Patents

Literature

37results about How to "Avoid molding quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

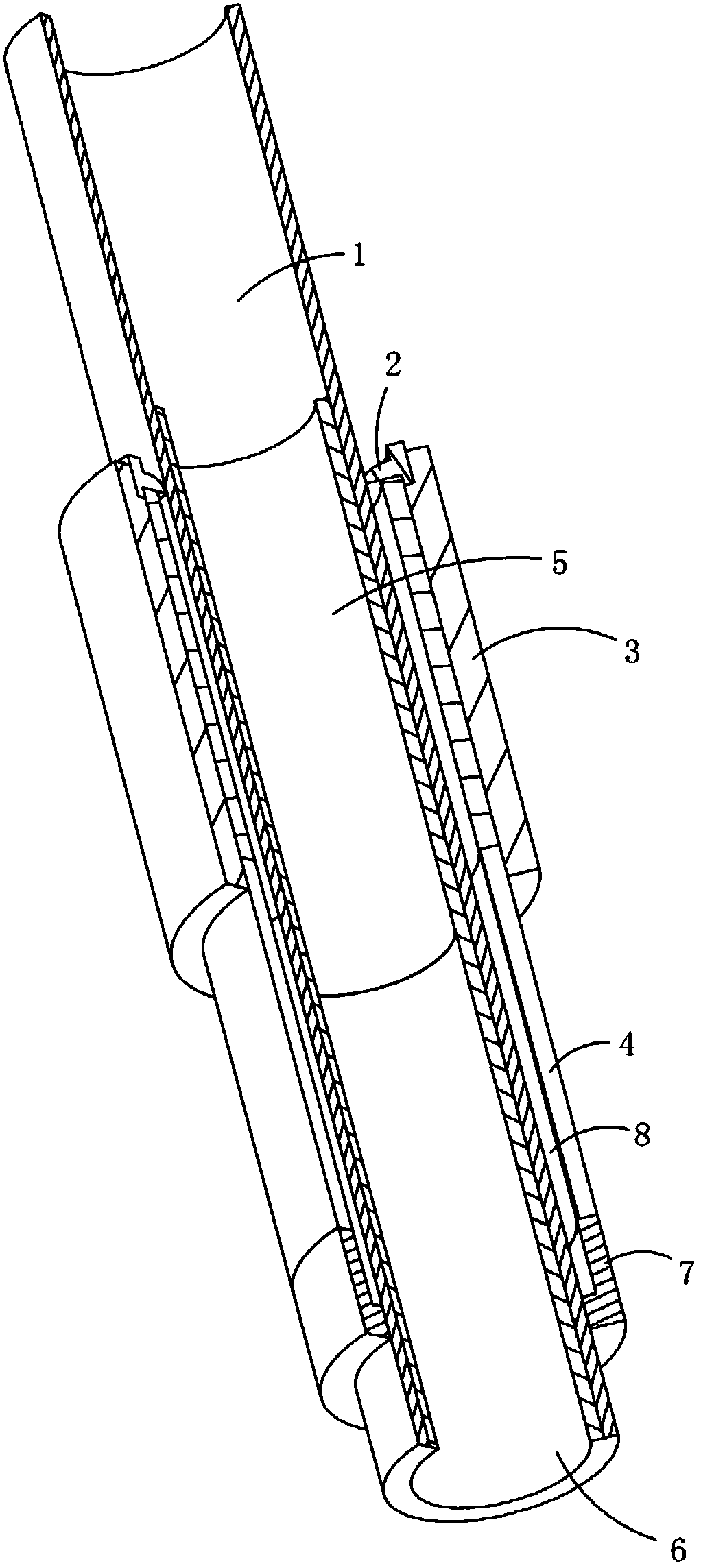

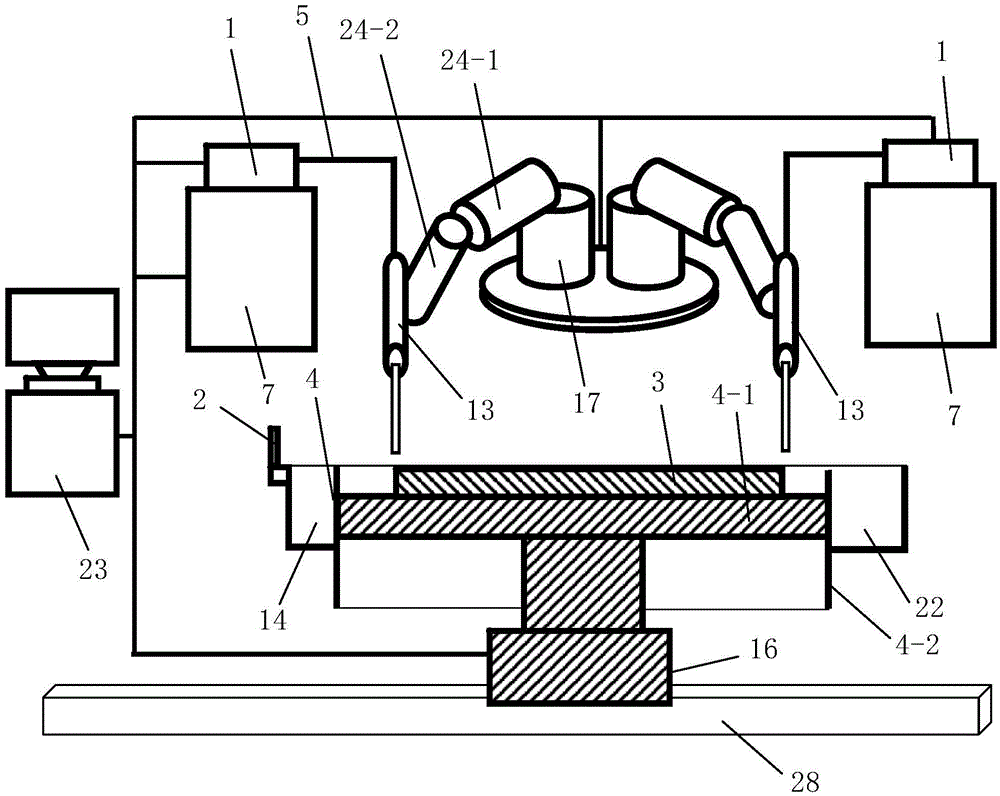

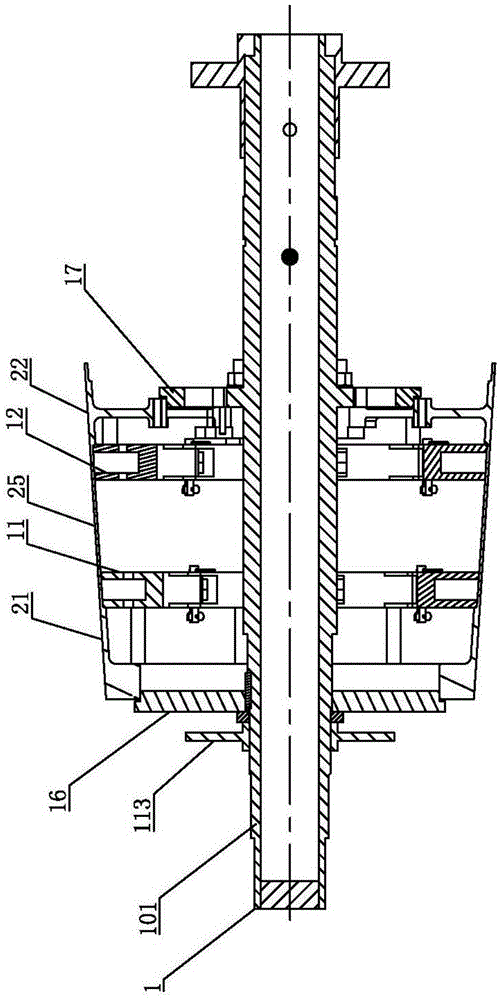

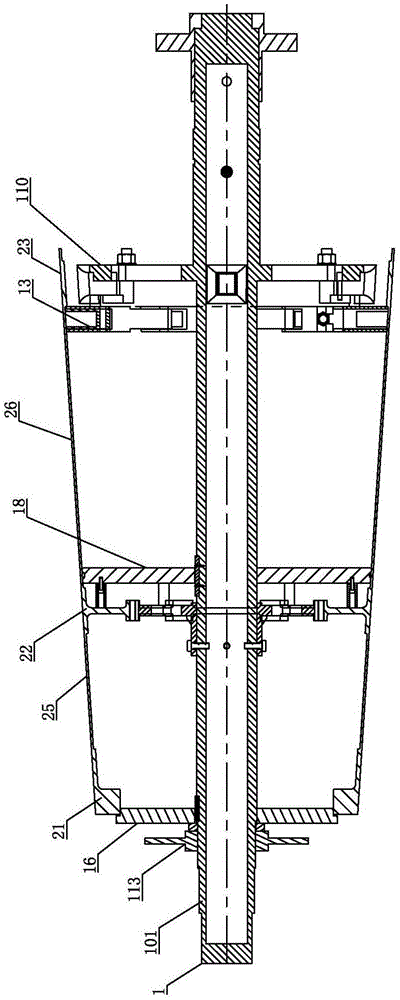

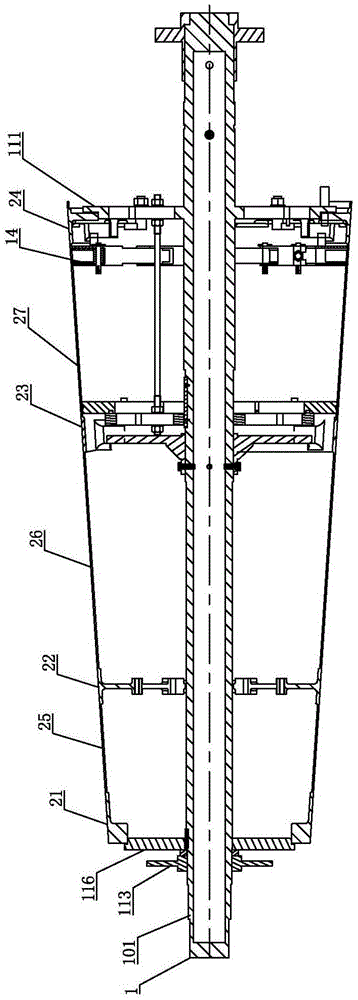

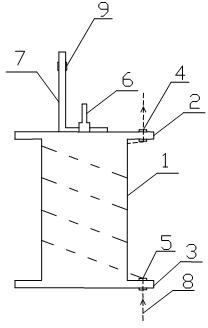

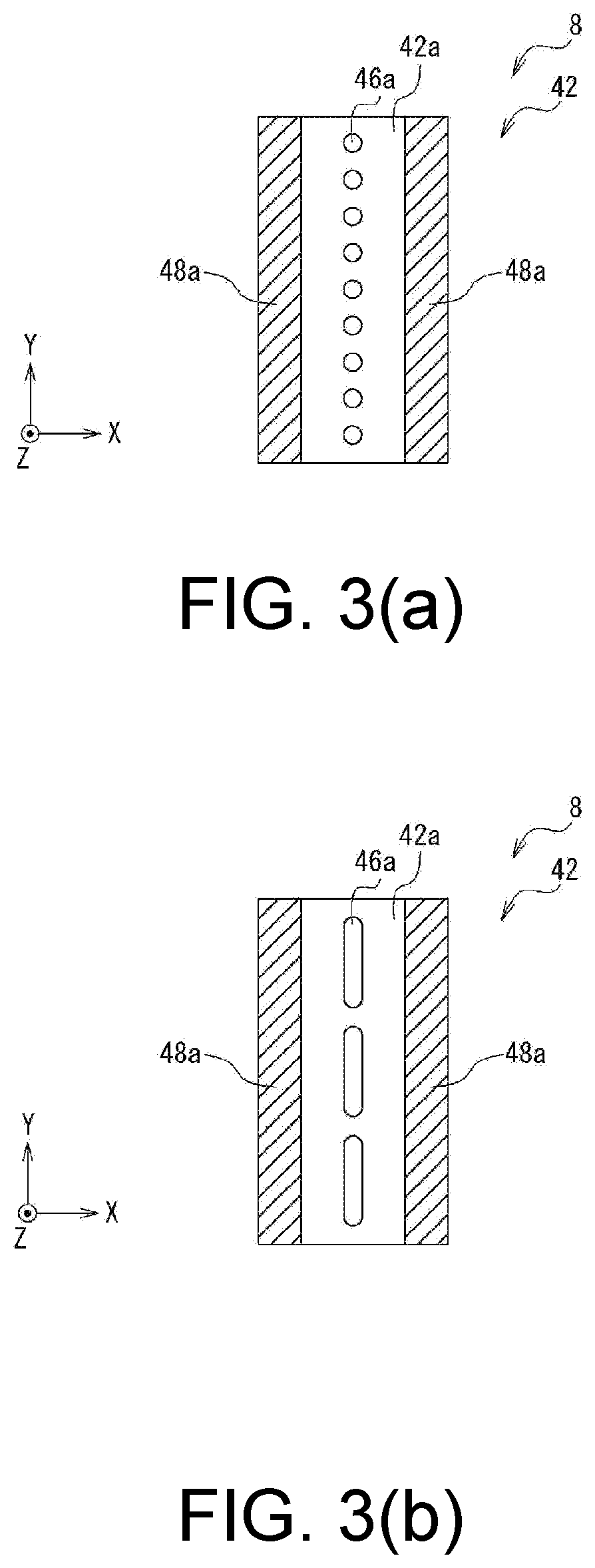

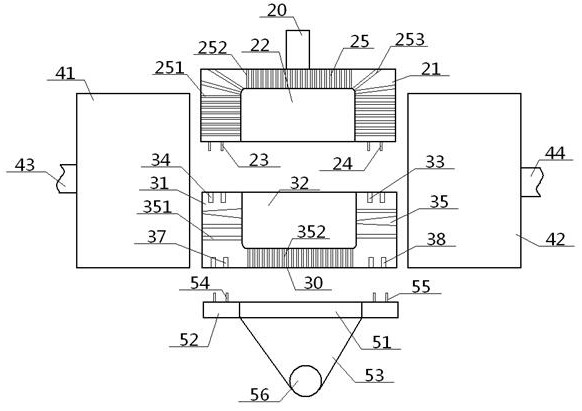

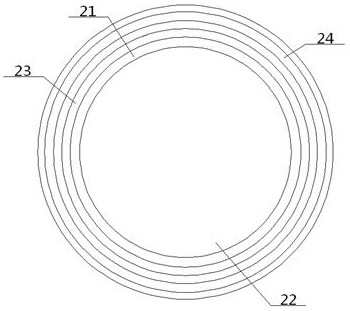

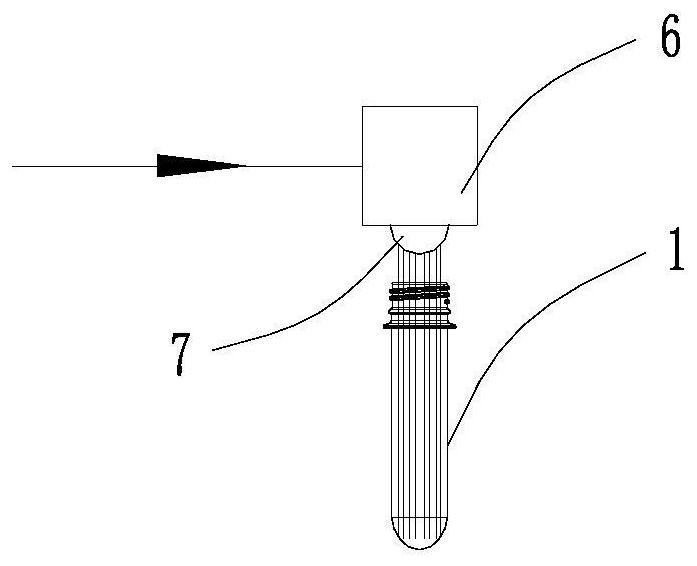

Sectional binding apparatus and sectional binding method for rotary targets

PendingCN108677151AReduce the number of configurationsSimple structureVacuum evaporation coatingSputtering coatingMetalMaterials science

According to the present invention, through the positioning matching of the external heating device and the internal heating device, the multiple sections of the metal layer casting spaces are sequentially formed on the back surface of the back pipe, the multiple sections of the metal layers are sequentially casted on the back surface of the back pipe, and the two adjacent metal layers are connected to form the integration; and with the apparatus and the method, the back pipe molding metal layers with any lengths can be produced, the structure is simple, the number of the heating elements andthe number of various detection elements can be reduced, the adjusting is flexible according to the material of the metal layer, the binding welding rate is improved, the welding quality is improved,the deformation is reduced, the rotary targets with different specifications and different lengths can be produced, the versatility of the device is strong, and the use is convenient.

