Patents

Literature

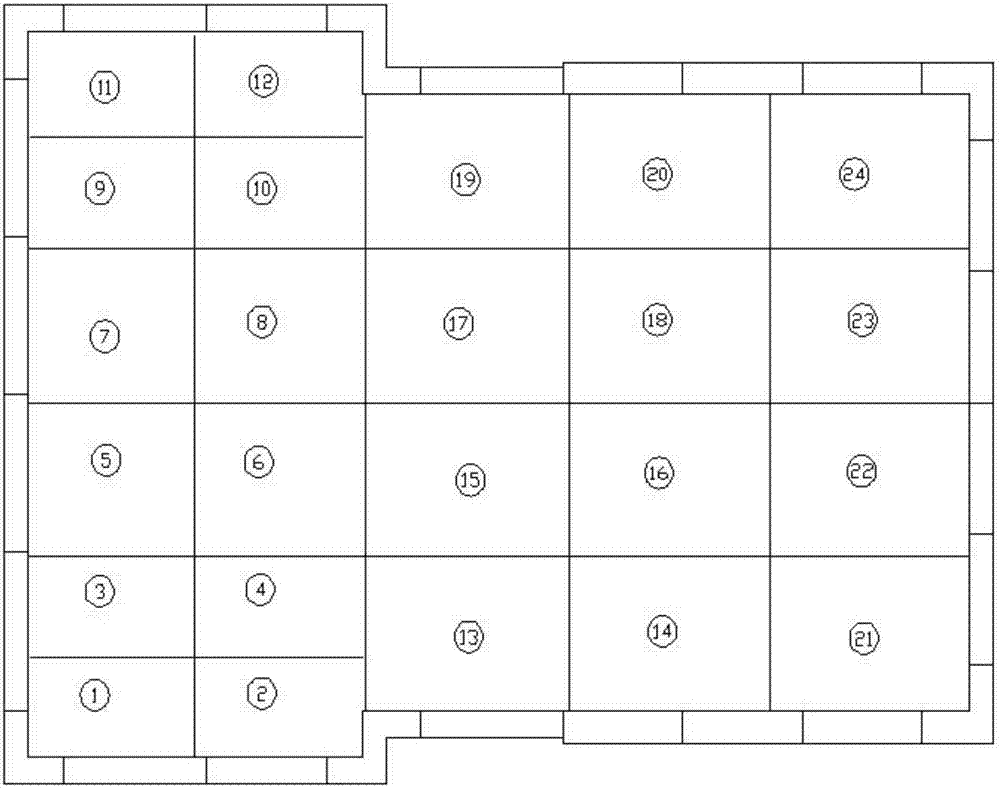

53 results about "Red sandstone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

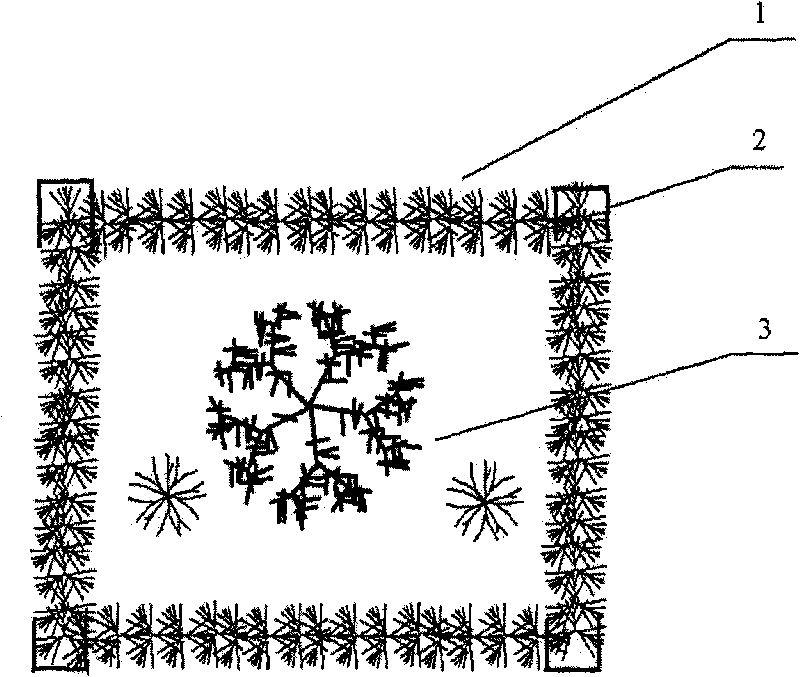

Method for greening and restoring hard side slope

InactiveCN110089353ALower pHEffectively replenish organic matterFlowers cultivationHops/wine cultivationRevegetationAutomatic control

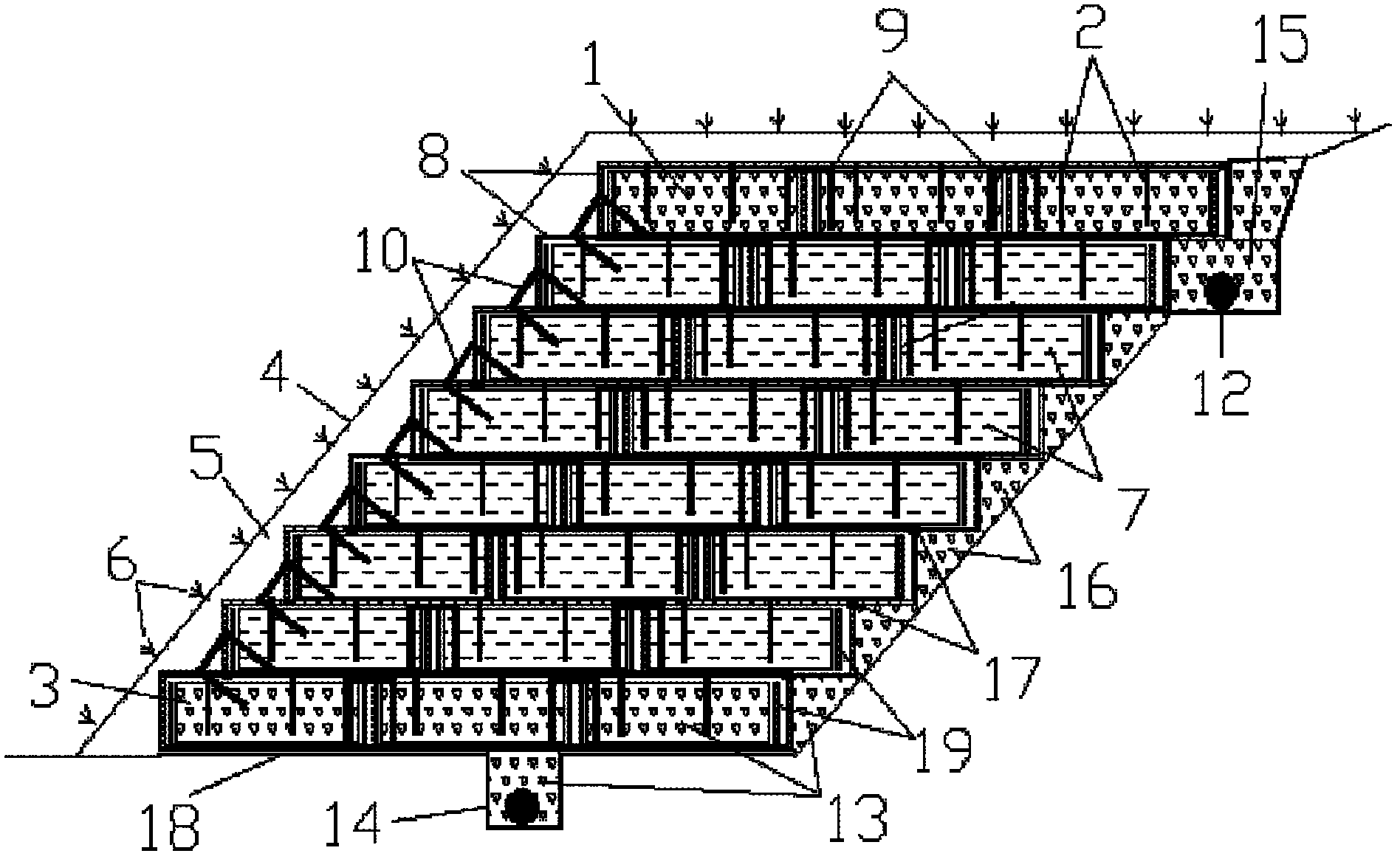

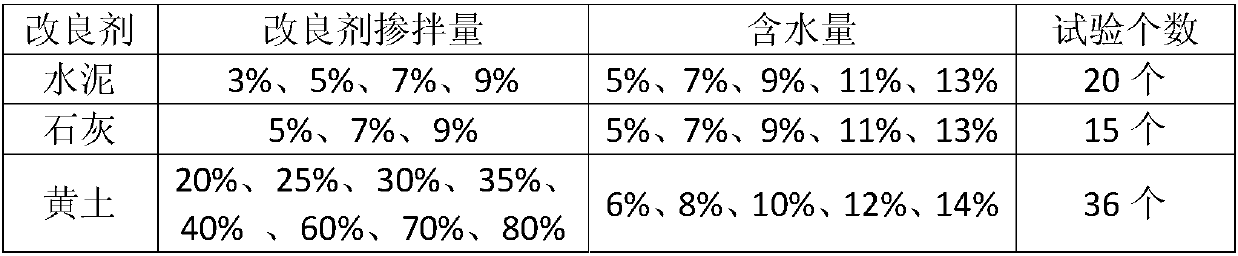

The invention discloses a method for greening and restoring a hard side slope. The method comprises the steps of cleaning a slope surface, arranging an anchor rod, laying a galvanized wire mesh sheet,improving red sandstone into planting soil, laying a geomembrane, executing sowing, establishing an automatic irrigation system and executing operation and maintenance, wherein the red sandstone soillayers with different sandstone contents are improved by adding an improver, meanwhile spray heads are installed on a pre-buried spray system by utilizing an automatic control system, and planted plants are irrigated by using the spray heads. A sprinkling irrigation system can be automatically controlled according to temperature and humidity. The invention provides a hard slope greening restoration technology for improving red sandstone into planting soil. Long-term growth conditions are provided for vegetations, the ecological restoration requirements of a rock slope and a hard slope are met, slope protection greening planting plants are combined with a traditional vegetation concrete ecological-restoration technology, vegetation restoration and anchoring fixation are simultaneously carried out, and the vegetation growth on slopes and slope fixation can be better achieved.

Owner:CHINA FIRST METALLURGICAL GROUP

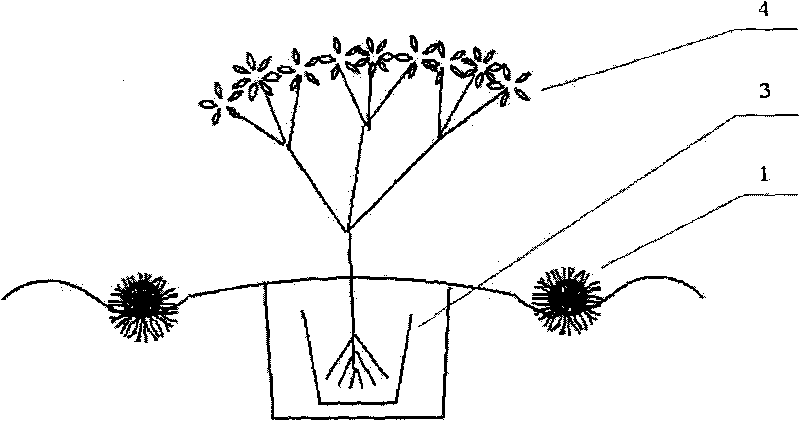

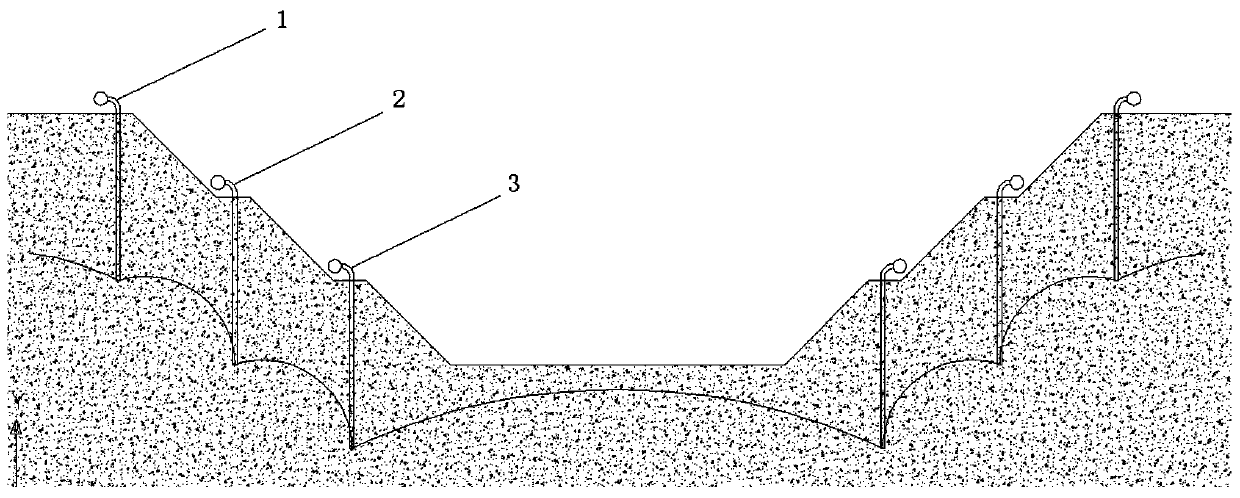

Recovery method of bare red sandstone abrupt slope vegetation

InactiveCN101731092AAvoid direct splashPrevent runoffCultivating equipmentsSoilless cultivationRevegetationRecovery method

The invention relates to a recovery method of bare red sandstone abrupt slope vegetation, which comprises the steps of: preparing an abrupt slope; preparing grass square lattices; distributing and fixing the grass square lattices in an interlaced way along the abrupt slope; preparing plants growing base material with soil, sand and fertilizer; filling the plants growing base material into nutrition bags; growing herbal and shrub plants in the growing base material; digging growing points in the grass square lattices; and embedding the nutrition bags and the herbal and shrub plants into the growing points together. By adopting the method, the grass square lattices and slope soil layers are jointly formed into a protection system of the abrupt slope, thereby effectively preventing the abrupt slope from being directly splashed by raindrops to avoid that the surface of the ground is washed by radial flow and play an important part in the stabilization of the abrupt slope; the nutrition bags provide a good growing condition for growing the vegetation; and the grass and the shrub are grown in a mixing way to be capable of guaranteeing that the vegetation can take roots on the bare red sandstone abrupt slope, thereby recovering the vegetation in a large area and achieving the aim of soil and water conservation. The method has convenient construction, small investment, wide application and good effect, is hardly destroyed by water, can fast conserve the soil and the water, and performs ecological restoration.

