Castable and method for manufacturing coke tank lining

A castable and lining technology, used in coke cooling, coke oven, petroleum industry, etc., can solve problems such as low service life, reduce unit cost, reduce tank wall temperature, and have good thermal shock resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

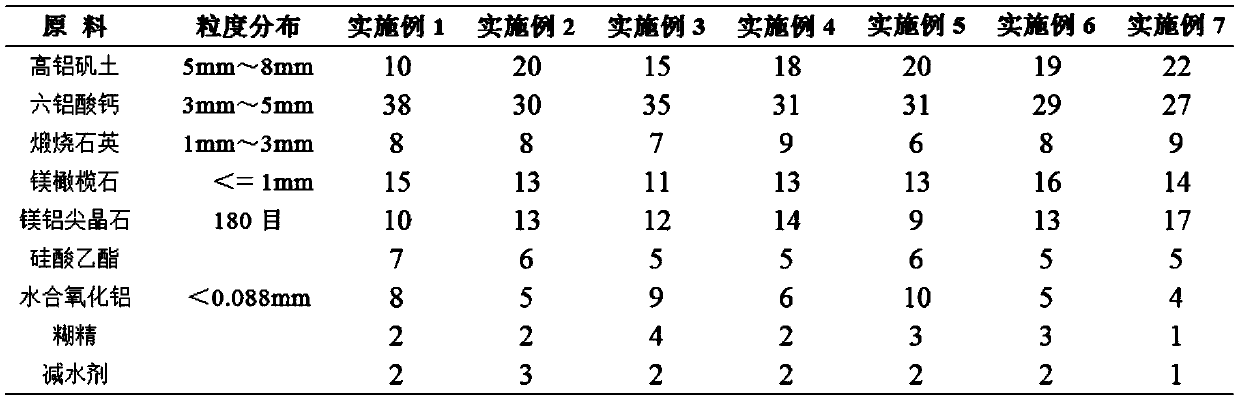

[0097] In Example 1, a castable for manufacturing coke tank lining is provided, and the coke tank lining is a refractory coke tank lining, and its raw material formula is shown in Table 1. Specifically, the castable may include the following chemical components by weight percentage:

[0098] High alumina bauxite with a particle size ranging from 5mm to 8mm: 10%;

[0099] Calcium hexaaluminate with a particle size ranging from 3mm to 5mm: 38%;

[0100] Calcined quartz with a particle size ranging from 1mm to 3mm: 8%;

[0101] Forsterite with particle size less than or equal to 1mm: 15%;

[0102] Magnesia-aluminum spinel with a particle size of 180 mesh: 10%;

[0103] Ethyl silicate: 7%;

[0104] Hydrated alumina with particle size less than 0.088mm: 8%;

[0105] Dextrin: 2%;

[0106] Water reducer: 2%.

[0107] Weigh various materials except ethyl silicate according to the proportions stated in Table 1, then put the above materials into a mixer and mix and stir for 5-8 m...

Embodiment 2

[0116] In Example 2, a castable for manufacturing a coke tank lining is provided. The coke tank lining is a refractory coke tank lining, and its raw material formula is shown in Table 1.

[0117] The method for manufacturing coke tank lining with above-mentioned casting material is the same as embodiment 1, and its main physical and chemical index is as follows:

[0118] Refractory temperature > 1500°C;

[0119] The bulk density after 24 hours at 110°C is 2.2g / cm 3 , and the bulk density after 24 hours at 1200°C is 2.6g / cm 3 ;

[0120] The compressive strength after holding at 110°C for 24 hours is 65MPa, and after holding at 1200°C for 3 hours, the compressive strength is 75MPa;

[0121] The flexural strength after holding at 110°C for 24 hours is 14MPa, and after holding at 1200°C for 3 hours, the flexural strength is 19MPa;

[0122] The thermal conductivity at 350°C is 0.25W / (m·k);

[0123] The change of the burnt line after holding at 1550°C for 24 hours is ±0.3%.

Embodiment 3

[0125] In Example 3, a castable for manufacturing the coke tank lining is provided. The coke tank lining is a refractory coke tank lining, and its raw material formula is shown in Table 1.

[0126] The method for manufacturing coke tank lining with above-mentioned casting material is the same as embodiment 1, and its main physical and chemical index is as follows:

[0127] Refractory temperature > 1500°C;

[0128] The bulk density after 24 hours at 110°C is 2.1g / cm 3 , and the bulk density after 24 hours at 1200°C is 2.6g / cm 3 ;

[0129] The compressive strength after holding at 110°C for 24 hours is 65MPa, and after holding at 1200°C for 3 hours, the compressive strength is 73MPa;

[0130] The flexural strength after holding at 110°C for 24 hours is 13MPa, and after holding at 1200°C for 3 hours, the flexural strength is 18MPa;

[0131] The thermal conductivity at 350°C is 0.26W / (m·k);

[0132] The change of the burnt line after holding at 1550°C for 24 hours is ±0.3%. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Refractory temperature | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com