Patents

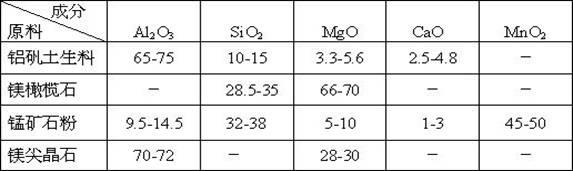

Literature

94 results about "Peridot" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Peridot (/ˈpɛrɪdɒt/ or /ˈpɛrɪdoʊ/) (sometimes called chrysolite) is gem-quality olivine and a silicate mineral with the formula of (Mg, Fe)₂SiO₄. As peridot is a magnesium-rich variety of olivine (forsterite), the formula approaches Mg₂SiO₄.

Material for thermal barrier coating

InactiveCN1764613AImprove efficiencyReduce weightMolten spray coatingEfficient propulsion technologiesCrystal structureThermal expansion

The invention provides a novel thermal insulation coating material with no phase transfer problem, a melting point higher than the working temperature range, a thermal conductivity lower than that of zirconia, and a thermal expansion rate higher than that of zirconia. The thermal barrier coating material has an orthorhombic or monoclinic crystal structure derived from perovskite (for example, a platy perovskite structure represented by the composition formula A2B2O7), or a c-axis / a-axis ratio of 3 or more The composition of the tetragonal layered structure (such as K2NiF4 structure and Sr3Ti2O7 structure, Sr4Ti3O10 structure), and the composition represented by the composition formula LaTaO4, and the composition with the composition formula M2SiO4 or (MM') 2SiO4 (wherein M, M 'is a divalent metal element) composition of the olivine structure represented as the main body.

Owner:MITSUBISHI HEAVY IND LTD

Magnesium gunning refractory for copper smelting-furnace

A magnesium gunning refractory used in copper smelting furnace can be used to gun and repair large area or partial erosive part of the furnace lining of nonferrous metals smelting furnace, the material thereof comprises aggregate, powder, binding agent and additive; the material of aggregate and powder comprises fused magnesite chrome sinter, fused magnesia, sintered magnesia and forsterite; the critical particle size of the aggregate is 0.1-5mm, and the particle size of the powder less than 0.088mm; the weight ratio is that fused magnesite chrome sinter 0-20%, sintered magnesia 10-30%, forsterite 0-20% for particle size of 3-5mm; sintered magnesia10-40%, forterite 10-40% for particle size of 1-3mm; fused magnesia 0-20%, sintered magnesia 5-20%, forsterite 5-20% for particle size of 0.1-1mm; fused magnesia 6-20%, forsterite 0-15% for particle size less than 0.088mm; binding agent 5%-15%; additive 6%-20%. The invention has the advantages of delaying the date of retirement, increasing the service life of the whole furnace lining, decreasing the repairing expenses and working intensity, and ensuring the continuity of production.

Owner:河南荣耀产业管理有限公司 +1

MgO-SiC-C refractory material synthesized by forsterite-C and method

The invention relates to MgO-SiC-C refractory material synthesized by forsterite-C and a method. The technical proposal to be adopted is as follows: firstly, forsterite mineral powder and industrial carbon powder are blended according to molar ratio of 1: (1-5); and then the mixture is added with 4 to 10 wt% of bonding agent, stirred or mulled for 10 to 30 minutes, pressed to be formed and dried; and finally under the Ar gas condition, the mixture is sintered in the sintering temperature of 1530 to 1800 DEG C with heat preservation for 2 to 8 hours to obtain MgO-SiC-C refractory material synthesized by forsterite-C. The invention is characterized by comparatively simple processing technique, low producing cost, high producing efficiency, wide raw material source and being capable of reducing energy consumption of high temperature synthesis reaction. The prepared MgO-SiC-C refractory material has the advantages of excellent high temperature performance, anti-corrosion and good durability.

Owner:WUHAN UNIV OF SCI & TECH

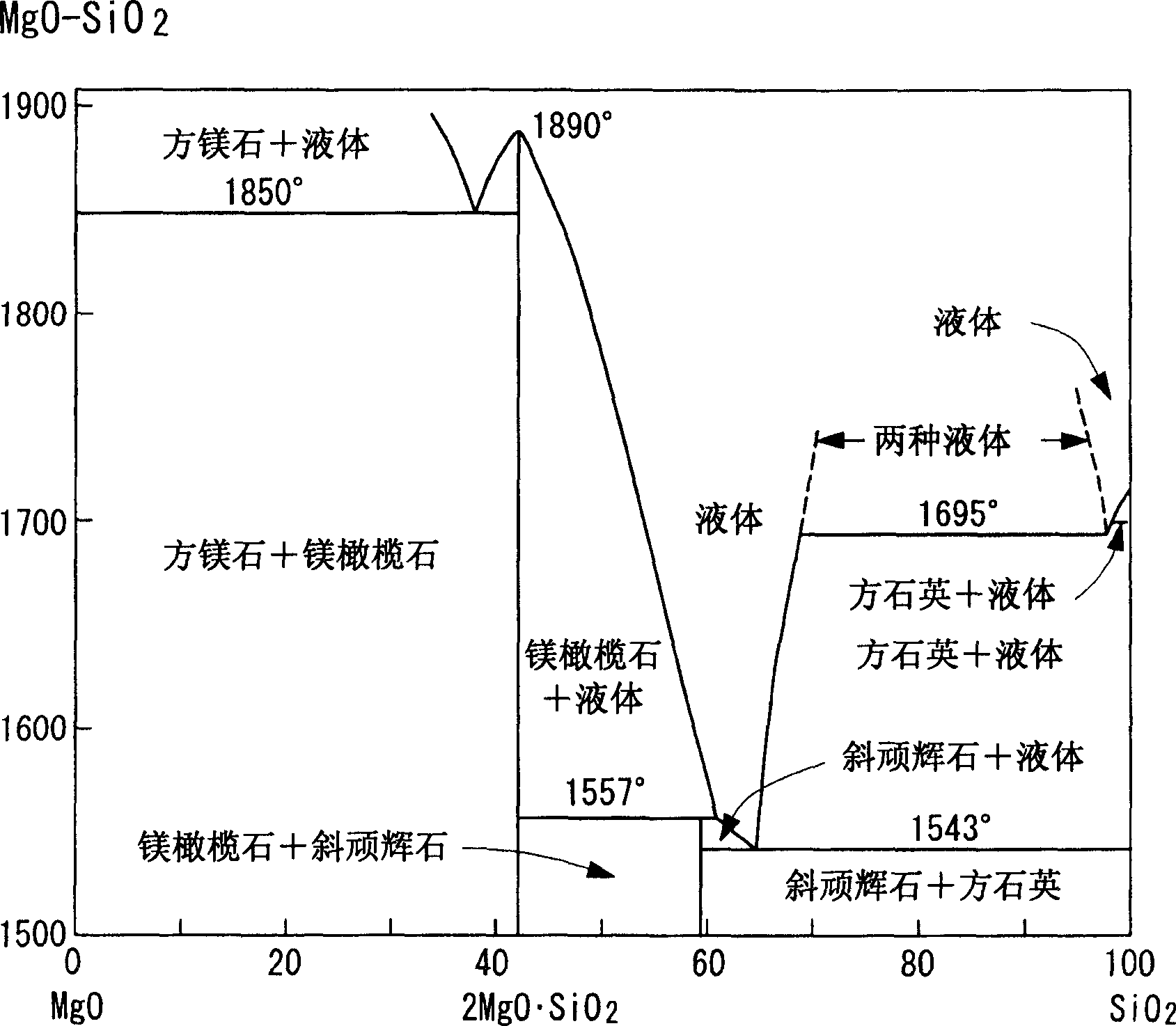

Method of producing forsterite refractory

A method for producing forsterite refractory is characterized by comprising: a. mixing the raw magnesite flotation tailing or magnesite shaft kiln dust removing powder, light burning magnesite powder and cabosil, wherein the weight ratio Mgo / SiO[2] is 1.342-1.476; b. according to the weight ratio, uniformly mixing 80-100 portions of mixed materials obtained in step a and 0-20 portions of burnable lost property, additionally with 30-70 portions of water, producing briquette; drying the briquette obtained in step b at 15-50 DEG C for 3-24 hours, drying at 110 DEG C for 12 hours, burning at the oxidative atmosphere; keeping warm at 500-650 DEG C for 2-3 hours, 1500 DEG C for 3-5 hours. The invention uses the industrial waste to produce the forsterite refractory, greatly reduces the production cost of the forsterite refractory, decreases the dust pollution and improves the ecologic environment.

Owner:海城华宇耐火材料有限公司

High melting metal liquid die forging paint, producing and using method thereof

InactiveCN101293270AHigh refractorinessImprove insulation performanceFoundry mouldsFoundry coresSodium BentoniteSoluble glass

The invention discloses a high-melting metal liquid die forging coating, a preparation method and a using method thereof, which can effectively solve the problem of short service life of a high-melting metal liquid die forging die. A bottom layer and a surface layer are consists of 100 portions of 200-500 mesh matrix, 100-300 portions of carrier, 2-25 portions of a cementing agent, 0.1-25 portions of suspending agent and 0.01-0.05 portion of foam suppressor. The matrix of the surface layer coating is forsterite or chromite, while the matrix of the bottom layer coating is processed diatomite. The suspending agent is the mixture of sodium bentonite and CMC sodium salt. The cementing agent of the surface layer coating is the mixture of aluminum phosphate and sodium hexametaphosphate, while the cementing agent of the bottom layer coating is the mixture of soluble glass and sodium hexametaphosphate. The components are evenly blended according to the proportion and stand for 3-8 hours to be ready for use. When in use, the bottom layer coating is coated on the surface of a metal die which is preheated to the temperature of 150-300 DEG C; after drying, the surface layer coating is coated on the bottom layer coating, and then liquid die forging is carried out after drying.

