Molybdenum tailing aerated concrete block and manufacturing method thereof

A technology of aerated concrete and molybdenum tailings, applied in the field of building materials, to achieve high compressive strength, shorten normal hardening time, and low production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

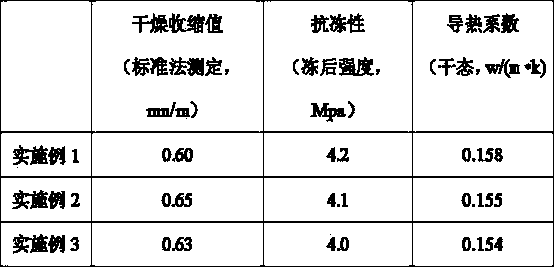

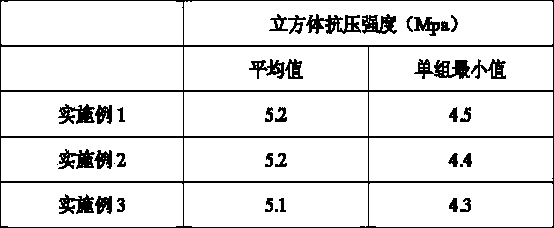

Embodiment 1

[0027] A molybdenum tailings aerated concrete block is composed of the raw materials and weight percentages shown in Table 1.

[0028] The preparation method of the above-mentioned molybdenum tailings aerated concrete block is as follows:

[0029] (1) Raw material pretreatment:

[0030] (a) Mix the tailings and gypsum in proportion, add them to the ball mill, add an appropriate amount of water, turn on the ball mill to grind the above raw materials to obtain a slurry, and the slurry first flows into the slurry tank, and the concentration is adjusted by adding water quantitatively It is 30% ground pulp, and then pumped into the batching slurry storage tank for standby, and a density meter for controlling the specific gravity of the ground pulp is installed in the pumping pipeline of the ground pulp, so as to control water replenishment in real time according to the feedback value of the density meter , to achieve uniform quality of ground pulp;

[0031] (b) Quicklime is crush...

Embodiment 2

[0038] A molybdenum tailings aerated concrete block is composed of the raw materials and weight percentages shown in Table 1.

[0039] The preparation method of the above-mentioned molybdenum tailings aerated concrete block is as follows:

[0040] (1) Raw material pretreatment:

[0041] (a) Mix the tailings and gypsum in proportion, add them to the ball mill, add an appropriate amount of water, turn on the ball mill to grind the above raw materials to obtain a slurry, and the slurry first flows into the slurry tank, and the concentration is adjusted by adding water quantitatively It is 50% ground pulp, and then pumped into the batching slurry storage tank for standby, and a density meter for controlling the specific gravity of the ground pulp is installed in the pipeline for pumping the ground pulp, so as to control water replenishment in real time according to the feedback value of the density meter , to achieve uniform quality of ground pulp;

[0042] (b) Quicklime is crus...

Embodiment 3

[0049] A molybdenum tailings aerated concrete block is composed of the raw materials and weight percentages shown in Table 1.

[0050] The preparation method of the above-mentioned molybdenum tailings aerated concrete block is as follows:

[0051] (1) Raw material pretreatment:

[0052] (a) Mix the tailings and gypsum in proportion, add them to the ball mill, add an appropriate amount of water, turn on the ball mill to grind the above raw materials to obtain a slurry, and the slurry first flows into the slurry tank, and the concentration is adjusted by adding water quantitatively It is 40% ground pulp, and then pumped into the batching slurry storage tank for standby, and a density meter for controlling the specific gravity of the ground pulp is installed in the pipeline for pumping the ground pulp, so as to control water replenishment in real time according to the feedback value of the density meter , to achieve uniform quality of ground pulp;

[0053] (b) Quicklime is crus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com