Owner:HUAZHONG AGRI UNIV

Method for preparing glaze self-releasing ceramic material by red mud and red sandstone

The present invention discloses a method for preparing self glaze ceramic material; the molar percent of the raw material is that: 15-50 percent of red soil; 40-80 percent of red sandstone; 3-10 percent of molding material; the detailed steps are that: (1) the red soil and the red sandstone are put into a ball grilling tank for grilling; (2) the product obtained in step (1) is added with the molding material and then to be mixed in the ball grilling tank for grilling; (3) the product obtained in step (2) is taken with molding or pressed mode to form the mold and to become the blank body; (4) the blank body obtained in step (3) is baked for 0.5-3 hours under the temperature of 900 Celsius system -1350 Celsius system, and then to be cooled to the room temperature naturally to become the finished product. The finished product of the glaze level in the present invention is plump, smooth, bright and clear; the ceramic process degree from the blank body is much better; the raw material for the product is abundant; the cost is low; the technical process is simple; the advantages are good for solving the synthesized utilization problem for the red soil as well as enhancing the utilization ratio and utilization value for the red sandstone.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Construction method of red sandstone roadbed

ActiveCN101831851AHigh linearity standardLarge amount of filling and cuttingRoadwaysArchitectural engineeringRed sandstone

The invention relates to a construction method of a red sandstone roadbed, which adopts special mechanical assembly. Aiming at the mechanics of the I type red sandstone roadbed and the II type red sandstone roadbed and the analysis of the road performance, a large-tonnage special compacting machine is used for rolling, wherein the rolling comprises the rolling, the crushing and the compactly extruding through a YZTY-22T pulling type cavel with the vibrating force of 45t, the rolling through a YZ32 ultra-large vibrating force vibrating road rolling machine, and the shocking and the reinforcing through a QCY360 (25KJ trilateral double wheels) shocking road rolling machine. The linear standard of the super highway is high and the work amount of filling and cutting is large, so that the design of wiring can not avoid a wider red sandstone zone and a mass of red sandstones have to be dug up during constructing. If the roadbed can not be filled with the red sandstones but the far-distant other materials, not only the construction period is delayed, but also the construction cost is high. Meanwhile, areas for borrowing and abandoning the soil are difficult to find, so that the existing construction mode can pollute the environment and bring much future troubles. The construction method well makes use of the spot red sandstones, reduces the construction cost, saves the resources, and is good for the civilized construction and the environment protection.

Owner:ANHUI ROAD & BRIDGE GRP +1

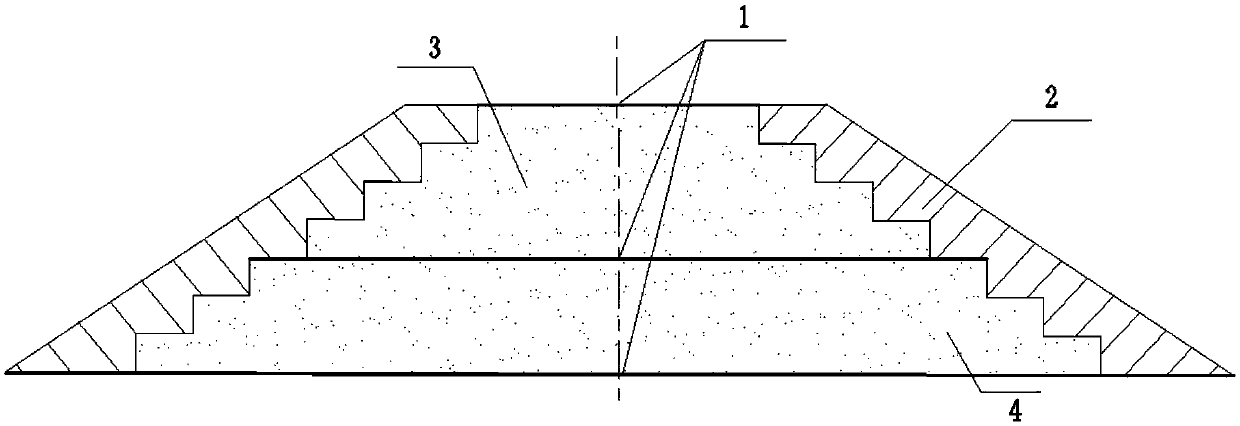

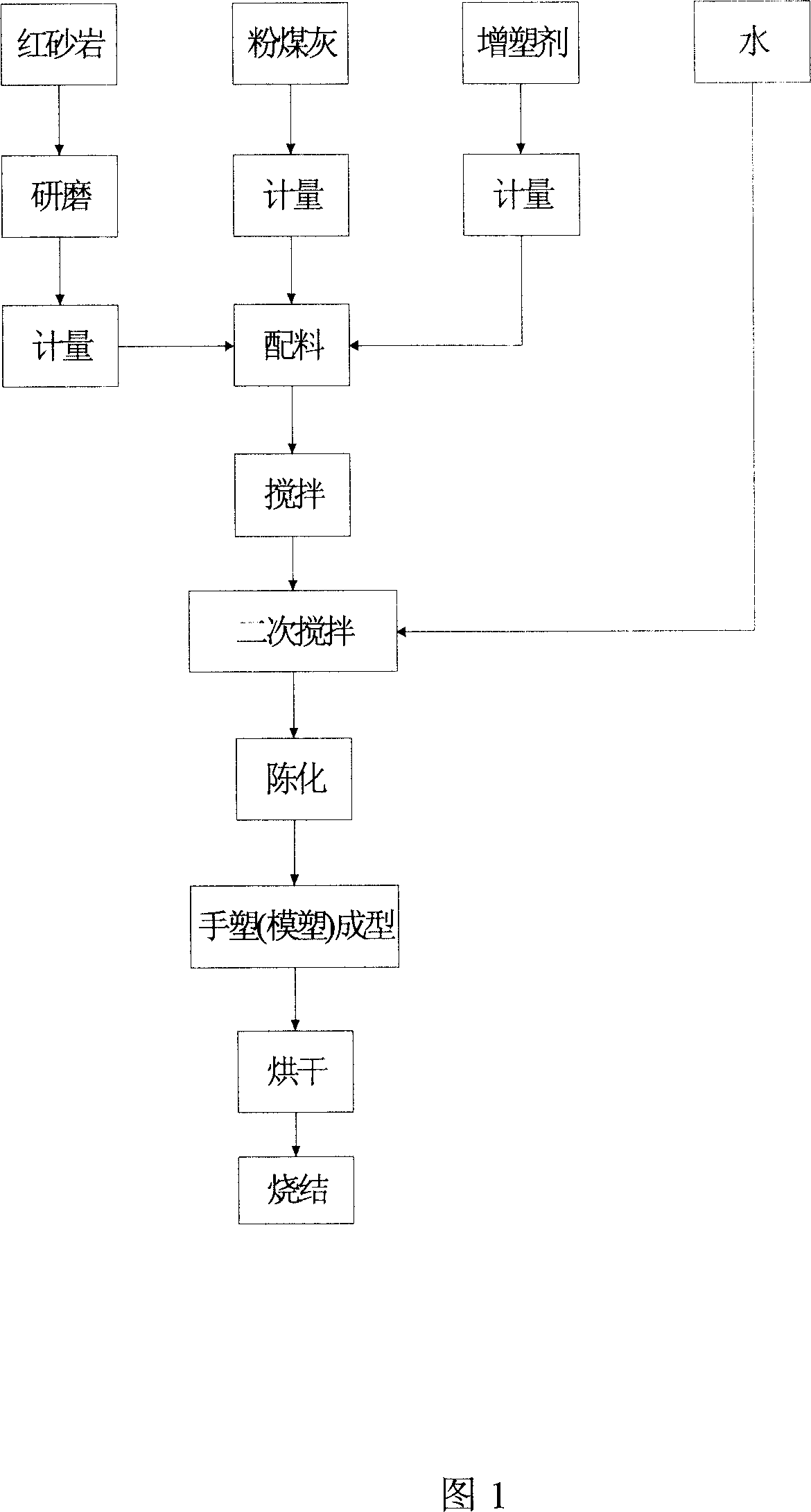

Red sandstone subgrade filling structure used in rainy area and construction method of same

In one embodiment, a red sandstone subgrade filling structure used in a rainy area and a construction method of same are provided. The construction method employs red sandstone earthwork, cement, waterproofing geotechnical cloths, edge-covering cohesive soil, and a subgrade construction mechanical device. Three layers of waterproofing geotechnical cloths are respectively arranged on the bottom ofthe subgrade, on the bottom of the roadbed, and on the top of the roadbed. Subgrade slopes are coated by the edge-covering cohesive soil. Embankments are formed with the red sandstone via layered filling. The roadbed is processed by cement mixed with ash. The method not only effectively protects the stability of the red sandstone, but also guarantees quality and security. The structure is economical and environment-friendly when being used in a south rainy red sandstone area where soil is difficult to fetch.