Owner:BEIJING JIAOTONG UNIV

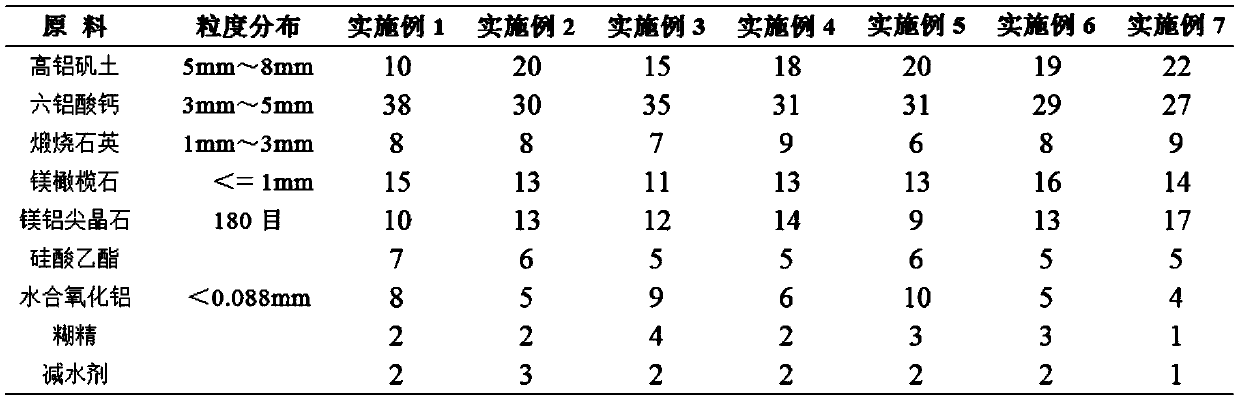

Castable and method for manufacturing coke tank lining

The invention discloses a castable for manufacturing a coke tank lining. The castable comprises, by weight, 10-22% of high-alumina bauxite having a particle size of 5-8 mm, 20-38% of calcium hexaaluminate having a particle size of 3-5 mm, 6-10% of calcined quartz having a particle size of 1-3 mm, 11-21% of forsterite having a particle size of 1 mm or less, 9-19% of magnesium aluminate spinel having a particle size of 180 meshes, 2-7% of ethyl silicate, 2-10% of hydrated alumina having a particle size of below 0.088 mm, 1-4% of dextrin and 1-3% of a water reducer. The present invention also discloses a method for manufacturing the coke tank lining. The castable of the invention can meet the internal use conditions of the coke tank, and the coke tank lining made from the castable has the advantages of good resistance to the high temperature, wear and thermal shock, low thermal conduction coefficient, long service life, low price and energy saving; and the method has the advantages of simplicity, and easiness in industrialize production.

Owner:SHANDONG IRON & STEEL CO LTD

High-performance forsterite refractory raw material and preparation method thereof

The invention relates to a high-performance forsterite refractory raw material and a preparation method thereof. The method comprises the following steps: mixing 65-85 weight percent of fine magnesite powder with 15-35 weight percent of siliceous raw material fine powder, adding 1-10 weight percent of binding agent, and ball-milling for 1-3 hours to obtain a ball-milling material; then adding water being 3-10 weight percent of the ball-milling material into the ball-milling material, stirring, pressing to form a blank body, drying, and calcining at 1200-1400 DEG C to obtain a calcining material; grinding the calcining material to the particle size smaller than 0.045mm, and adding an additive being 0.2-2 weight percent of the calcining material and the binding agent being 1-10 weight percent of the calcining material, and ball-milling to obtain a secondary ball-milling material; and adding 3-10 weight percent of water into the secondary ball-milling material, stirring, pressing to form a blank body, drying, and secondary calcining at 1450-1650 DEG C to obtain the high-performance forsterite refractory raw material. The raw material has the advantages of wide sources, low production cost and easiness in sintering, and the prepared high-performance forsterite refractory raw material has large volume density, low porosity and stable high temperature properties.

Owner:WUHAN UNIV OF SCI & TECH

Fluorescence standard, and the use thereof

InactiveUS20110076687A1Improve homogeneityBioreactor/fermenter combinationsPhotometry using reference valueFluorescenceApatite

The invention concerns fluorescence standards, and in particular fluorescence standards for calibrating optical detectors. According to the invention, a fluorescent mineral or mixtures of minerals are employed for use as a fluorescence standard. The fluorescent mineral can be a naturally occurring mineral or a synthetically produced mineral. Preferred fluorescent minerals for use as fluorescence standards are corundum, fluorite, turquoise, amber, zircon, zoisite, iolite or cordierite, spinel, topaz, calcium fluorite, sphalerite or zincblende, calcite or calcspar, apatite, scheelite or calcium tungstate, willemite, feldspars, sodalite, a uranium mineral, a mineral containing Al3+, and in particular ruby and sapphire.

Owner:QIAGEN LAKE CONSTANCE GMBH

MgO-SiC-C material synthesized by forsterite-C and method for preparing same

The invention relates to an MgO-SiC-C material synthesized by forsterite and C and a method for making the same. The method adopts the following technical proposal that: according to molar ratio, 1 to 4 mol of forsterite mineral powder and 3 to 6 mol of C powder are mixed, and a bonding agent occupying 4 to 10 percent of the mass percentage content of the mixed materials is added; the mixture is stirred or ground for 10 to 30 minutes, and is dried after press forming; then, sintering is carried out under a reducing atmosphere at a temperature of between 1,450 and 1,700 DEG C with the heat preservation time of between 2 and 8 hours, thereby obtaining an MgO-SiC-C composite material. The industrial carbon powder raw material adopted by the method has wide sources, and the forsterite mine has abundant resources, thereby not only effectively solving the problem of magnesia resource shortage, but also having low production cost; moreover, the made MgO-SiC-C composite material can maintain excellent properties and reduce corrosion wear, thereby prolonging service life.

Owner:WUHAN UNIV OF SCI & TECH

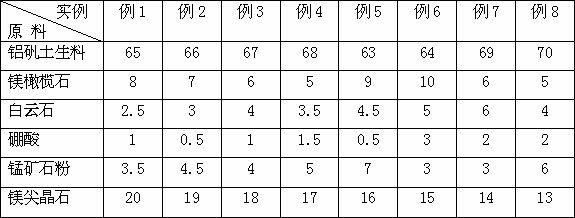

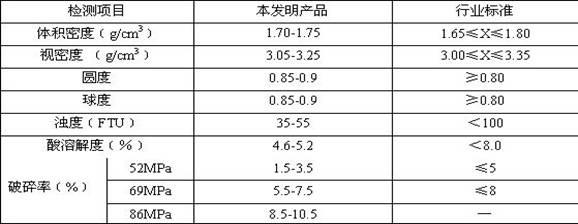

Spinel high-strength petroleum fracturing proppant and production method thereof

The invention relates to spinel high-strength petroleum fracturing proppant and a production method thereof. The proppant comprises the following raw materials: 63-70% of raw bauxite, 5-10% of forsterite, 2.5-6% of dolomite, 0.5-3% of boric acid, 3-7% of manganese ore powder and 13-20% of magnesium spinel. The production method comprises the following steps of: respectively grinding each raw material into fine powder during the preparation and screening by a 320-mesh sieve; mixing uniformly to obtain a mixture, then feeding the mixture to a rotary granulator while adding atomized moisture, preparing the mixed material into round grains and screening by a sieve with 18-30 meshes to obtain a half-finished product; drying the half-finished product till the moisture content is less than 6%; and transferring the dried half-finished product to a rotary kiln to bake, controlling temperature of a kiln head to be 1285 to 1400 DEG C and temperature of a kiln end to be 280 to 325 DEG C and burning for 6-8h and the discharging out of the kiln. According to the invention, the raw materials form a large amount of magnesium aluminate spinel phases at high temperature so as to play a supporting role of a skeleton; the obtained spinel high-strength petroleum fracturing proppant has the advantages of good compactness and strong anti-crushing capacity; the breakage rates of the spinel high-strength petroleum fracturing proppant at 52 MPa, 69 MPa and 86 MPa respectively are respectively less than 3.5%, less than 7.5% and less than 10.5%, the strength of the spinel high-strength petroleum fracturing proppant is higher than that of the products of the same kind and the performance of the spinel high-strength petroleum fracturing proppant is excellent; and meanwhile, the production techniqueis optimized, low in cost and easy to promote and implement.

Owner:郑州德赛尔陶粒有限公司

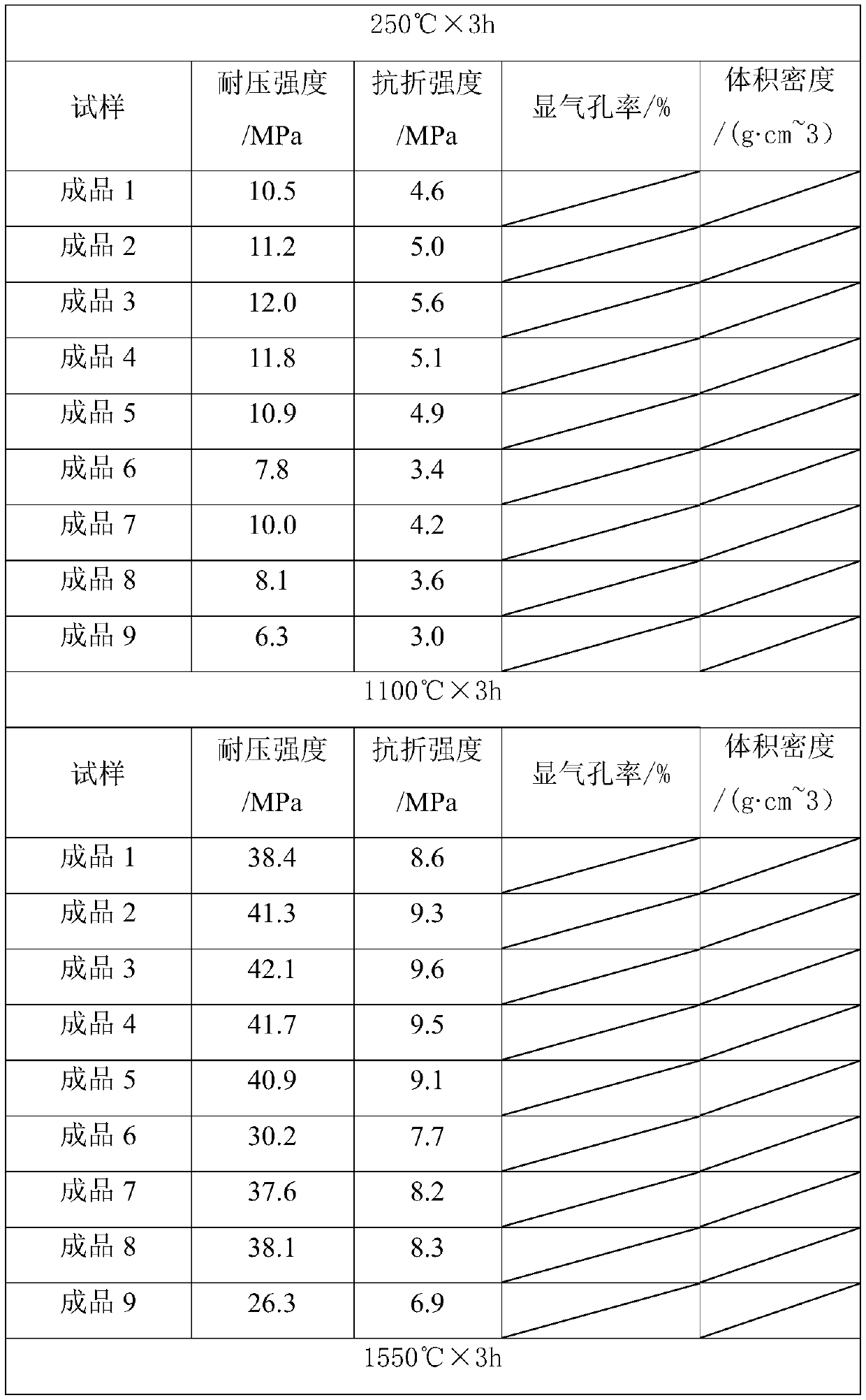

High-strength white olivine light material and method of producing the same

InactiveCN101492298AWide variety of sourcesReduce manufacturing costMagnesium silicatesHigh intensityOlivine

The invention relates to a high-strength forsterite lightweight material and a preparation method thereof. The invention adopts a technical proposal that carbonate powder accounting for 20 to 70 percent of the total weight and talc raw-ore powder accounting for 30 to 80 percent of the total weight are mixed and then added with a bonding agent accounting for 3 to 10 percent of the weight of a mixture of the carbonate powder and the talc raw-ore powder, and the mixture of the three materials is stirred for 5 to 25 minutes, pressed, molded, dried for 12 to 36 hours at a temperature of between 60 and 110 DEG C or naturally dried indoors for 24 to 48 hours, sintered in air for 2 to 6 hours at a temperature of between 800 and 1,400 DEG C, naturally cooled, soaked in water for 24 to 48 hours and finally dried for 12 to 36 hours at a temperature of between 60 and 110 DEG C or naturally dried indoors for 24 to 48 hours, so that the high-strength forsterite lightweight material can be obtained. The preparation method has the characteristics of extensive raw material sources, low production cost and easiness for industrial production. The material prepared by the method has the advantages of excellent performances, compressive strength of between 10 and 40 MPa, volume density of between 0.6 and 1.5 g / cm, long life span, service temperature at 1,200 DEG C and benefit to energy conservation and consumption reduction.