Owner:东莞市欧莱溅射靶材有限公司 +1

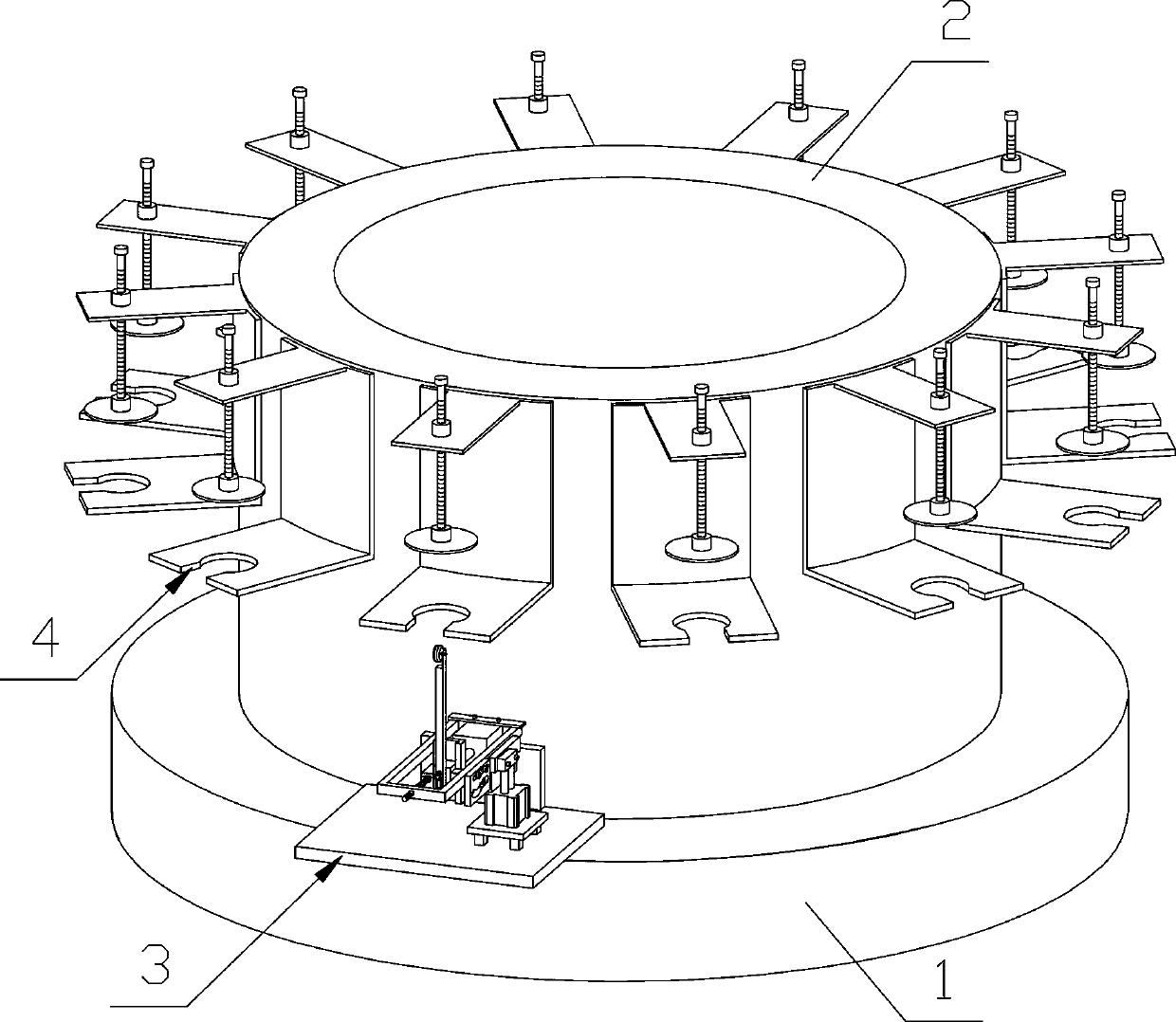

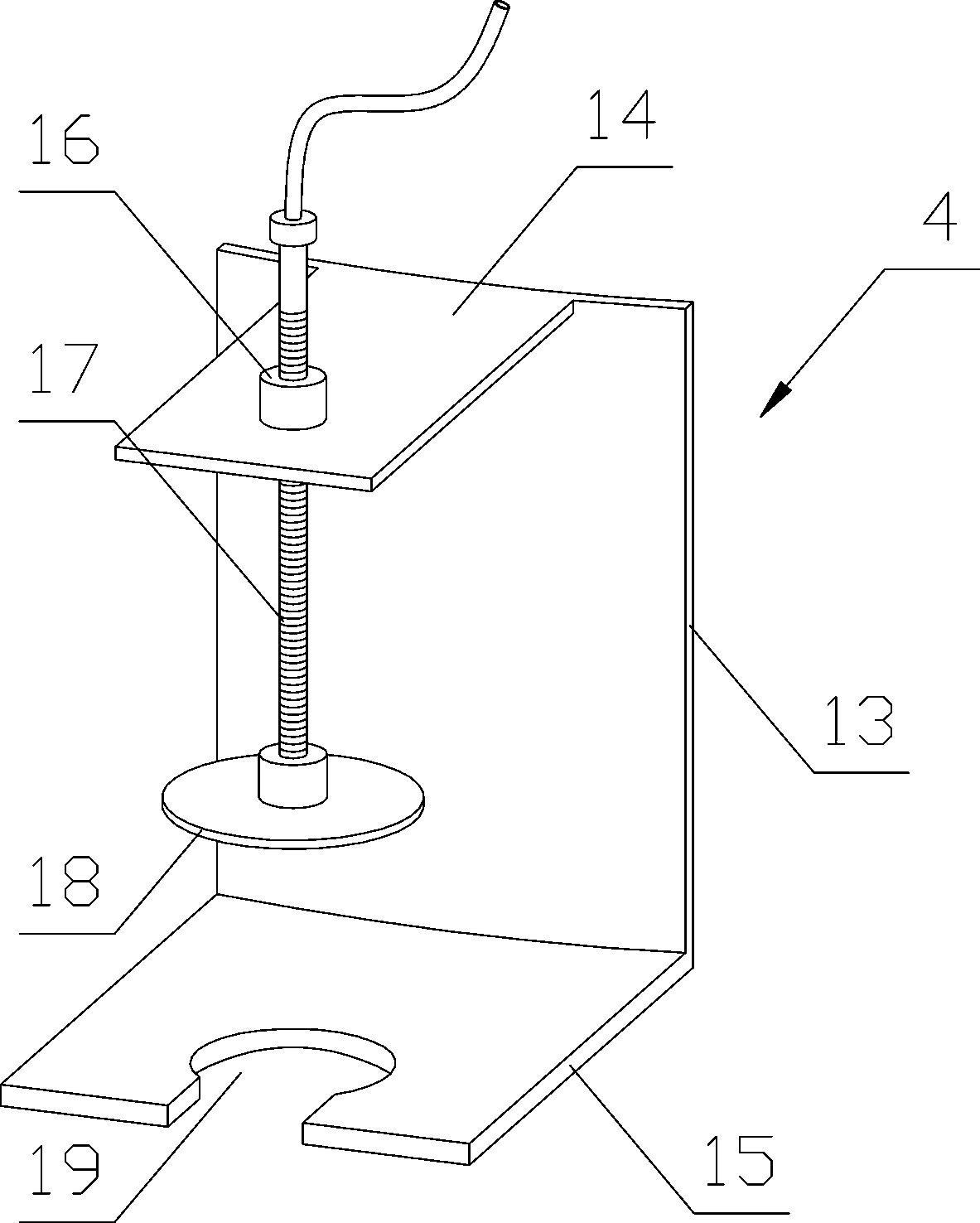

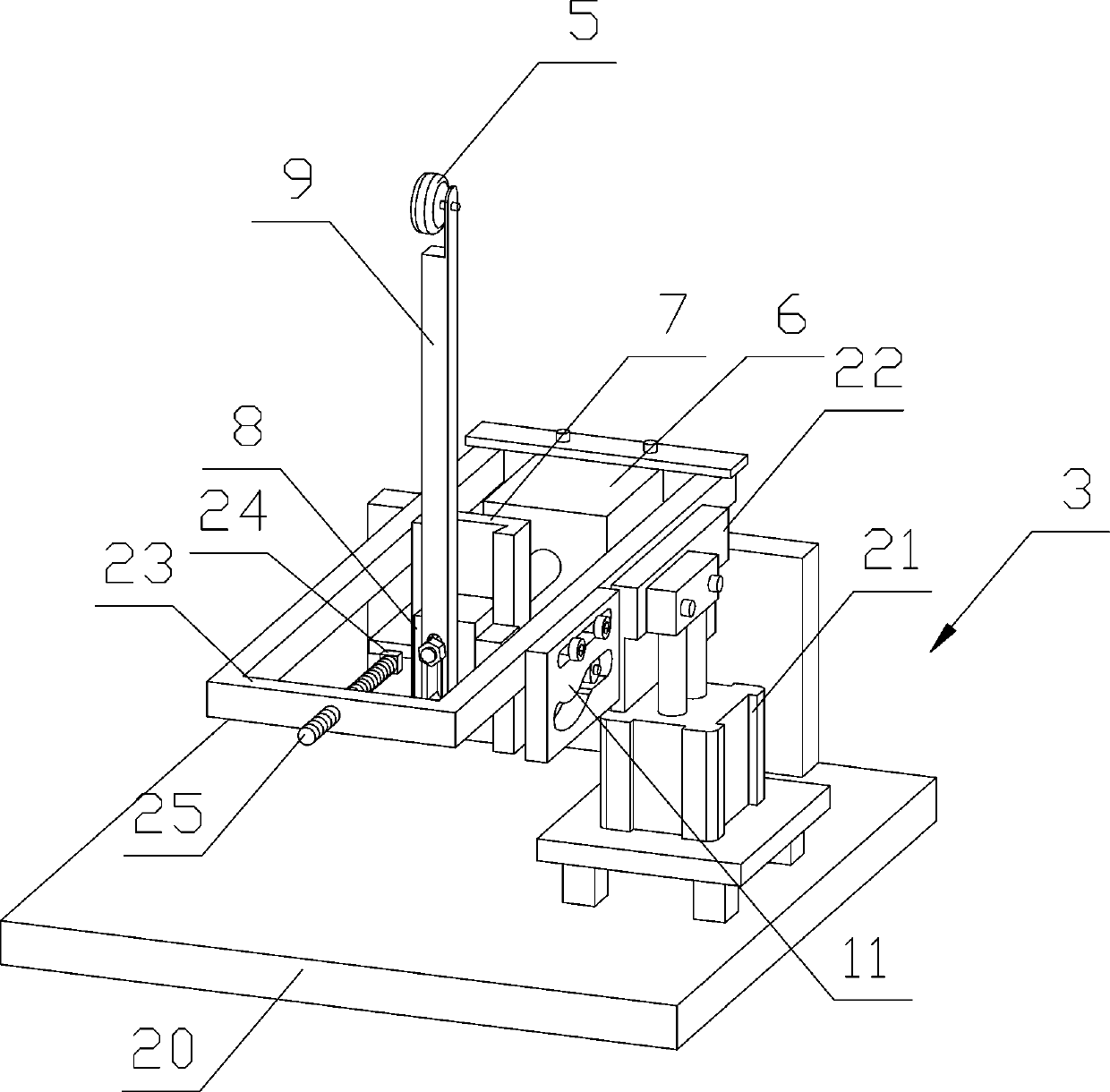

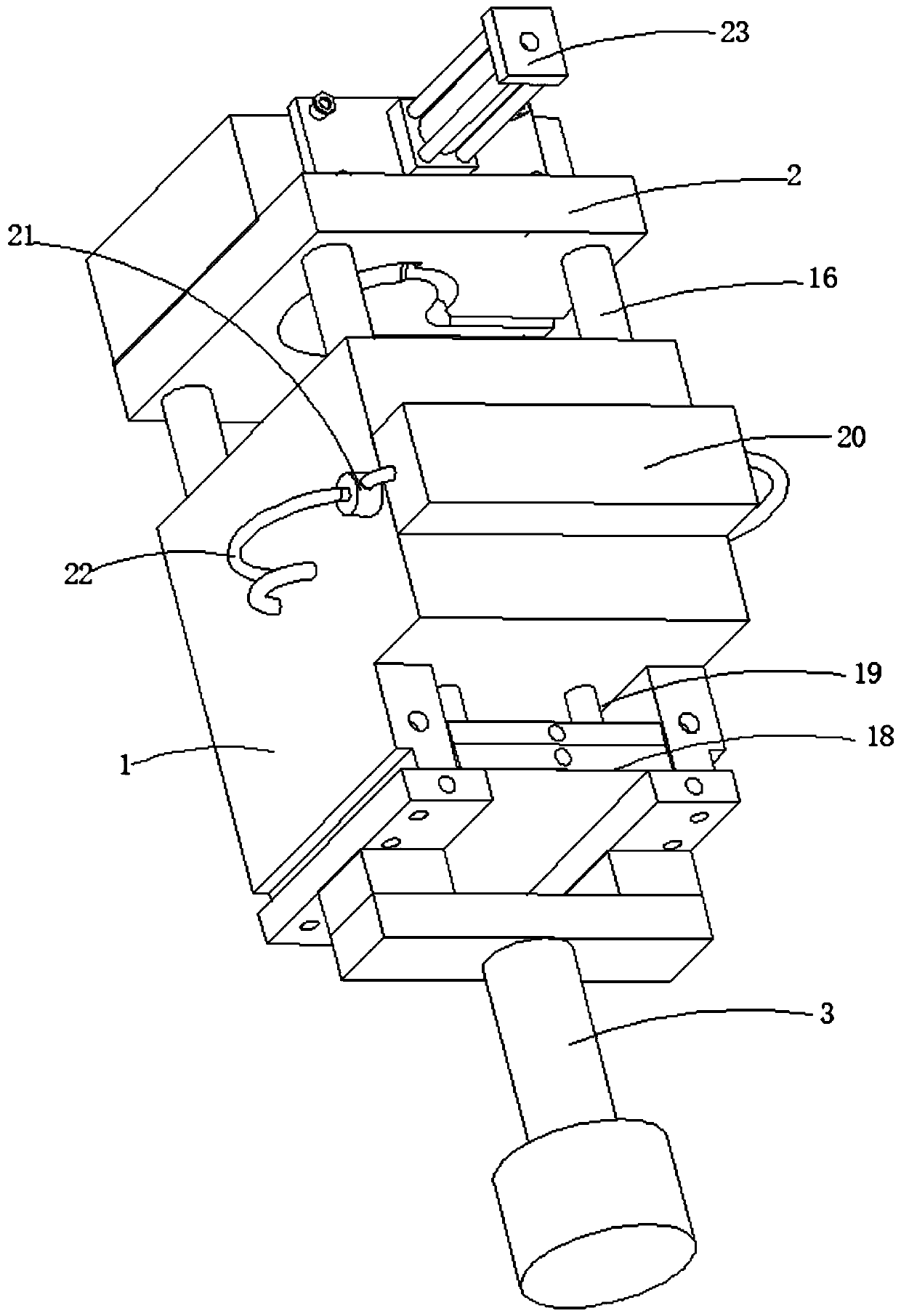

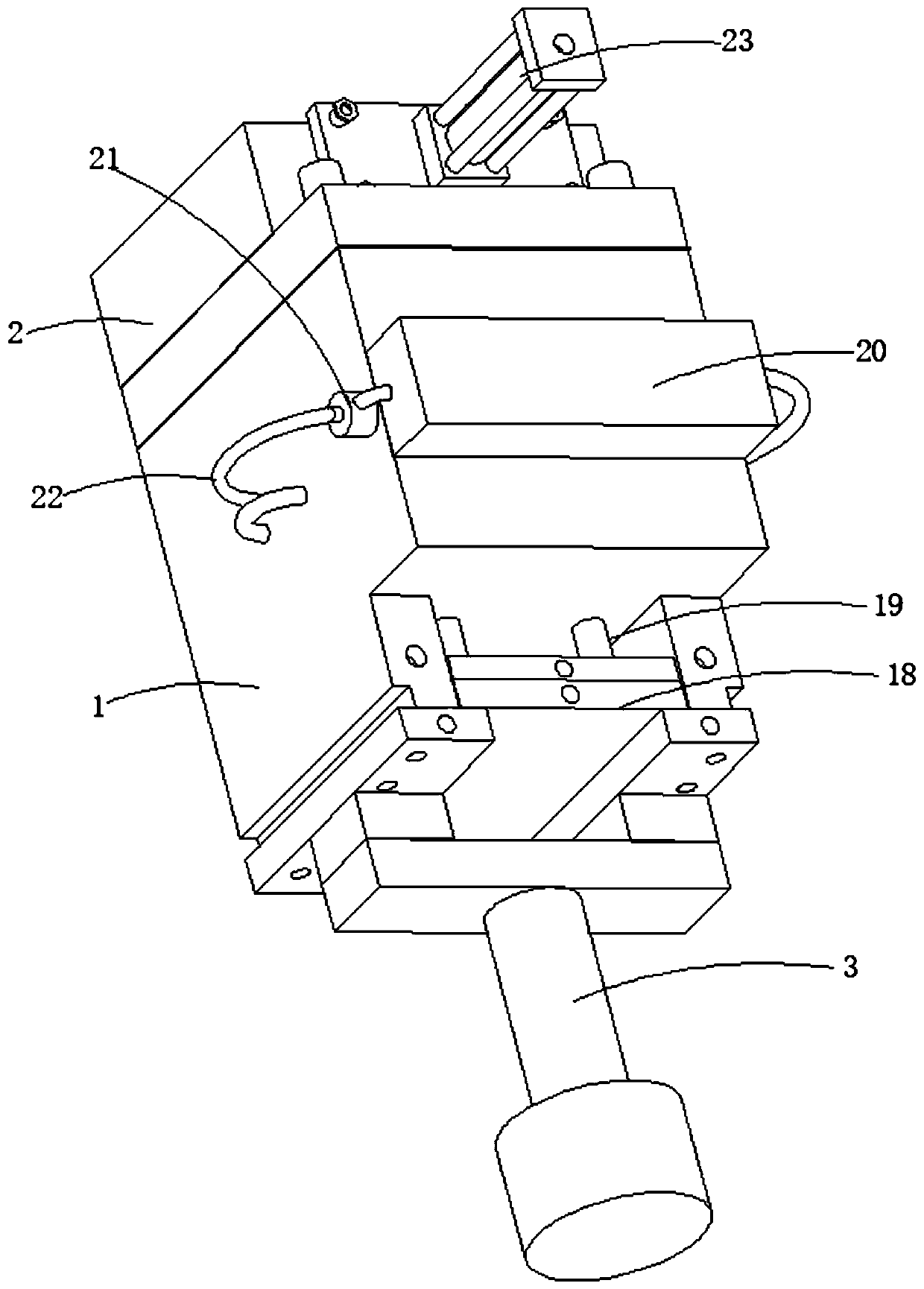

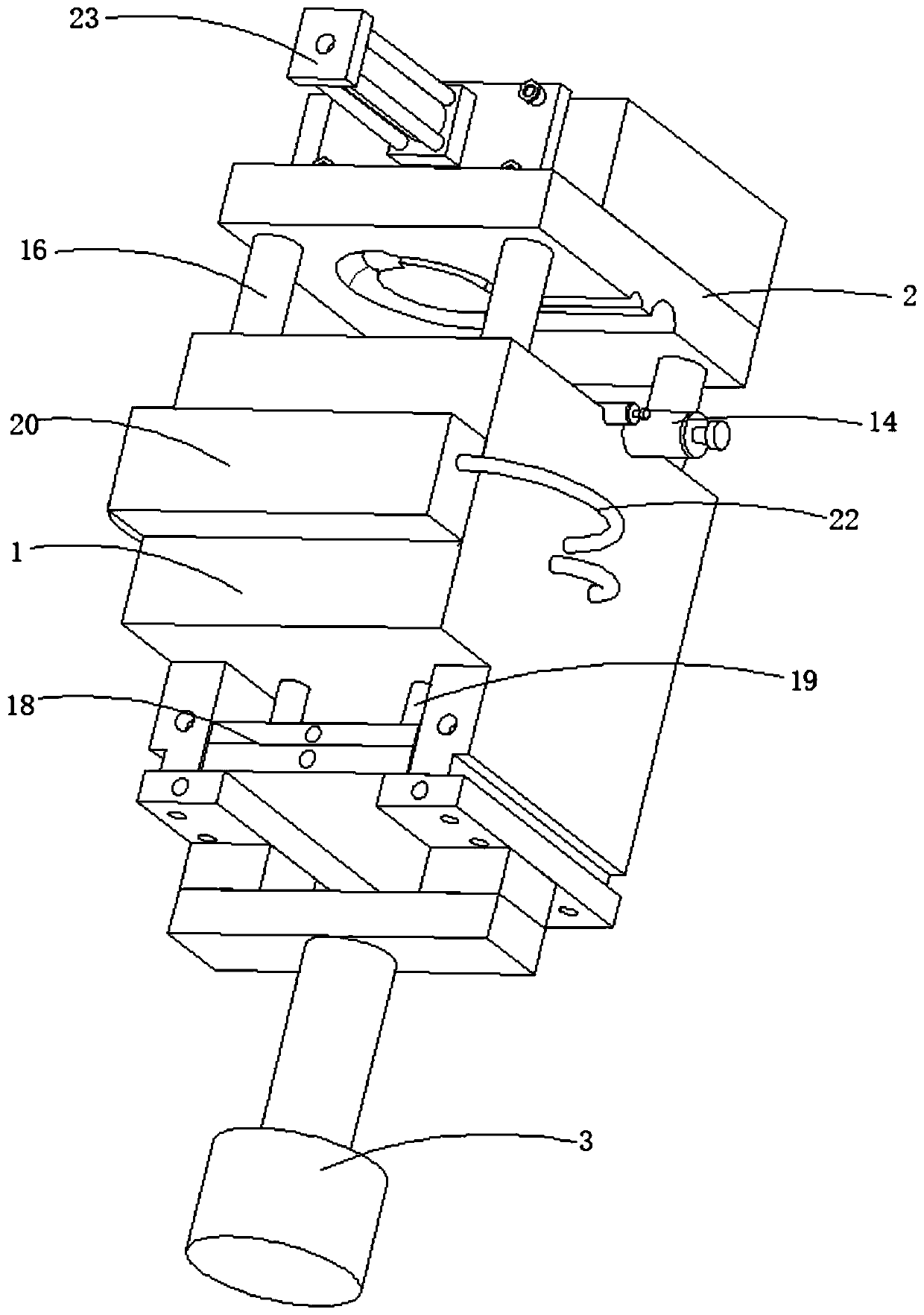

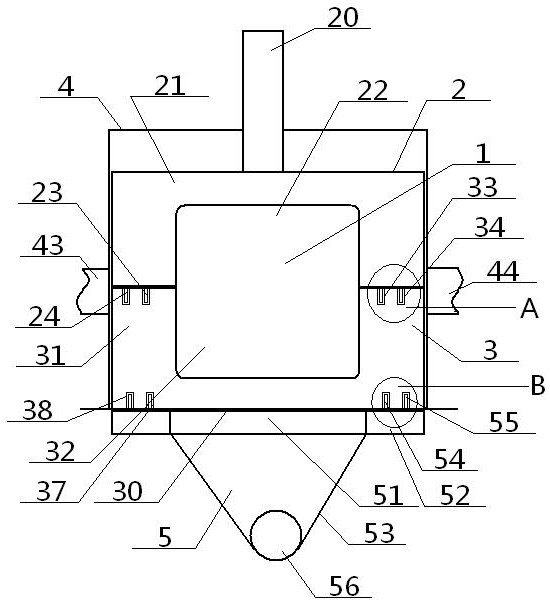

High borosilicate glass pot mouth moulding device

InactiveCN109970325ARealize mass production operationsAvoid molding qualityGlass reforming apparatusEngineeringMechanical equipment

The invention relates to the technical field of glassware mechanical equipment, in particular to a high borosilicate glass pot mouth moulding device. The device includes a base, and an indexing turntable mechanism and a pot mouth modeling mechanism. Several sets of clamping mechanisms uniformly arranged along the circumference are installed on the indexing turntable mechanism. The pot mouth modeling mechanism includes a modeling wheel and a driving mechanism thereof, the driving mechanism has an air cylinder A arranged along the radial direction of the indexing turntable mechanism, a sliding groove in longitudinal arrangement is fixed at the telescopic end of the air cylinder A, and a sliding block is assembled in the sliding groove. A stand column for installing the modeling wheel is fastened on the sliding block, the left side and / or right side of the sliding block is equipped with a guide wheel, which cooperates with a guide groove on a fixedly installed guide seat, and the guide groove consists of a front arc-shaped groove section and a rear linear groove section. The high borosilicate glass pot mouth moulding device provided by the invention has the characteristics of simple structure and ingenious design, realizes the mass production of high borosilicate glass pots, and ensures the moulding quality of high borosilicate glass pot mouths.

Owner:HUBEI RUIXIN HEALTH CARE PROD SCI & TECH CO LTD

Forming method for composite product formed by conical metal shell and conical glass reinforced plastic heat-proof layer

The invention discloses a forming method for a composite product formed by a conical metal shell and a conical glass reinforced plastic heat-proof layer. The forming method comprises the following steps: 1, forming the conical metal shell; 2, forming the conical glass reinforced heat-proof layer; and 3, sleeving the metal shell by the conical glass reinforced heat-proof layer. Due to the sleeving manner, an aluminum alloy and glass reinforced plastic heat-proof layer composite product is formed by sleeving, and various indexes are controlled when the conical metal shell and the conical glass reinforced plastic heat-proof layer are formed respectively, so that coaxiality between the metal shell and the glass reinforced plastic heat-proof layer is ensured, the quality, the center of mass, centroidal deviation and the roundness of the product are guaranteed, debonding is prevented, and the technical problems occurring when the small-taper long composite product is formed are solved.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

