Anti-skid colored paving material for roads, and preparation method and construction process of paving material

A pavement material and anti-slip technology, applied in the field of road pavement materials, can solve the problems of driver suffocation, complicated construction procedures, and increase of total social costs, and achieve the prevention of environmental pollution and safety accidents, shortening of hardening time, and complicated operating procedures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A road anti-slip colored paving material, comprising the following components in parts by weight:

[0047] 41 parts of polymethyl methacrylate resin; 12 parts of calcium carbonate with a particle size of 325 mesh; 3 parts of nano silicon dioxide with a diameter of 5 mm; 2 parts of magnesium oxide; 8 parts of bauxite; 5 parts of quartz sand.

[0048] The diameter of the bauxite in this embodiment includes three sizes, which are respectively less than 0.6 mm, 0.6 mm to 1 mm, and 2 mm to 5 mm. The parts by weight of the three sizes of bauxite added are respectively 12 parts, 8 parts, 8 parts, the diameter of quartz sand includes 1.5mm to 2.5mm, and the added weight is 5 parts.

Embodiment 4

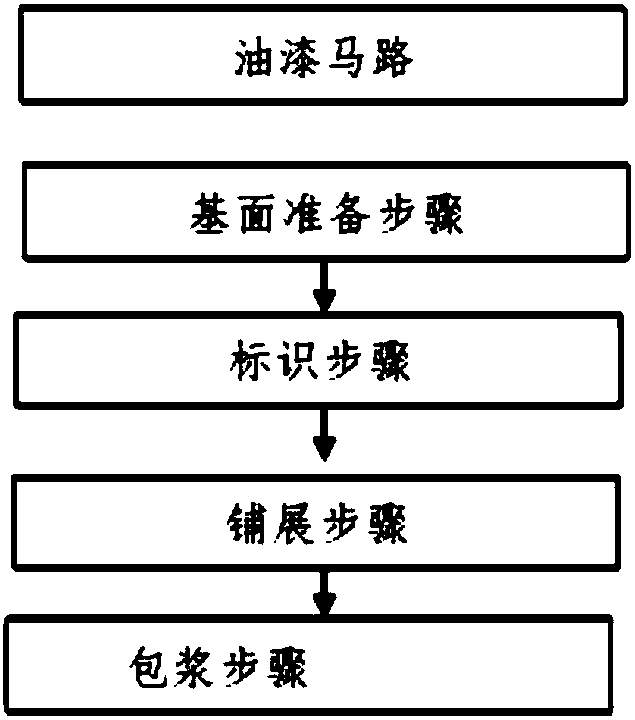

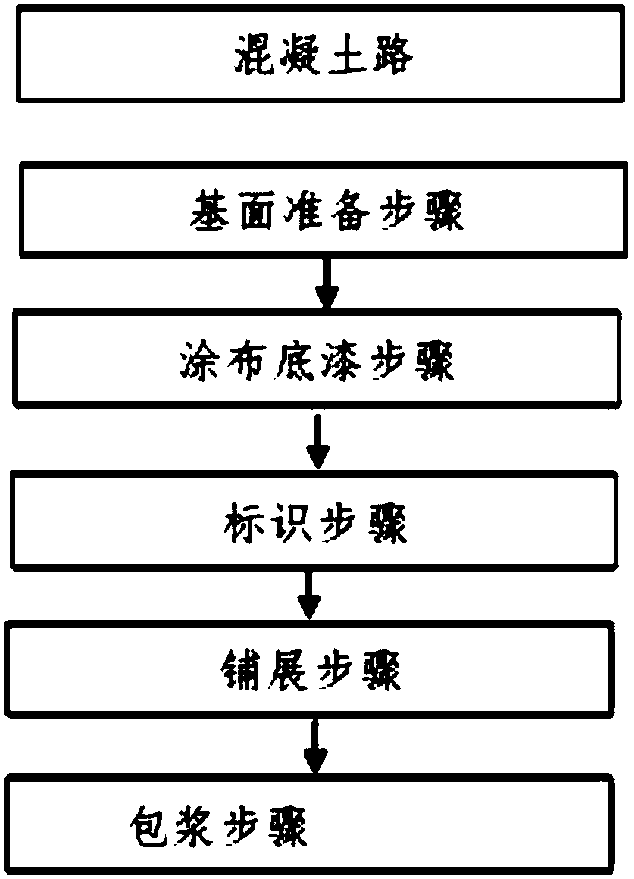

[0063] The construction technique of the road anti-slip colored paving material that application embodiment 2 makes comprises the steps (pavement is concrete road):

[0064] S1. Base surface preparation step: remove construction road surface impurities;

[0065] S2. Marking step: Paste tape on the construction road surface to delineate the construction area;

[0066] S3. The step of applying the primer: apply the primer within the construction range.

[0067] S4. Spreading step: Stir the road non-slip colored pavement material and BPO, mix evenly, spread it in the construction area with a push rod or extrusion roller, and promote the thicker high-strength bauxite to protrude on the road surface to form a non-slip layer.

[0068] S5. Patching step: coating MMA resin primer on the pavement surface of paved road non-slip colored pavement material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com