Environment-friendly magnesian dry material and preparation process thereof

A dry material, environment-friendly technology, applied in the field of refractory materials, can solve the problems of non-compliance with clean, green and high-quality steel billet production requirements, on-site construction workers and environmental hazards, and affect the use effect of dry materials, so as to increase the overall Diffusion effect, shortening of hardening time, and improvement of erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

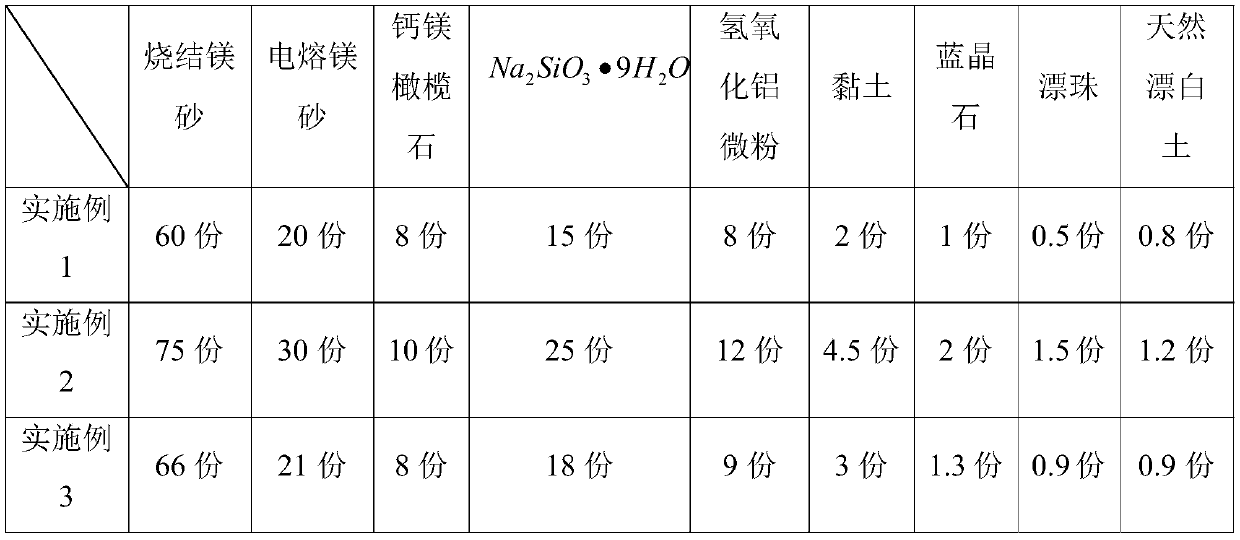

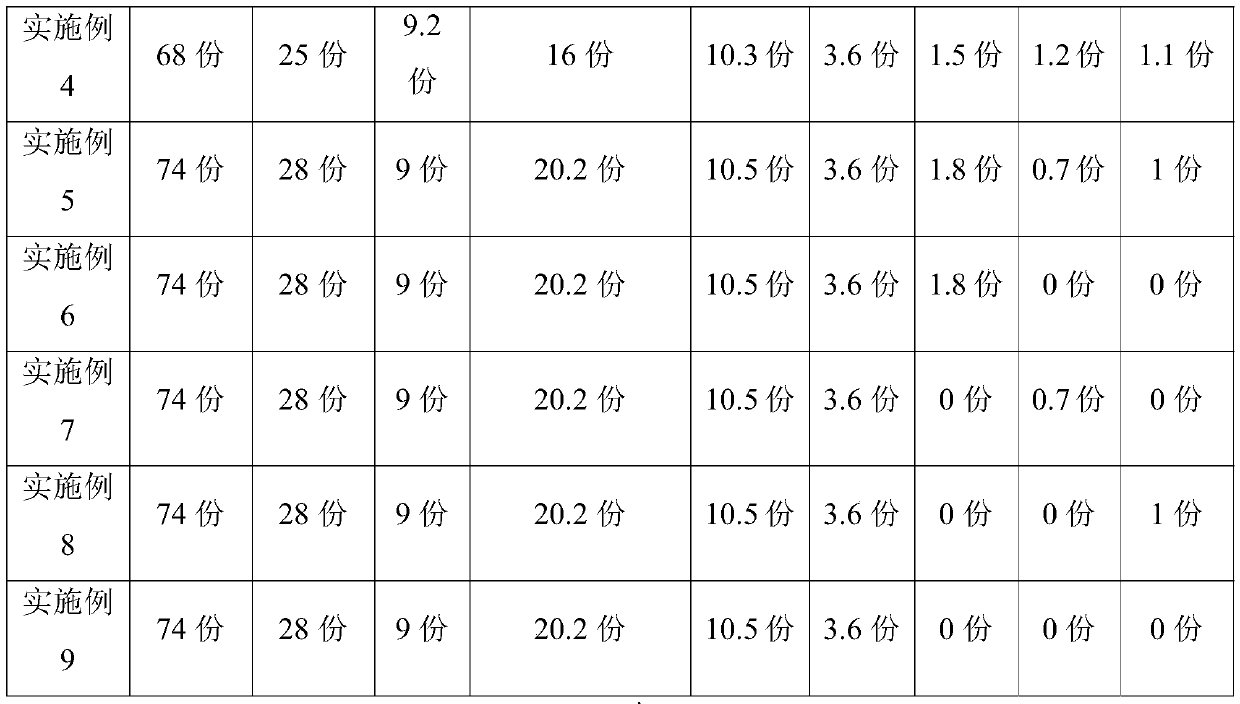

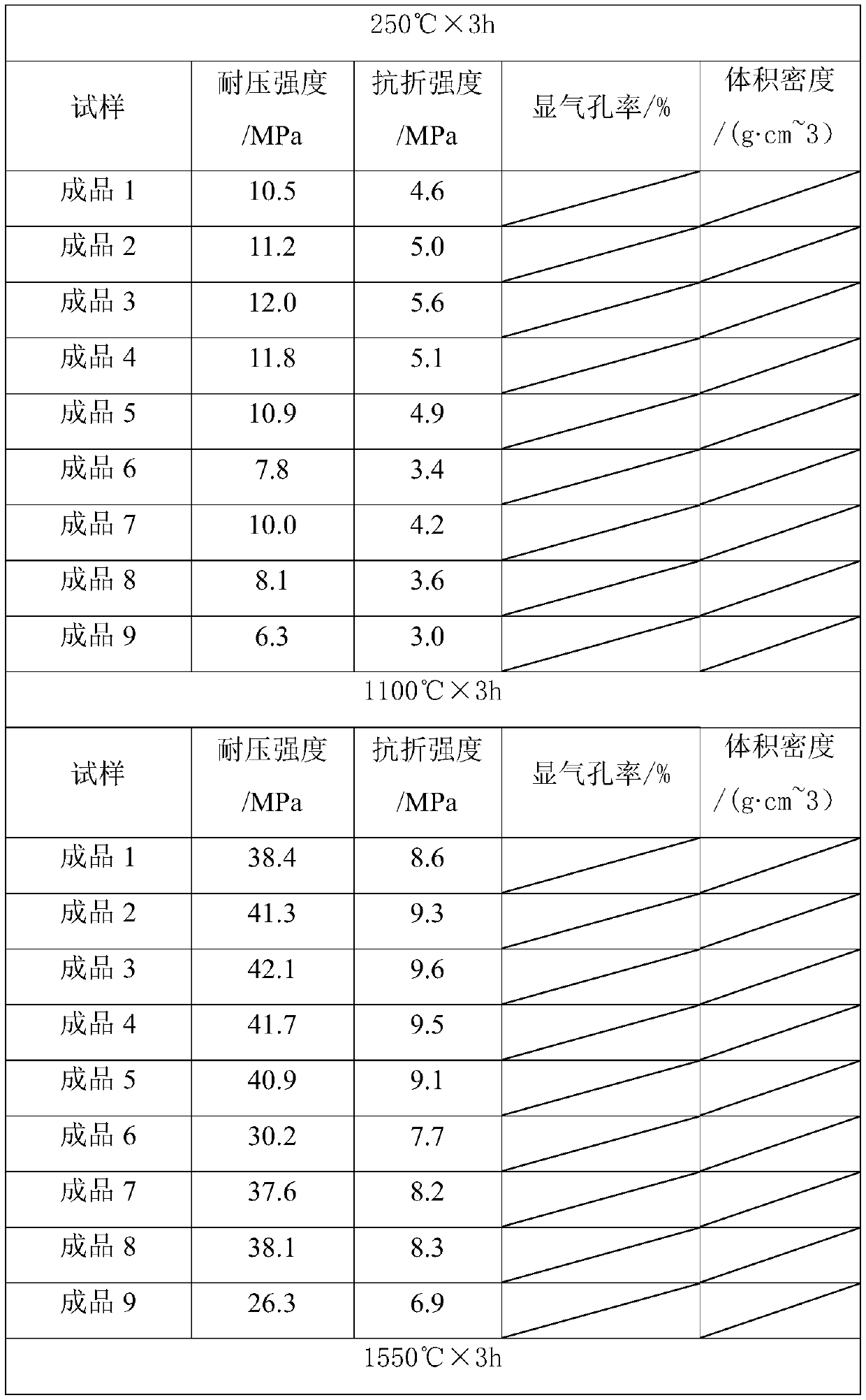

[0028] The invention provides an environment-friendly magnesium dry material, which comprises a mass ratio of 60-75:20-30:8-10:15-25:8-12:2-4.5:1-2:0.5-1.5: 0.8-1.2 sintered magnesia, fused magnesia, calcium magnesium olivine, binder, aluminum hydroxide micropowder, high temperature sintering agent, expansion agent, floating beads, bentonite. Among them, the binding agent is Na 2 SiO 3 9H 2 O, the high-temperature sintering agent is clay, the expansion agent is kyanite, and the bentonite is natural bleaching earth.

[0029] Table 1 shows the ratio of raw materials of environment-friendly magnesium dry materials in Examples 1-8 of the present invention.

[0030]

[0031]

[0032] Table 1

[0033] The dry-type material raw material of proportioning in implementing 1 is made dry-type material finished product in the following way:

[0034] 1. Grind the raw material fused magnesia, and sieve it with a 200-mesh screen to obtain fused magnesia that meets the requirements ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com