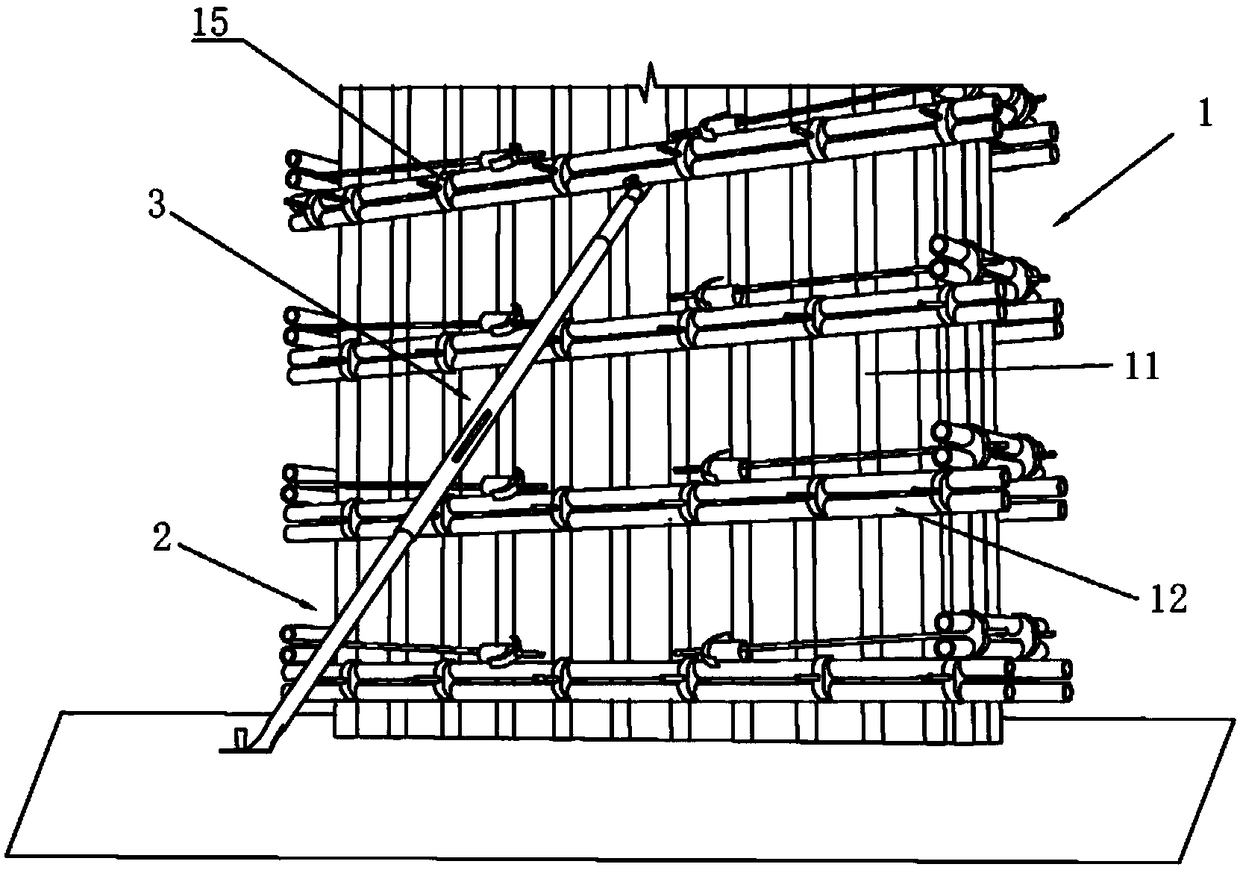

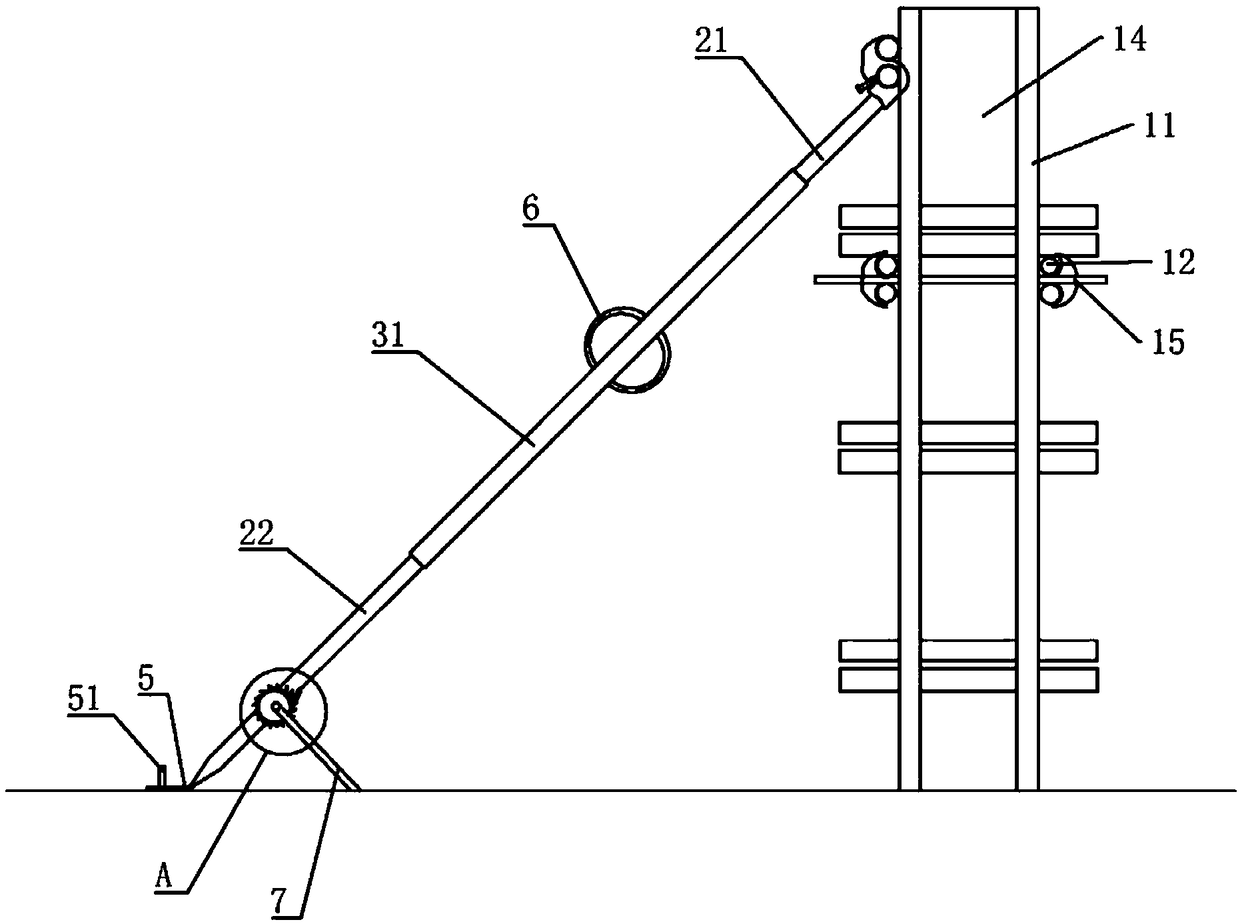

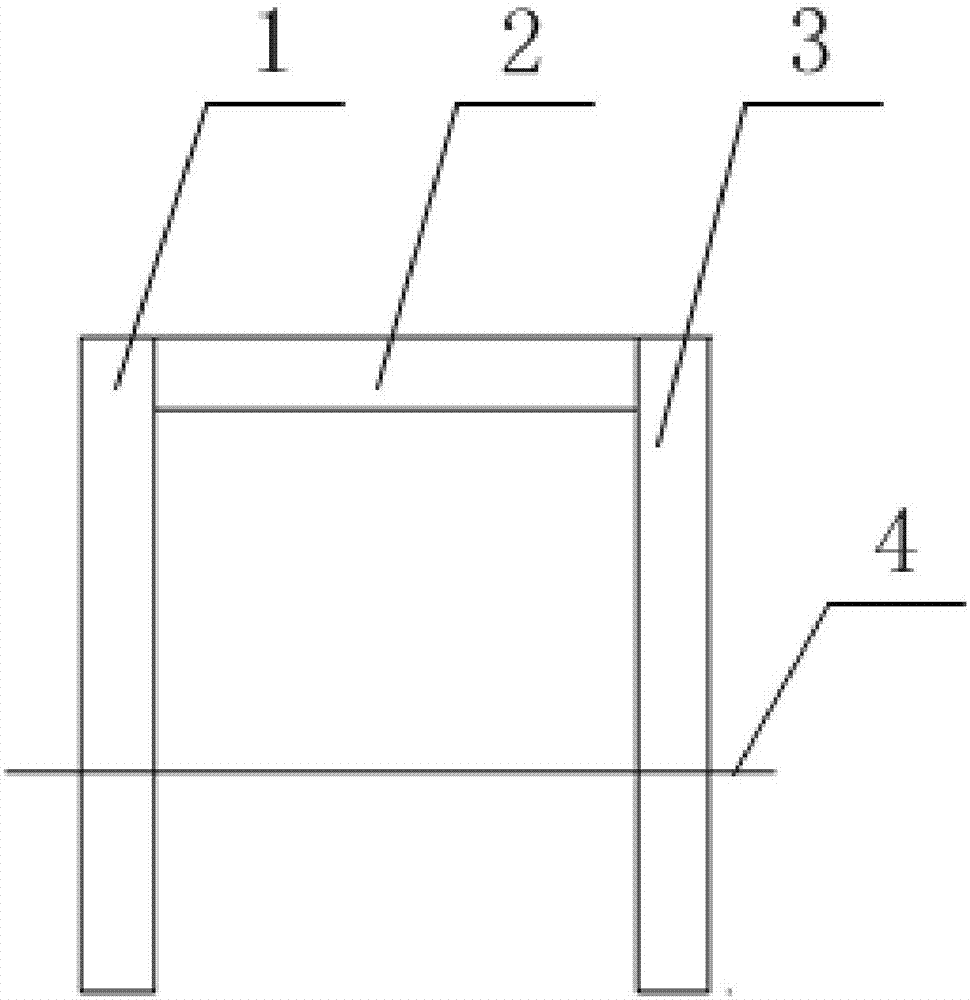

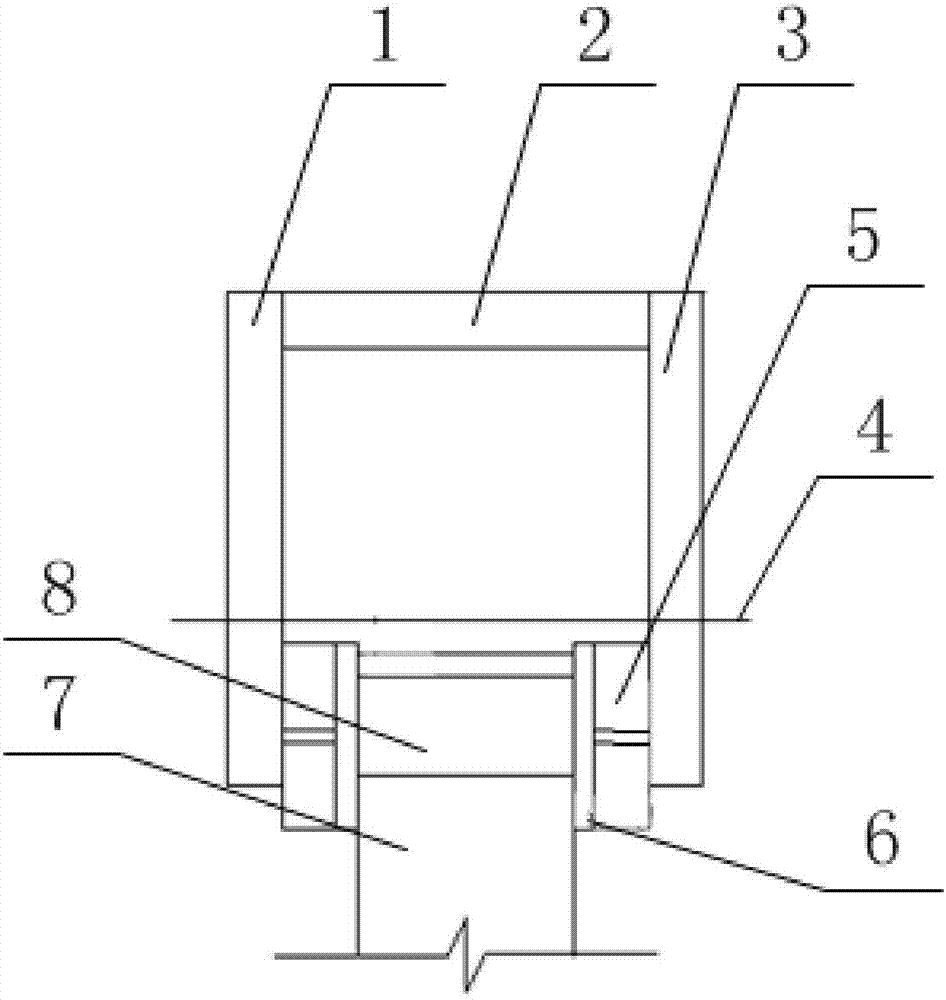

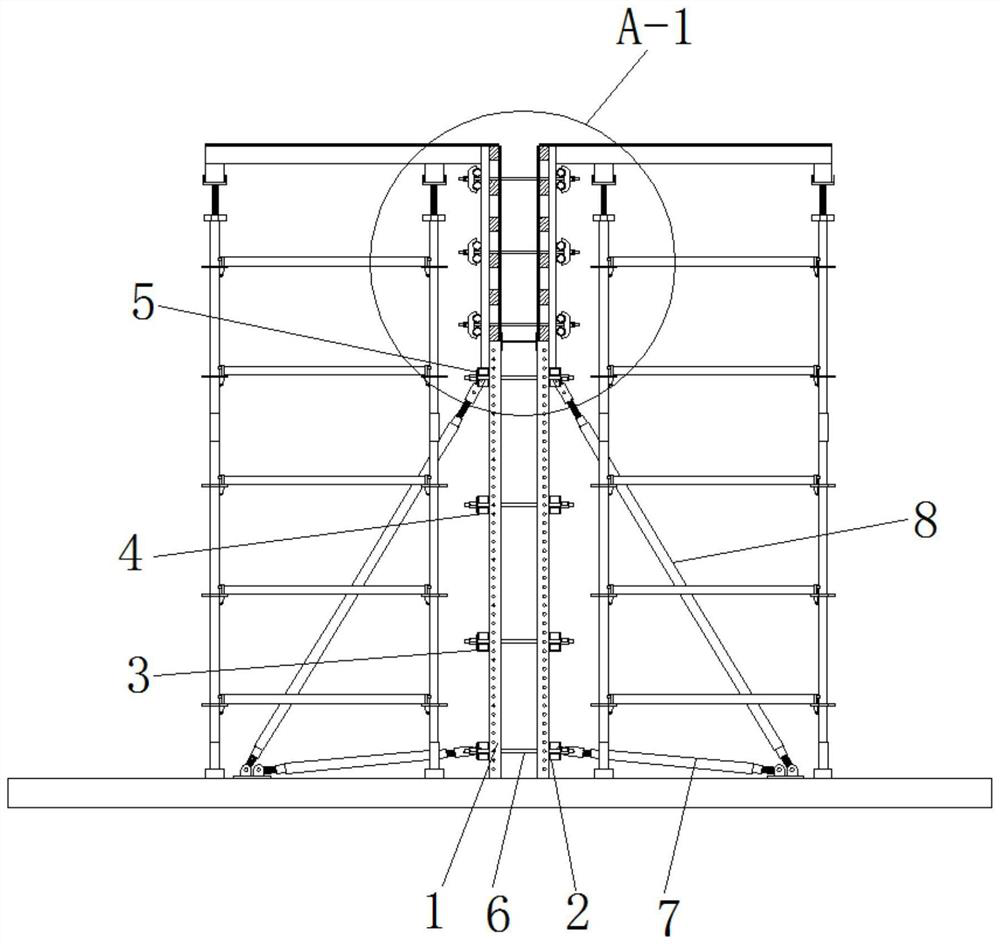

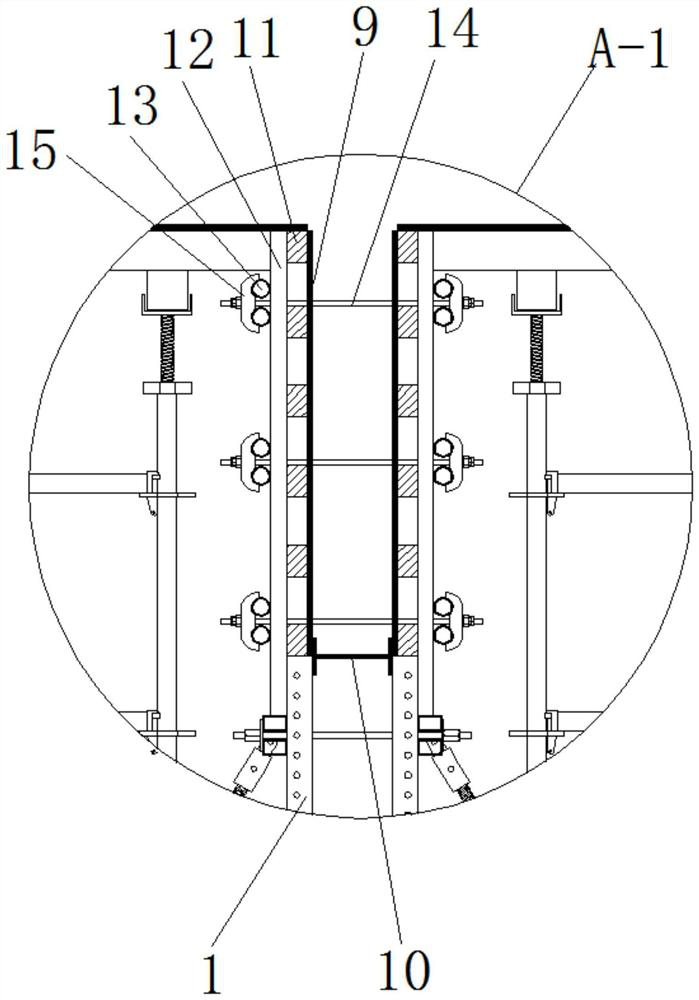

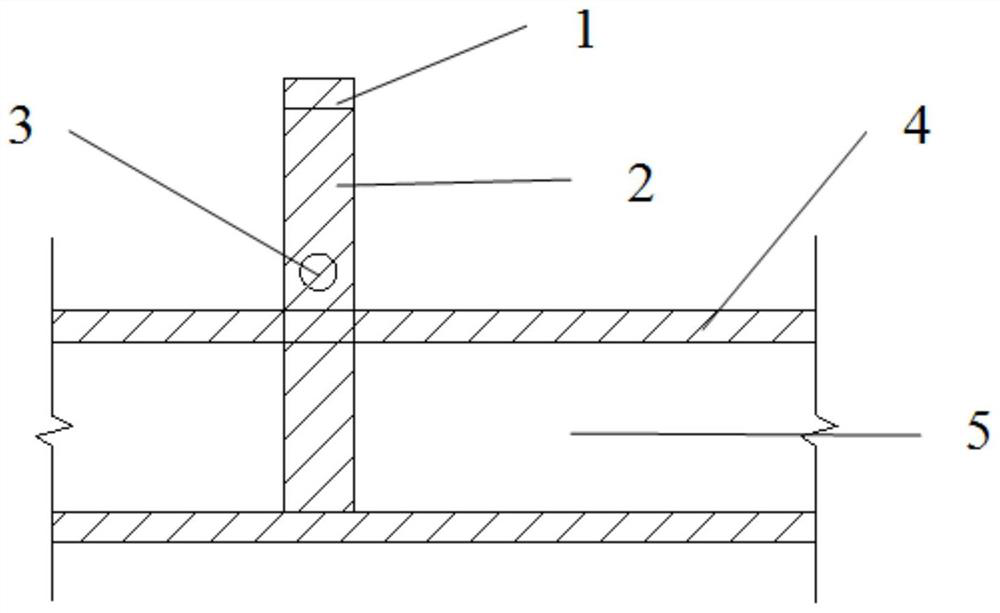

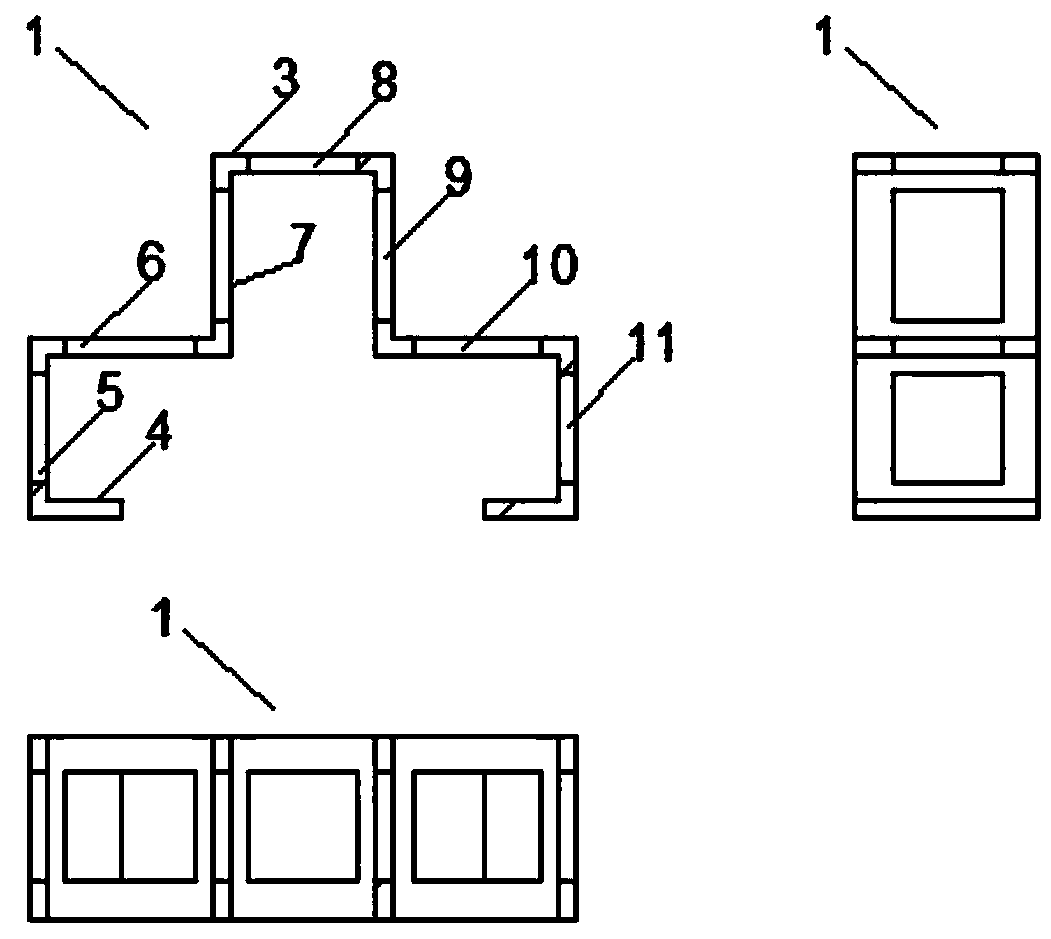

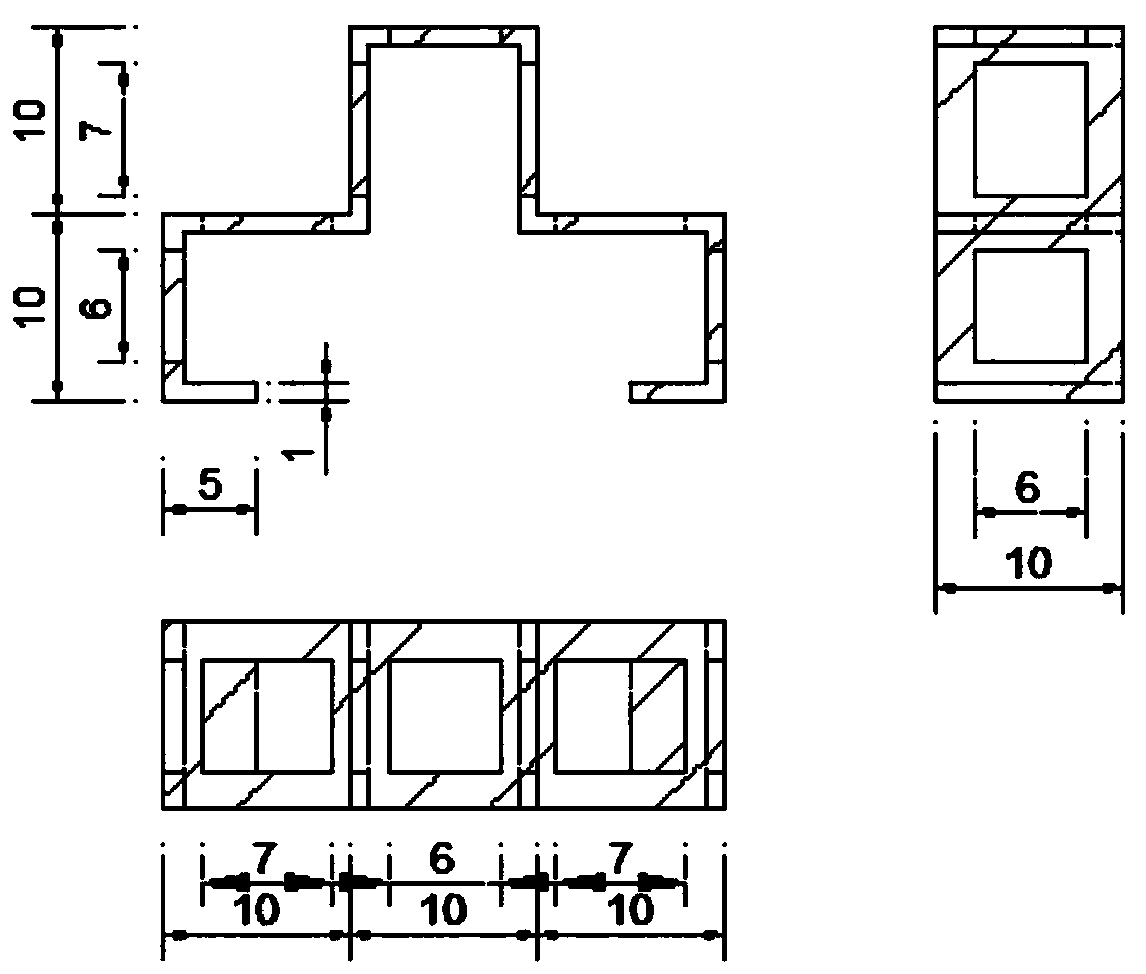

Convenient and adjustable reinforcing supporting structure of cast-in-situ wall column formwork and construction method of reinforcing supporting structure

PendingCN109322482AAvoid molding qualityImprove molding qualityForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksFloor slabSteel tube

The invention provides a convenient and adjustable reinforcing supporting structure of a cast-in-situ wall column formwork. The reinforcing supporting structure comprises a wall column cast-in-situ formwork. The wall column cast-in-situ formwork comprises a plurality of vertical longitudinal steel pipes, a plurality of horizontal transverse steel pipes, and a pair of black formworks oppositely arranged. A cast-in-situ space is formed between the pair of black formworks. The longitudinal steel pipes and the transverse steel pipes are respectively located on the outer sides of the pair of blackformworks. The transverse steel pipes on two sides are connected by split bolts. Adjusting supporting rods used for supporting the wall column cast-in-situ formwork are respectively arranged on two sides of the wall column cast-in-situ formwork. The top ends of the adjusting supporting rods are connected with the transverse steel pipes. The bottom ends of the adjusting supporting rods are connected with a floor. The adjusting supporting rods are provided with adjusting mechanisms used for adjusting the supporting length. The forming quality of cast-in-sit concrete in the construction site canbe effectively controlled. The forming quality of a shear wall and a structure column processed by the method is obviously improved. The invention further provides a construction method of the convenient and adjustable reinforcing supporting structure of the cast-in-situ wall column formwork. The method is used for processing and designing a convenient and adjustable reinforcing supporting structure of the cast-in-situ wall column formwork.