Owner:CHINA MCC17 GRP

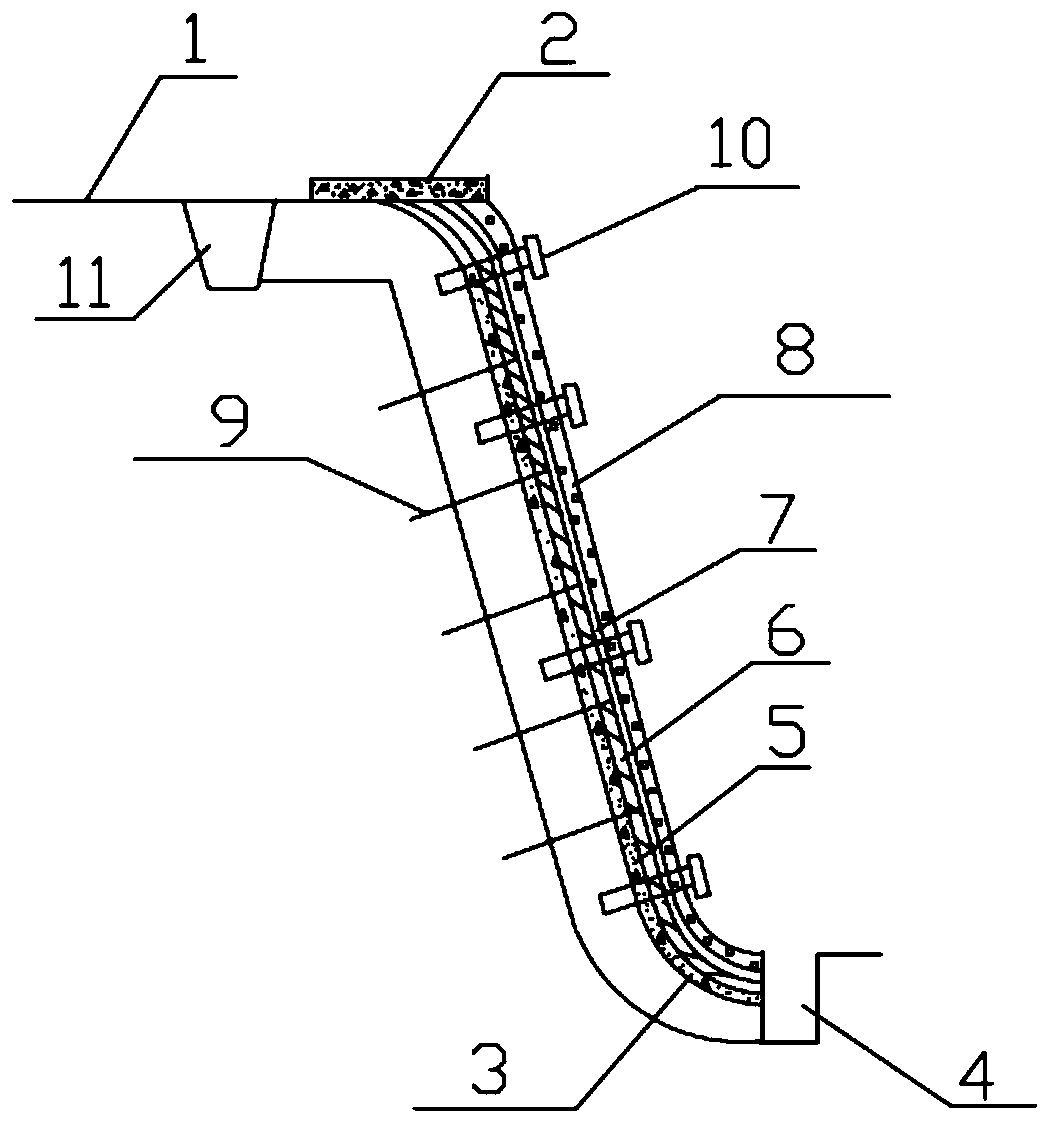

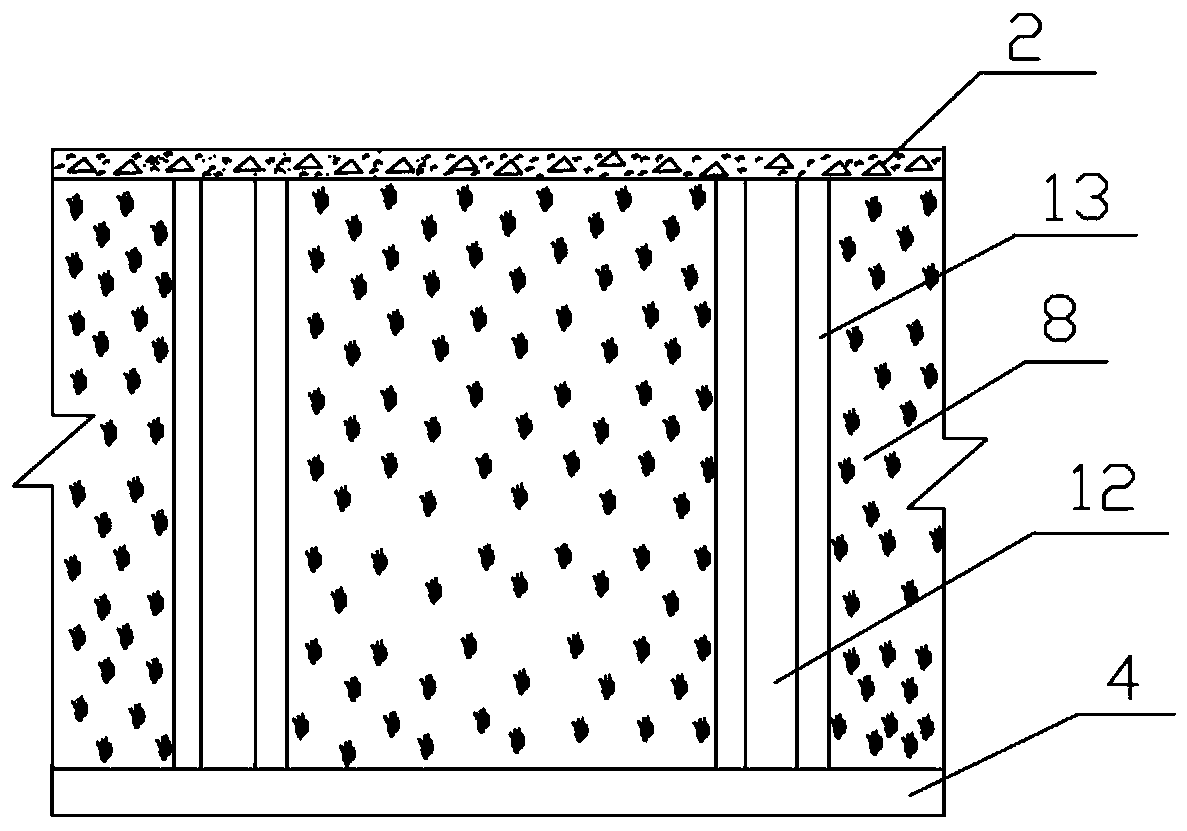

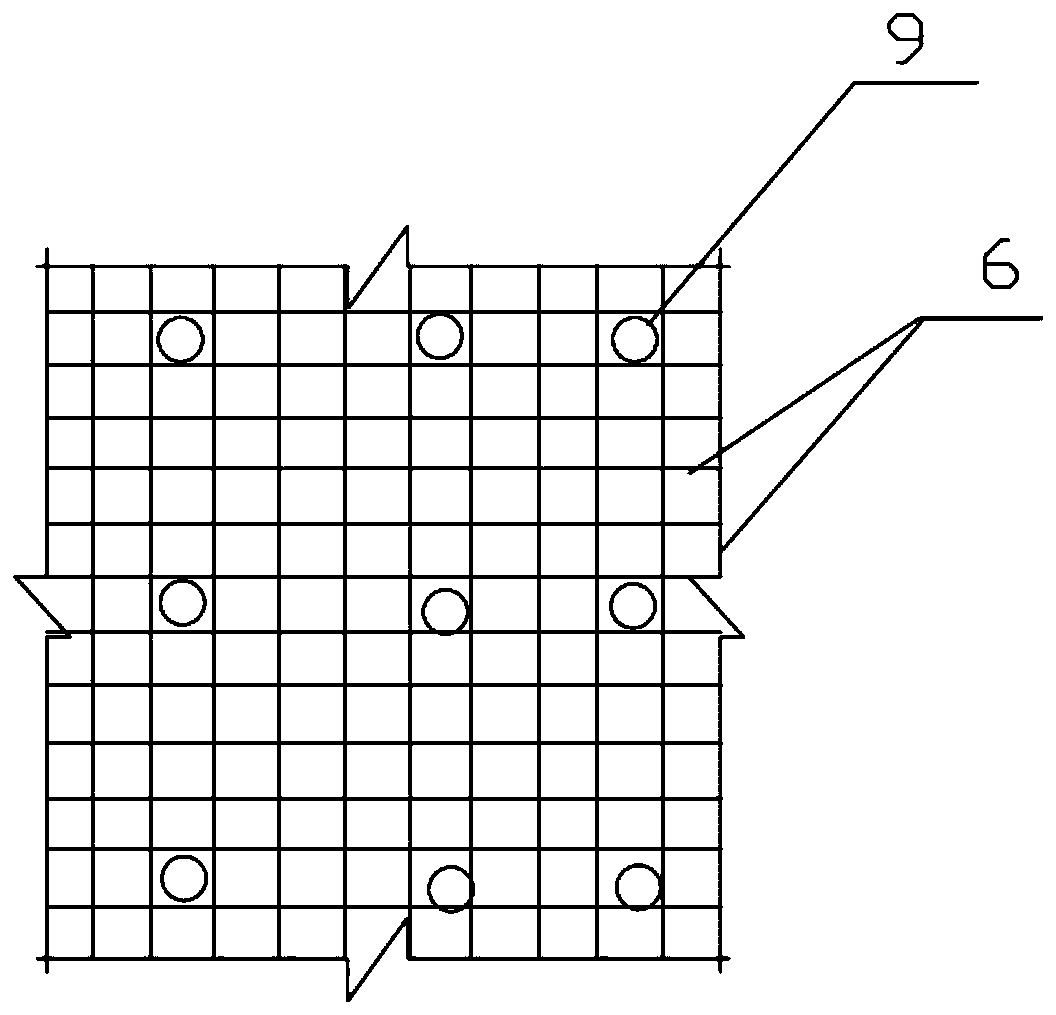

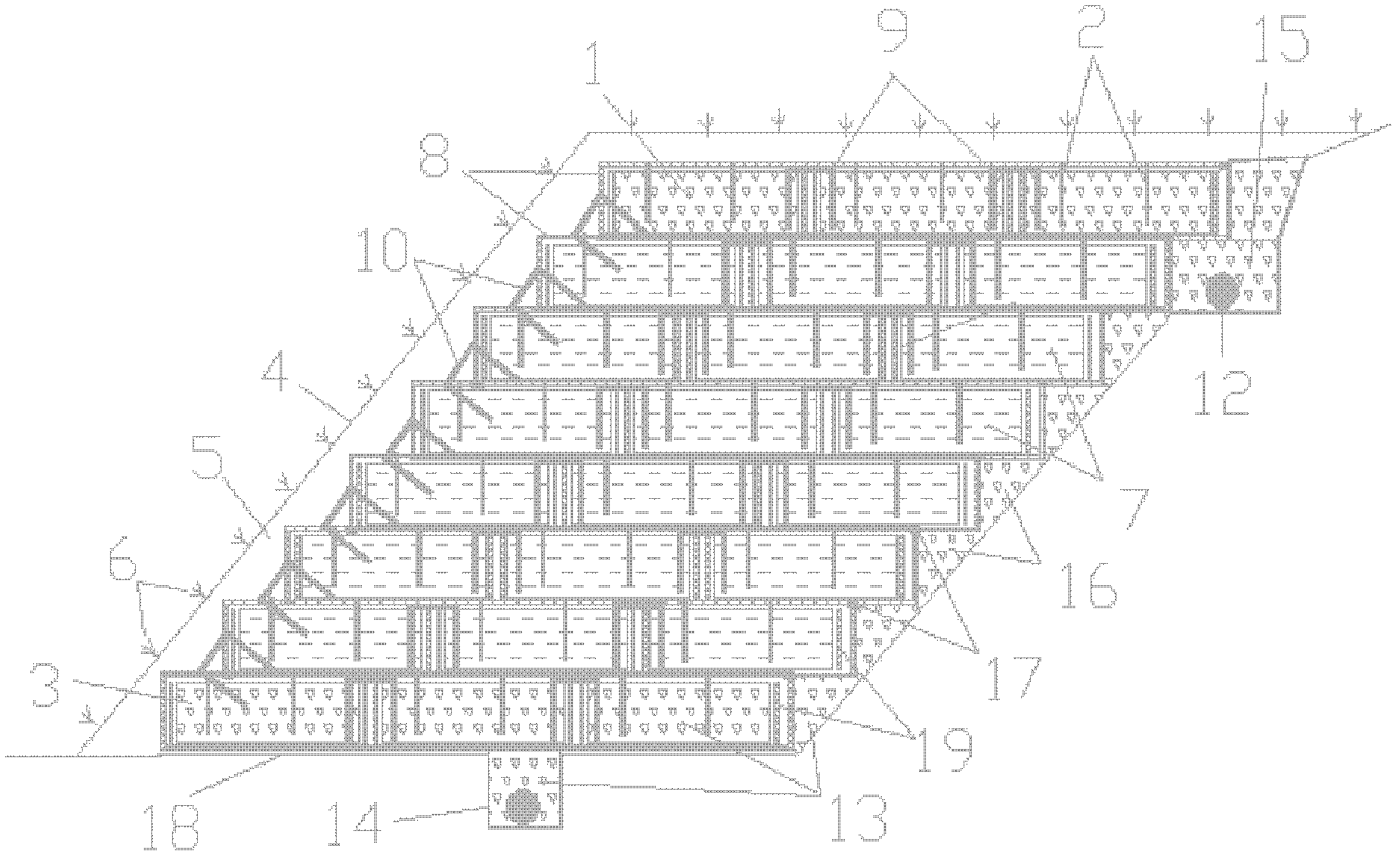

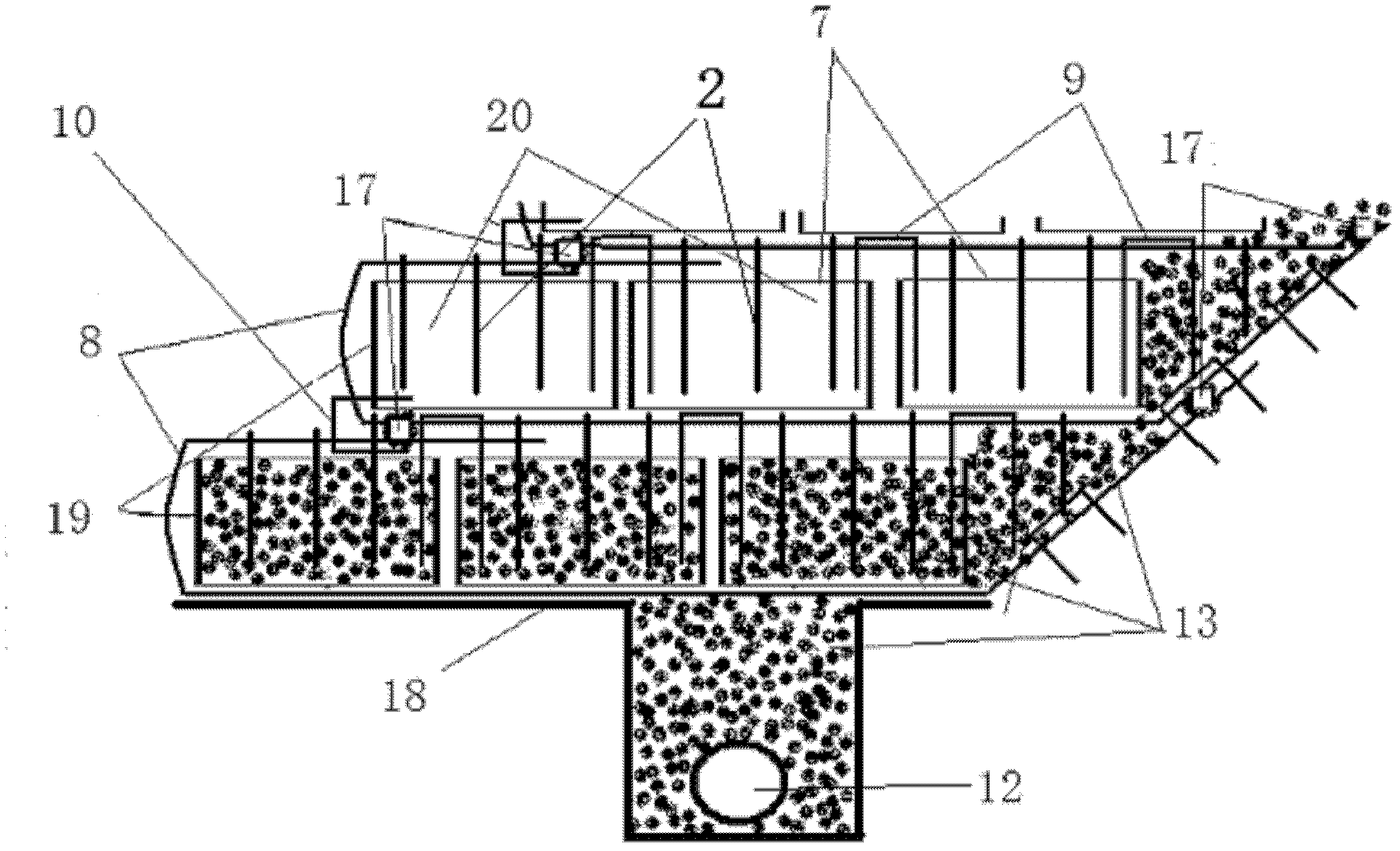

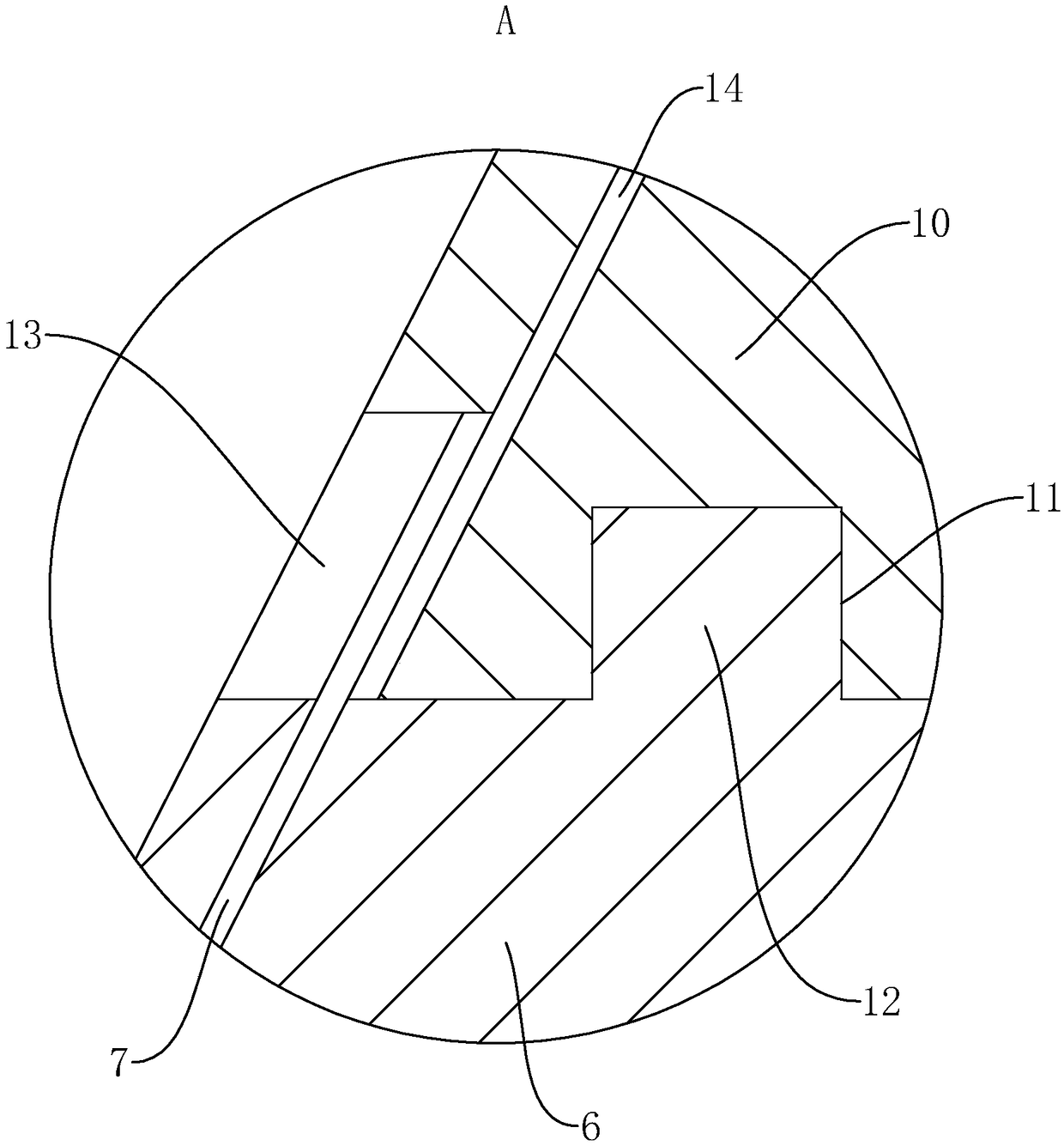

Pre-compacted reinforced soil block flexible supporting structure

ActiveCN102561368AAvoid molding qualityAvoid blocking trafficProtective foundationExcavationsSoil aggregateCrushed stone

The invention discloses a pre-compacted reinforced soil block flexible supporting structure, wherein the intermediate course is a layered integral body formed by wrapping plural horizontal annular reinforced pre-compacted soil blocks (7) with vertical annular geogrids (8) at each layer and connecting by a nail, soil aggregate (13) is filled between the horizontal annular reinforced pre-compacted soil block (7) at the inner side and a side slope to form an inner side drainage layer (16), the vertical annular geogrids (8) at two layers are connected through a connection rod (17), the horizontal annular reinforced pre-compacted soil blocks (7) at each layer are connected with each other via a nail (9), and the pre-compacted horizontal annular wrapped reinforced soil block in a bottom water permeable layer (3) and a slope top water permeable layer (1) is formed by filling soil aggregate (13) in a horizontal annular geogrid (19) and compacting on field. The invention is suitable for rapid repair of water damaged or collapsing road slope of expansive soil, red clay and red sandstone, and has low application cost, no road occupation in construction, convenient process and fast construction speed.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for preparing low-radioactivity radiating red mud ceramic material by using self-releasing glaze

InactiveCN101805208AReduce radioactive radiationReduce radioactive radiation doseRed mudRoom temperature

The invention discloses a method for preparing a low-radioactivity radiating red mud ceramic material by using a self-releasing glaze, which comprises the following steps of: (1) taking the following raw materials in percentage by mass: 20 to 70 percent of red mud, 20 to 70 percent of red sandstone, 2 to 10 percent of plasticizing agent, and 1 to 