Owner:WUHAN UNIV OF SCI & TECH

Preparation method of composite sagger

The invention relates to a preparation method of a composite sagger. The method adopts forsterite and mullite as the main raw materials, takes potassium feldspar, calcined bauxite, sepiolite, montmorillonite, aluminum phosphate, zirconium silicate, aluminum nitride and high aluminum fiber as the auxiliary materials, at the same time adopts the process of water quenching, oil cooling and post-treatment during preparation to improve the physical and chemical properties of the prepared product. The prepared sagger has the advantages of good thermal stability, strong compressive ability, corrosion resistance, and difficult cracking.

Owner:姚焕根

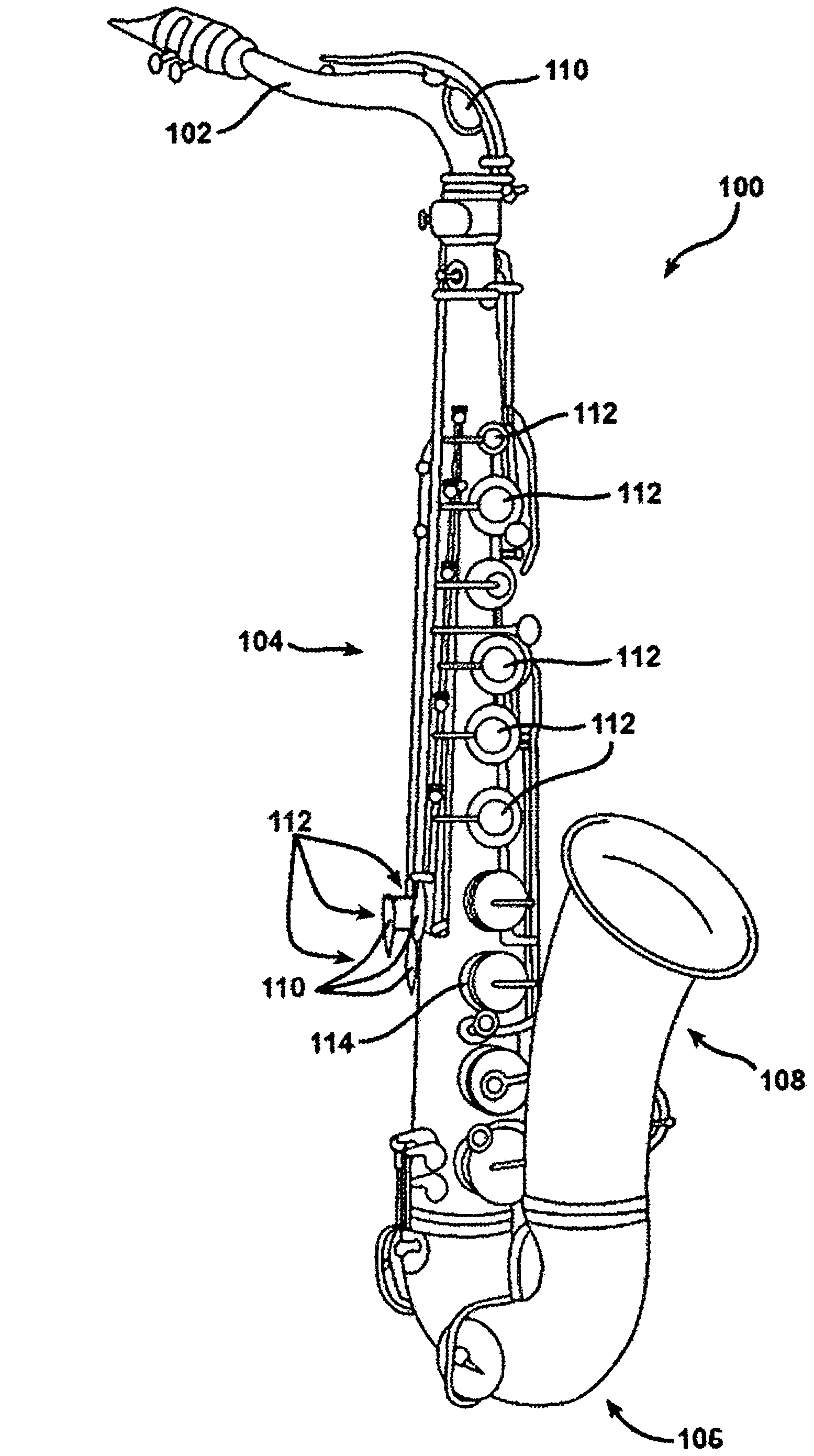

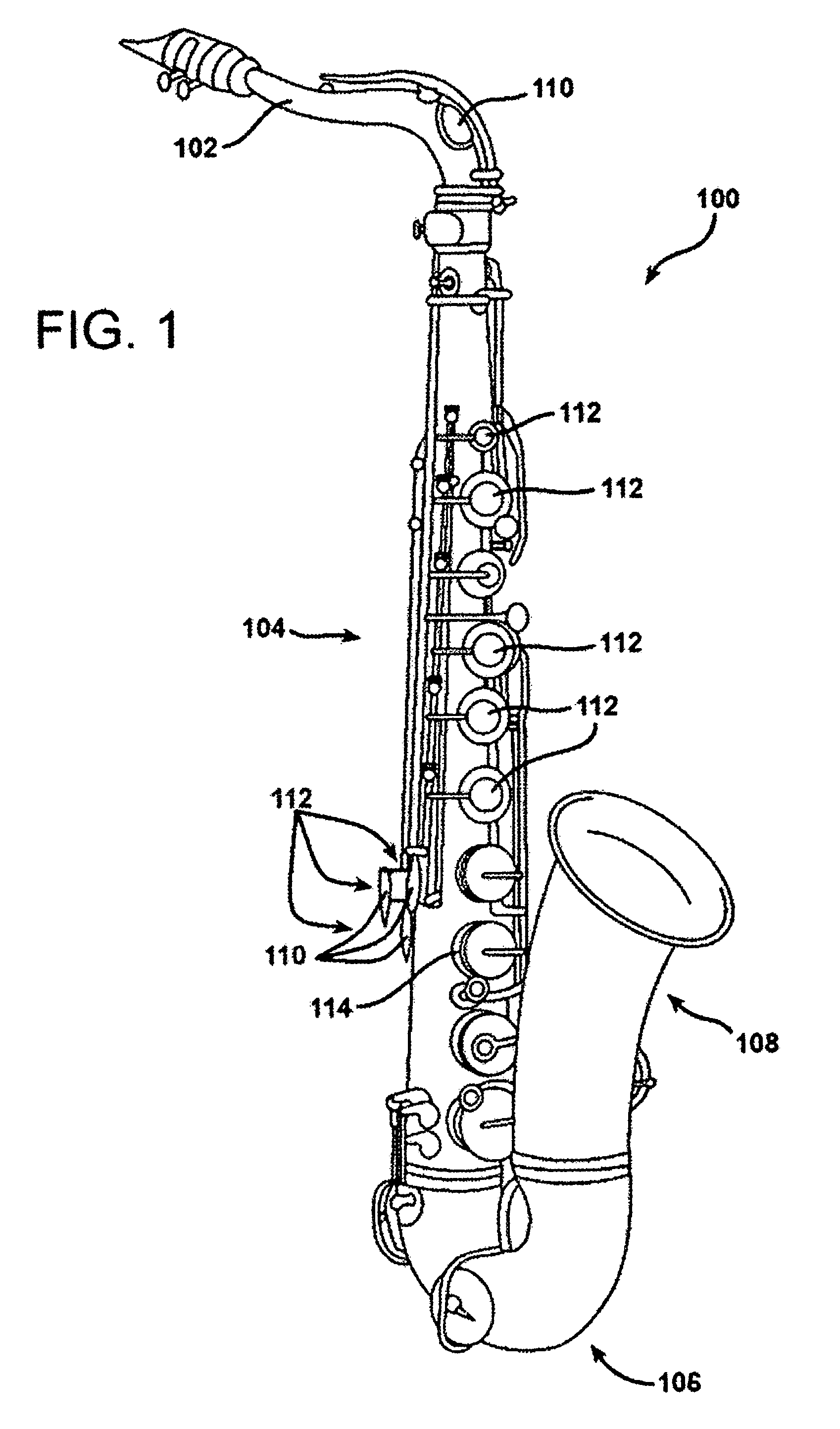

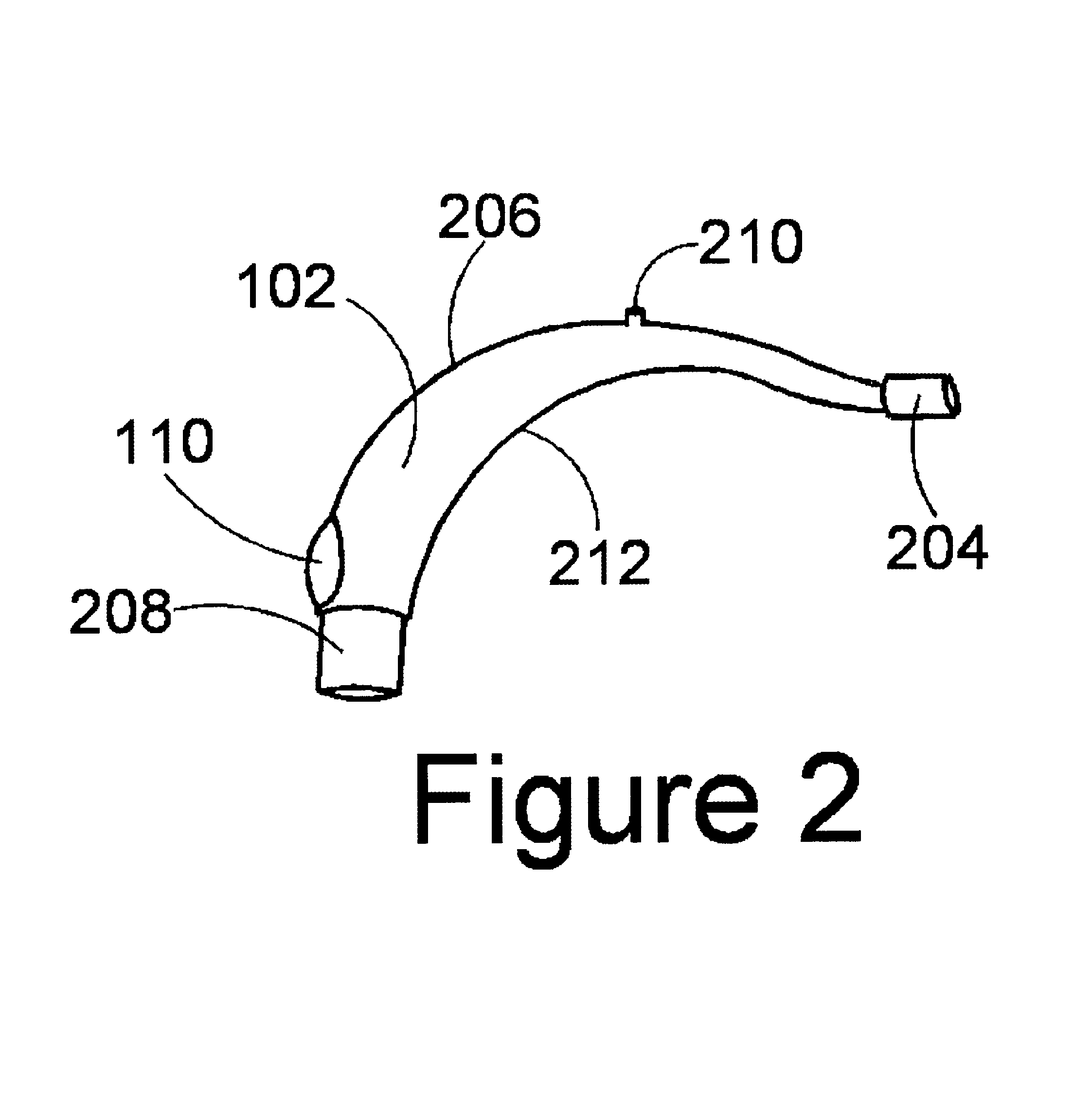

Woodwind instrument

A method of improving the tonal characteristics of a woodwind instrument. The method includes identifying a position on the woodwind instrument, wherein placement of a tonal material thereto causes a lowering of overtone amplitude during play, by observing overtone characteristics during play; positioning the tonal material to the woodwind instrument; measuring the overtone amplitude; playing the woodwind instrument; and repositioning the tonal material to optimal overtone amplitude position; and attaching the tonal material to the woodwind instrument, at the optimal overtone amplitude position. The tonal material comprises one of the group consisting of: garnet, jasper, agate, aventurine, carnelian, citrine, fluorite, hematite, malachite, obsidian, onyx, tiger's eye, turquoise, unakite, moonstone, peridot, jade, alexandrite, amethyst, chalcedony, quartz, aquamarine, lolite, rhodolite, opal, topaz, tourmaline, tanzanite, diamond, emerald, sapphire, ceylon sapphire, ruby, woodwind, other metals, and combinations thereof.

Owner:CANNONBALL MUSICAL INSTRUMENTS

Method of solidifying and detoxifying soil (including soil contaminated with dioxins and/or heavy metals), incinerated ash (including incinerated ash contaminated with dioxins, heavy metals and the like) and coal ash (including coal ash contaminated with heavy metals and the like) and method of detoxifying polluted water containing dioxins and polluted water containing PCB

ActiveUS20090272163A1Easy to useQuality improvementCalcareous fertilisersMagnesium fertilisersPolychlorinated biphenylEnvironmental standard

A method of solidifying and detoxifying a soil, incinerated ash and coal ash to yield a solidified substance detoxified to a level complying with the environmental standards and a method of detoxifying polluted water containing dioxins and polluted water containing PCB are provided. First solidifying and detoxifying agent contains light burnt magnesite as component (1) and chrysolite powder as component (2), in which a ratio by weight of the component (1) and the component (2) is 1:5 to 