Floating type sea wave power station

A wave power station, floating technology, applied in the field of floating wave power stations, can solve the problems of undeveloped and utilized renewable energy, increased excessive emissions of greenhouse gases, pollution of land and atmosphere, etc., to achieve novel design and high installed capacity Big, Durable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

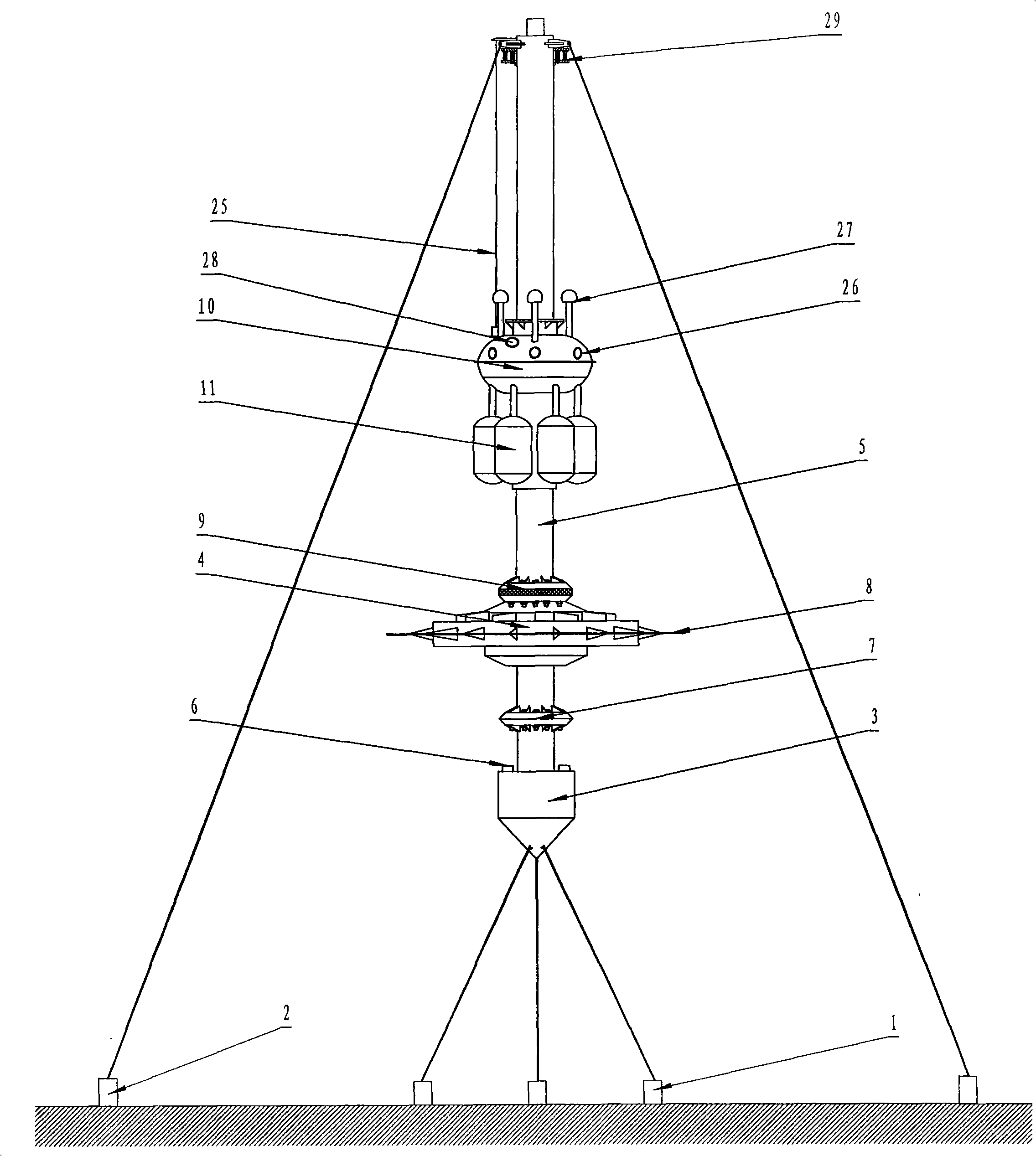

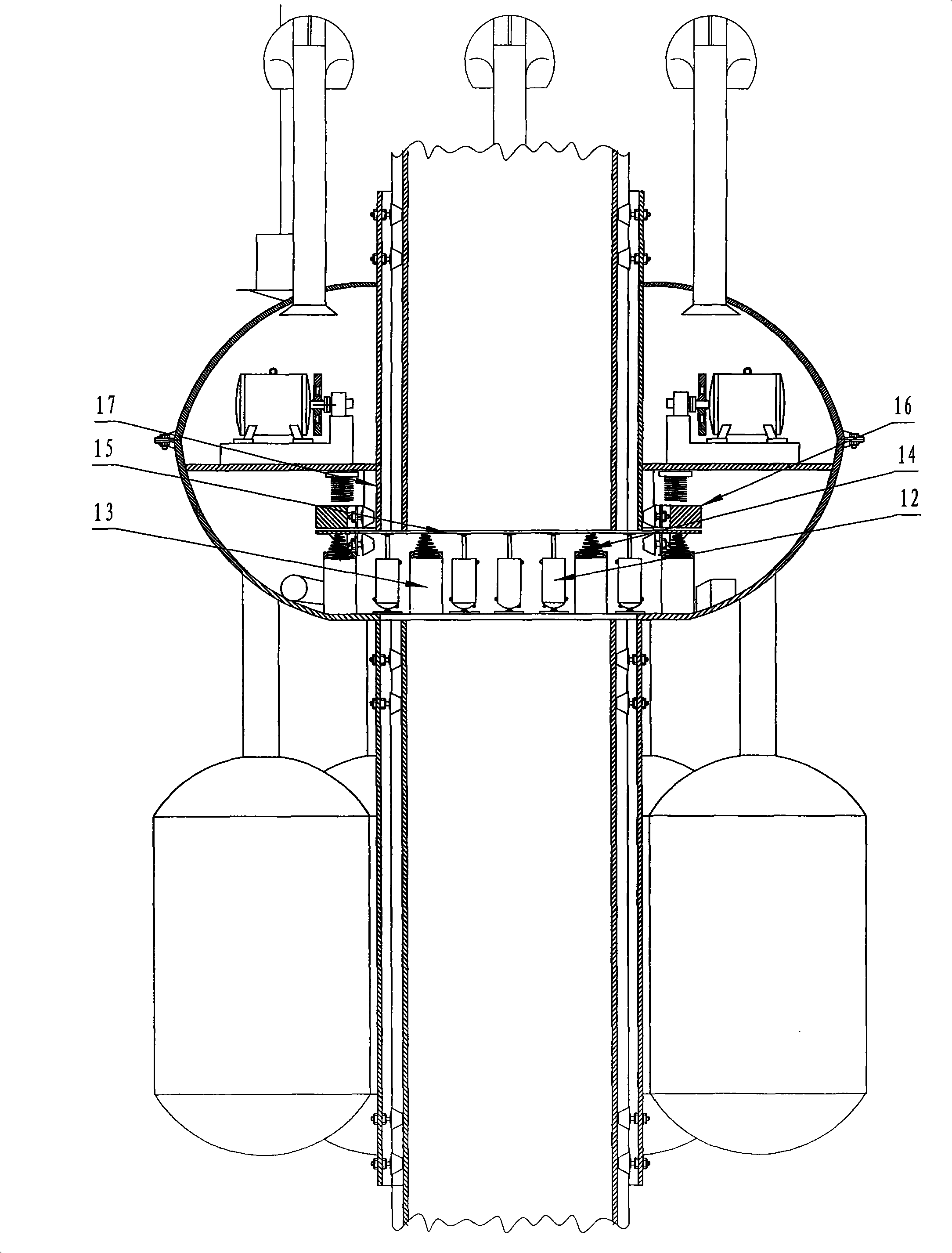

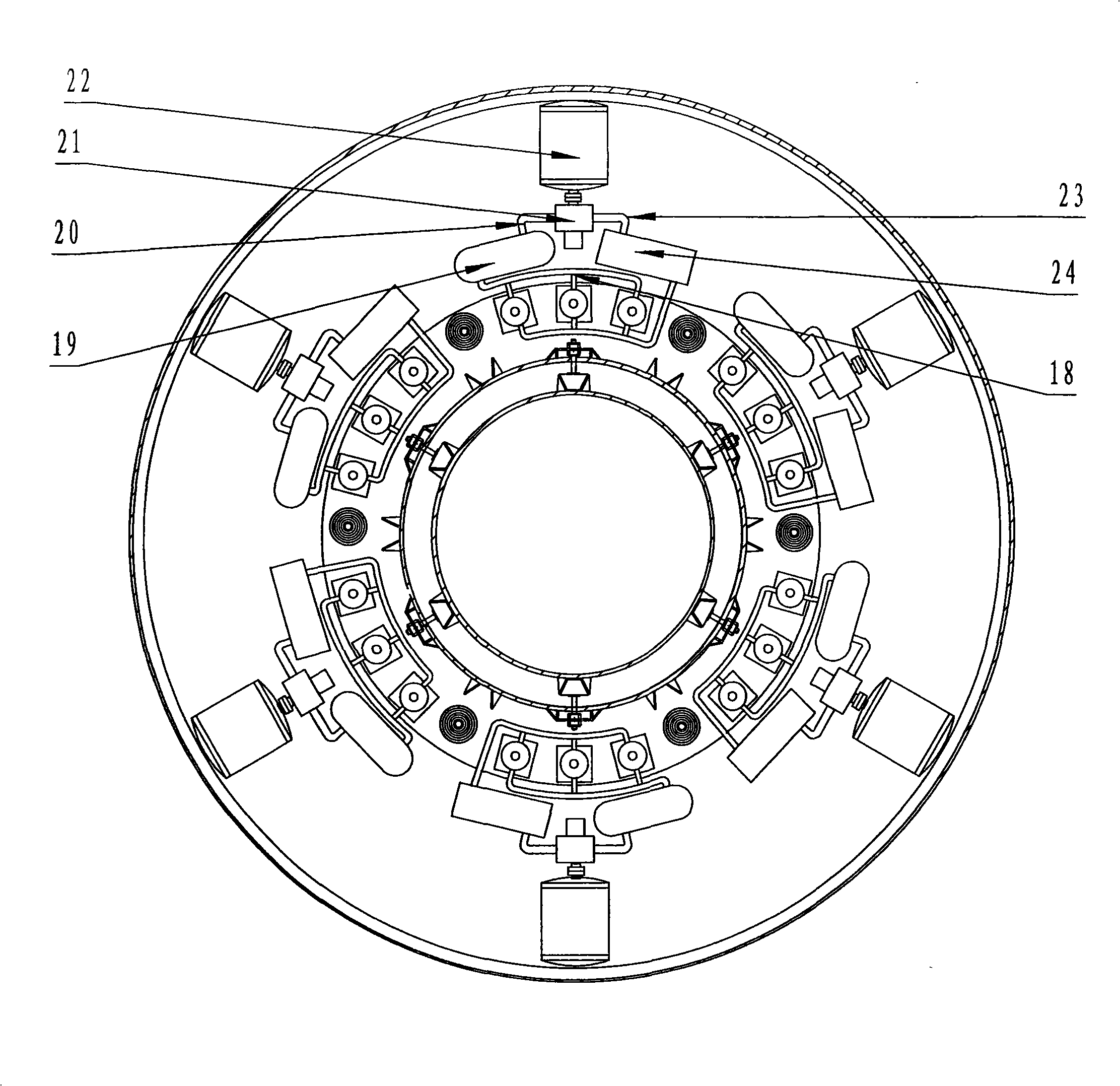

[0034] Combine below Figure (1)-(3) The ocean wave power plant of the present invention will be described in detail below.

[0035] As shown in the figure (1): the hard cabin pile anchor group 1 guide post pile anchor group 2 will be moored by the cable in the appropriate position in the ocean vertically with the floating hard cabin 3 watertight soft cabin 4 and the guide column 5 .

[0036] As shown in the figure (1), the iron ore is filled into the ballast in the hard tank 3 by the filling port 6, and the hard tank 3 and the soft tank 4 are connected by the connecting plate 7 of the soft and hard tank.

[0037] As shown in the figure (1); the circular watertight soft cabin 4 is provided with a horizontal heave plate 8 so that the guide column will not tilt excessively around after being stressed, and the soft cabin will not heave up and down.

[0038] As shown in the figure (1); the connecting plate 9 connects the soft cabin 4 and the guide column 5 as a whole, because the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com