25 percent of one or two of compounds of barium, boron and lead; (2) putting the raw materials in the step (1) into a ball mill to perform ball milling and mixing for 12 to 36 hours; (3) drying a material obtained in the step (2) for 3 to 24 hours at the temperature of between 50 and 120 DEG C; (4) performing press forming or plastic forming on a material obtained in the step (3) to prepare a body; and (5) sintering the body obtained in the step (4) for 0.5 to 6 hours at the temperature of between 900 and 1,350 DEG C, and cooling the sintered body to the room temperature to obtain a finished product. The method has a wide range of raw material sources and an extremely low cost, and uses a coating of the self-releasing glaze so that the radioactive radiation of the red mud is greatly reduced.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

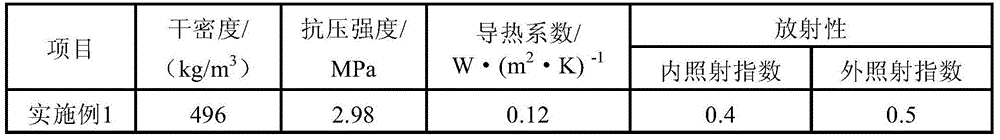

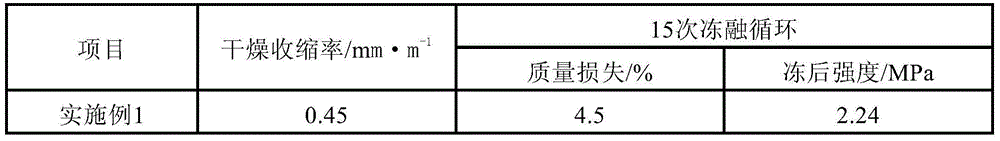

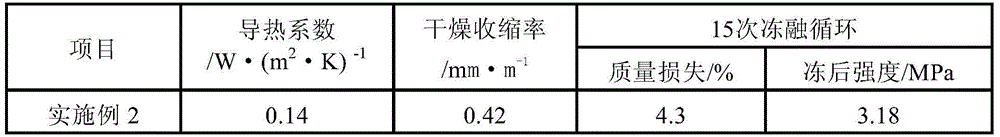

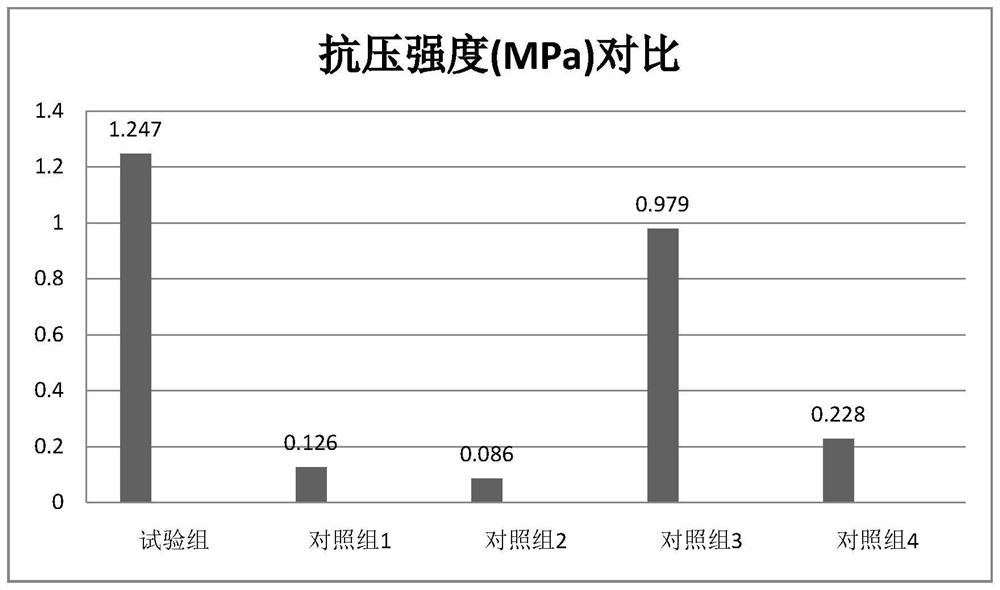

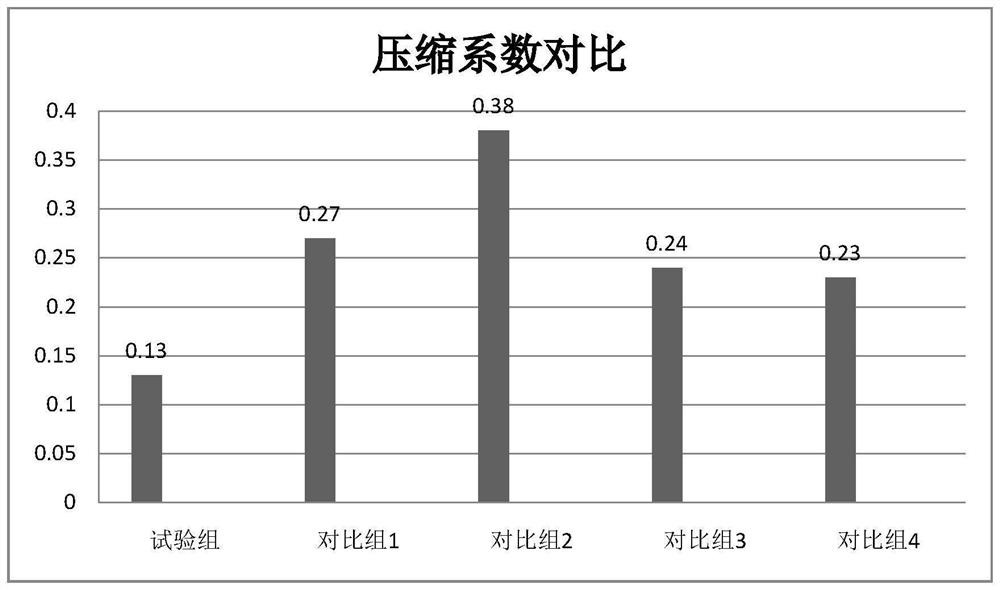

Red sandstone aerated concrete and preparation method thereof

The invention belongs to the field of building materials. A red sandstone aerated concrete is characterized by being prepared from dry materials and water, and the ratio of water to material is 0.50-0.64. The dry materials include, by weight, 8%-15% of cement, 50%-75% of red sandstone, 10%-20% of lime, 1%-5% of gypsum, 0.5%-3% of metakaolin, 0%-3% of calcined hydrotalcite, 0.02%-0.15% of aluminum powder paste, 0.2%-5% of water glass and 0.05%-2% of a modifier, wherein the water glass is calculated by the solid content, and the ratio of water to material calculates the water contained in the water glass. The invention utilizes the red sandstone to prepare the energy-saving insulation wall material in line with the standard requirements, improves utilization of red sandstone, and eases the problem of shortage of river sand resources.

Owner:HUBEI PROVINCIAL CENT FOR QUALITY SUPERVISION AD TEST OF CONSTR ENG

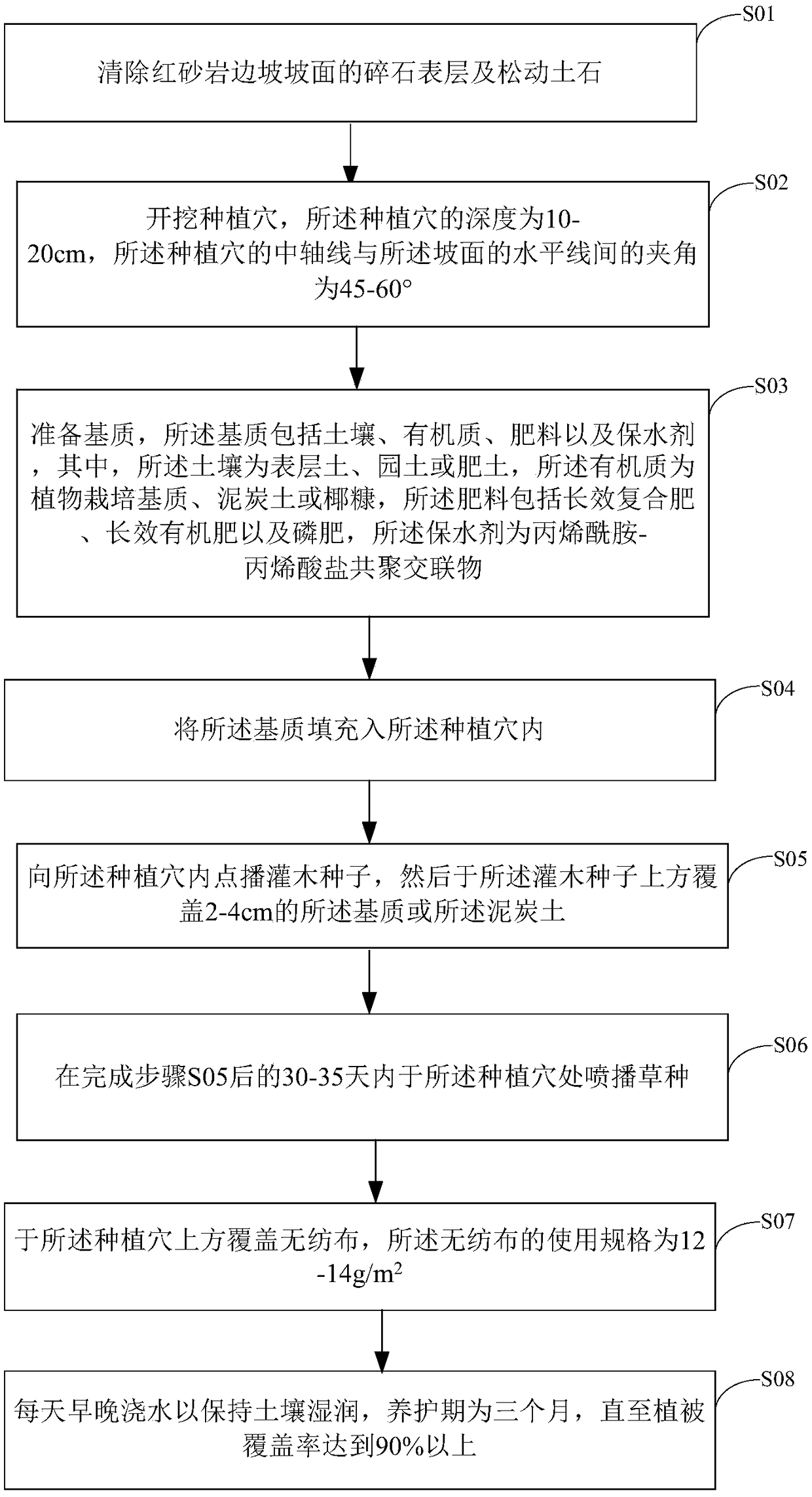

Method for rapidly realizing re-greening of red sandstone slope

InactiveCN108967020AKeep moistSolve the problem of poor water retentionGrowth substratesCulture mediaMoisturePlant growth