5:1, preferably 1:3 to 3:1, more preferably 1:2 to 2:1 and is the solidifying and detoxifying agent applied to one kind selected from soil, incinerated ash and coal ash as well as polluted water containing dioxins and polluted water containing PCB. Other solidifying and detoxifying agent further contains as an additional component a fused phosphate fertilizer and titanium dioxide powder as well as anhydrous gypsum powder, light burnt dolomite and / or calcined lime powder.

Owner:OKADA KIKUO +1

MgO-SiC-C fire resistant pouring material based on forsterite and method for preparing same

The invention relates to a MgO-SiC-C fireproof casting material based on forsterite-C and a preparation method thereof. In the technical proposal, forsterite and C powder are mixed according to the mol ratio of (1 to 4) to (3 to 6), and a binder of 1 to 10 percent of the mixture by weight is added. After the mixture is beaten, moulded and dried, the mixture is synthesized into MgO-SiC-C material for two to eight hours at the temperature of 1450 to 1700 DEG C under the reducing atmosphere. 10-25 weight percent of 10-5mm granule, 15-25 percent weight of 5-3mm granule, 15-25 weight percent of 3-1mm granule, 10-20 weight percent of 1-0mm granule, 25-35 weight percent of 0.1-0mm fine powder are mixed with 2-8 weight percent of the binder, and are beaten uniformly, thus getting the MgO-SiC-C fireproof casting material. The manufacturing cost of the invention is low; the process is simple; and the fireproof casting material prepared has good performance, and is widely applied.

Owner:WUHAN UNIV OF SCI & TECH

Pyroxene peridotite type ilmenite depressing agent and preparation method thereof

InactiveCN103721853AResolve recovery rateSolve the technical problem of low concentrate gradeFlotationPhysical chemistryIlmenite

The invention belongs to the ilmenite flotation technology, and particularly relates to a pyroxene peridotite type ilmenite depressing agent and a preparation method of the pyroxene peridotite type ilmenite depressing agent. The preparation method of the pyroxene peridotite type ilmenite depressing agent comprises the step of carrying out oscillation, stir and curing on a mixed solution formed by sodium silicate, ferric nitrate and sulfuric acid to obtain the pyroxene peridotite type ilmenite depressing agent, wherein oscillation, stir and curing are carried out for 30-40min. The obtained pyroxene peridotite type ilmenite depressing agent comprises, by weight, 5-15 parts of the sodium silicate, 5-15 parts of the ferric nitrate and 1-10 parts of the sulfuric acid. The pyroxene peridotite type ilmenite depressing agent obtained through the preparation method has a good selective depressing effect on olivine and pyroxene, and has extremely important significance in obtaining of good technical indexes of titanium flotation of pyroxene peridotite type ilmenite.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI +1