Owner:THE SECOND CONSTR ENG CO LTD CCSEB

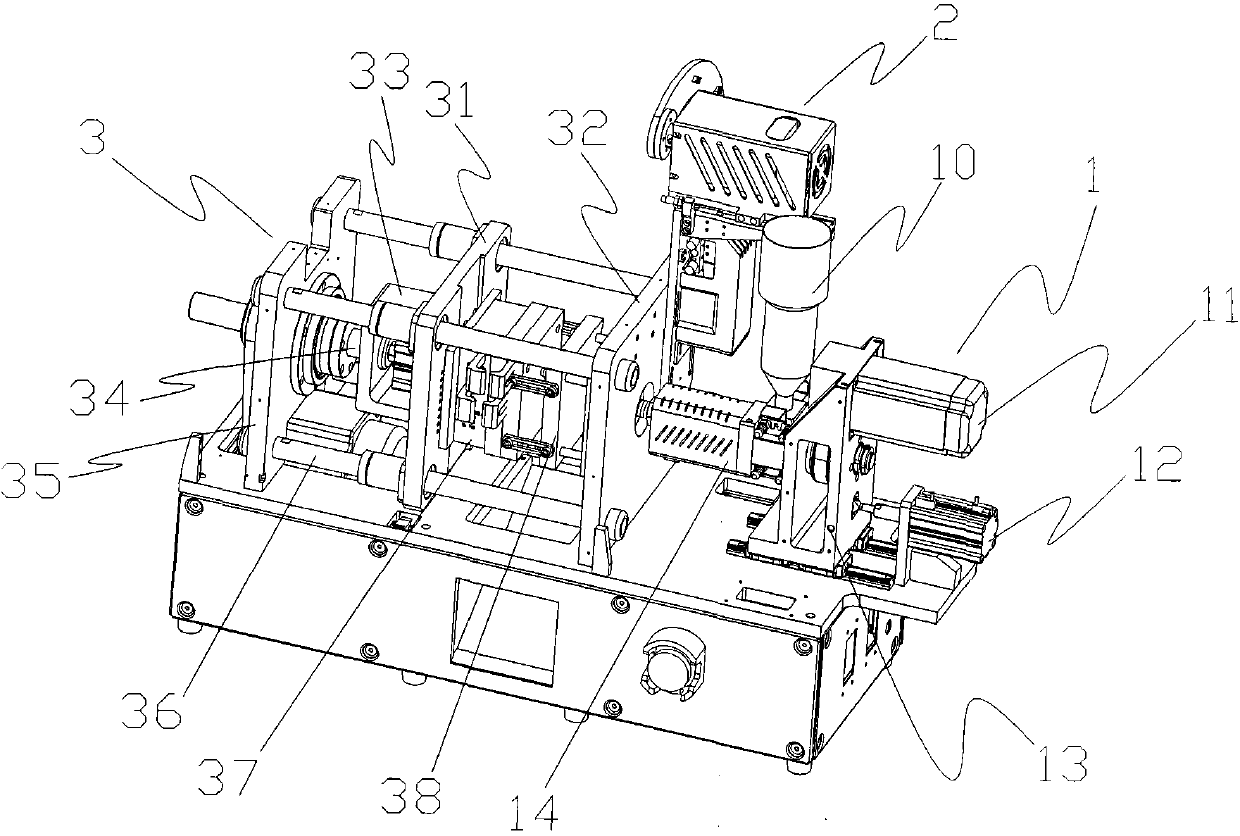

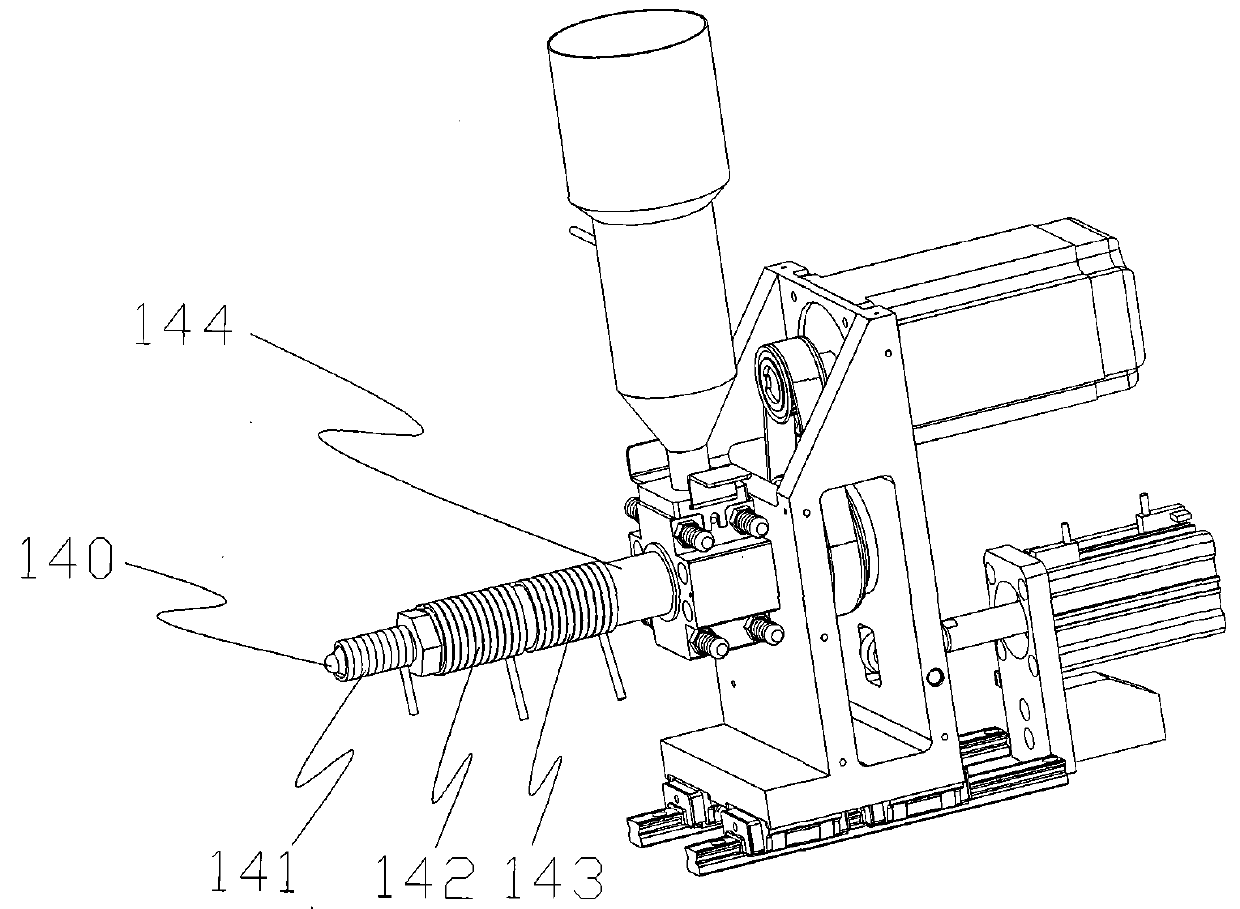

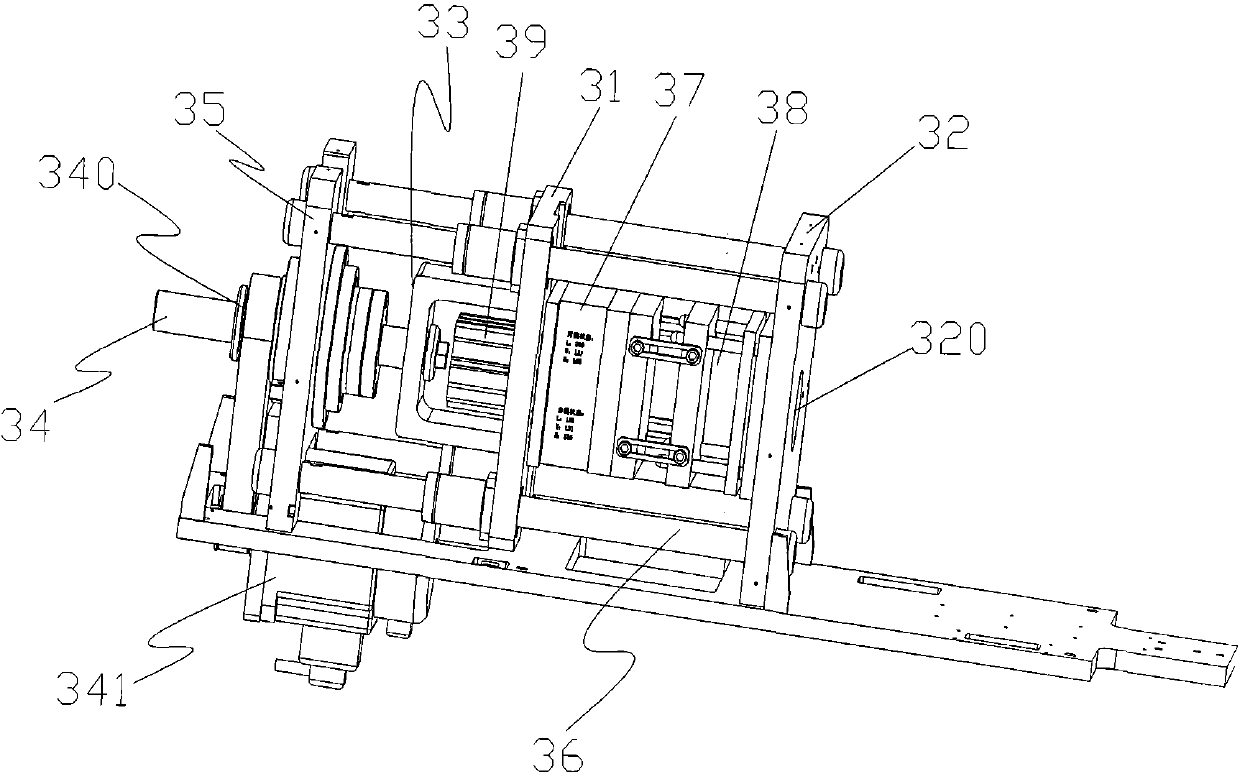

Micro injection molding machine

The invention discloses a micro injection molding machine. The micro injection molding machine comprises an extrusion device and a mold locking device, wherein the extrusion device comprises a screw support frame and an injection nozzle; a single screw controlled by a servo motor and arranged in a sol cylinder is pivoted on the screw support frame; the injection nozzle is communicated with the free end of the sol cylinder; the mold locking device comprises a first vertical plate which is fixed on a baseplate and used for fixing a front mold and a second vertical plate which is used for fixing a rear mold and connected with a roller lead screw of the servo motor; the roller lead screw can perform mold closing motion for diving the rear mold to move forwards; the lower end of the support frame is in sliding fit with the baseplate and provided with a cylinder for driving the screw support frame to move; the cylinder is used for driving the injection nozzle on the support frame to be butted with an injection opening of the front mold. The injection molding machine disclosed by the invention has the advantages that the closing of the extrusion device and a mold runner opening is completed through the forward and backward motion of the cylinder; the design of mold runner balance can be easily realized and the molding quality of parts is easy to control; the machine is small in floor space, low in energy consumption and easy in realizing automation.

Owner:深圳市铠钜电子科技有限公司

Low-temperature rapidly-vulcanized solid silicon rubber raw material and production method thereof

InactiveCN105255195AShorten vulcanization timeFast vulcanizationMetal working apparatusMasterbatchPlatinum complex

The invention discloses a low-temperature rapidly-vulcanized solid silicon rubber raw material and a production method thereof. The solid silicon rubber raw material contains a silicon rubber raw material, a platinum vulcanizing agent and a color masterbatch which are uniformly mixed together, wherein the platinum vulcanizing agent comprises the main components A and B; the component A is a mixture containing raw vinyl rubber, fumed silica and a platinum complex; the component B is a mixture containing raw vinyl rubber, fumed silica, terminated poly(methylhydrosiloxane) and an inhibitor; the weight ratio of the component A to the component B is 1:1 to 3:1; the mixing ratio of the platinum vulcanizing agent to the silicon rubber raw material is 100:0.1 to 100:5.0; the color masterbatch comprises the following components: raw silicon rubber, an organic toner, silicon oil and a dispersing agent; and the mixing ratio of the mixture of the silicon rubber and the platinum vulcanizing agent to the color masterbatch is 100:0.1 to 100:3.0. The solid silicon rubber raw material disclosed by the invention is particularly suitable for integrally molding a high-temperature-nonresistant material and solid silicon rubber.

Owner:GUANGDONG JANUS SMART GRP CO LTD

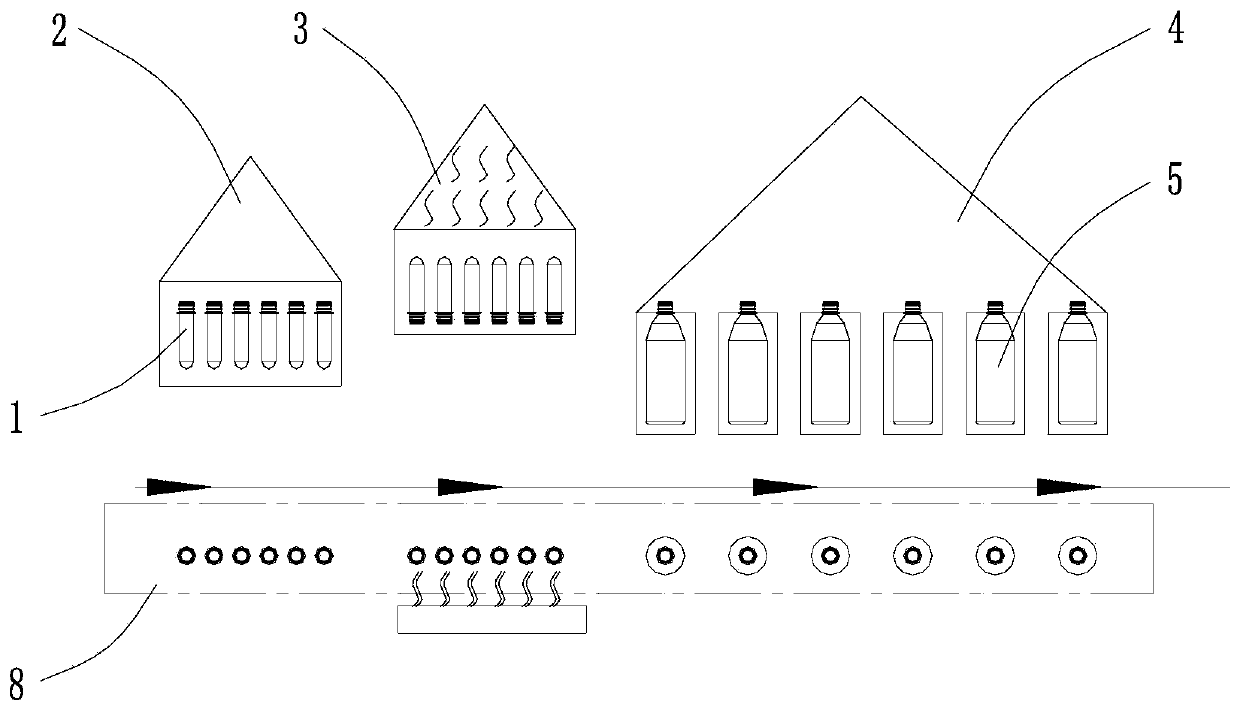

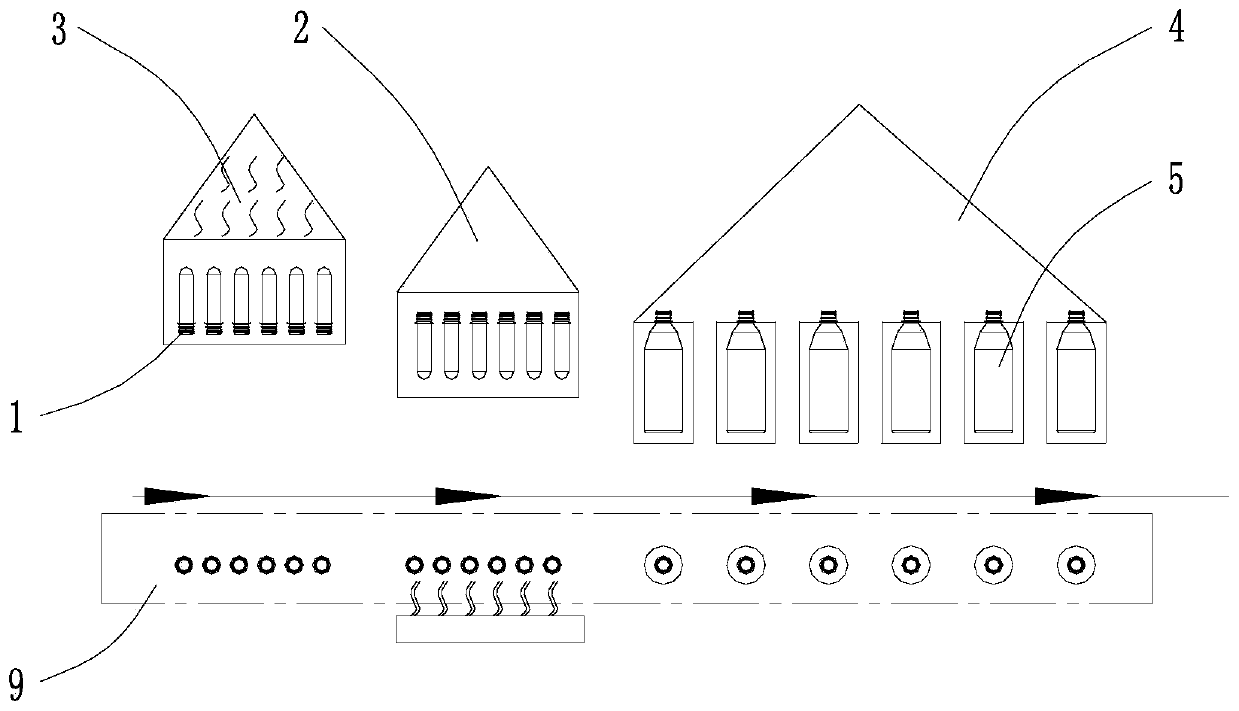

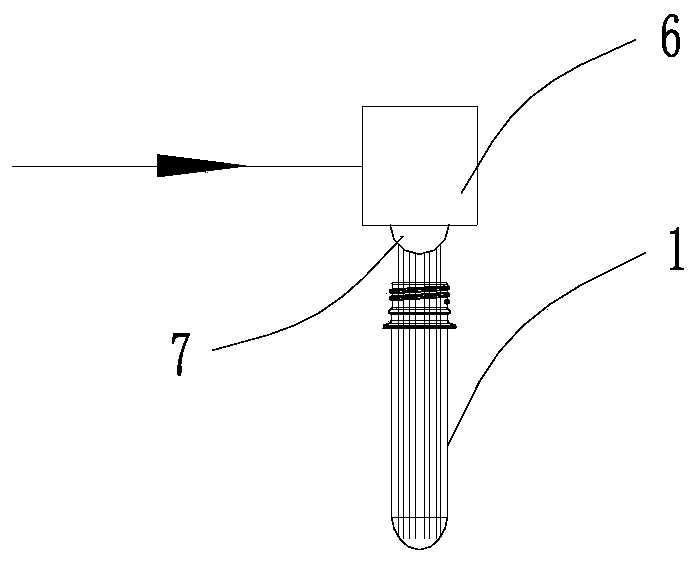

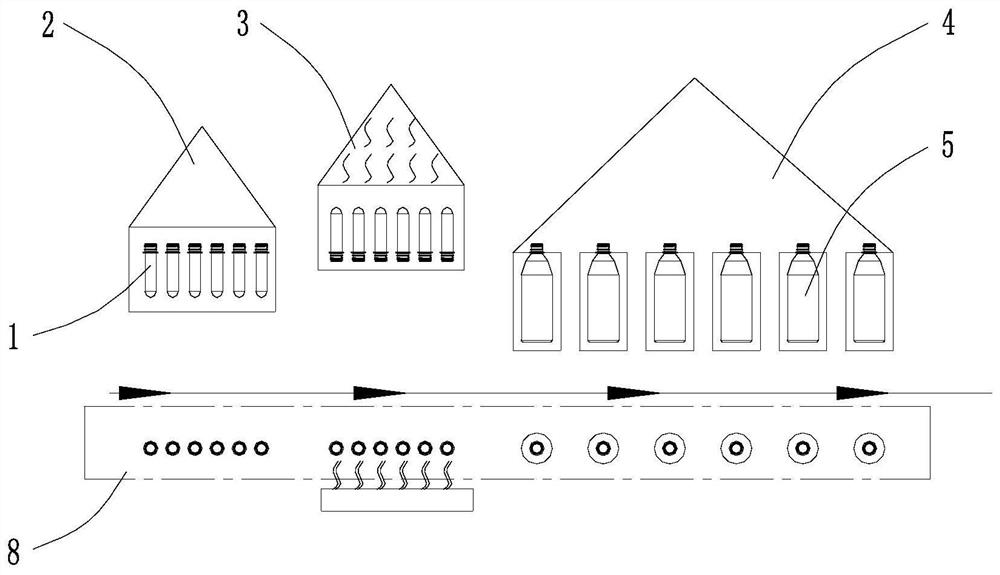

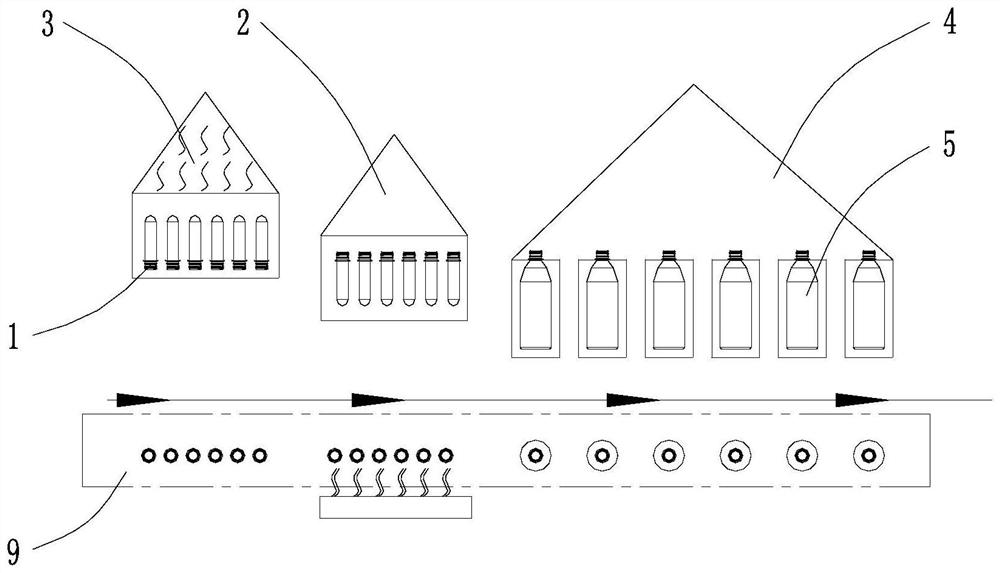

Preform disinfection method and bottle making equipment

ActiveCN111231273AReduce consumptionAvoid molding qualityDomestic articlesHeatProcess engineeringRadiative heating