The application provides a method for rapidly realizing re-greening of a red sandstone slope. The method comprises steps of slope cleaning, excavation of planting holes, base material filling in planting holes, spaced sowing of bushes, grass seed spraying, non-woven fabric covering and maintenance management. Planting holes are dug in the surface of a red sandstone slope and thus water storage containers are installed at the slope surface similarly, so that moisture and nutrients that are need for long-time plant growing are kept in the base material and thus a problem of the poor water retention effect of the weathering or semi-weathering red sandstone slope is solved. The base material is a plant cultivation base material that is produced based on a scientific proportion after fermentation of agricultural and forestry wastes and contains lots of beneficial microorganisms; and since the base material contains lots of humic acid and beneficial microorganisms capable of realizing soil degradation, the speed of weathering of the red sandstone into soil is increased and minerals and nutrients absorbed by the roots of the plants are released, so that problems that the red sandstone soil is impoverished, the weathering speed is fast, and the own minerals can not be absorbed by the plant and the like are solved.

Owner:HUNAN XIANGZHI LANDSCAPE GARDEN TECH

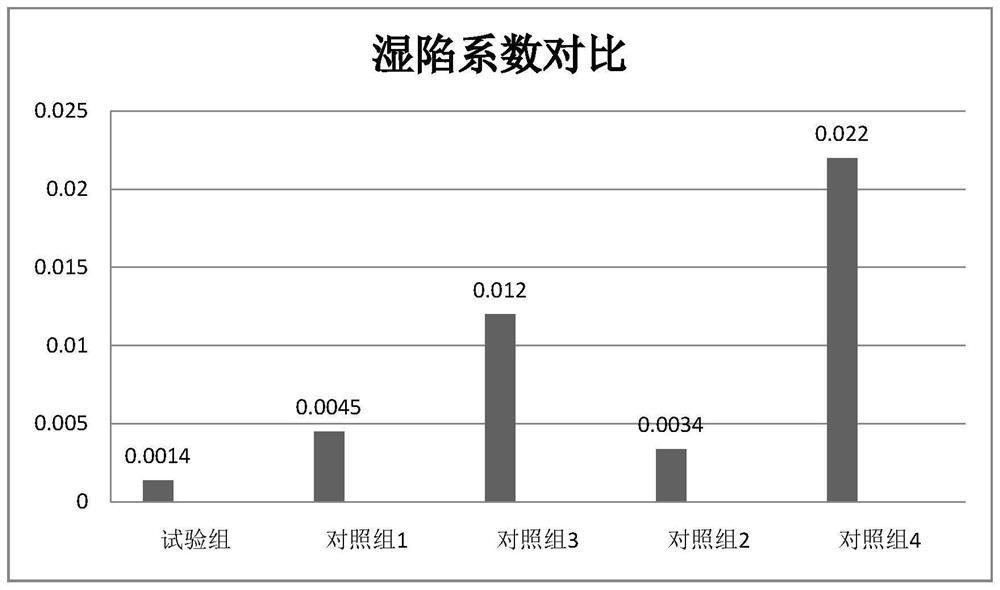

Collapsible loess aggregate filling material

PendingCN113636809AAggregate material selection is convenientEasy material selectionSoil scienceFirming agent

The invention discloses a collapsible loess aggregate filling material, which is formed by jointly mixing aggregate, a curing agent, an additive and water, and the aggregate contains collapsible loess. The mixed filling material with the collapsible loess as the main body is provided by combining the raw materials such as the collapsible loess and the red sandstone which are common in northwest regions, and the mixed filling material is weak in shrinkage performance, low in consolidation settlement, free of collapsibility, low in permeability, capable of meeting the strength requirement and low in price in the backfilling process.

Owner:甘肃西部岩土工程有限责任公司 +1

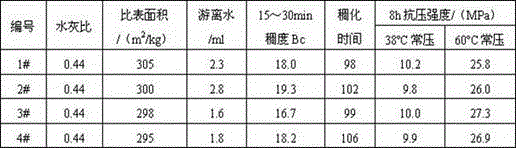

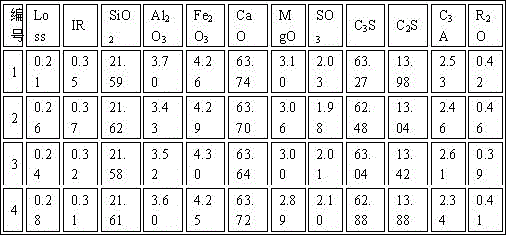

Method for preparing high-early-strength oil well cement from industrial waste residue

InactiveCN105800970AShort setting timeHigh compressive strengthCement productionSlagCompressive strength

The invention discloses high-early-strength oil well cement. The raw high-early-strength oil well cement is prepared from the following raw materials in percentage by mass: 60-75% of limestone, 10-15% of red sandstone, 3-6% of phosphorus slag, 4-7% of steel slag and 15% of calcium added slag. The oil well cement disclosed by the invention has the characteristics of short setting time at low temperature, high compressive strength, minimum inflation, and the like, and is in good compatibility with additives; moreover, the dosage of additives can be reduced while the well cementation conditions are met, the site operation is simple, and the well cementation quality is good.

Owner:GEZHOUBA SONGZI CEMENT

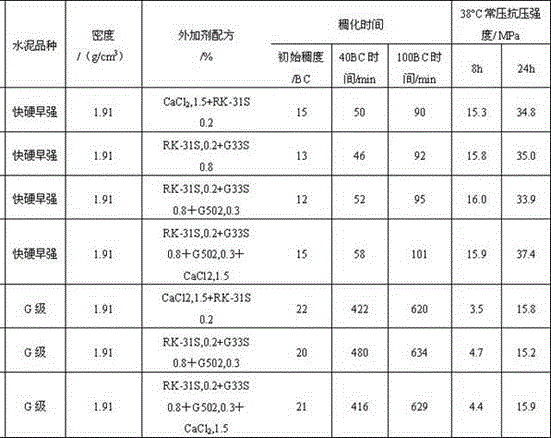

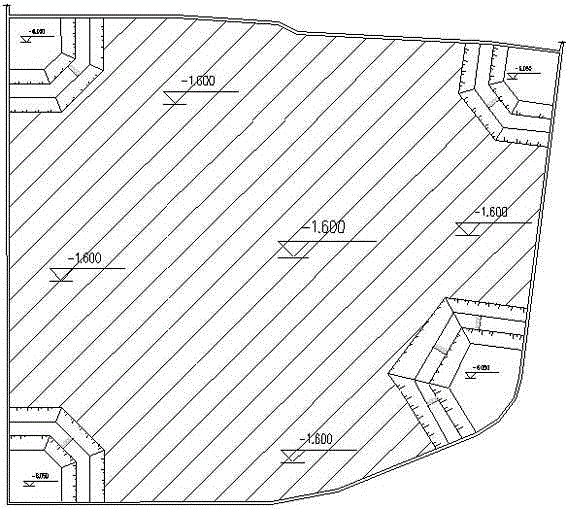

Construction method of watery red sandstone geological underground water level control

ActiveCN104762982AReduce intensityReduce disturbanceFoundation engineeringVacuum pumpWatertable control

The invention provides a construction method of watery red sandstone geological underground water level control. The construction method is characterized by comprising the following steps: 1) construction preparation; 2) deepening design and optimization of a light well point precipitation scheme; 3) installation of a plurality of light well point precipitation devices; 4) running of a vacuum pump, debugging and pumping, and pumping running; 5) layered earthwork excavation and layered precipitation; 6) reducing a cushion layer by several times, reducing a branch pipe and re-debugging the pumping; 7) closing the cushion layer, and continuously precipitating; 8) stopping precipitation of light well point precipitation devices. Specific to the characteristics of high underground water level and big water content of red sand rock, the construction method can well control the excavation depth of every layer in case of softened red sand rock, reduced intensity and disintegrated earthwork for the seepage of underground water since the precipitation is not timely.