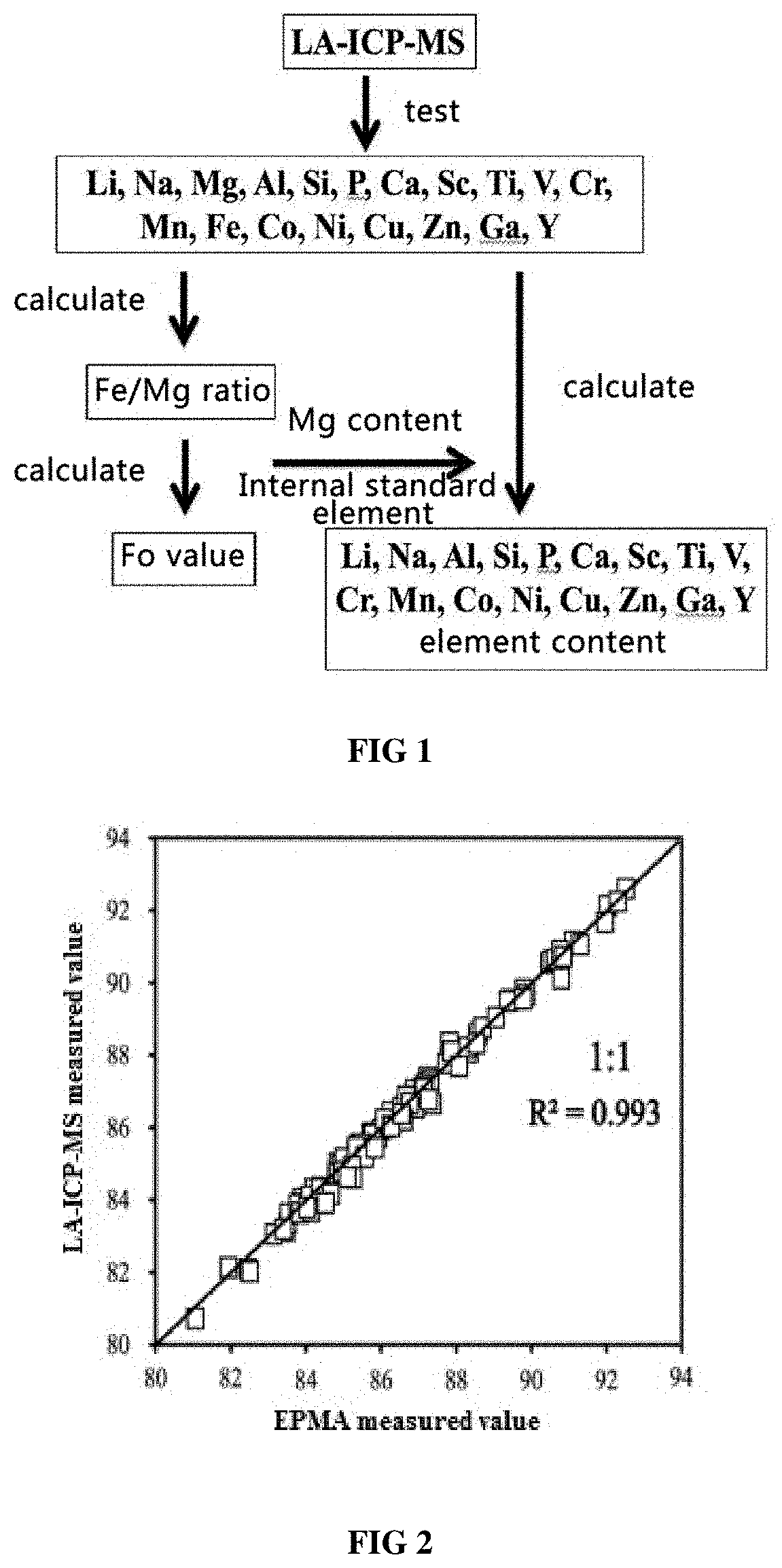

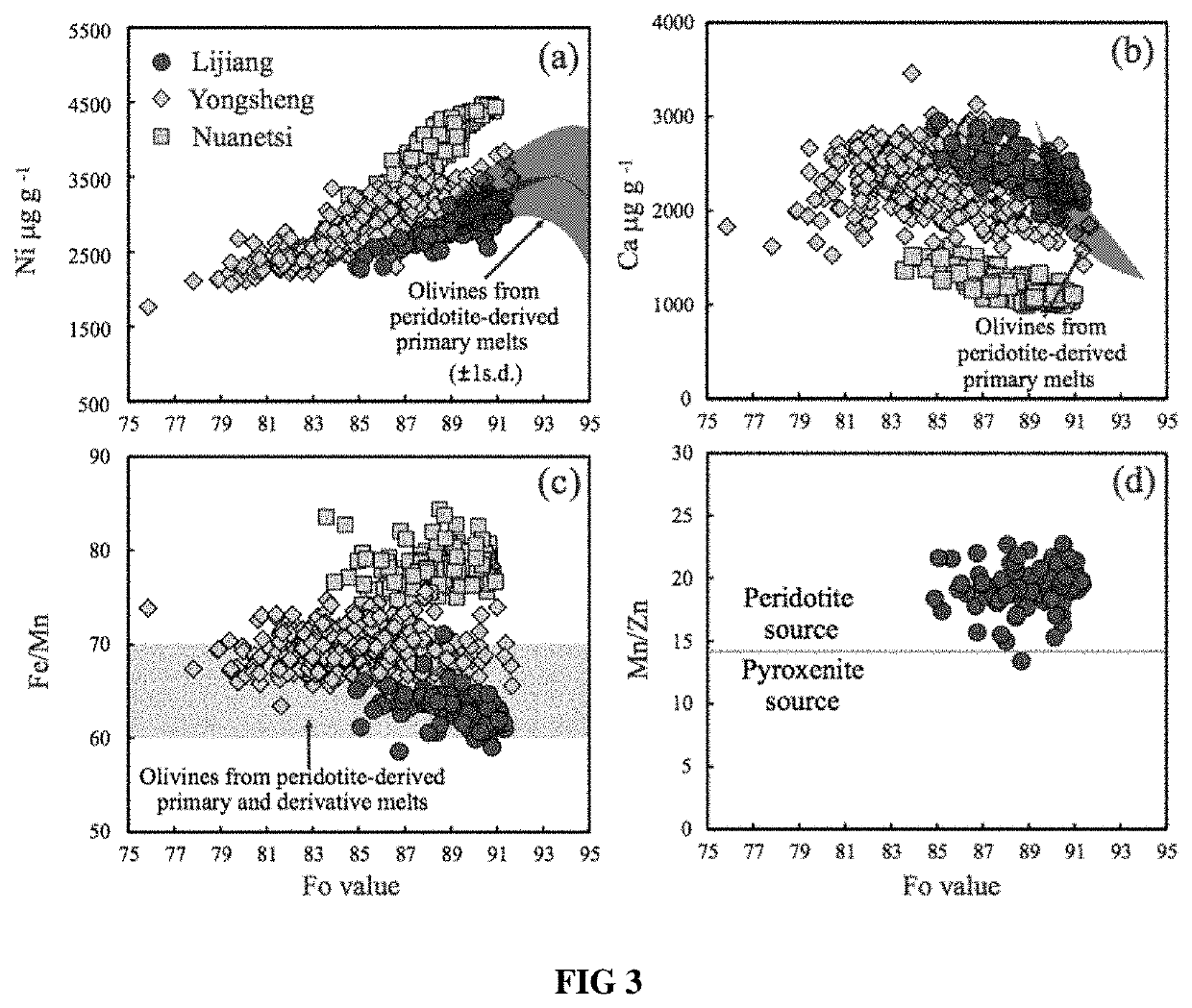

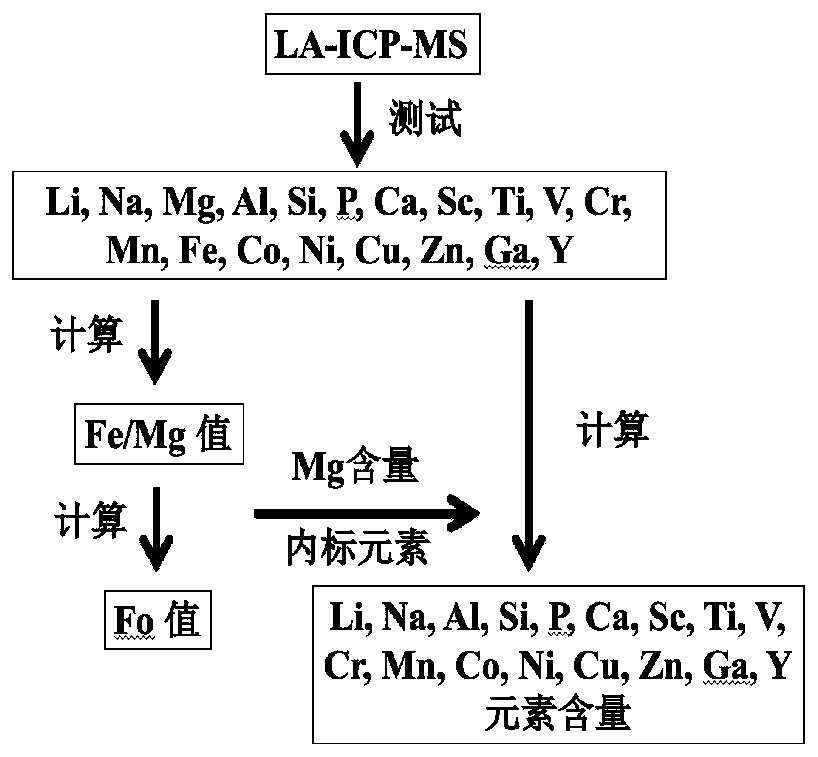

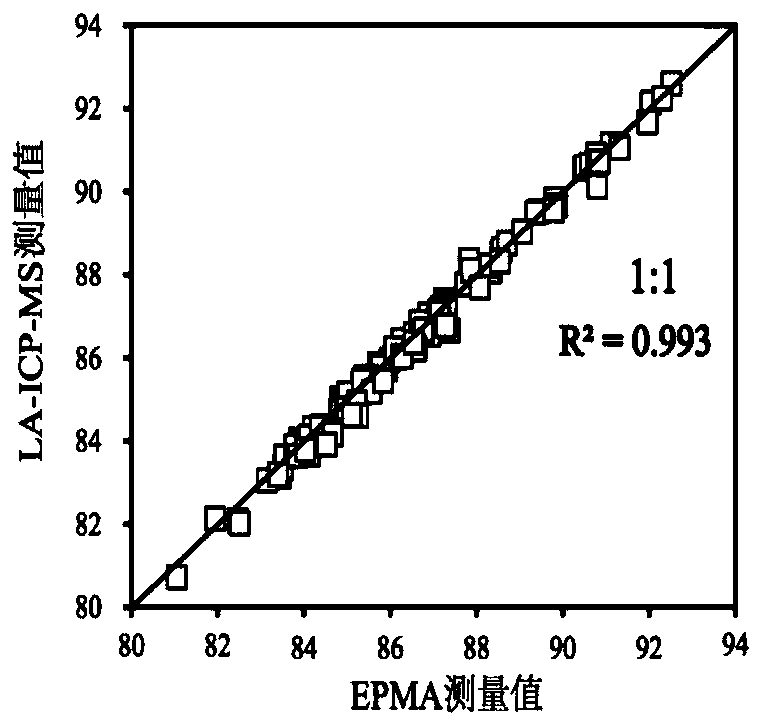

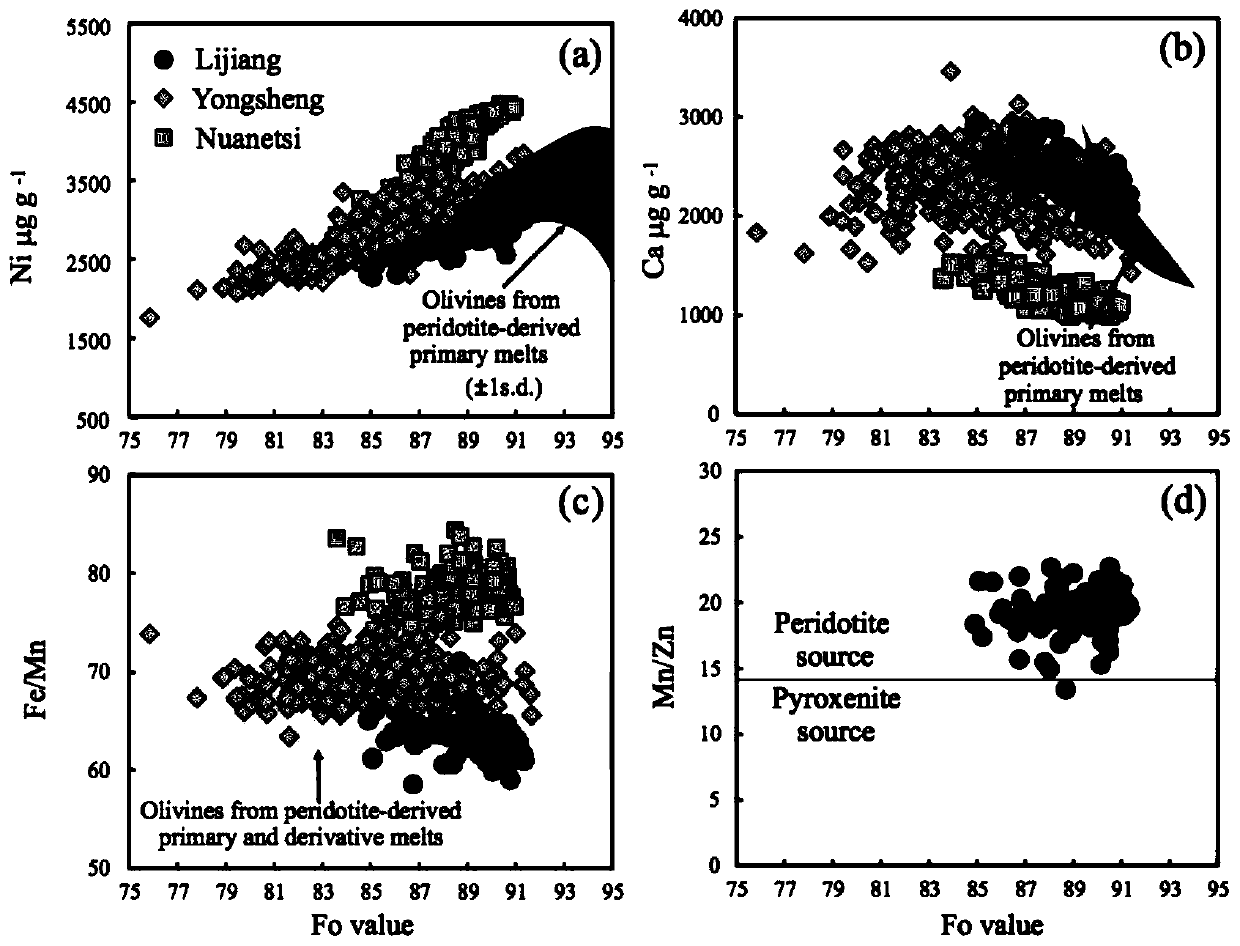

Method for simultaneously measuring the value of forsterite and trace elements in olivine

