Spinel high-strength petroleum fracturing proppant and production method thereof

A fracturing proppant and spinel-based technology, applied in the field of fracturing proppant, can solve the problems of unsatisfactory performance requirements and low pressure bearing capacity, and achieve easy promotion and implementation, strong anti-fragmentation ability, and excellent product performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: spinel high-strength ceramsite proppant and production method thereof

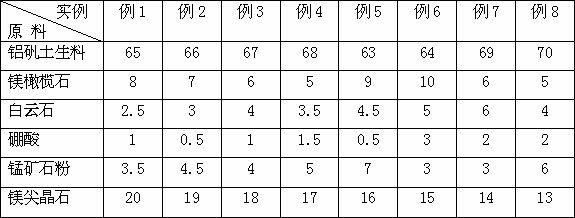

[0020] Raw materials: by weight percentage, bauxite raw meal 65%, forsterite 8%, dolomite 2.5%, boric acid 1%, manganese ore powder 3.5%, magnesium spinel 20%, see Table 2.

[0021] Production method: Weigh each raw material, grind them into fine powder, pass through a 320-mesh sieve, and the sieving rate is greater than 98.5%; mix the raw materials evenly, add atomized water into the rotary granulator at the same time, and make the mixture into a size Different round grains are passed through a 18-30 mesh sieve, and the sieving rate is required to be greater than 90%, and then rotated for 15-20 minutes, and the semi-finished product is obtained after passing through a 18-30 mesh sieve;

[0022] Send the semi-finished product into an oven at 200-250°C for 2-3 hours, and dry it until the moisture content is below 6%; lift the semi-finished product into the silo, and send it to the rotar...

Embodiment 2

[0023] Embodiment 2: The raw material composition is shown in Table 2, and the production method is basically the same as in Example 1, the difference being:

[0024] When the baked semi-finished product is fired in the rotary kiln, the temperature at the kiln head is 1300-1350°C, the temperature at the kiln tail is 295-310°C, and it will leave the kiln after firing for 7.5 hours.

Embodiment 3

[0025] Embodiment 3: The raw material composition is shown in Table 2, and the production method is basically the same as in Example 1, the difference being:

[0026] When the baked semi-finished product is fired in the rotary kiln, the temperature at the kiln head is 1320-1365°C, the temperature at the kiln tail is 300-315°C, and it will leave the kiln after firing for 7.5 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crush indicators | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com