Owner:NO 1 CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU CO LTD +1

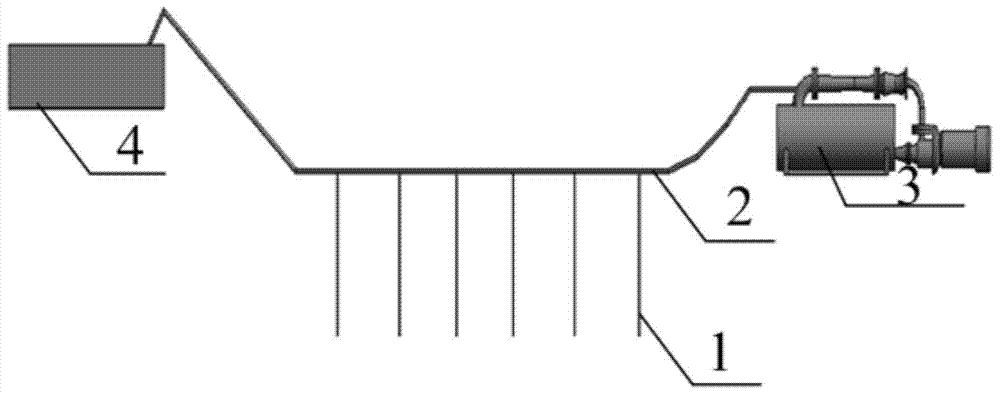

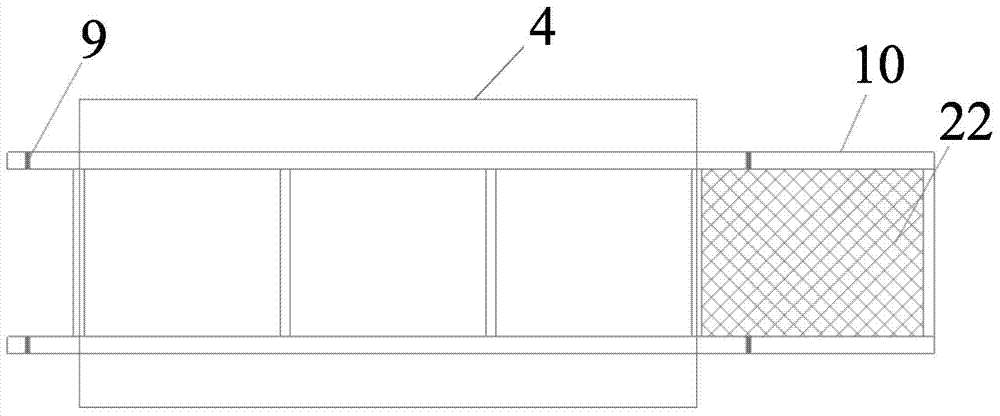

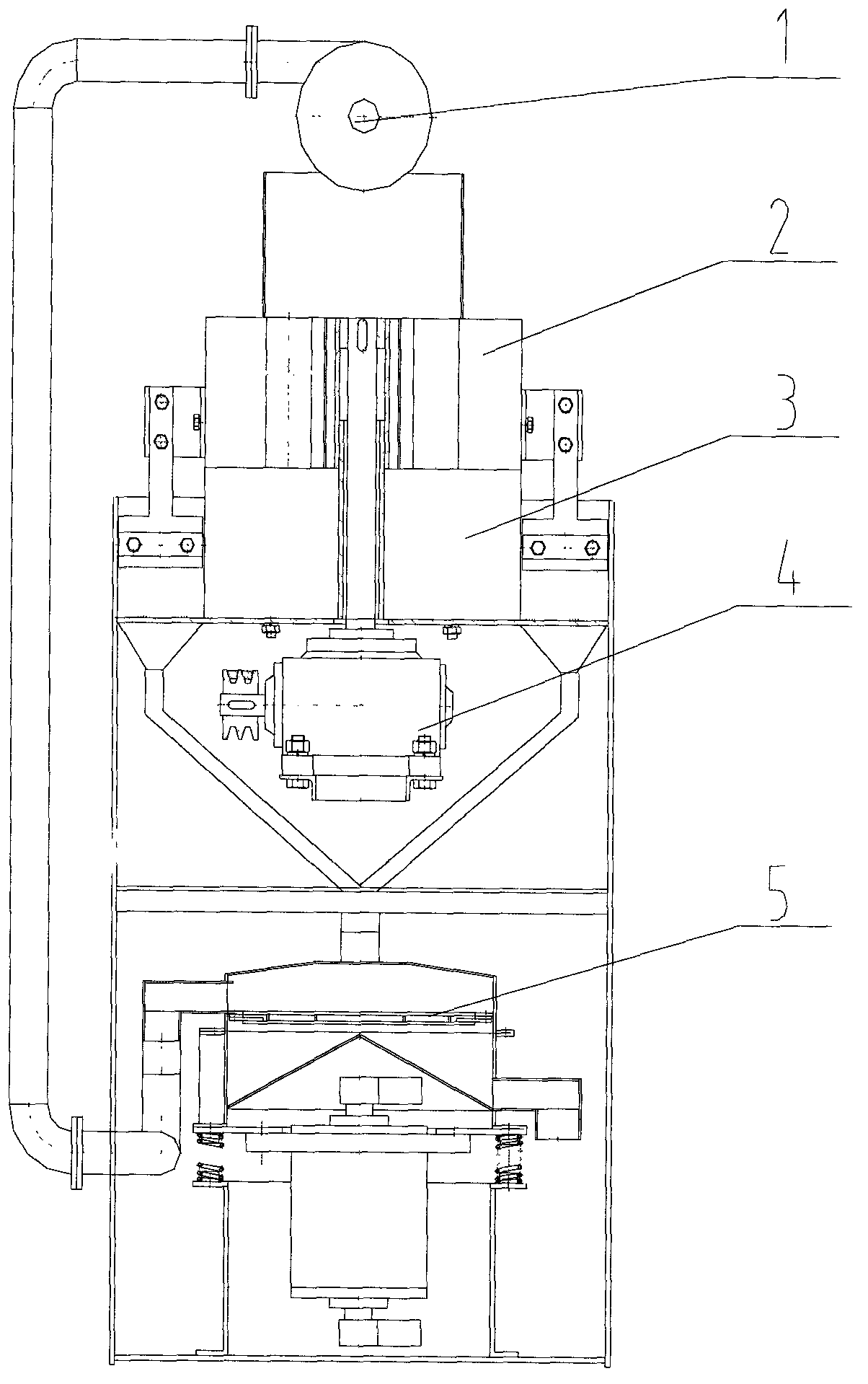

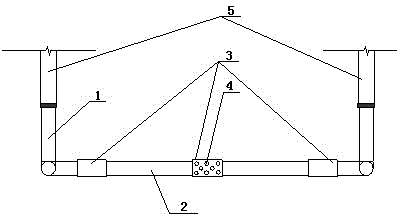

Milling method for small automatic feeding experiment with automatic stone mill

InactiveCN103447115ASolve accurate calculationImprove grinding effectCocoaGrain treatmentsEngineeringOrganic glass

The invention provides a milling method for a small automatic feeding experiment with an automatic stone mill. The method comprises following steps: (1) material feeding, choosing high-quality materials, transporting the materials into a material feeding hopper by utilizing a horizontal material unloading device 1, wherein the material feeding hopper is prepared from organic glass, and thus the preparation process can be observed clearly; (2) grinding, grinding the materials by utilizing threads between an upper stone mill moving disc 2 and a lower stone mill static disc 3, wherein the upper stone mill moving disc 2 and the lower stone mill static disc 3 are prepared from natural red sandstone by forging, making the product more environment-friendly, fresher, more delicious, and better taste; (3) stone mill transmission device: driving the upper stone mill moving disc 2 to rotate by utilizing a combined transmission device 4, the combined transmission device 4 being composed of turbines and worms; (4) sieving device: transporting the grinded materials into a vibration sieve 5 through a transportation pipeline to carry out the separation of wrapper and powder. The method mentioned above can provide precise experiment data for calculation, has a good grinding effect, reduces the using cost, and improves the work efficiency, and besides the product is environment-friendly, fresh, and delicious.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

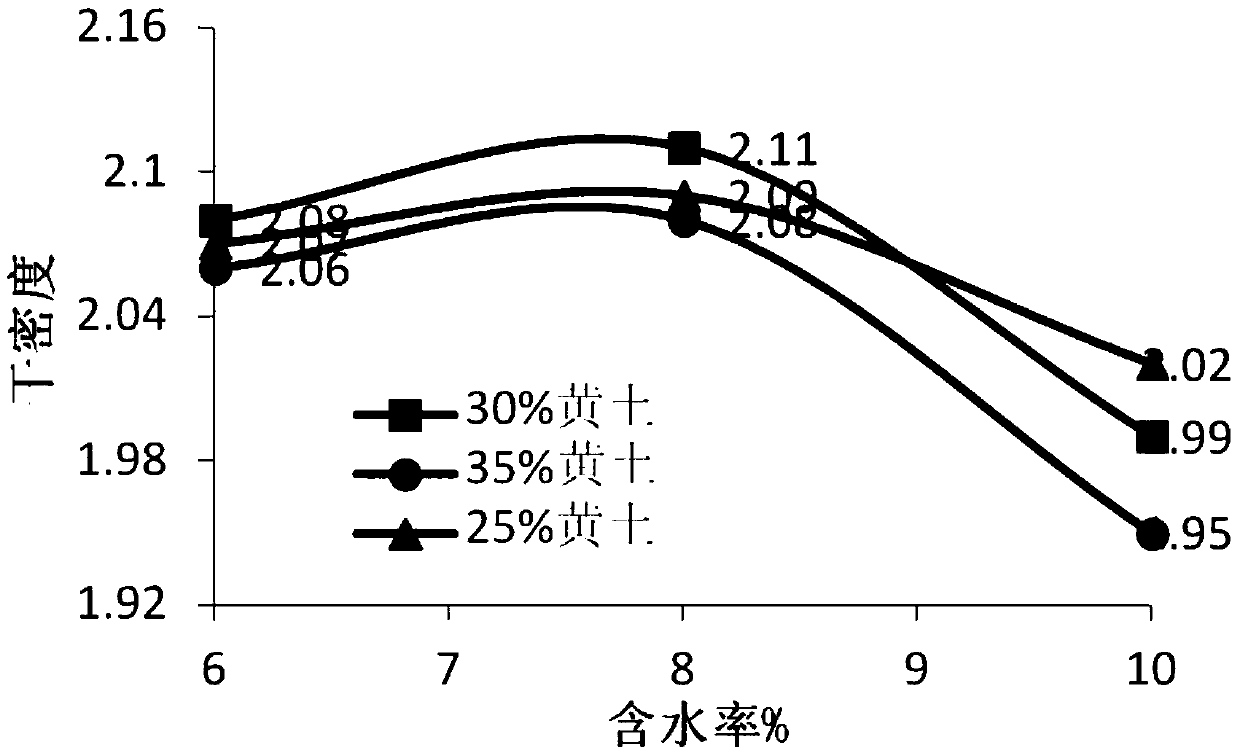

Roadbed filling material using red sandstone and production method thereof

The invention relates to a roadbed filling material using red sandstone and a production method thereof. The roadbed filling material is prepared from the following raw materials in percentage by mass: 25 to 35 percent loess and the balance of the red sandstone, wherein the water content of the roadbed filling material is 6 to 10 percent. The corresponding production method comprises the followingsteps of weighing the loess and the red sandstone according to a mixing proportion; sufficiently rolling and crushing the red sandstone, then uniformly mixing with the loess, and measuring the watercontent of a mixed material; with reference to a relationship between the water content and a preset water content range, taking a sun-curing and air-drying or water sprinkling treatment measure to enable the water content of the mixed material to be in the preset water content range, so that the roadbed filling material is obtained. According to the roadbed filling material, the red sandstone isimproved by adopting the loess to enable the roadbed filling material to become a high-quality filling material which is up to a roadbed filling standard; the roadbed filling material is high in maximum dry density, good in compaction effect and further low in engineering cost; the characteristic that the red sandstone is poor in engineering property is effectively overcome; making waste profitable is realized for the red sandstone and the roadbed filling material has enormous economic benefit and the significance of protecting an ecological environment.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

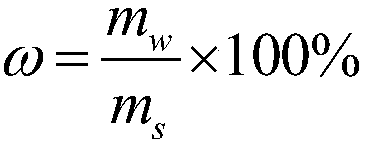

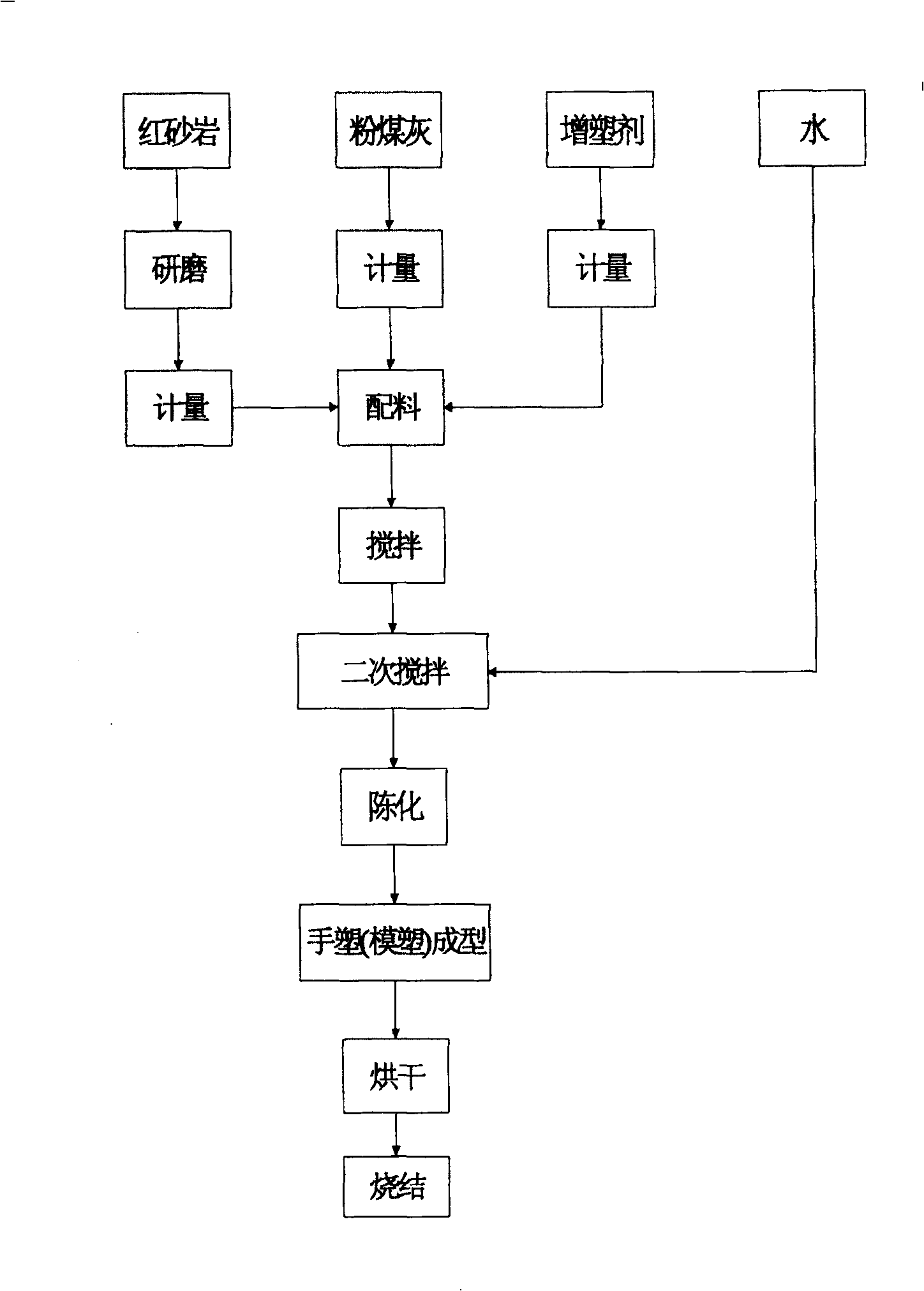

Building bricks sintered from fly ash and red sandstone, and preparation technique

InactiveCN1958508ALarge displacementProne to subsidenceCeramic materials productionClaywaresSodium BentoniteBrick

This invention discloses a method for preparing construction bricks by sintering fly ashes and red sandstone. The raw materials comprise: fly ashes, red sandstone, plasticizer (kaolin or bentonite), and water at a weight ratio of (50-60) :( 40-50) :( 1-5) :( 18-30). The fly ashes are the mass fly ashes from fluidized bed furnace and piled on the material field. The red sandstone is from waste roadbed materials or lost natural resources in mountain areas. The construction bricks can be used for bearing or non-bearing inner and outer walls. The method has such advantages as simple process, easy operation, high efficiency, low sintering temperature, low energy consumption, high performance and wide applications.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

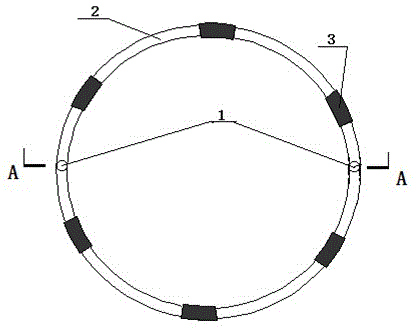

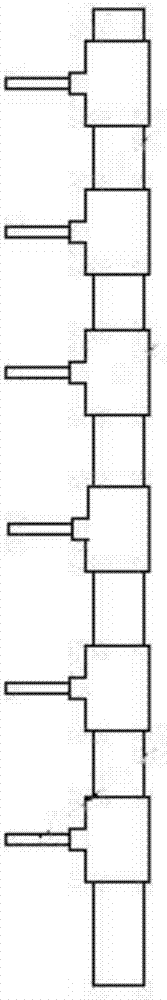

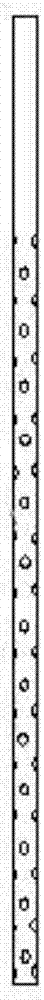

Annular post-grouting device for lower pile tips under sandstone geological conditions

InactiveCN103603356AEven distribution of groutSolve the problem of not being able to insertFoundation engineeringQuincunxEngineering

The invention relates to an annular post-grouting device for lower pile tips under sandstone geological conditions. The annular post-grouting device comprises a grouting device and grout. The annular post-grouting device is characterized in that the grouting device is an annular galvanized iron pipe, the outer diameter of the annular galvanized iron pipe is slightly smaller than the inner diameter of cast-in-place pile reinforcement cage, six groups of grouting holes which are annularly uniformly distributed are formed in the annular galvanized iron pipe, opening directions of four groups of grouting holes face the outside of a circle, opening directions of two groups of symmetrical grouting holes face the inside of the circle, and the grouting holes in each group are uniformly distributed on the annular galvanized iron pipe to form a quincunx. The annular post-grouting device has the advantages that the problem that a conventional grouting device cannot be inserted into hard strata under sandstone geological conditions can be solved, the grout can be uniformly distributed at the pile tips, effects of grouting partial pile sides and uniformly distributing the grout on the partial pile sides can be realized, the post-grouting construction efficiency for the pile tips under the red sandstone geological conditions can be improved, and the post-grouting quality and a post-grouting success rate can be guaranteed; the annular post-grouting device for the lower pile tips under the sandstone geological conditions can effectively adapt to the sandstone geological conditions, is simple in structure and brings convenience for construction.