The invention discloses a preform disinfection method and bottle making equipment, and particularly relates to a disinfection method for performing disinfection on a plastic preform which is used formolding in sterile bottle producing equipment. The method at least comprises the following steps of (1) preparing disinfectant into disinfectant mist by using an ultrasonic atomizer, and spraying thedisinfectant mist to the preform, attaching a substantially uniform thin disinfectant layer to at least the inner surface of the to-be-disinfected preform; and (2) carrying out radiation heating on the preform treated in this way, enabling at least the inner surface of the preform to be heated to a first temperature, wherein the first temperature is greater than or equal to the activation temperature of the disinfectant so as to at least carry out disinfection on the inner surface of the preform. According to the preform disinfection method and the bottle making equipment, the disinfectant isultrasonically atomized and directly sprayed to be evenly attached to the surface of the preform, disinfectant does not need to be heated to the steam temperature, energy consumption is relatively low, and meanwhile loss caused by making disinfectant into disinfectant steam is avoided.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

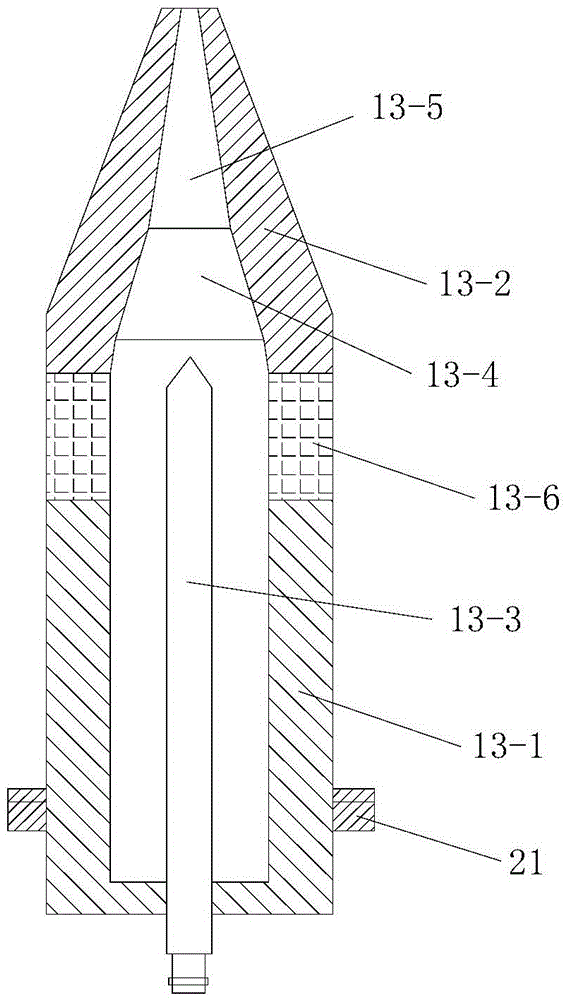

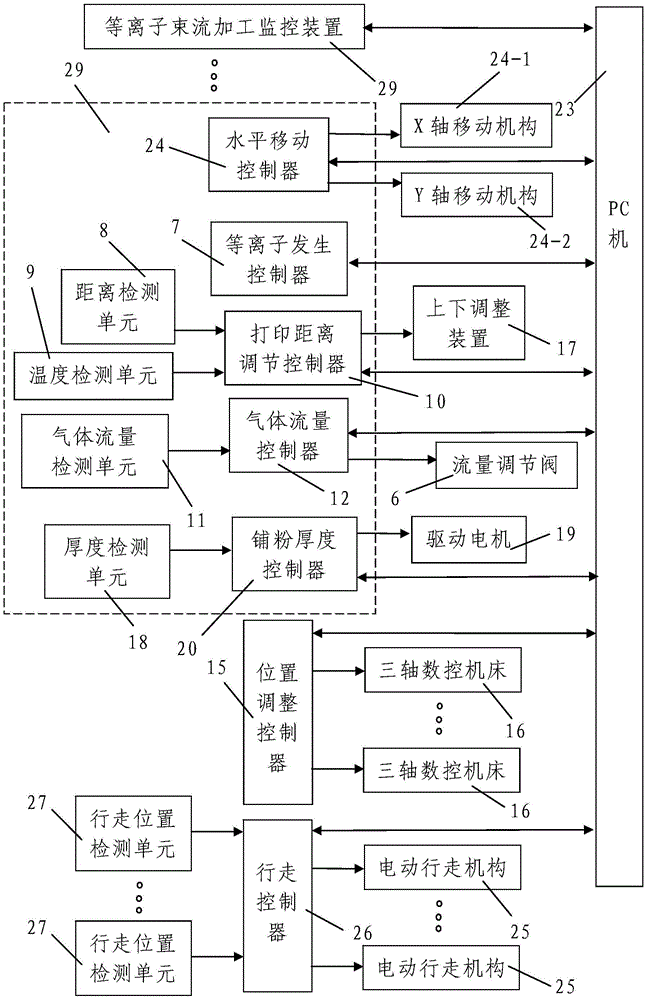

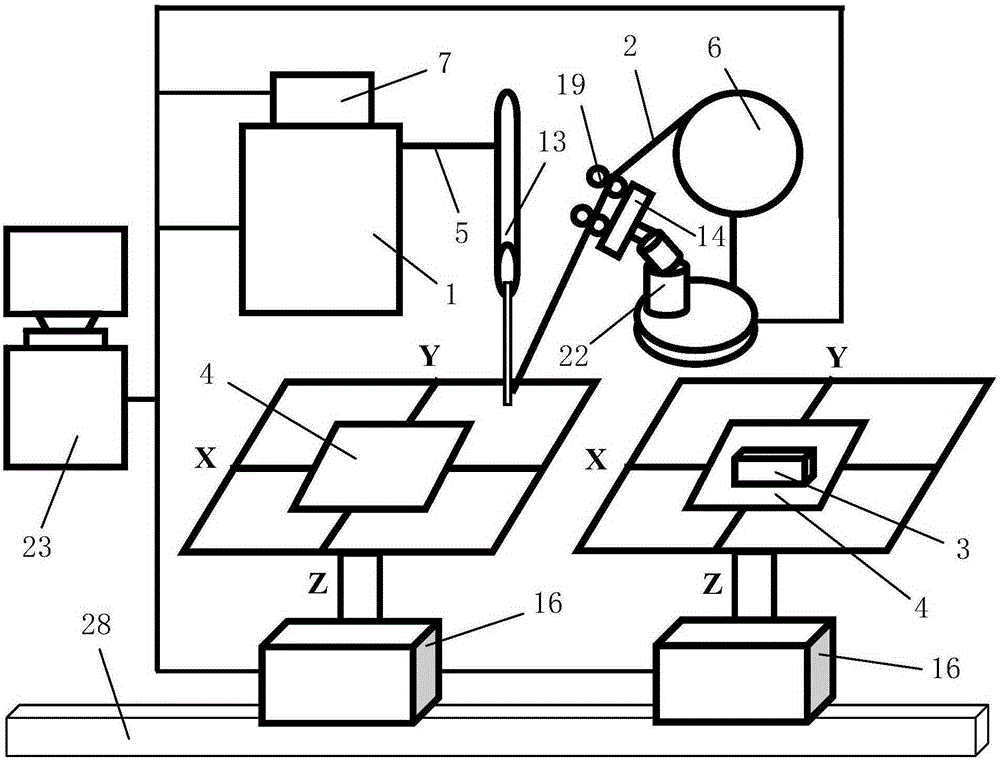

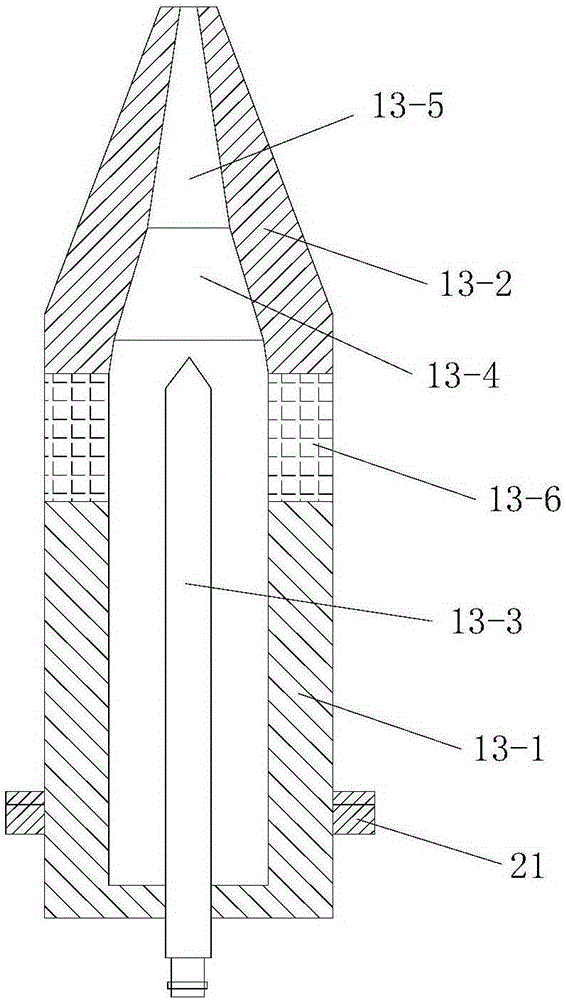

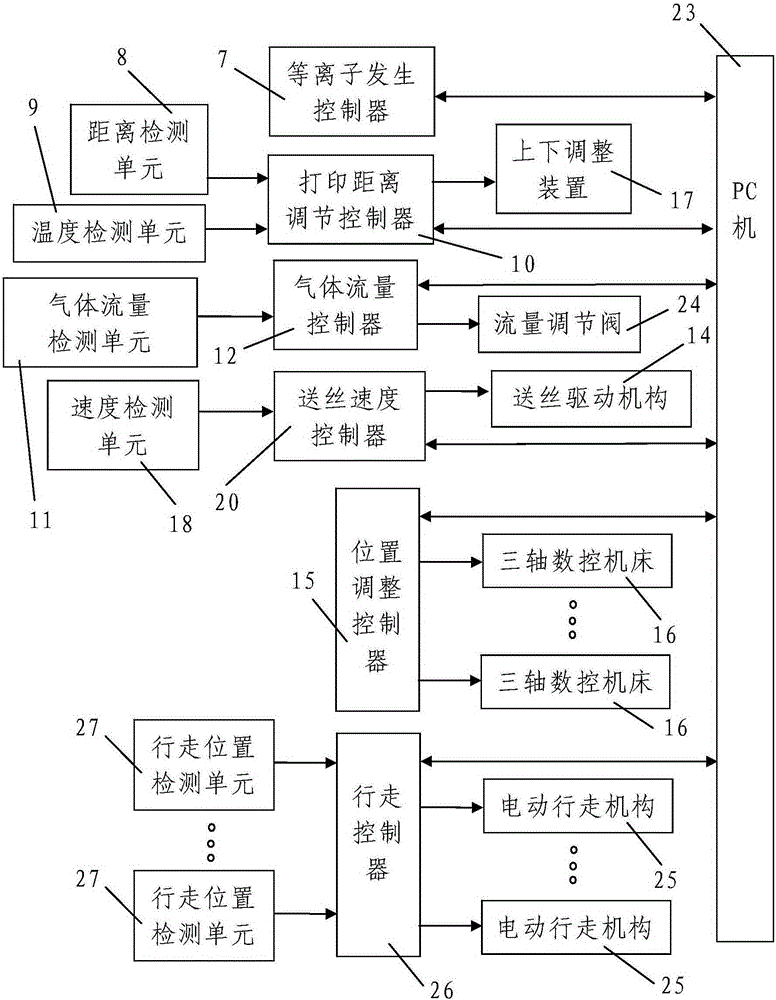

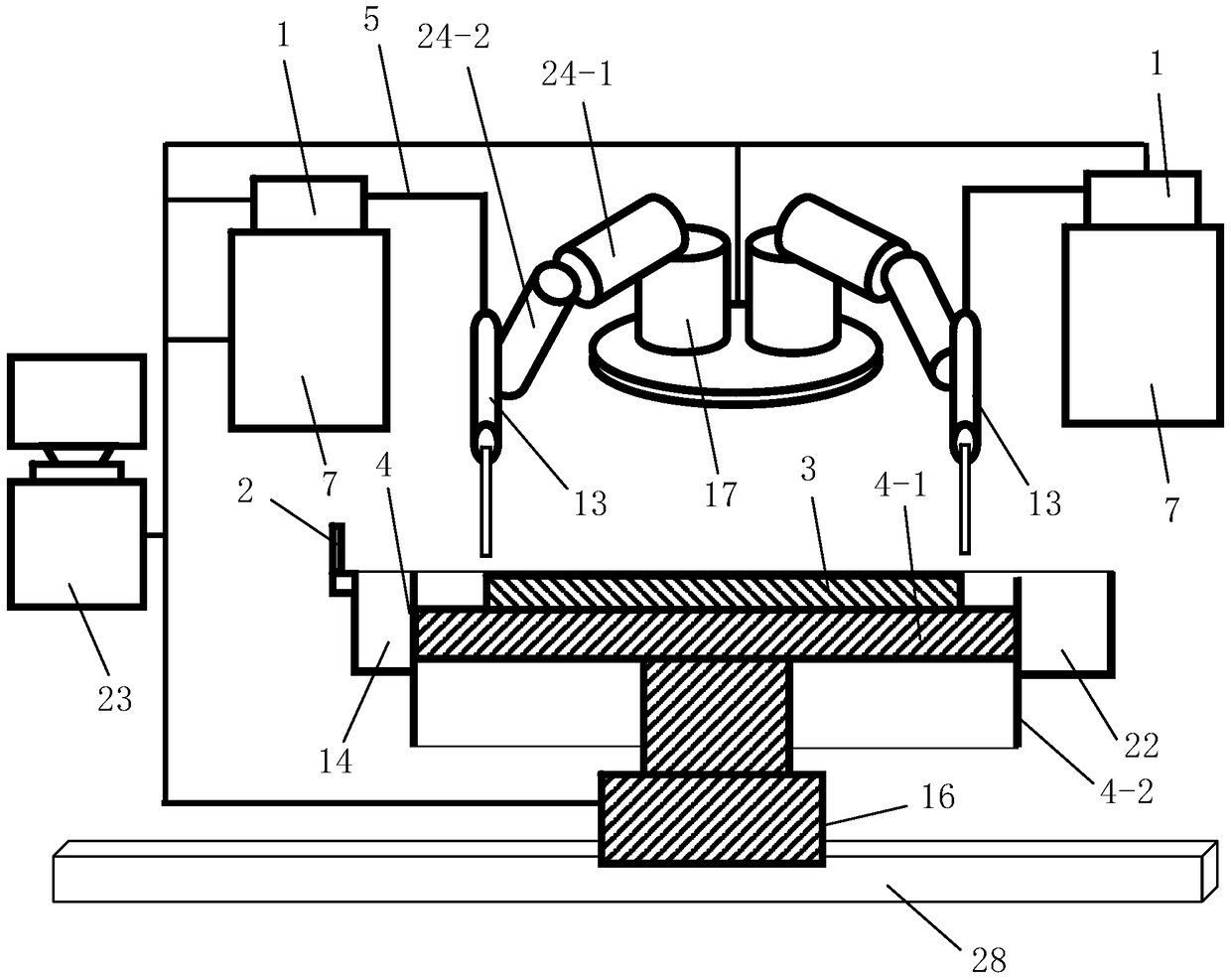

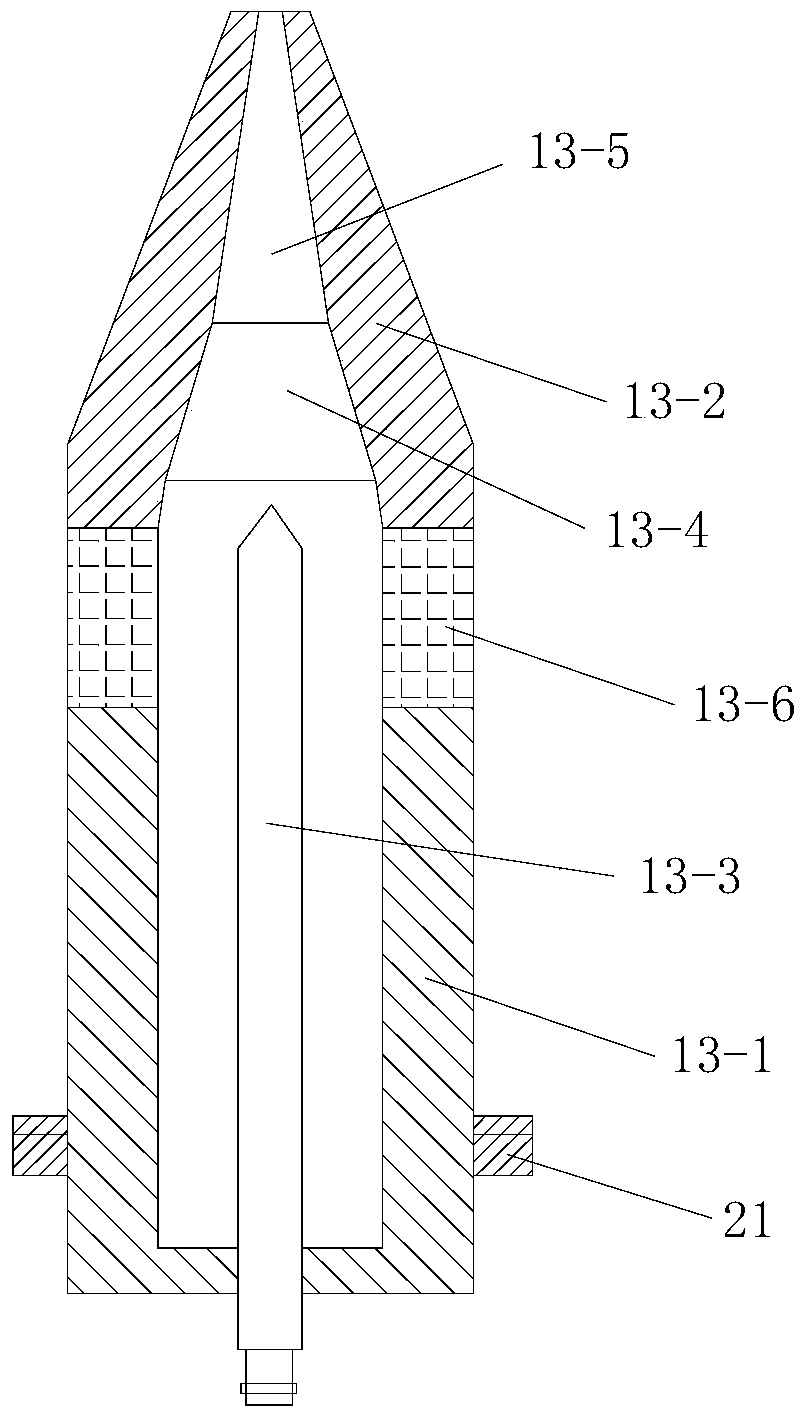

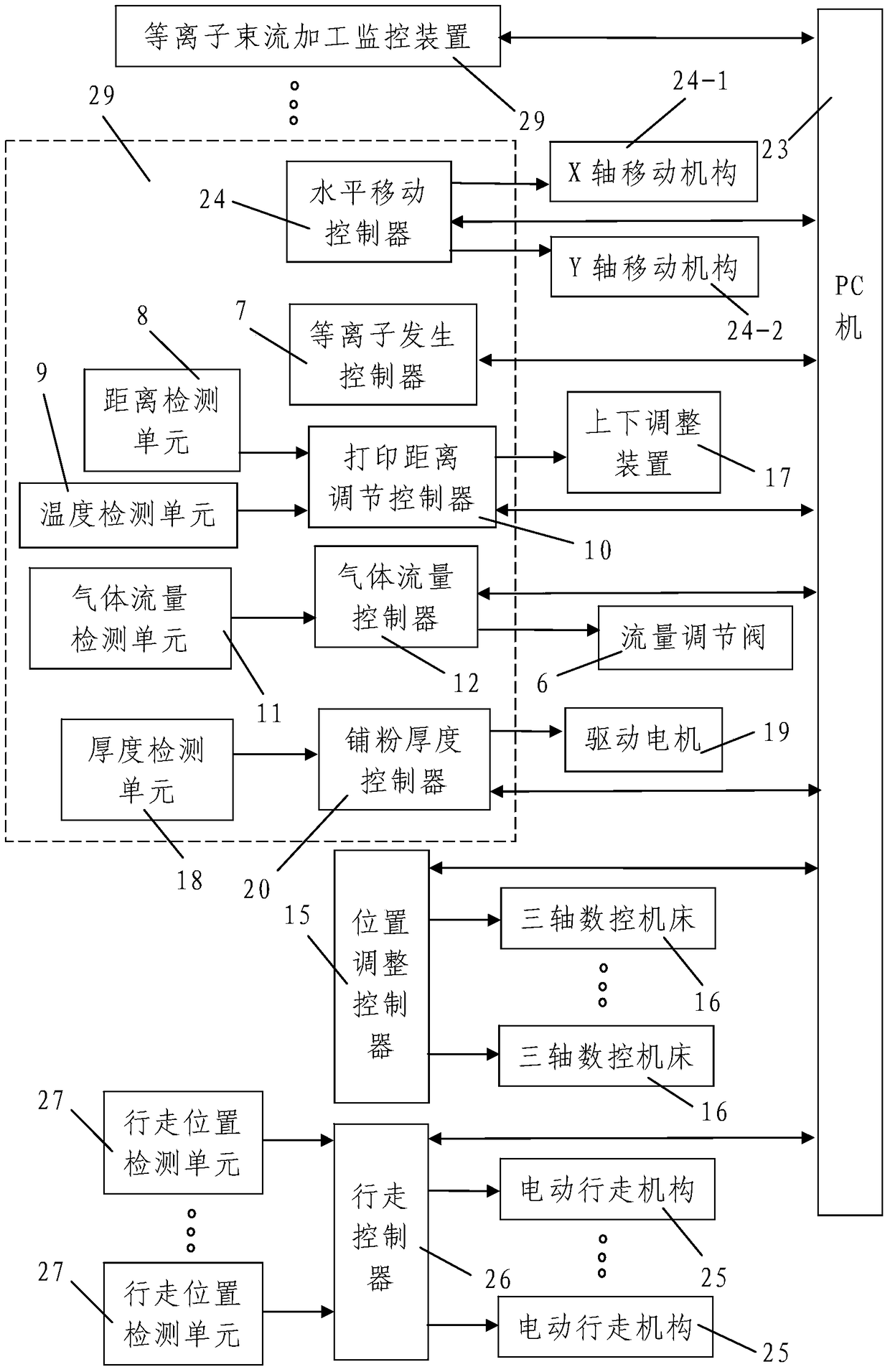

Selective plasma melting rapid prototyping equipment and rapid prototyping method

ActiveCN105922570ASimple structureReasonable designAdditive manufacturing apparatusCeramic shaping apparatusMonitoring systemPlasma generator

The invention discloses selective plasma melting rapid prototyping equipment and a rapid prototyping method. The equipment comprises a monitoring system, a plasma beam processing system, a level printing table and a powder sending and spreading device. The plasma beam processing system includes a plurality of plasma beam processing devices; each plasma beam processing device is composed of a plasma generator, a printing position adjusting device and a gas supply device; the monitoring system includes a plurality of plasma beam processing monitoring devices; each plasma beam processing monitoring device includes a temperature detection unit, a horizontal movement controller, a distance detecting unit and a printing distance adjusting controller. The method comprises the following steps: 1, acquisition of a 3D model of a workpiece to be molded, and hierarchical slicing processing; 2, scanning path filling; 3, printing path acquisition; and 4, printing layer by layer from top to bottom. The invention has the advantages of reasonable design, simple operation, high molding efficiency, good usage effect, no need of protective atmosphere or the vacuum environment, and direct operation in atmosphere environment.