ActiveUS20210358731A1Long test periodIncreased cost of testingSamples introduction/extractionMaterial analysis by electric/magnetic meansSingle electronOptical axis

The present disclosure provides a method for simultaneously measuring the value of forsterite and trace elements in olivine, comprising the following steps: Step S1: selecting samples, wherein the samples are olivine samples; Step S2: placing the samples in a sample chamber of LA-ICP-MS, and adjusting the position of the samples in the optical axis direction so that the laser beam is well focused; Step S3: optimizing the instrument to make the signal-to-noise ratio of 57Fe be the best; Step S4: adopting LA-ICP-MS peak hopping mode and receiving all the mass peaks of the samples by single electron multiplier (SEM). The present disclosure overcomes the disadvantages of long test cycle and high test cost in the prior art.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

Ceramic having rare earth elements and preparation method thereof

The invention discloses a ceramic having rare earth elements and a preparation method thereof. The ceramic having the rare earth elements comprises the following components in parts by weight: 12-14 parts of flint clay, 15-18 parts of forsterite, 1-3 parts of calcium oxide, 4-6 parts of sodium oxide, 1-3 parts of titanium dioxide, 6-8 parts of purple grit mud, 35-38 parts of red clay, 30-40 parts of deionized water, 12-14 parts of kaolin, 6-8 parts of triethanolamine, 5-7 parts of rare earth elements, and 3-5 parts of auxiliaries. The rare earth elements comprise the following components in percentage by weight: 8-10% of lanthanum, 1-3% of cerium, 12-14% of praseodymium, 17-19% of neodymium, 13-17% of promethium, 2-6% of samarium, 8-15% of europium, 13-15% of dysprosium, and the balance of erbium and unavoidable impurities.

Owner:SUZHOU TONGMING MACHINERY

Flame-retardant product and use thereof

ActiveUS9403728B2Improve moisture resistanceImprove penetration resistanceMaterial nanotechnologyFurnace liningsOlivineForsterite

A flame-retardant batch, and the use thereof, primarily contains—at least 30% by weight of a coarse-grain olivine raw material with a forsterite content of, e.g. at least 70% by weight and having grain sizes of, e.g. 100% by weight over 0.1 mm, —at least 35% by weight in magnesia in meal form with grain sizes of, e.g. 100% by weight.

Owner:REFRATECHNIK HLDG GMBH

Environment-friendly magnesian dry material and preparation process thereof

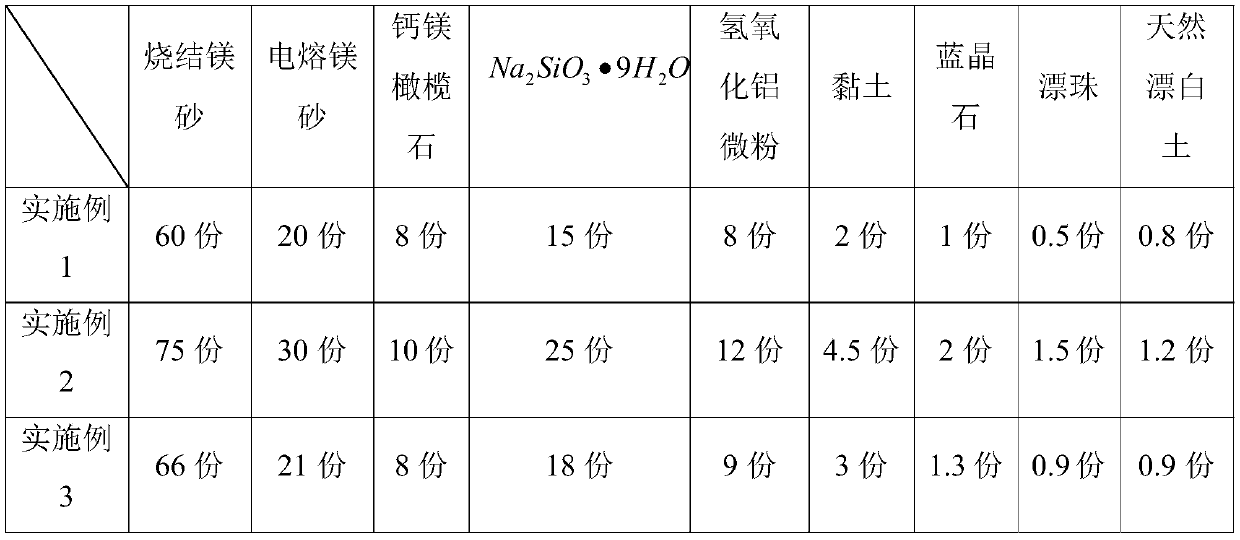

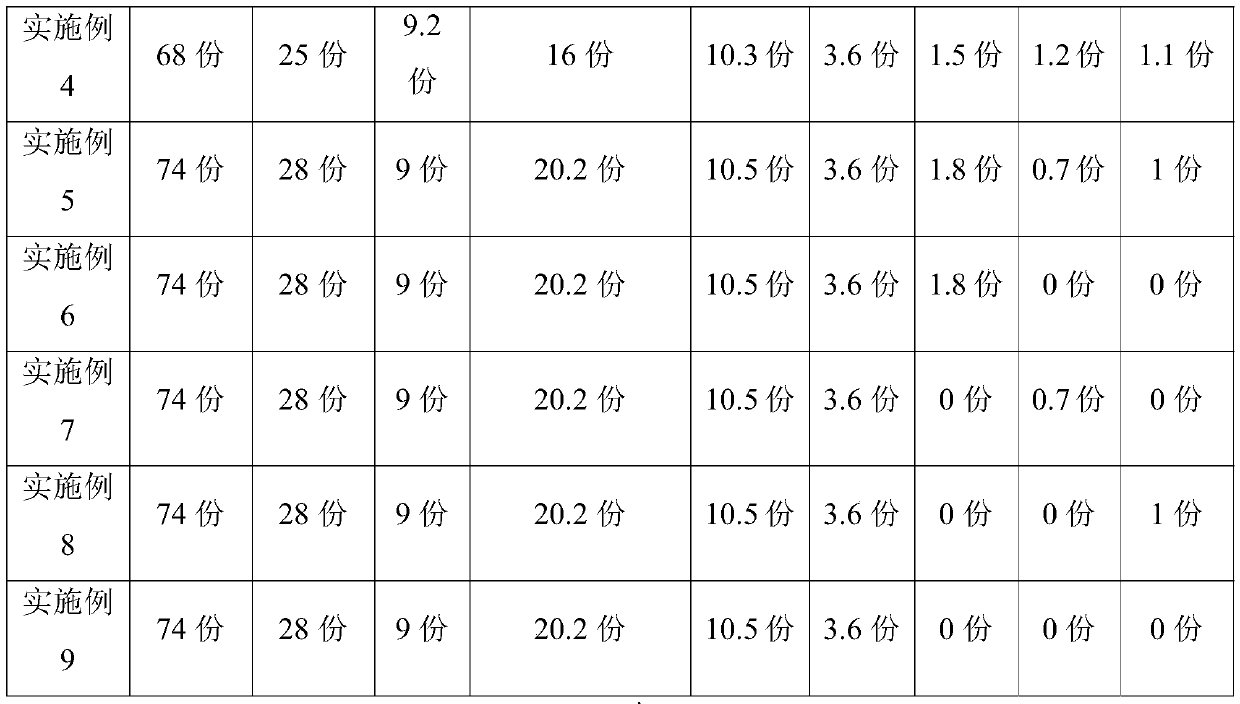

An environment-friendly magnesian dry material comprises sintered magnesia, fused magnesia, calcium forsterite, a binding agent, aluminum hydroxide micro powder, a high-temperature sintering agent, anexpanding agent, floating beads and bentonite in a mass ratio of (60-75): (20-30): (8-10): (15-25): (8-12): (2-4.5): (1-2): (0.5-1.5): (0.8-1.2). According to the invention, the proportion of each component of the dry material is optimized; by adopting the environment-friendly binding agent, the problem that the binding agent is decomposed into toxic and harmful substances under a high-temperature condition can be effectively solved, the dry material is more energy-saving and environment-friendly, the hardness requirement of the dry material in the using process can be ensured on the premisethat the dry material has no pungent smell in the using process and is more beneficial to the production environment, and the scouring resistance of the dry material is ensured.

Owner:浙江欣辉耐火材料股份有限公司

Method for simultaneously determining forsterite value and trace elements in olivine

ActiveCN111398403AAccurate Fo value dataAccurate trace element dataParticle separator tubesMaterial analysis by electric/magnetic meansElectron multiplicationOptical axis

The invention discloses a method for simultaneous determining forsterite value and trace elements in olivine, and the method comprises the following steps: S1, selecting a sample which is an olivine sample; S2, placing the sample into an LA-ICP-MS sample chamber, and adjusting the position of the sample in the optical axis direction to enable a laser beam to be well focused; S3, optimizing the instrument so that the noise ratio of the 57Fe signal is optimal; S4, receiving all mass peaks of the sample by using an electron multiplier (SEM) of a single receiving system in an LA-ICP-MS peak hopping mode. The problems in the prior art that the testing period is long and the testing cost is high are solved.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