Owner:SHANGHAI FOUND ENG GRP +1

Deep foundation pit excavation construction method adopted under pebble bed red sandstone geological condition

The invention relates to a deep foundation pit excavation construction method adopted under the pebble bed red sandstone geological condition. The method includes the specific steps that pre-rainfall is performed before foundation pit excavation, after an assigned depth is achieved through pre-rainfall, block separation and grooving excavation are performed till the elevation that the distance from the current position to the bottom of a capping beam is 1m is achieved, and the capping beam is constructed; while the capping beam is maintained, earthwork in a foundation pit is excavated downwards in sequence in a smashing mode from a first concrete circuit purlin bottom to a last concrete circuit purlin, each concrete circuit purlin bottom is supported by a supporting rod piece after being excavated, after the last concrete circuit purlin and the corresponding rod piece are completed, basin type excavation is performed till the foundation base elevation is achieved, and communicating cushion layers are poured in time. The method can meet the deep foundation pit excavation requirement under the pebble bed red sandstone geological condition, the technical problems that deep foundation pit excavation construction under the existing pebble bed red sandstone geological condition is difficult, cost is high and the construction period is long are solved, the foundation pit excavation speed is increased, safety in the excavation process is guaranteed, and the method has practical guiding significance.

Owner:SHANGHAI FOUND ENG GRP +1

Bridge joint ultrahigh crack-resistance concrete and preparation method thereof

The invention relates to bridge joint ultrahigh crack-resistance concrete and a preparation method thereof. The concrete is prepared from cement, silica fume, diatomite, slag powder, red sandstone powder, polycarboxylate water reducing agent, steel fibers, polyacrylonitrile fibers and water. The preparation method comprises the following steps: uniformly mixing and stirring the cement, the slag powder and the red sandstone powder, and obtaining a cement mixture; then mixing the silica fume, the diatomite, the steel fibers and the polyacrylonitrile fibers, uniformly stirring, and obtaining a silica fume mixture; dissolving the polycarboxylate water reducing agent in water, and obtaining an additive aqueous solution; adding half of the additive aqueous solution into the cement mixture, and uniformly stirring; adding the remaining additive aqueous solution into the silica fume mixture, and uniformly stirring; and finally uniformly stirring the obtained mixture. The concrete of the invention has excellent crack resistance and durability, the flexural crack resisting strength is greater than 40MPa, the breaking strength is greater than 10J / m<2>, the chlorine ion permeation resistance can reach grade RCM-V, and the pressure resisting strength is not less than 150MPa.

Owner:JIANGXI PROVINCIAL EXPRESSWAY INVESTMENT GRP CO LTD

Method for preparing lower-radioactivity radiating red mud ceramic material

The invention discloses a method for preparing a lower-radioactivity radiating red mud ceramic material, which comprises the following raw materials in percent by mass: 28-70 percent of red mud, 28-70 percent of red sandstone, 1-20 percent of barium compound or witherite and 1-10 percent of fluxing agent, wherein the fluxing agent is one or more of calcium fluoride, aluminum oxide, magnesium oxide, calcium oxide and silica. The method comprises the steps of: 1, placing the raw materials in a ball-milling device for ball-milling and mixing for 12-48h; 2, drying the raw materials obtained from the step 1 at a temperature of 60-120 DEG C for 6-24h; 3, pressing and forming or plastically forming the raw materials obtained from the step 2 to prepare a blank body; and 4, sintering the blank obtained from the step 3 at a temperature of 900-1300 DEG C for 1-5h, and cooling to the room temperature to prepare a finished product. The invention has the advantages of wide sources of the raw materials and extremely low cost, and is favorable for reducing the red mud radioactivity radiation dose by 30-45 percent to reach the natural radioactivity background level.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Red sandstone surface modified polyurethane material smeared in water level variation zone and preparation method thereof

InactiveCN111690108AImprove water resistanceImprove reinforcementFireproof paintsChloropene polymer coatingsPtru catalystSODIUM SILICATE SOLN

The invention relates to a red sandstone surface modified polyurethane material smeared in a water level variation zone and a preparation method thereof. The material comprises a component A and a component B, wherein the component A comprises a sodium silicate solution, a catalyst, a plasticizer and nano titanium dioxide; and the component B comprises diisocyanate (MDI), polypropylene glycol (PPG) and a waterproof agent. The material has the advantages of good reinforcing performance, no toxicity and the like of a traditional polyurethane reinforcing material, the water resistance of the material can be effectively improved by adding the waterproof agent, and the material is tightly attached to the surface of red sandstone for water isolation, so that the water environment is isolated, and degradation of the physical and mechanical properties of the red sandstone is inhibited; and finally, considering that the problems that red sandstone is subjected to a large amount of solar ultraviolet radiation for a long time in a dry season in a water level variation zone, water loss of the red sandstone is caused, the surface of the red sandstone falls off, the interior of the red sandstonecracks, and finally, the physical and mechanical properties of the red sandstone are deteriorated, the ageing resistance of the red sandstone can be effectively improved by adding the nano titanium dioxide.

Owner:HEFEI UNIV OF TECH

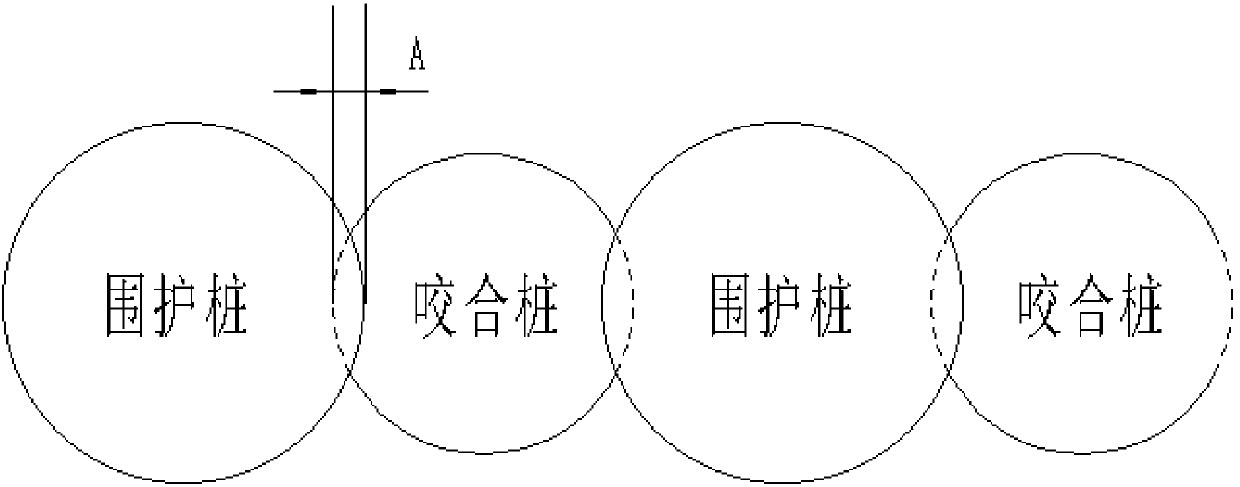

Secant pile of sand-gravel red sandstone composite stratum and construction method of secant pile

InactiveCN107842021AHole forming process is simpleLow hole forming costExcavationsBulkheads/pilesSlurry wallArchitectural engineering

The invention relates to the technical field of civil construction, in particular to a secant pile of a sand-gravel red sandstone composite stratum and a construction method of the secant pile. The problem of balance between the construction cost and the water stop effect during construction of a deep foundation pit enclosure structure of the sand-gravel red sandstone composite stratum currently is mainly solved. In a traditional method, delta-shaped piles and jet grouting piles are low in construction cost but poor in water stop effect, and underground diaphragm walls or traditional secant piles can guarantee the water stop effect but are high in construction cost. According to construction of the secant pile, coagulation hard occlusion is conducted by directly adopting a rotary digging drill to form a secant pile water stop curtain, and the construction cost is far lower than that of a traditional full casing secant pile technology; compared with the traditional construction technology, the construction progress is quick, the number of construction associated equipment is small, construction investment is small, and under the same condition, the steel bar pile hole-forming time of the secant pile is only 40% of that of the traditional full casing construction technology; and through verification of the scheme, the water stop effect of the secant pile can reach 95% or over that of the underground diaphragm walls or the traditional secant piles.

Owner:CHINA RAILWAY 21ST BUREAU GRP TRACK TRAFFIC ENG +1

Coolant capable of inhibiting anchor rod drill hole collapse in red sandstone zone

InactiveCN103627373AEnhanced inhibitory effectAvoid disintegrationDrilling compositionAlcoholAqueous solution

The invention discloses a coolant capable of inhibiting anchor rod drill hole collapse in a red sandstone zone. The formulation of the coolant is as follows: the concentrations of all materials in an aqueous solution are that the concentration of calcium ions is 0-0.8 mol / L, the volume fraction of ethyl alcohol is 8-10 percent, and the pH value is 10-14. The coolant capable of inhibiting anchor rod drill hole collapse in the red sandstone zone has a better inhibition effect on red sandstone collapse and is low in cost.

Owner:HUNAN UNIV

Construction method of water-rich red sandstone geological underground water level control

InactiveCN111206609AReduce disturbanceEnsure construction safetyFoundation engineeringMining engineeringWater level

The invention discloses a construction method of water-rich red sandstone geological underground water level control. According to the construction method of water-rich red sandstone geological underground water level control, layered excavation is adopted, a set of independent light well point dewatering equipment is arranged on the layer before each layer is excavated, and before the next layeris excavated, the water level of the water-rich red sandstone soil layer is lowered to below 1 meter of the excavated layer through the light well point dewatering equipment on the layer; and the steps are repeated till a foundation pit is excavated to 0.5 m above the designed elevation of a pit bottom, manual excavation is adopted, and the foundation pit is excavated manually to the designed elevation and leveled. According to the construction method, the underground water level of the red sandstone-rich construction area can be effectively controlled, the red sandstone is prevented from being disturbed by the disturbance intensity when encountering water, and meanwhile the construction efficiency is improved.

Owner:CHINA MCC17 GRP

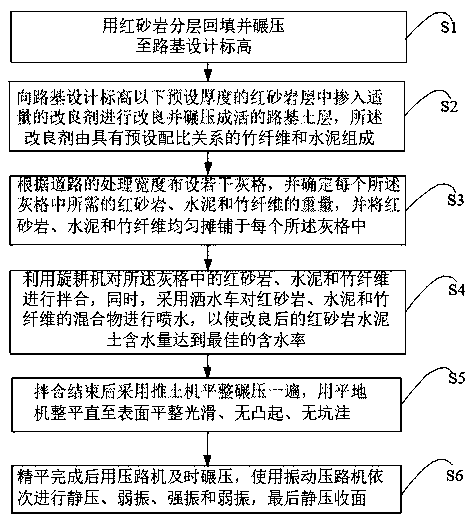

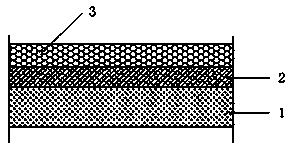

Red sandstone improved construction method

InactiveCN110528346AReduce the problem of dehydration and easy crackingReduce purchasesBuilding constructionsRoads maintainenceFiberSurface layer

The invention provides a red sandstone improved construction method. According to the main technical scheme, an appropriate amount of improver is mixed into a red sandstone layer with a preset thickness below the design elevation of a roadbed for improvement, and is compacted into a viable roadbed soil layer. The improver consists of bamboo fiber and cement in a preset ratio. In the method, bamboofiber is added to red sandstone to pull aggregate in the red sandstone, so that the problems that the red sandstone is easy to soften and disintegrate in water, and the red sandstone surface layer iseasy to crack due to water loss are reduced, the red sandstone material of the abandoned soil can meet the requirements of backfill soil of the roadbed to be reused after being improved, a virtuous cycle of soil resources is achieved, the excavation, transportation and disposal of the original earthwork, and the purchase of new materials are reduced when a road is built, the construction cost canbe greatly reduced, and pollution caused by soil disposal is avoided. In addition, the bamboo fiber and cement are used to improve the red sandstone of the abandoned soil, so that the amount of cement is greatly reduced, and costs are further reduced.

Owner:CHINA FIRST METALLURGICAL GROUP

Method for selecting red sand stone

The invention relates to the technical field of rock body selection, and in particular relates to a method for selecting a red sand stone, and the method comprises the following steps: 1) primarily screening and grading the red sand stone; 2) performing strong magnetic deliming and cleaning; 3) dissolving fluorosilicic acid, magnesium sulfate and light burning powder in water to prepare a soakingliquid, soaking the red sand stone in the soaking liquid, and then drying the red sand stone after picking up; 4) after the red sand stone is dried, spraying the red sand stone with a vegetable dye evenly until saturation, until the vegetable dye is absorbed by the red sand stone, further spraying the red sand stone with the vegetable dye for 2 to 3 times, and drying to obtain a selected red sandstone; wherein the vegetable dye is mainly prepared from safflower, rhus coriaria fruit, rose, trisiloxane polyoxyethylene ether, acetic acid and absolute ethanol. The method is simple in operation, can effectively strengthen the strength of the red sand stone, reduces the weathering erosion degree of the red sand stone, makes the red sand stone bright in color, improves the texture and visual effect of the red sand stone, thereby improving the quality and qualified utilization rate of the red sand stone.

