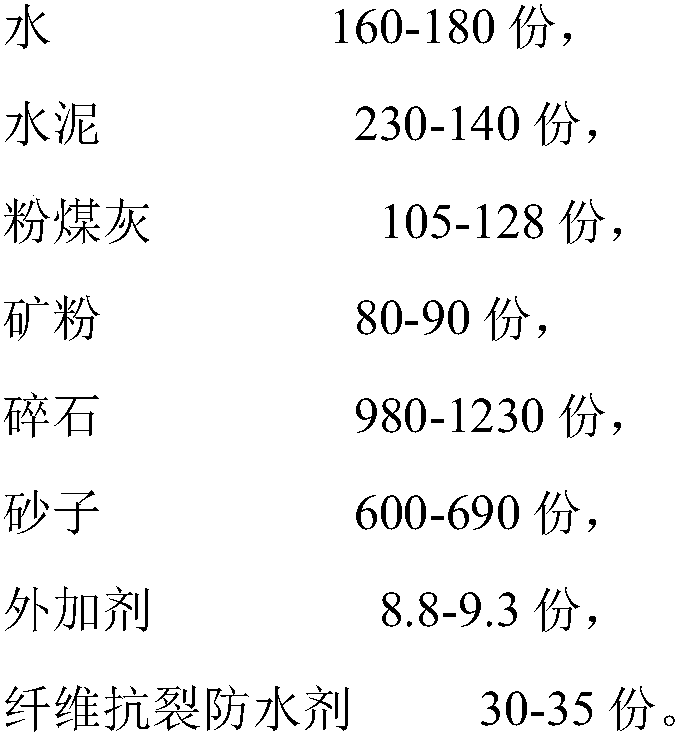

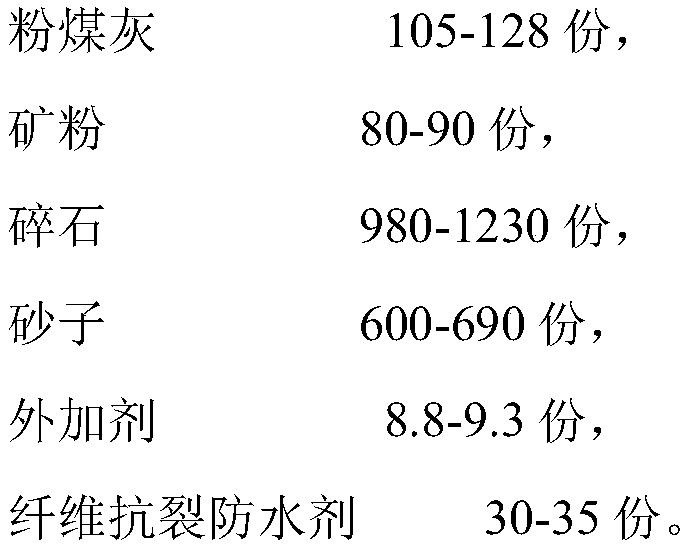

[0037] The quality of each component in each embodiment is as shown in table 2.

[0038] Table 2

[0039]

[0040]

Embodiment 2

[0041] The difference between embodiment 2 and embodiment 1 is that corncob powder and silica sol are added; the difference between embodiment 3-6 and embodiment 2 is that furfuryl alcohol mud is added. According to the "Code for Construction of Mass Concrete" (GB50496-2009), the performance test results of the crack-resistant mass concrete of Examples 1-6 are shown in Table 3.

[0042] table 3

[0043]

[0044] Based on the above test results, Example 6 has better performance, so Example 6 is a more preferred solution. The anti-crack mass concrete in embodiment 6 comprises the following components expressed in parts by weight: 165 parts of water, 240 parts of cement, 120 parts of fly ash, 86 parts of mineral powder, 1081 parts of gravel, 662 parts of sand, admixture 8.92 parts, 34 parts of fiber anti-cracking waterproof agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com