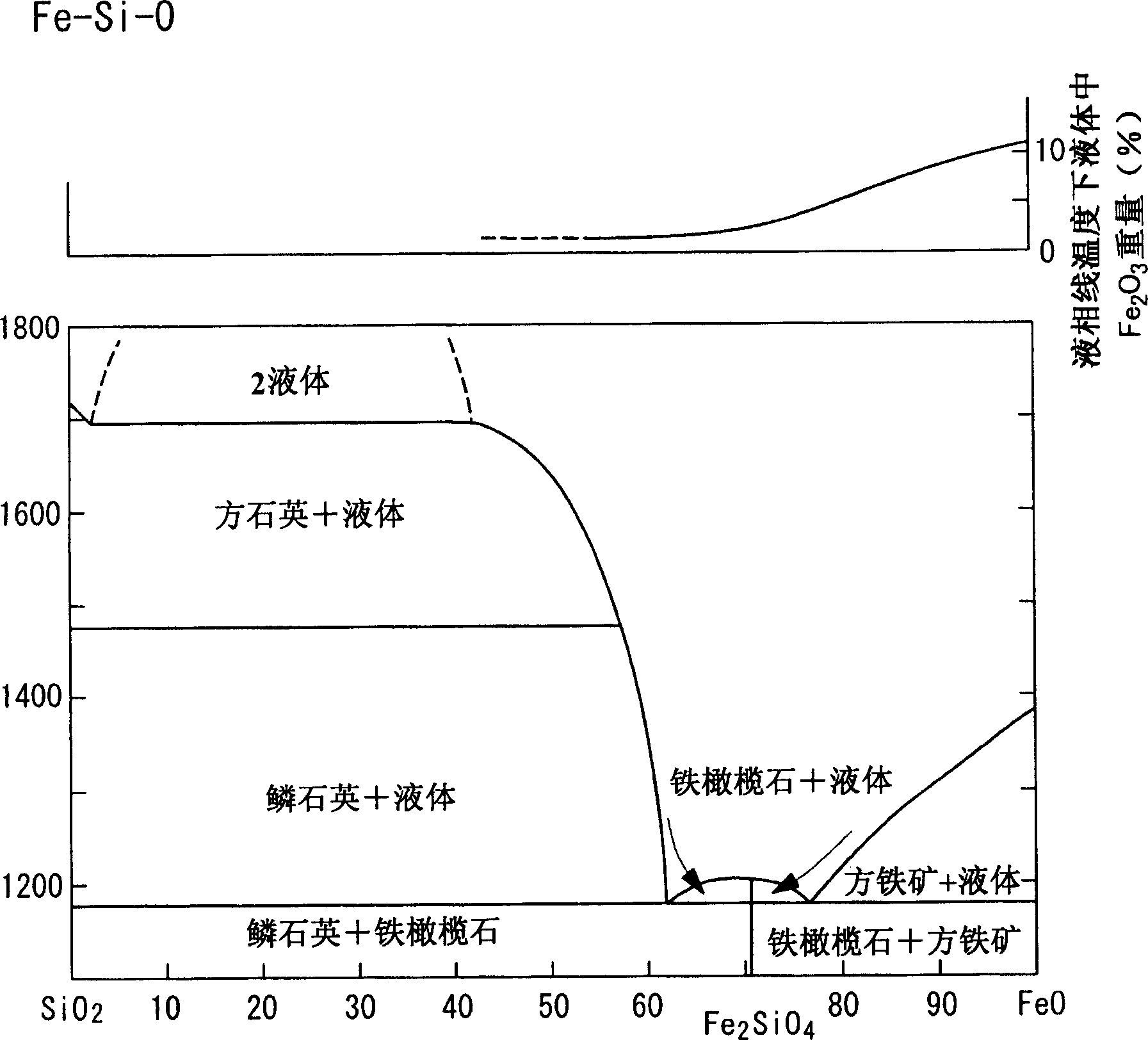

Fused forsterite and preparation method thereof

The invention relates to fused forsterite and a preparation method thereof. The technical scheme comprises the following steps: based on mass parts, mixing 100 parts of forsterite with 2-3 parts of reducing agent; and after bailing, placing spheres in an arc furnace, carrying out melting reduction at the temperature of 1900-2200 DEG C, insulating for 2-5 hours, naturally cooling and then separating so as to obtain the fused forsterite and antaciron. In the technical scheme, the reducing agent is coke or blind coal and has a particle size less than 0.5mm; the forsterite is waste forsterite fine powder or commercial forsterite fine powder and comprises the following main chemical components by weight percent: 38-47wt% of MgO, 39-44wt% of SiO2 and 7-11wt% of Fe2O3; and the particle size of the forsterite is less than 0.5mm. According to the invention, the efficient comprehensive utilization of the forsterite fine powder is realized, and the fused forsterite is cheap in cost, simple in process, high in additional value and wide in application, and has large commercial value.

Owner:WUHAN UNIV OF SCI & TECH +1

Dry type magnesium-calcium gravity flow fire-resistant material and preparation thereof

The invention relates to a dry magnesia-calcia free-flowing refractory material and a preparation method thereof. The adopted technical proposal is as follows: the refractory material is prepared by stirring and mixing 20-50wt% of electrocast magnesia-calcia clinker or sintered magnesia-calcia clinker, 10-40wt% of electrocast magnesia or sintered magnesia, 0.5-20wt% of forsterite, 10-30wt% of sodium silicate hydrate particles, 1-8wt% of fine silicon dioxide powder, 0.5-5% of fine limestone powder and 1-5% of polyphosphate sodium particles. The dry magnesia-calcia free-flowing refractory material prepared by the method has good fluidity and fire resistance, convenient site operation and use and no environmental pollution and can be used for quickly patching a liner material of a smelting furnace.

Owner:WUHAN UNIV OF SCI & TECH

Process for leaching rare earth elements

Described herein is a process for stepwise leaching of all rare earth elements capable of forming peroxide and superoxide compounds, in particular cerium, lanthanum, neodymium, europium, from minerals containing these elements, namely from bastnaesites, orthites, chevkinites, and britholites.

Owner:KUNZE BERND +1

Preparation method of novel casting coating

The invention discloses a preparation method of a novel casting coating, and relates to the field of casting coatings. The coating comprises the following raw materials of 20-30 parts of graphite, 25-35 parts of forsterite, 5-10 parts of bentonite, 20-40 parts of a filler, 3-5 parts of an antifoaming agent, 2-5 parts of quartz sand and 20-30 parts of water. According to the method, due to the factthat the use amount of the forsterite is increased, so that the proportion of the graphite in the coating is reduced, the adhesive force between the coating and the surface of a mold is reduced, cleaning is easy, and the possibility that the graphite generates pores is greatly reduced; and meanwhile, due to the fact that the forsterite is rich in source and low in price, so that the reduction ofthe production cost is facilitated.

Owner:埃肯铸造(中国)有限公司

Stopper rod head and preparation method thereof

The invention discloses a stopper rod head and a preparation method thereof, wherein the stopper rod head comprises spinel particles with different particle sizes, graphite 199, graphite 899, an additive and a binding agent, and specifically comprises, by weight, 30-40% of white corundum 36#, 10-20% of white corundum 80#, 30-40% of white corundum 325#, 10-20% of graphite 199, 5-10% of graphite 899, 5-10% of an additive, and 10-15% of a binder. According to the invention, spinel is adopted to replace previous corundum to serve as the main material of the stopper rod head, and reacts with the additive to generate forsterite or calcium forsterite to seal part of the gas holes in the material, so that the additive is prevented from permeating into the material, the erosion resistance is improved, and the service life of the stopper rod head is prolonged through the special ratio.

Owner:泰州市旺鑫耐火材料有限公司

Printing and dyeing wastewater purification agent and preparation method thereof

InactiveCN107720840AReduce CODCrReduce SS contentSpecific water treatment objectivesWater contaminantsEmission standardDeodorant

The invention discloses a printing and dyeing wastewater purification agent and a preparation method thereof. The printing and dyeing wastewater purification agent comprises, by weight, 11-25 parts ofpolyacrylamide, 13-18 parts of tourmaline powder, 6-12 parts of konjac glucomannan, 10-25 parts of durian extract, 5-10 parts of mineral powder, 3-6 parts of a deodorant and 0.5-1 part of an oxidant.The mineral powder comprises, by weight, 5-8 parts of peridot powder, 2-6 parts of humic acid, 2-5 parts of granite powder, 1-3 parts of alkaline feldspar powder, 2-10 parts of basalt powder, 1-3 parts of quartzite powder and 2-5 parts of spodumene powder. The printing and dyeing wastewater purification agent can effectively reduce CODCr, ammonia nitrogen and SS content of waste water dischargedby a printing and dyeing plant. The treated water can satisfy the national emission standards. The preparation method is simple, is suitable for industrial production and has a high economic value.

Owner:陈木镇

Forsterite heat light material and preparation method thereof

The invention relates to a lightweight forsterite material and a preparation method thereof. The invention adopts a technical proposal that the method comprises the following steps: firstly mixing 10 to 35 percent of carbonate powder, 10 to 35 percent of chlorate powder and 30 to 80 percent of crude steatite powder by weight, admixing 3 to 10 percent of bonding agent by weight of the mixture into the mixture, stirring the mixture for 5 to 25 minutes, and pressing and molding the mixture; drying the mixture for 12 to 36 hours at a temperature of between 60 and 110 DEG C or naturally drying the mixture for 24 to 48 hours indoors; and then sintering the dried mixture for 2 to 6 hours at a temperature of between 800 and 1,400 DEG C in the air, naturally cooling the sintered mixture and soaking the cooled mixture for 24 to 48 hours by water, and finally drying the soaked mixture for 12 to 36 hours at a temperature of between 60 and 110 DEG C or naturally drying the soaked mixture for 24 to 48 hours indoors to obtain the lightweight forsterite material. The preparation method has the characteristics of rich raw material resources, low production cost and easy industrialized production. The prepared material is used as an insulating material particularly suitable for industrial thermal equipment at a temperature of below 1,200 DEG C, and can reduce heat loss, reduce heat pollution of environment, can save energy and reduce consumption.