Owner:AIR FORCE MEDICAL CENT PLA

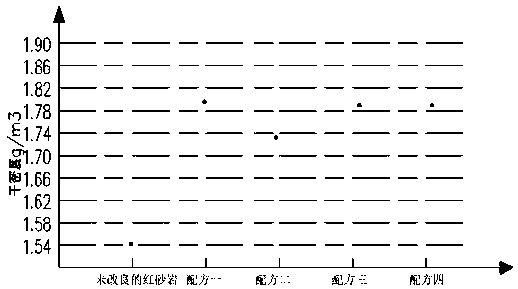

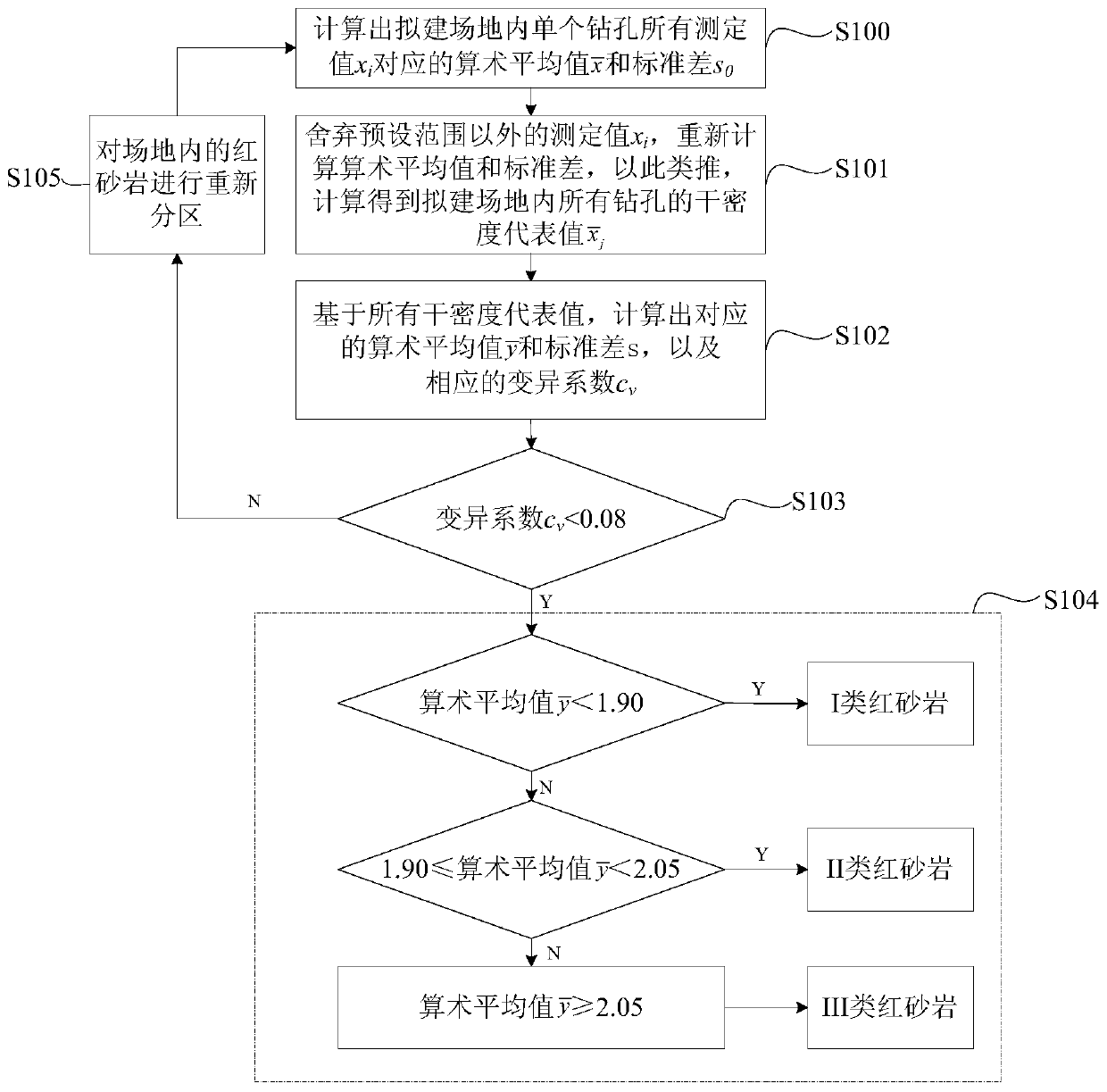

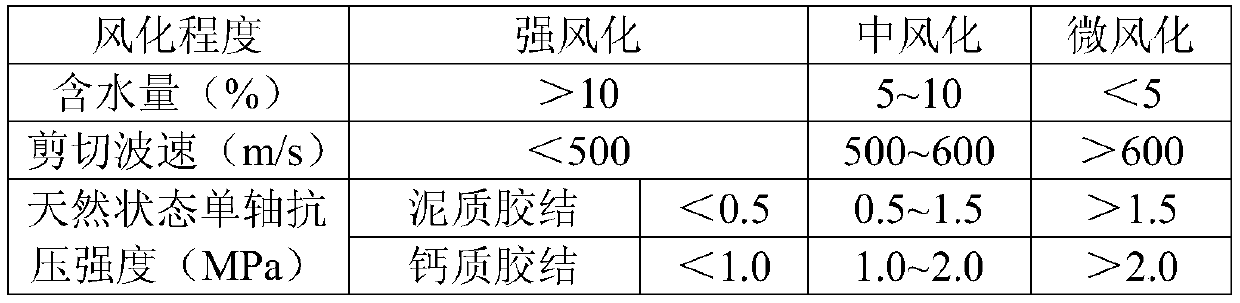

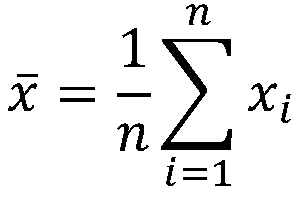

Classification method of Lanzhou red sandstone and selection method of corresponding engineering measures

ActiveCN110080197ADistinguish engineering characteristicsImprove scientific rationaleExcavationsIn situ soil foundationSupporting systemClassification methods

The invention relates to a classification method of Lanzhou red sandstone and a selection method of corresponding engineering measures. It is assumed that all dry density measured values of a single drill hole in the planned construction site are xi, dry density representative values of all the drill holes in the planned construction site are obtained after a series of operations, and red sandstone types are divided into three types I, II and III according to corresponding arithmetic mean values and variable coefficient cv values. The classification method based on the red sandstone diagenesisand with the dry density as the classification index is creatively provided, the engineering characteristics of red sandstone can be better distinguished, and the scientific rationality of red sandstone classification is improved. According to the method, the water permeability of the red sandstone and the field characteristics of the red sandstone of different types are redefined, different supporting systems and underground water control measure suggestions are provided for the red sandstone of different types, and therefore the key technical problems of water gushing and sand gushing of the Lanzhou red sandstone stratum deep foundation pit are solved, rapid excavation is achieved, and safety, reliability, economy and reasonableness are achieved.

Owner:BEIJING URBAN CONSTR EXPLORATION & SURVEYING DESIGN RES INST

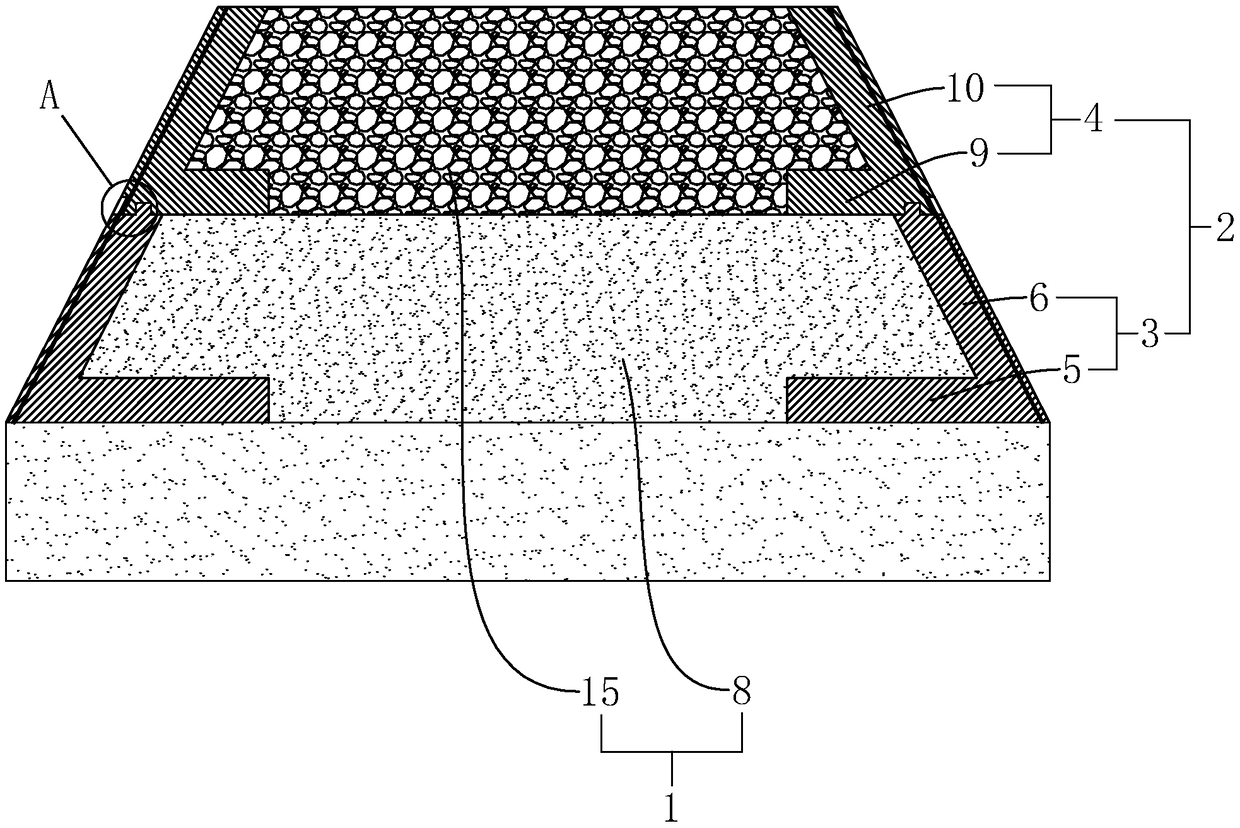

Red sandstone roadbed and construction method thereof

The invention relates to the technical field of road construction, in particular to a red sandstone roadbed and a construction method thereof. The red sandstone roadbed comprises a matrix and side slope modules located on two sides of the matrix, wherein the side slope modules comprise bottom layer modules and top layer modules; each bottom layer module comprises two bottom layer plates and bottomlayer side plates located on the deviating sides of the two bottom layer plates and extending upwards; bottom layer waterproof cloth disposed along a vertical direction is embedded in the bottom layer side plates; the top layer modules comprise top layer plates and top layer side plates located on the deviating sides of the two top layer plates and extending upwards; and top layer waterproof cloth disposed along the vertical direction is embedded in the top layer side plates. The matrix is reinforced by arranging the side slope modules on two sides of the matrix, so that the matrix is more stable. The bottom layer waterproof cloth and the top layer waterproof cloth are respectively arranged in the bottom layer side plates and the top layer side plates to enable the bottom layer modules and the top layer modules to play the waterproof effect, so as to avoid pavement settlement caused by disintegration of red sandstones as rainwater seeps into and enters the red sandstones.

Owner:安徽恒通交通工程有限公司

Building bricks sintered from fly ash and red sandstone, and preparation technique

InactiveCN100457674CLarge displacementProne to subsidenceCeramic materials productionClaywaresSodium BentoniteBrick

This invention discloses a method for preparing construction bricks by sintering fly ashes and red sandstone. The raw materials comprise: fly ashes, red sandstone, plasticizer (kaolin or bentonite), and water at a weight ratio of (50-60) :( 40-50) :( 1-5) :( 18-30). The fly ashes are the mass fly ashes from fluidized bed furnace and piled on the material field. The red sandstone is from waste roadbed materials or lost natural resources in mountain areas. The construction bricks can be used for bearing or non-bearing inner and outer walls. The method has such advantages as simple process, easy operation, high efficiency, low sintering temperature, low energy consumption, high performance and wide applications.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Mildtype well point dewatering construction method of deep foundation pit of red sandstone stratum

InactiveCN107975055AImprove precipitation effectImprove construction progressFoundation engineeringRebarRed sandstone

The invention relates to the technical field of civil engineering construction, and in particular relates to a mildtype well point dewatering construction method of a deep foundation pit of a red sandstone stratum. The method is particularly suitable for dewatering construction in construction of a deep foundation pit support structure of the red sandstone stratum. By arranging single wells of different depths in the foundation pit in a step manner in depth, the depths and quantity of the single wells are determined according to displacement of the foundation pit. Compared with a conventionalconstruction process, the mildtype well point dewatering construction method has the advantages that the dewatering effect can obviously accelerate the construction progress, construction matched equipment is few and construction input is low. The hole forming time of a reinforcing steel bar pile in the process is only 40% of that of a conventional full sleeve construction process in similar conditions. The water stopping effect of the method can improve the dewatering effect by 95% or above through verification.

Owner:CHINA RAILWAY 21ST BUREAU GRP TRACK TRAFFIC ENG +1

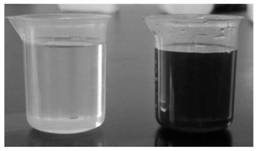

A method of inhibiting the disintegration of red sandstone

ActiveCN106675530BReduce concentrationEasy to getWithdrawing sample devicesDrilling compositionSURFACTANT BLENDChemistry

The invention discloses a method for inhibiting red sandstone from disintegration when contacting water during core-drilling sampling. In the core-drilling sampling, an anionic surfactant is added into the flushing fluid. The weight percent of the anionic surfactant effective component in the flushing fluid is not lower than 10%, and the optimum concentration is 10-20%. The method can effectively inhibit the red sandstone from disintegration when contacting water in the core drilling process, and is low in cost.

Owner:刘子儒

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com