Owner:中研碧诚(北京)科技有限公司

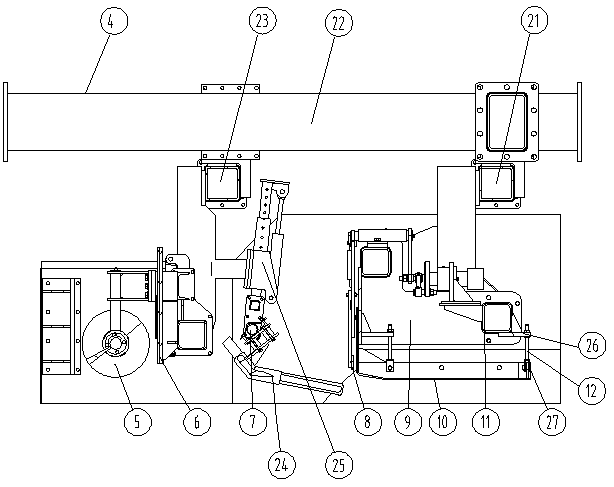

Slide mold paver provided with postposed mold mechanism

PendingCN108374309AAvoid molding qualityEvenly distributedRoads maintainenceAgricultural engineeringBuilding construction

The invention discloses a slide mold paver provided with a postposed mold mechanism, relating to the field of rod construction. The slide mold paver comprises a main machine, wherein a postposed moldassembly is connected to the back side of the main machine and comprises a postposed framework, a spiral distributing device, a material level control device, a rapping device, a vibrating device, a forming mold and two side mold plate devices; the postposed framework is connected to the main machine, the spiral distributing device, the material level control device, the rapping device, the vibrating device and the forming mold are successively arranged below the postposed framework front and back, the material level control device is connected to the postposed framework, the spiral distributing device and the rapping device are connected to the material level control device, the forming mold is connected to the postposed framework, the rapping device is connected to the forming mold, andthe two side mold plate devices are separately connected to the left and right sides of the forming mold. The working width of the postposed mold assembly cannot be limited by the width of a tractiondevice of the main machine, and can be wider than the traction device of the main machine and also can be not wider than the traction device of the main machine.

Owner:JIANGSU SIMING ENG MACHINERY

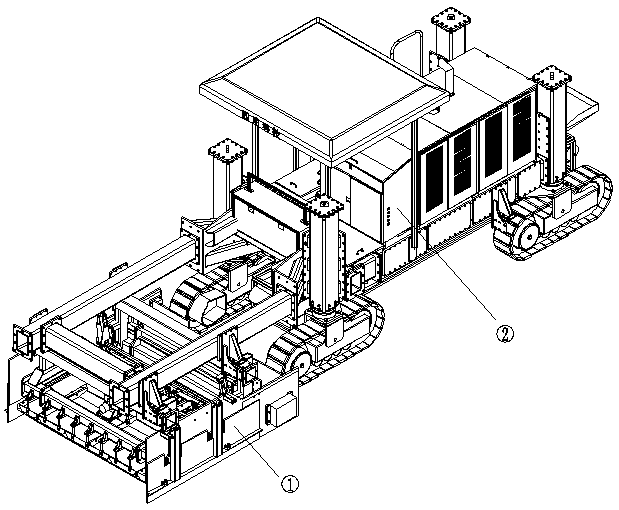

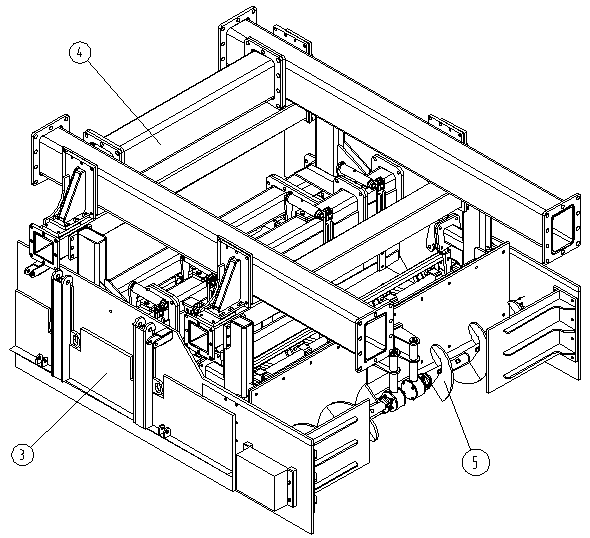

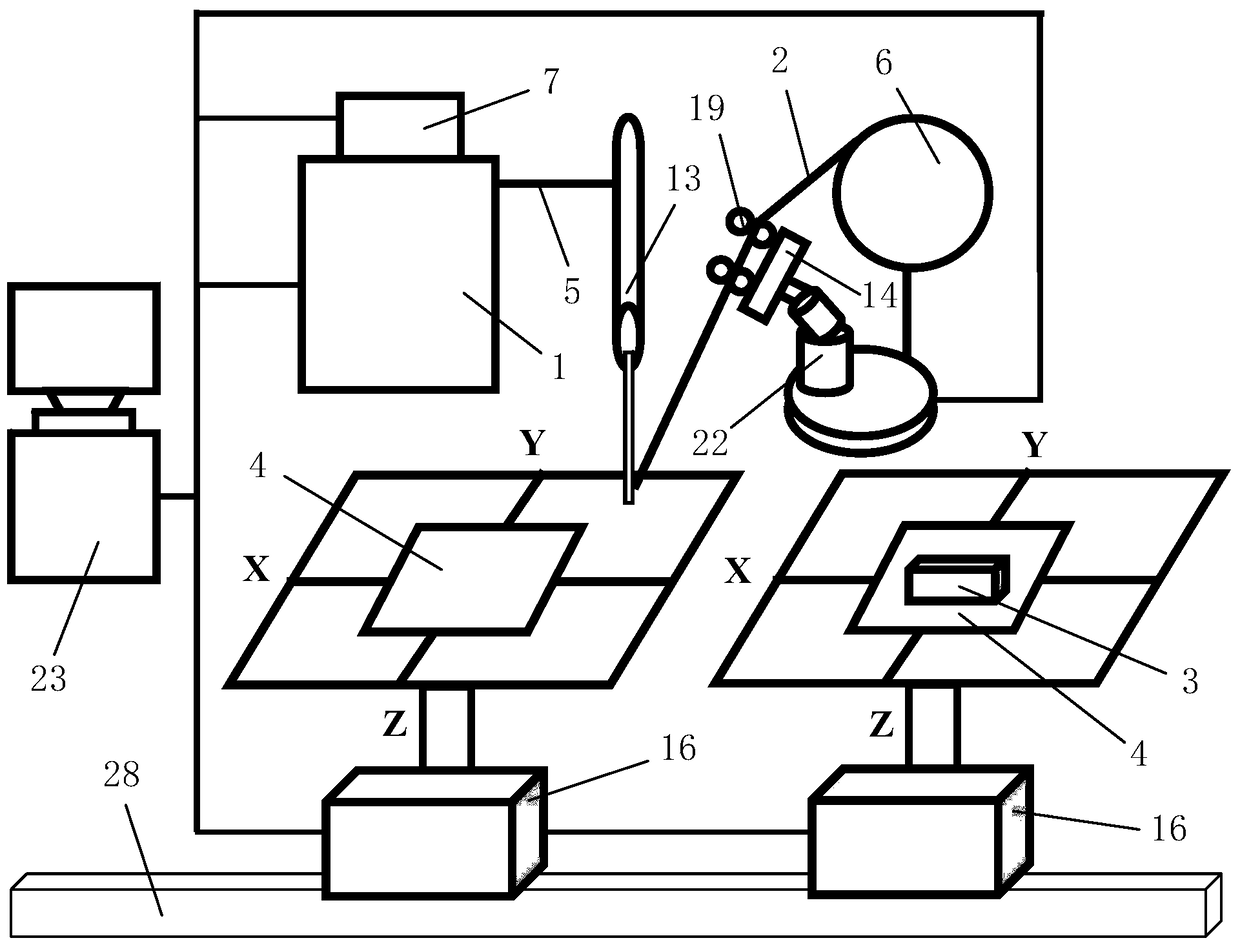

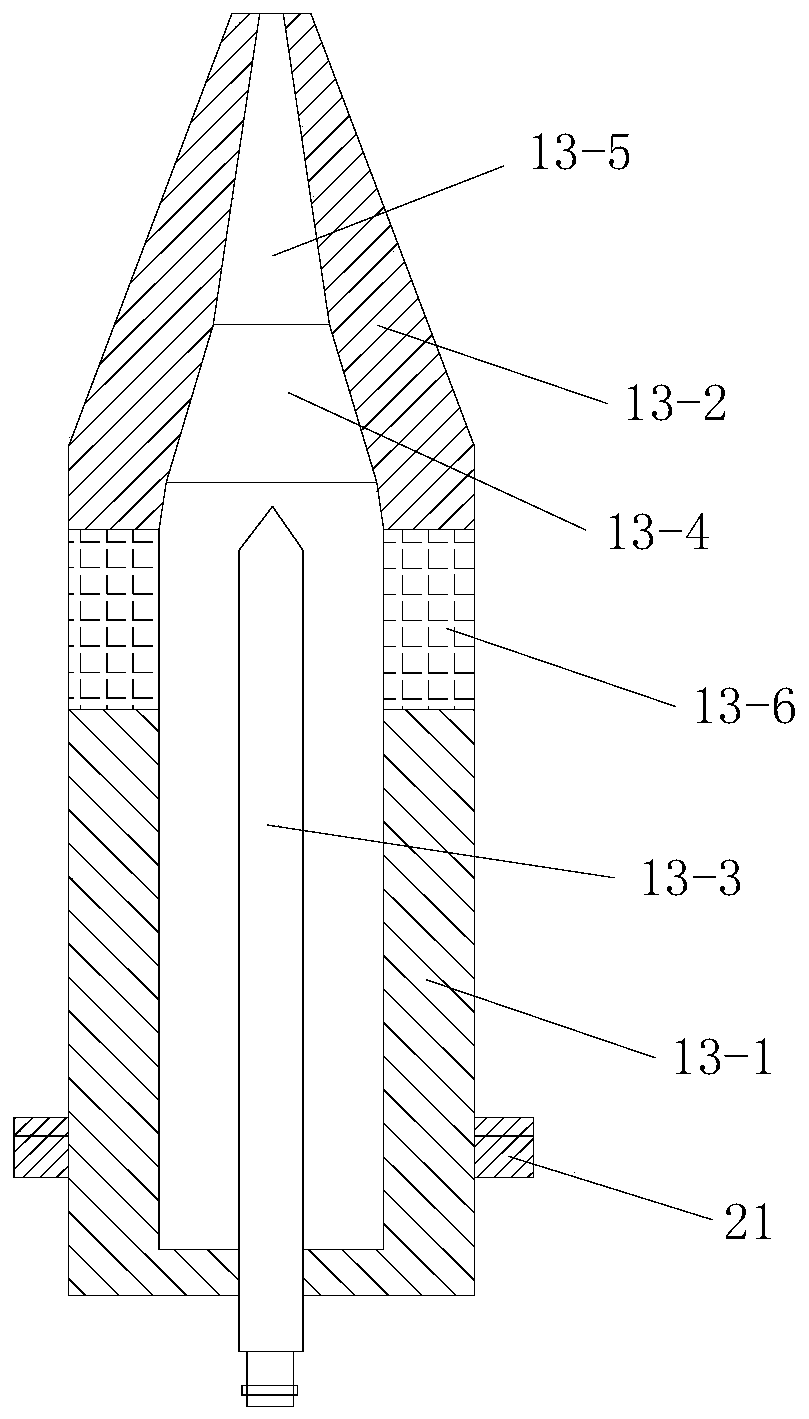

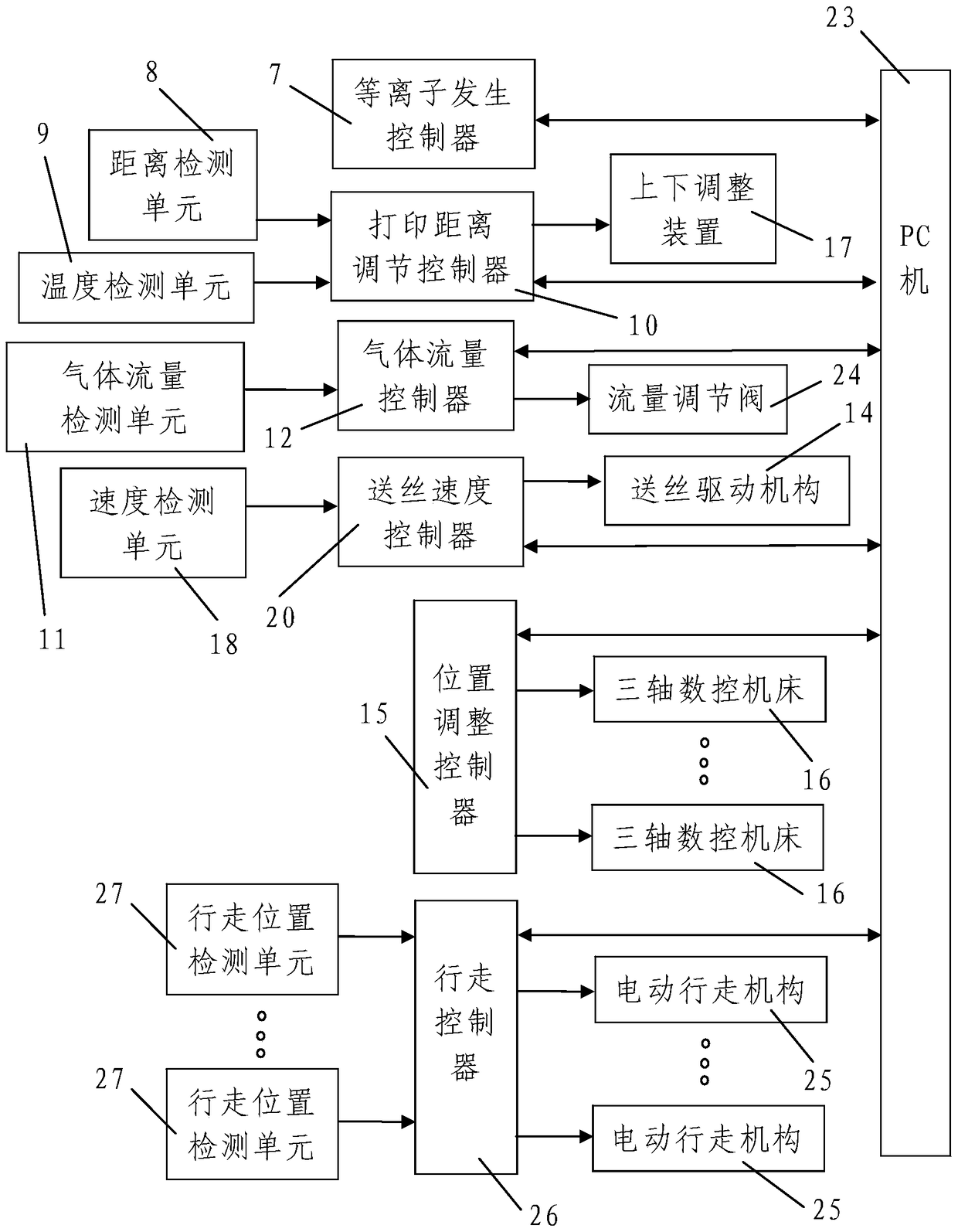

Plasma casting rapid molding equipment and rapid molding method

ActiveCN105922568ASimple structureReasonable designAdditive manufacturing apparatusCeramic shaping apparatusPlasma generatorDistance detection

The invention discloses plasma casting rapid molding equipment and a rapid molding method. The equipment comprises a monitoring system, a plasma beam processing system, and a plurality of printing platforms. Each printing platform comprises a horizontal printing table, a printing table position adjusting device and an electric walking device. The plasma beam processing system includes a plasma generator, a printing position adjusting device, a gas supply device and a wire sending device. The monitoring system includes a walking controller, a plurality of walking position detection units, a temperature detection unit, a distance detection unit and a printing distance adjusting controller. The method comprises the following steps: 1, acquisition of a 3D model of a workpiece to be molded, and hierarchical slicing processing; 2, scanning path filling; 3, printing path acquisition; and 4, printing layer by layer from top to bottom. The invention has the advantages of reasonable design, simple operation, high molding efficiency, good usage effect, no need of enclosed moulding chamber, protection atmosphere or vacuum environment, and direct molding of workpiece in atmosphere environment.