Owner:WUHAN UNIV OF SCI & TECH

Grain-oriented electrical steel sheet and method for producing the same

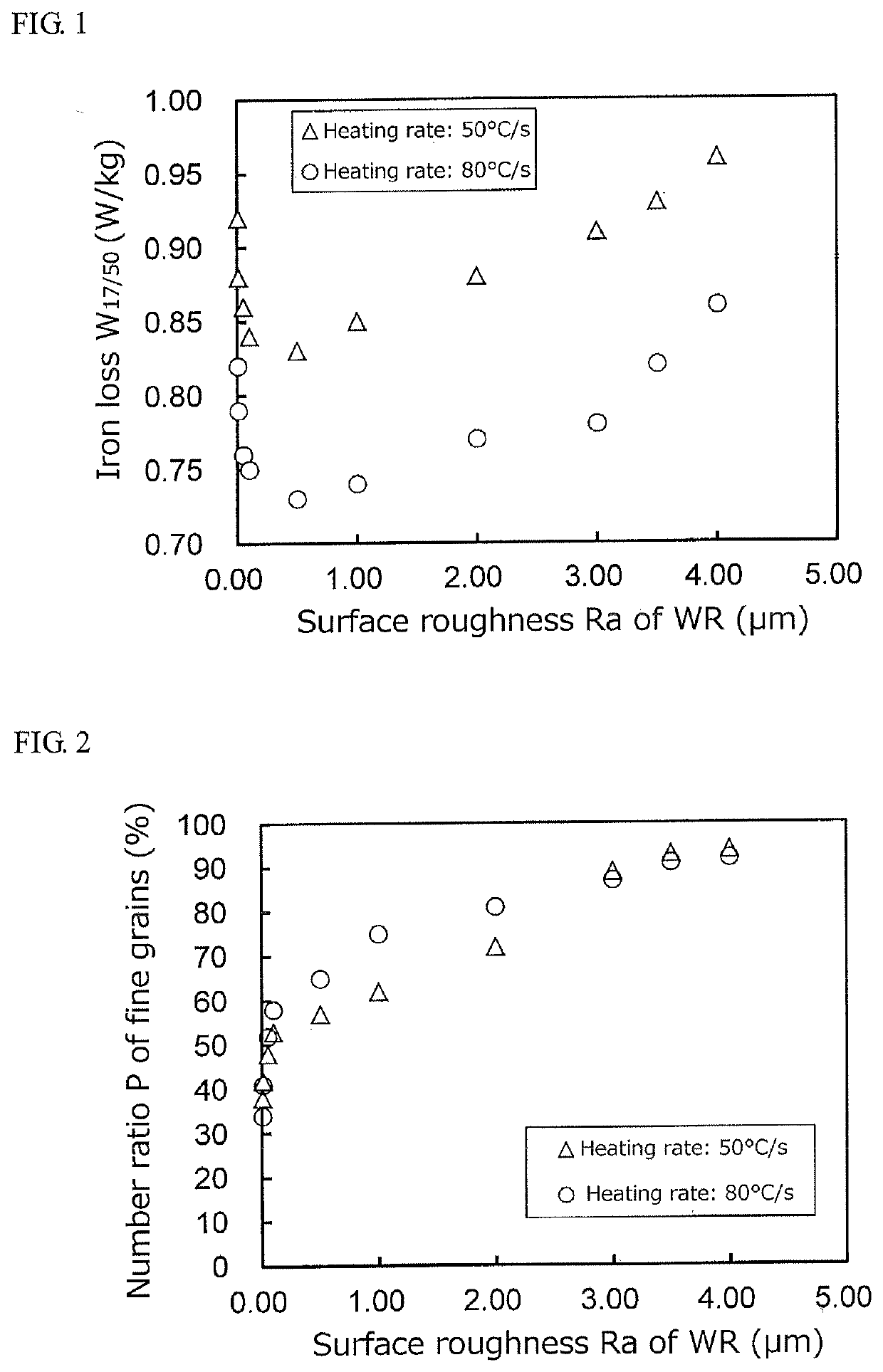

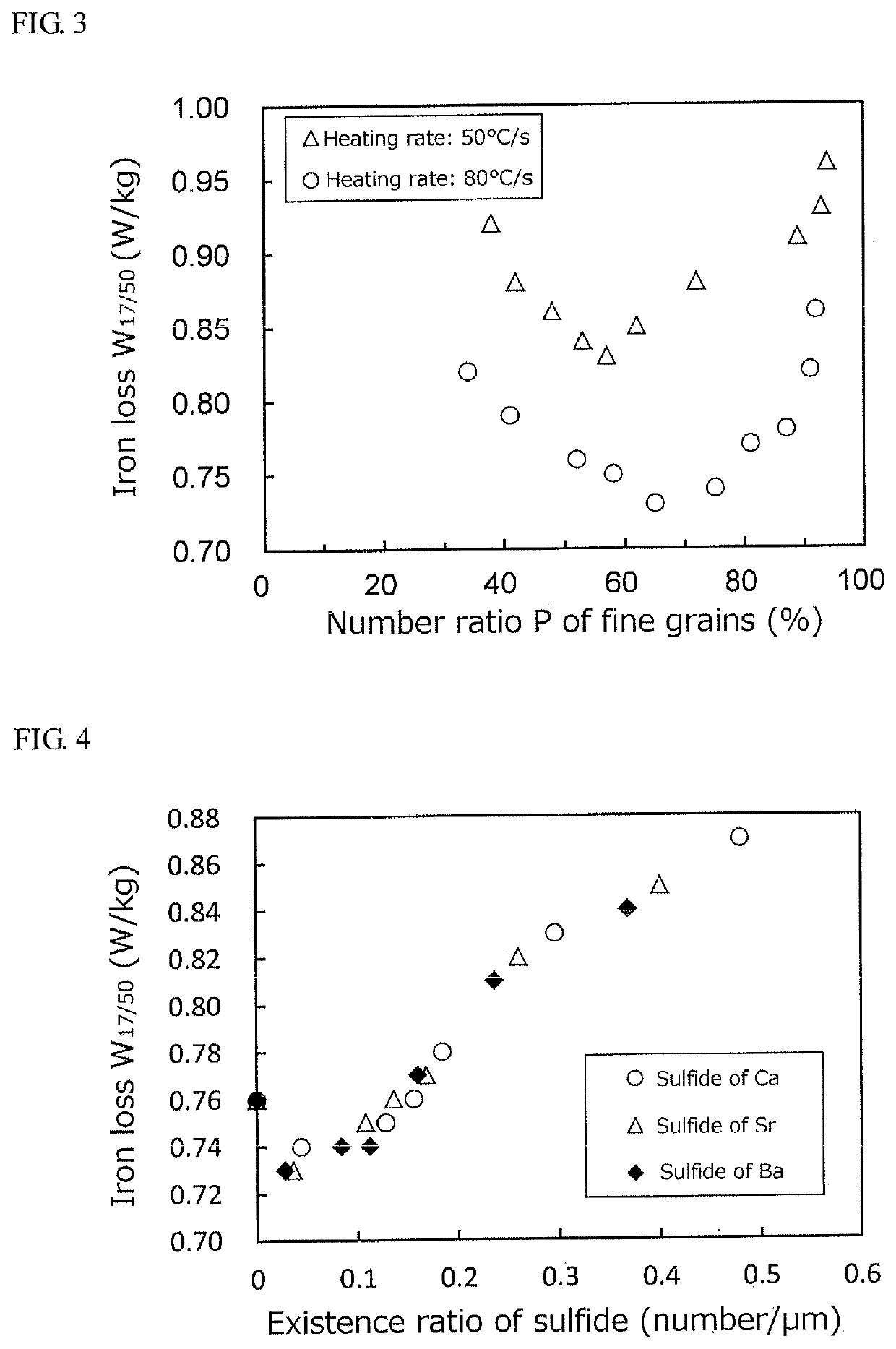

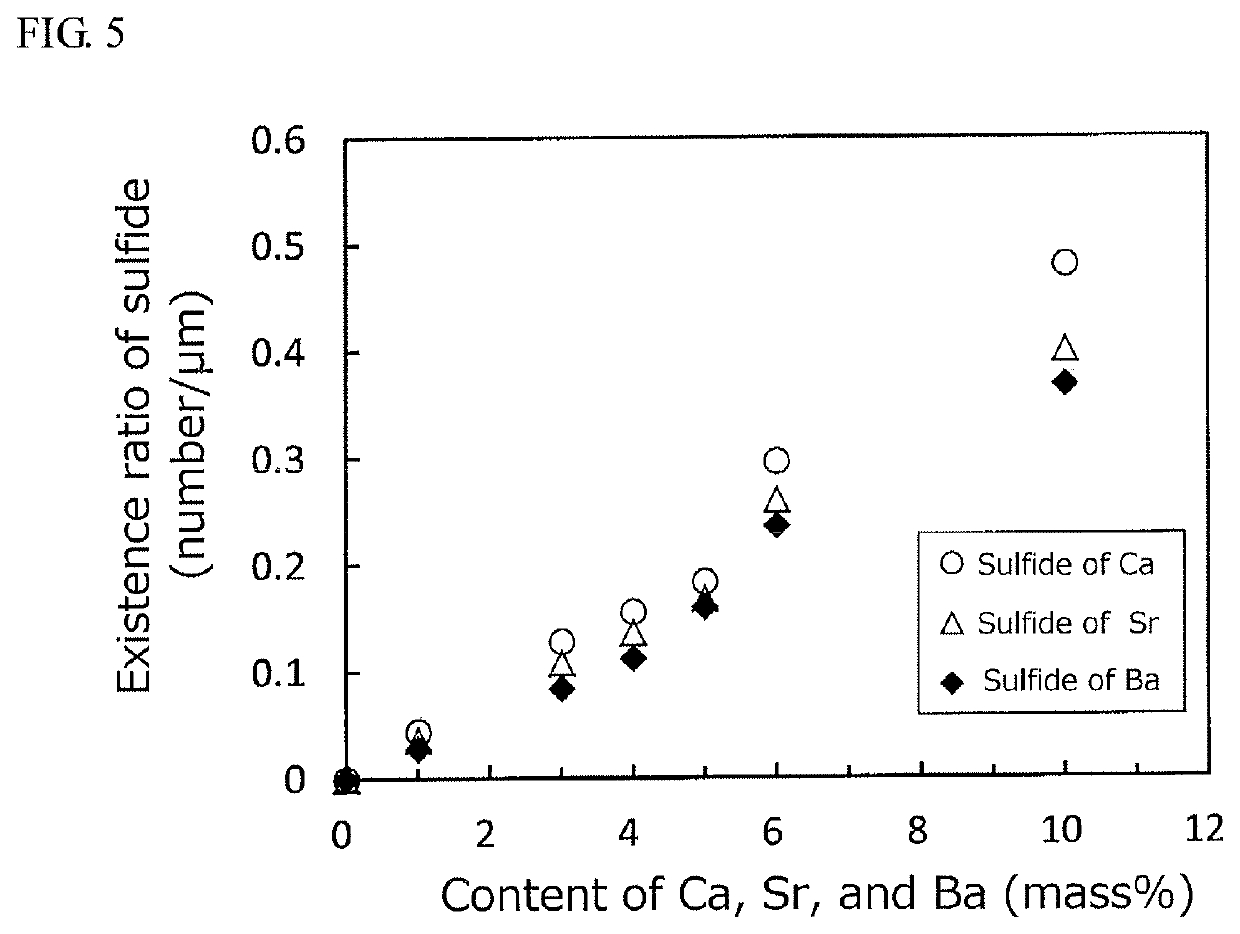

ActiveUS20200063234A1Low costExcellent iron loss propertyInorganic material magnetismFurnace typesAlkaline earth metalWork roll

A grain-oriented electrical steel sheet having excellent iron loss property is produced from a steel slab containing, by mass %, C: 0.002-0.15%, Si: 2.5-6.0%, Mn: 0.01-0.80%, Al: 0.010-0.050% and N: 0.003-0.020%, when: a heating rate between 500-700° C. In decarburization annealing is not less than 80° C. / s, a surface roughness Ra of a work roll in final cold rolling is 0.01-3.0 μm, a total content of alkaline earth metals to MgO in annealing separator is 0-5 mass %, an average length L in rolling direction of passed crystal grains is not more than 25 mm, a ratio of crystal grains having a length in rolling direction of not less than 0.5 μm is 40-90%, and an existence ratio of alkaline earth metal sulfides having a size corresponding to circle of not less than 0.5 μm in a cross section of forsterite film is not more than 0.2 / μm per unit length in sheet width direction.

Owner:JFE STEEL CORP

Filling method of double-layer stuffing sand and application thereof

ActiveCN111283181AEasy to operateMaterials are readily availableMelt-holding vesselsPhysical chemistryEngineering

The invention provides a filling method of double-layer stuffing sand. The filling method of the double-layer stuffing sand comprises the following step that an upper gate of a steel ladle is filled with a drainage substance, is characterized in that the upper layer of the drainage substance is stuffing sand A, the stuffing sand A is selected from one or more than two of forsterite stuffing sand,silicon stuffing sand, zirconium stuffing sand or chromite stuffing sand, the lower layer of a drainage substance is a stuffing sand B, the stuffing sand B comprises the following components of, in percentage by weight, 98%-99% of MgO, 0.3%-0.65% of SiO2, 0.2%-0.6% of Fe2O3, 0.3%-0.7% of C, 0.008%-0.012% of S and 0.06%-0.1% of H2O. According to the filling method, under the condition that the automatic casting rate of the molten steel is not affected, inclusions in the molten steel are reduced, and pollution to the environment is relieved.

Owner:首钢股份公司迁安钢铁公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com