Owner:中研碧诚(北京)科技有限公司

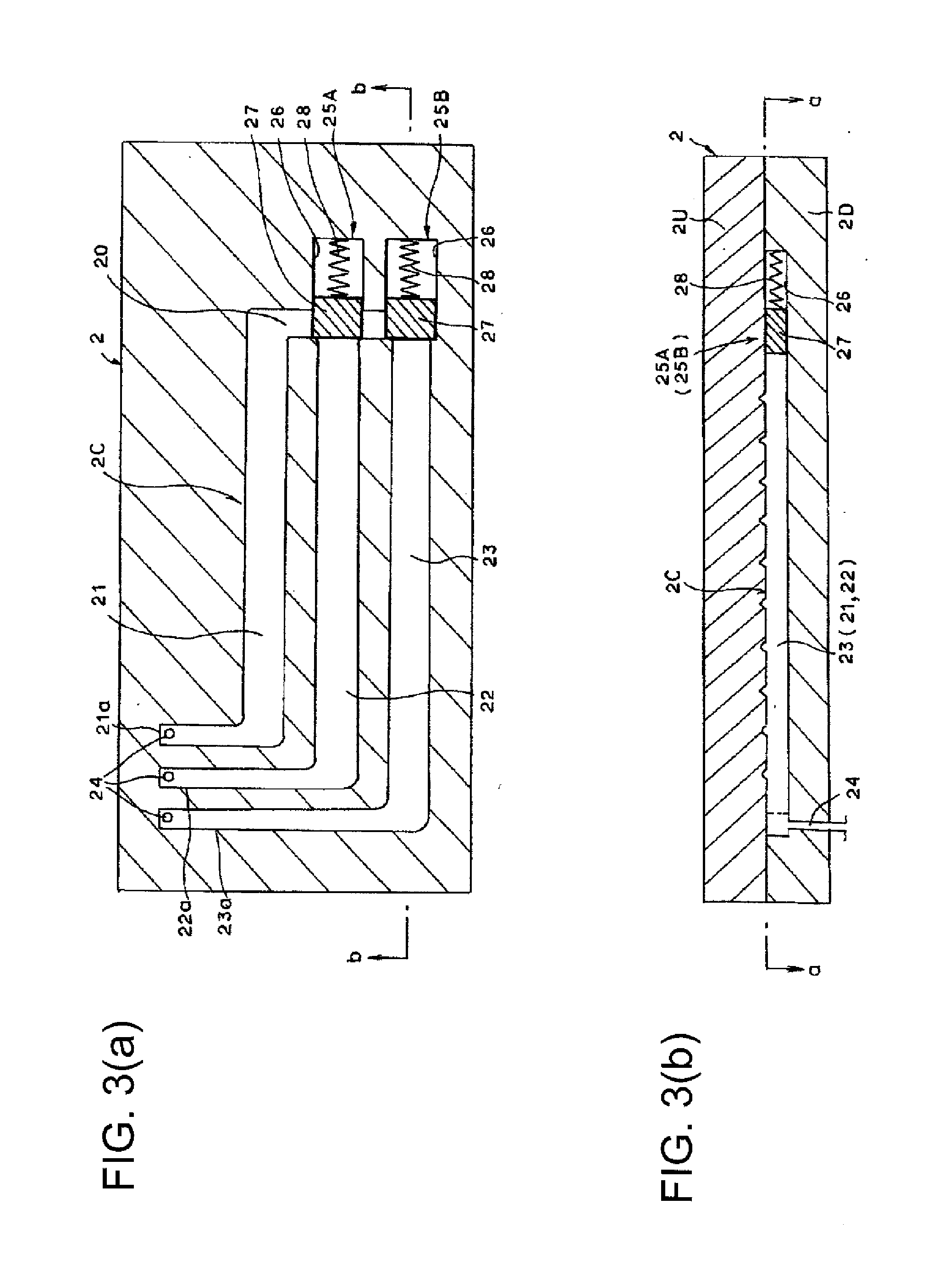

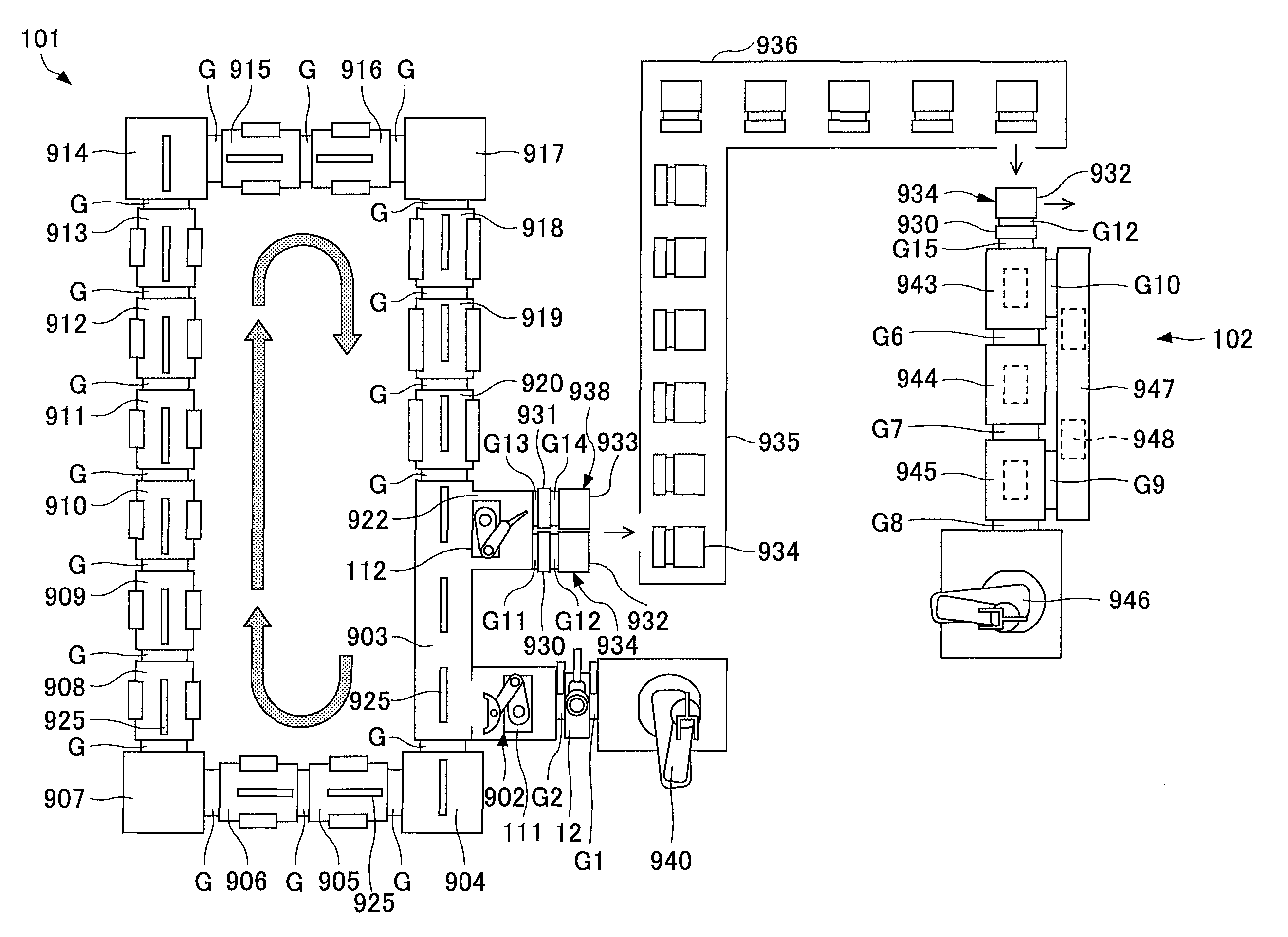

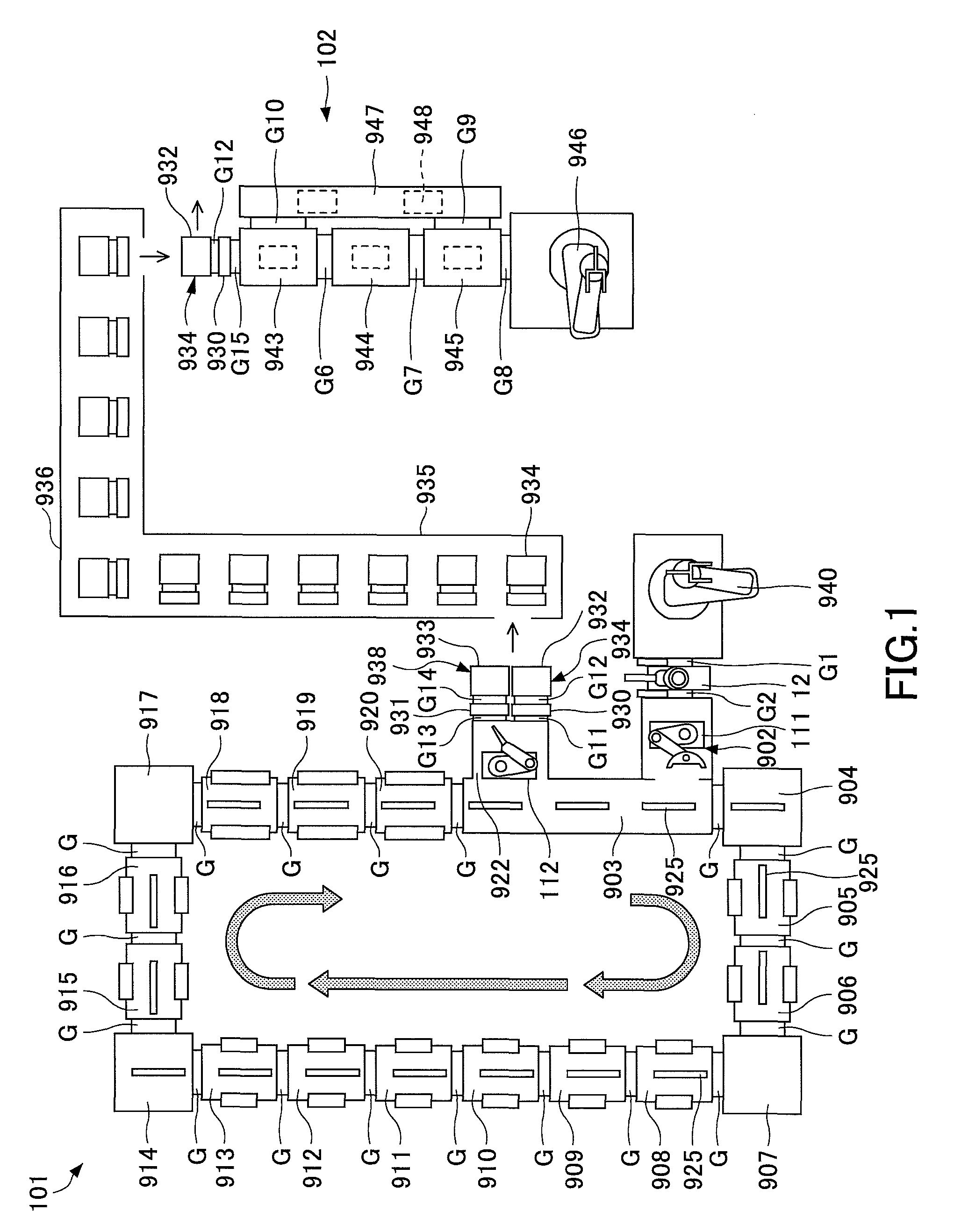

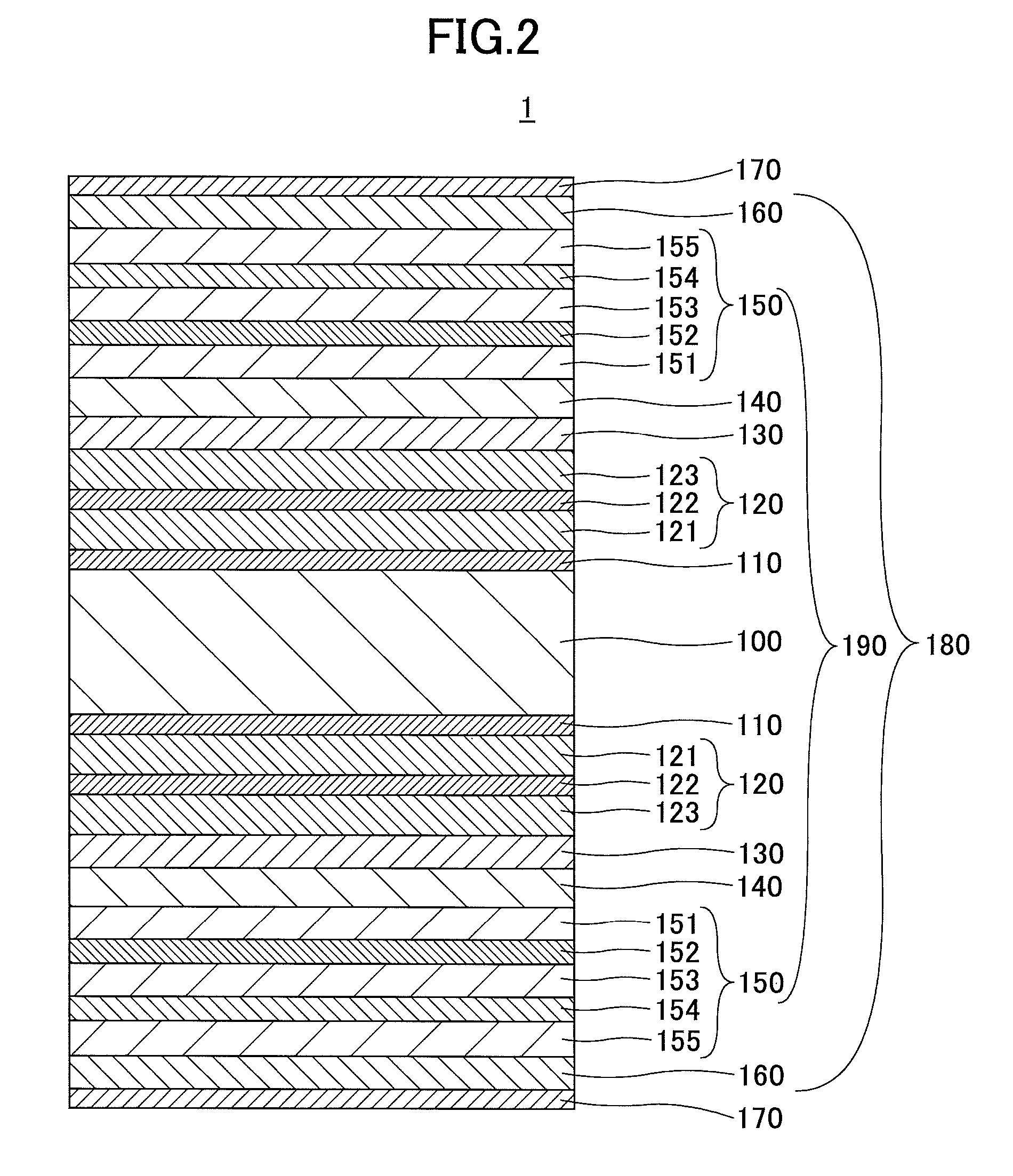

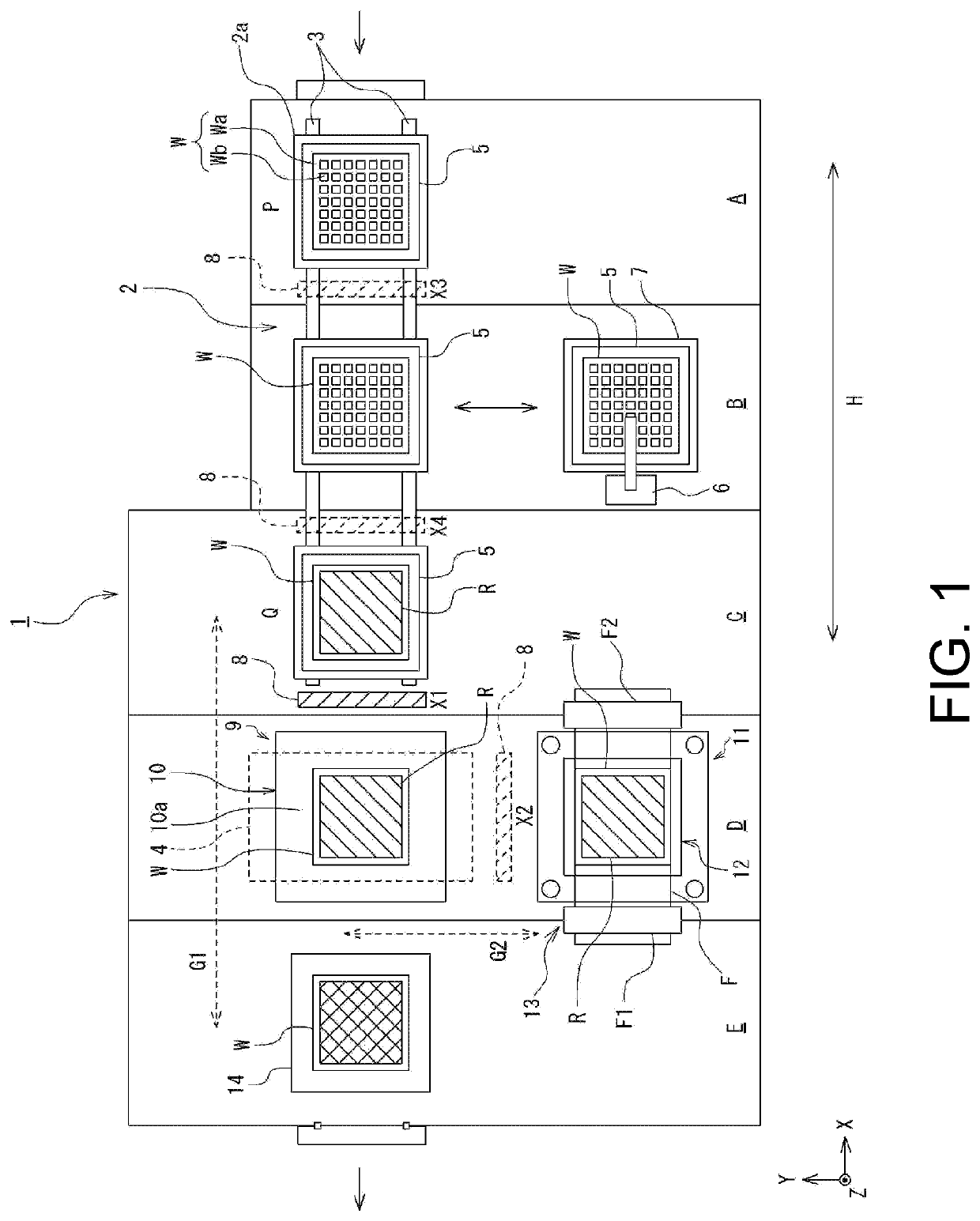

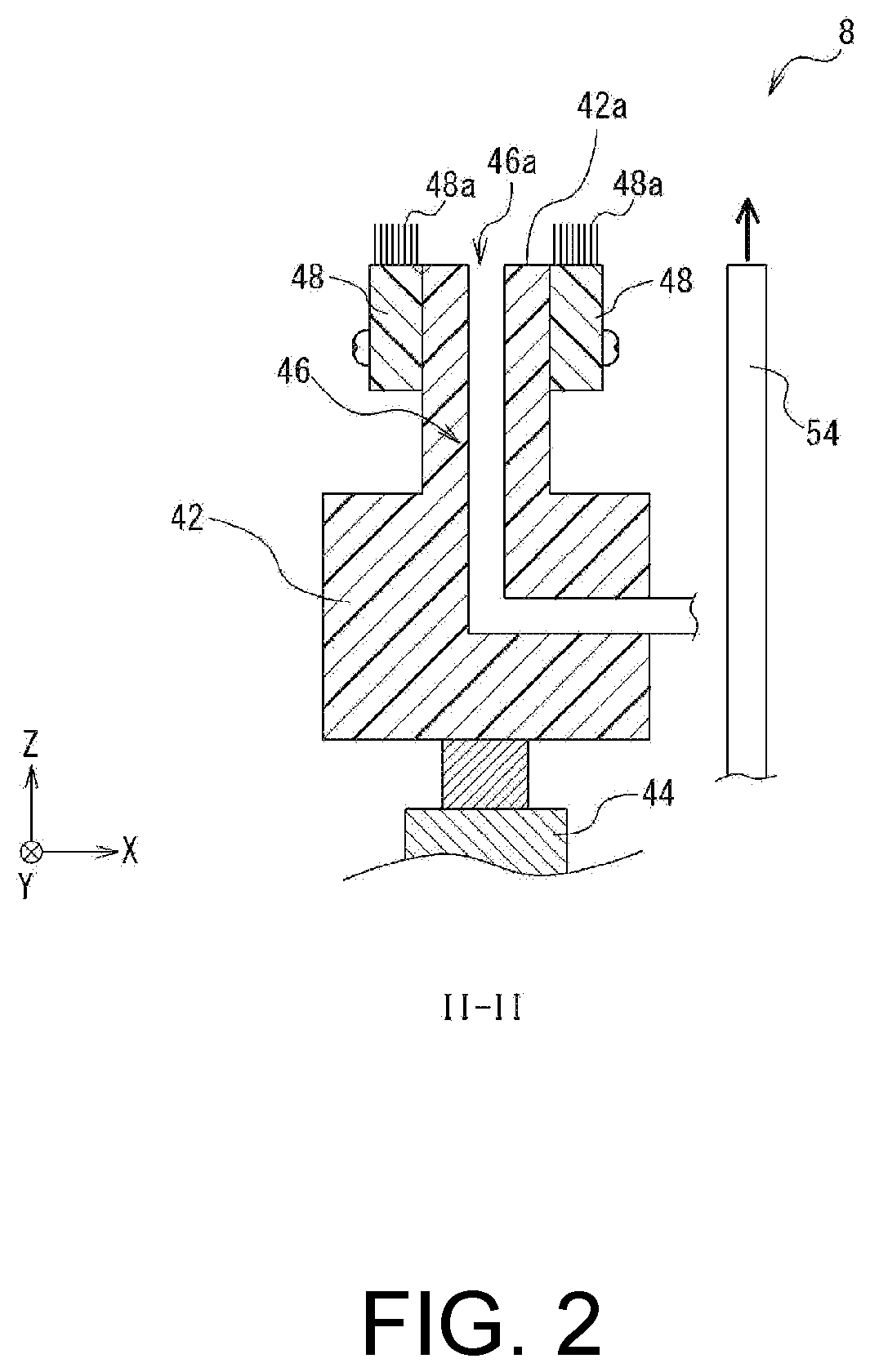

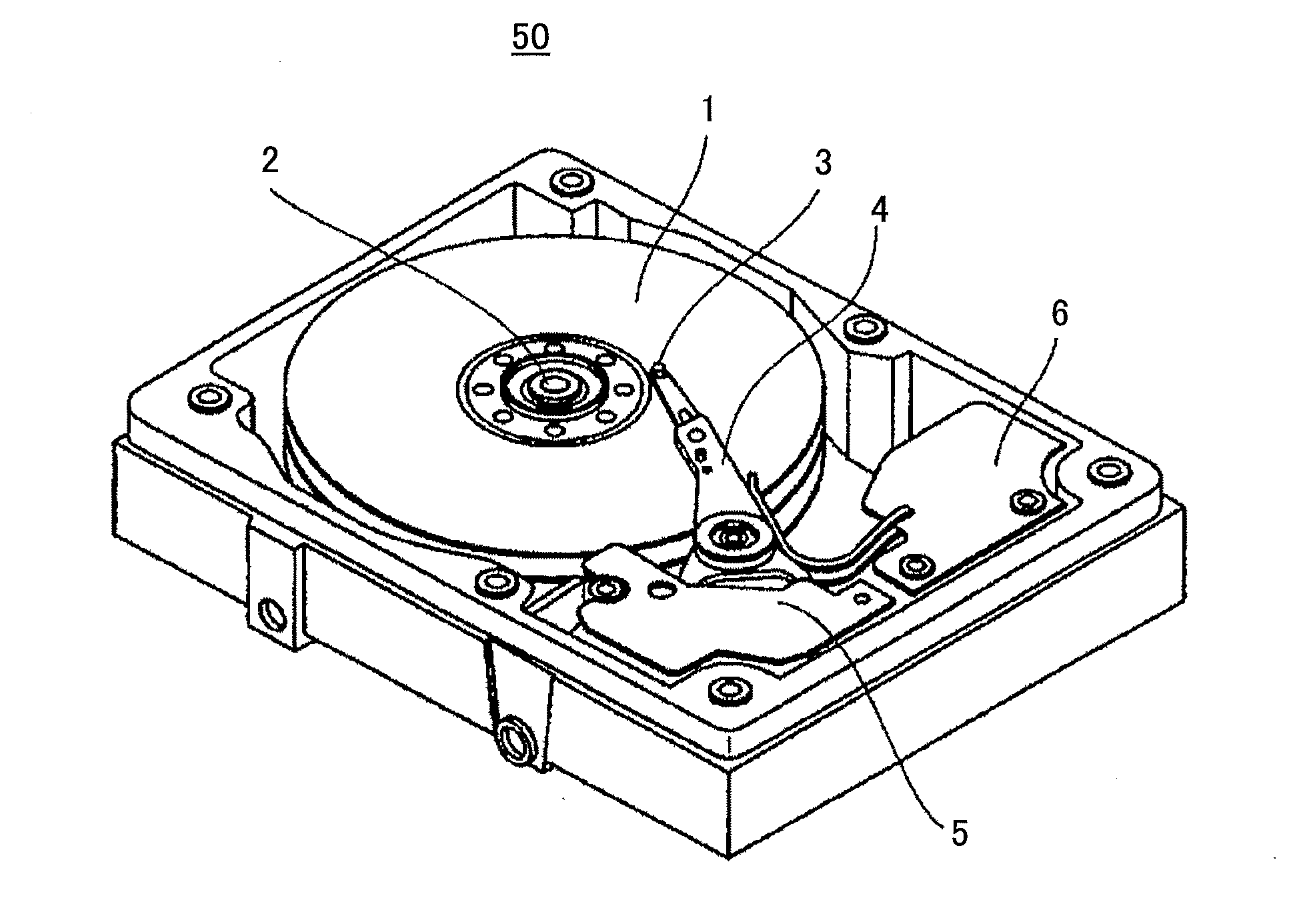

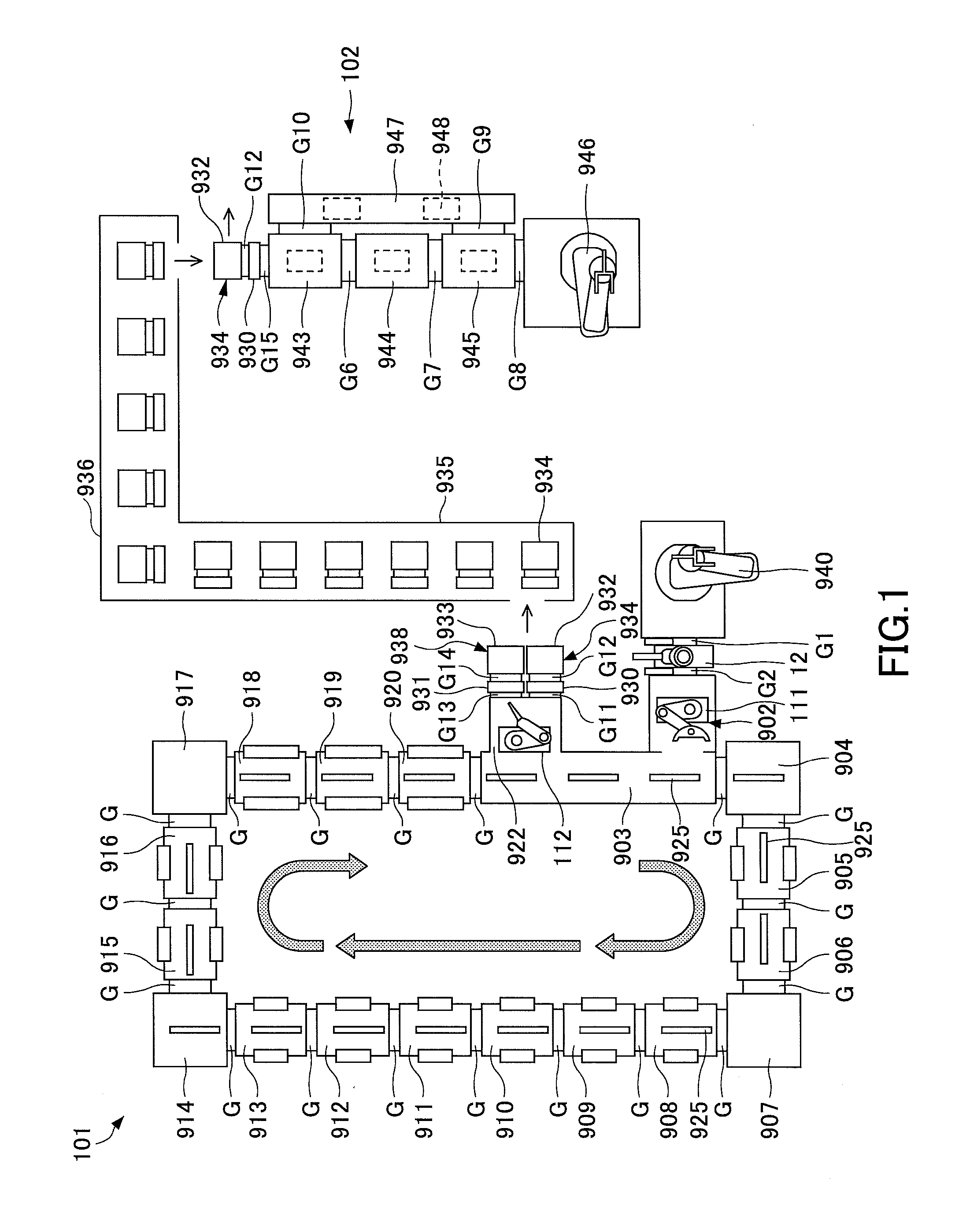

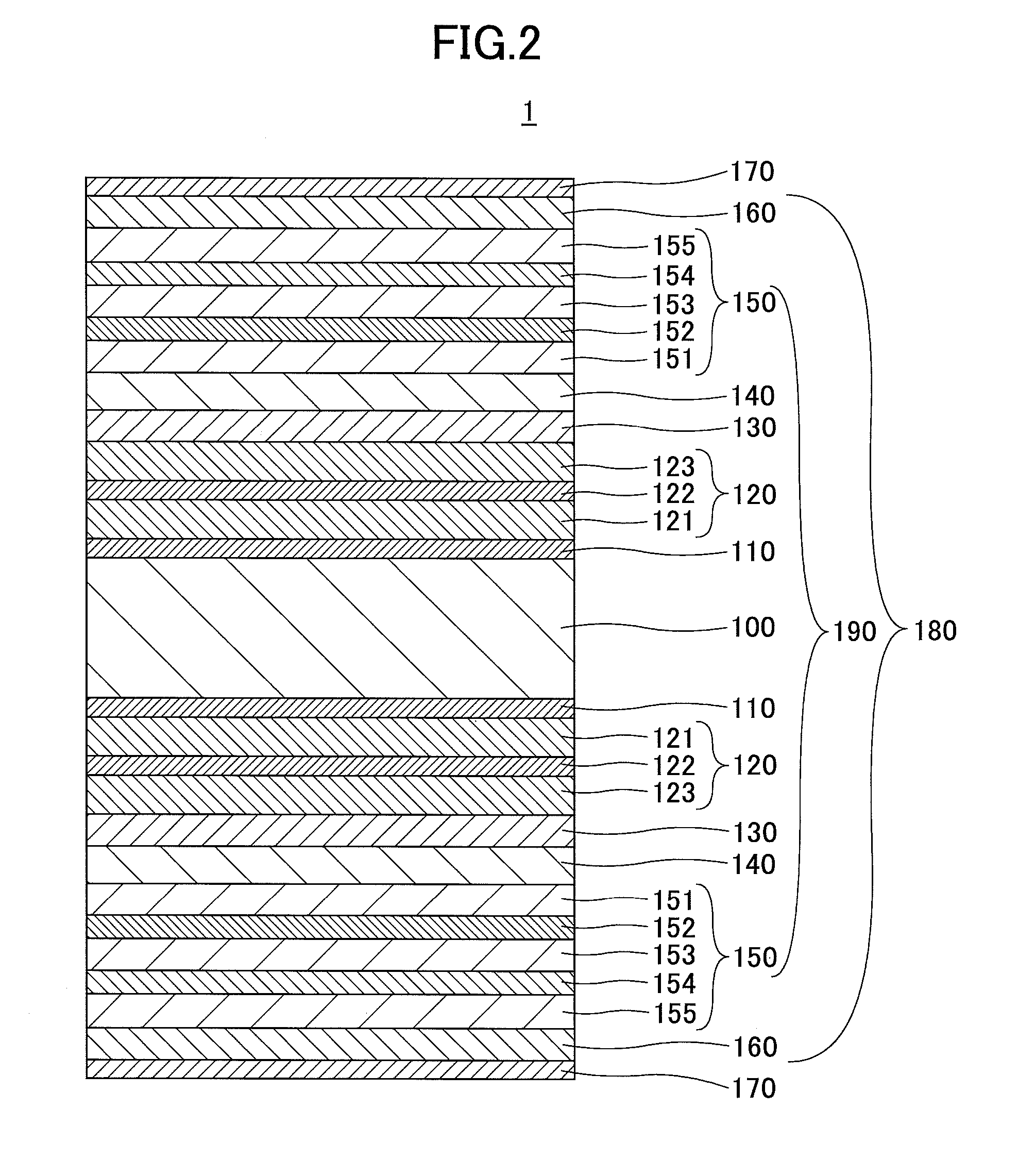

Magnetic recording medium fabrication method and apparatus

ActiveUS9214178B2Avoid molding qualityImprove productivitySemiconductor/solid-state device manufacturingMagnetic layer protectionGas phaseAtmospheric air

Owner:RESONAC CORPORATION

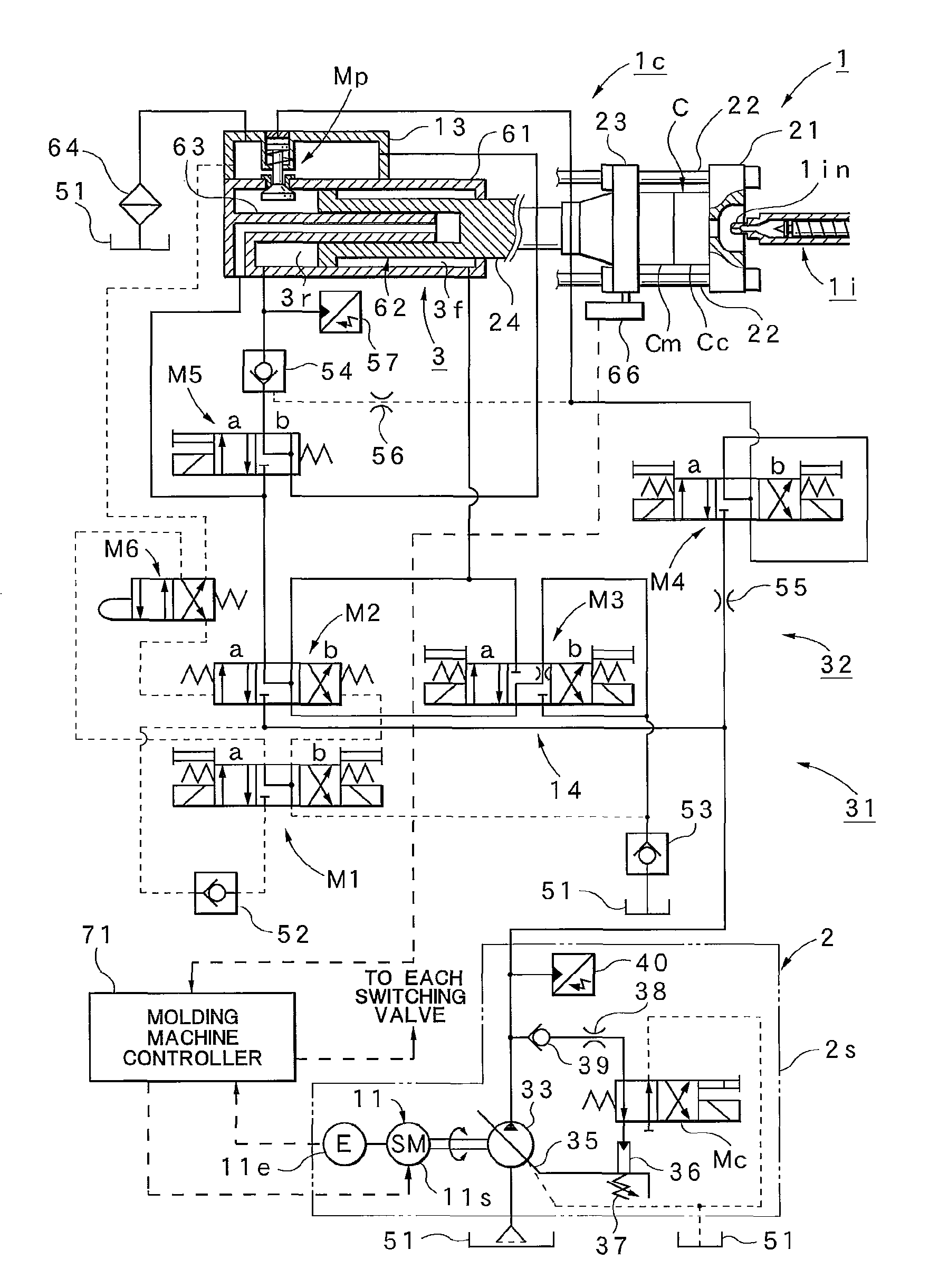

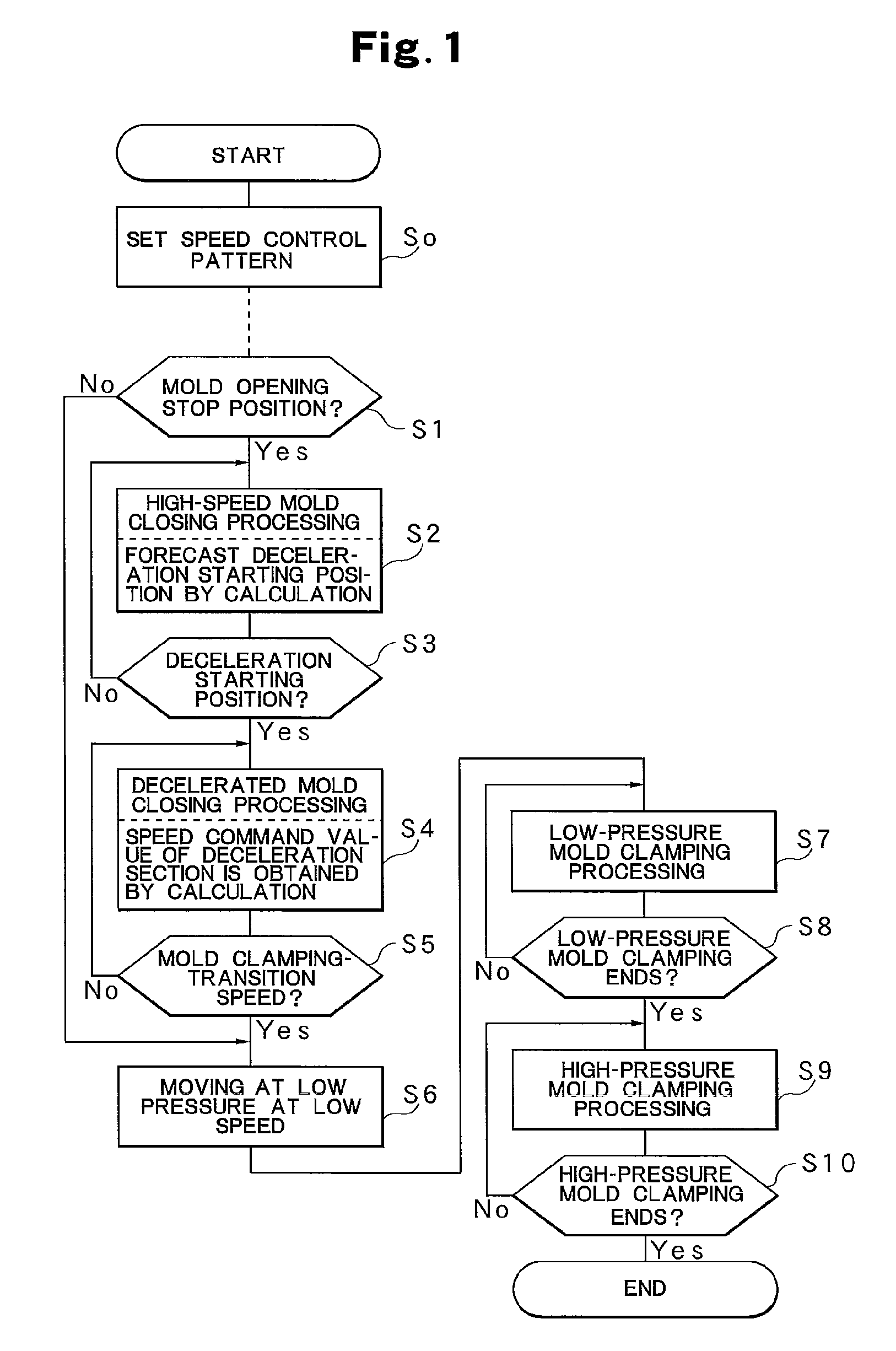

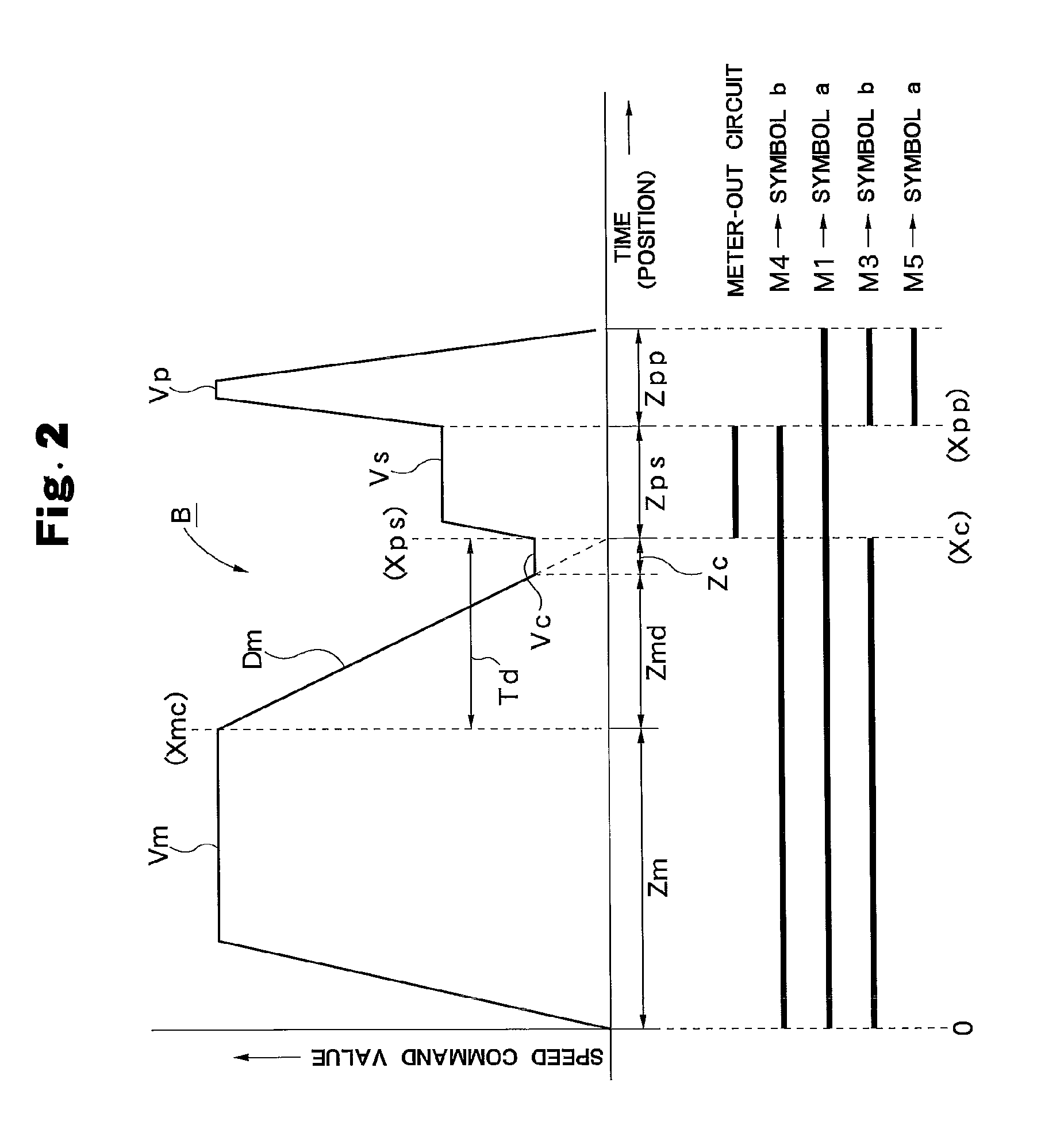

Method for controlling mold clamping device

ActiveUS8244397B2Reduce variationHigh control precisionAuxillary shaping apparatusLow speedControl theory

A predetermined speed control pattern B is sct. In a mold clamping process, in a mold closing section Zm, mold closing control is performed at a mold closing speed Vm, and based on a current mold closing speed Vd and a current mold closing position Xd, which are both detected, a deceleration starting position Xmc of the deceleration section Zmd, where the current mold closing speed Vd becomes a zero (O) at a virtual stop position Xc, is sequentially forecasted at each predetermined time interval by calculation. Upon reaching the deceleration starting position Xmc the deceleration section Zmd is started, and in the deceleration section Zmd, based on the detected current mold closing position Xd, a speed command value Dm corresponding to the speed control pattern B is obtained sequentially by calculation, and according to the speed command value Dm deceleration control is performed. Upon reaching a mold clamping-transition speed Vc, a predetermined mold clamping processing is performed via a low-pressure low-speed section Zc.

Owner:NISSEI PLASTIC IND CO LTD

A molding method of a composite product formed by a tapered metal shell and a glass fiber reinforced plastic heat-proof layer

The invention discloses a forming method for a composite product formed by a conical metal shell and a conical glass reinforced plastic heat-proof layer. The forming method comprises the following steps: 1, forming the conical metal shell; 2, forming the conical glass reinforced heat-proof layer; and 3, sleeving the metal shell by the conical glass reinforced heat-proof layer. Due to the sleeving manner, an aluminum alloy and glass reinforced plastic heat-proof layer composite product is formed by sleeving, and various indexes are controlled when the conical metal shell and the conical glass reinforced plastic heat-proof layer are formed respectively, so that coaxiality between the metal shell and the glass reinforced plastic heat-proof layer is ensured, the quality, the center of mass, centroidal deviation and the roundness of the product are guaranteed, debonding is prevented, and the technical problems occurring when the small-taper long composite product is formed are solved.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

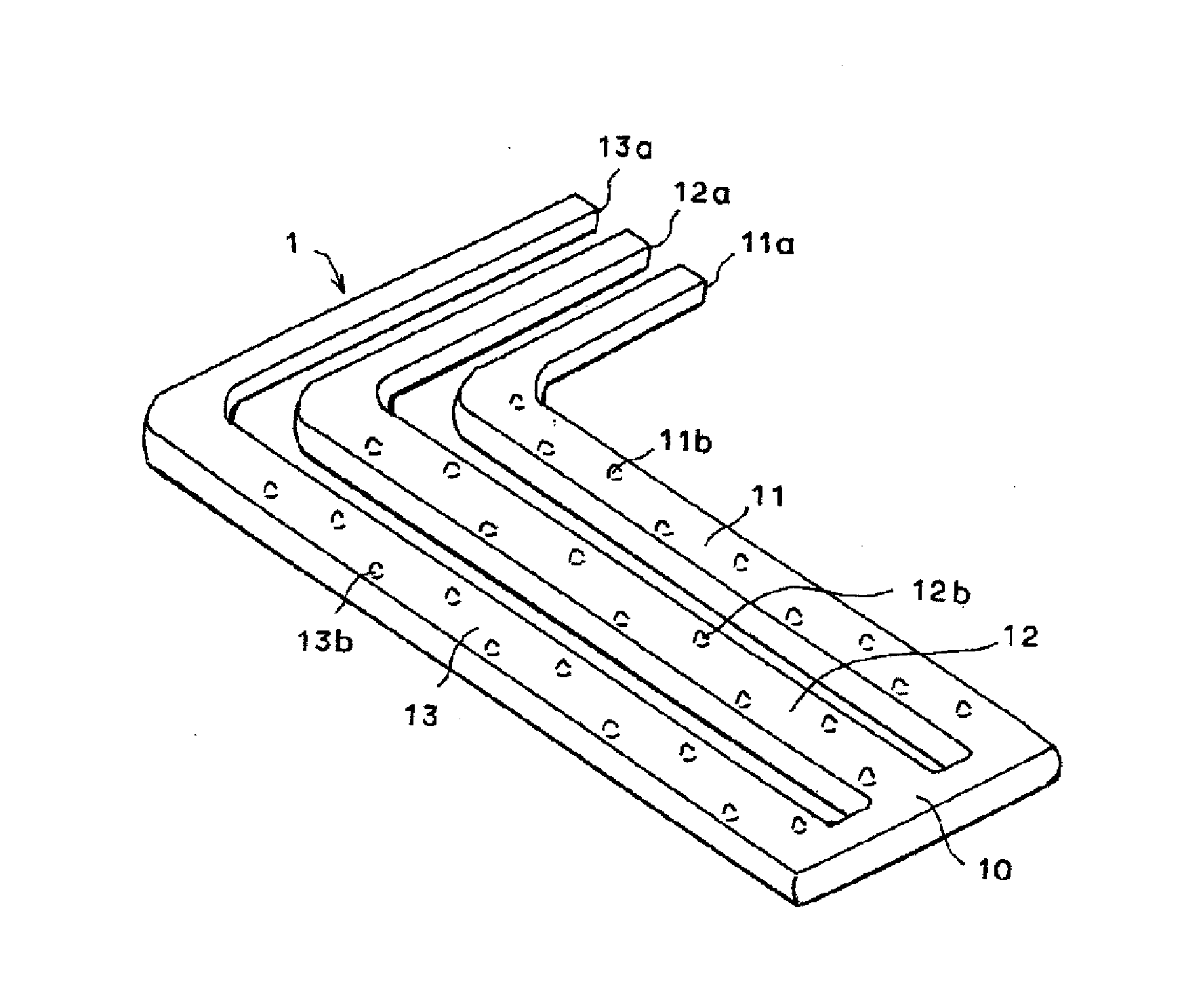

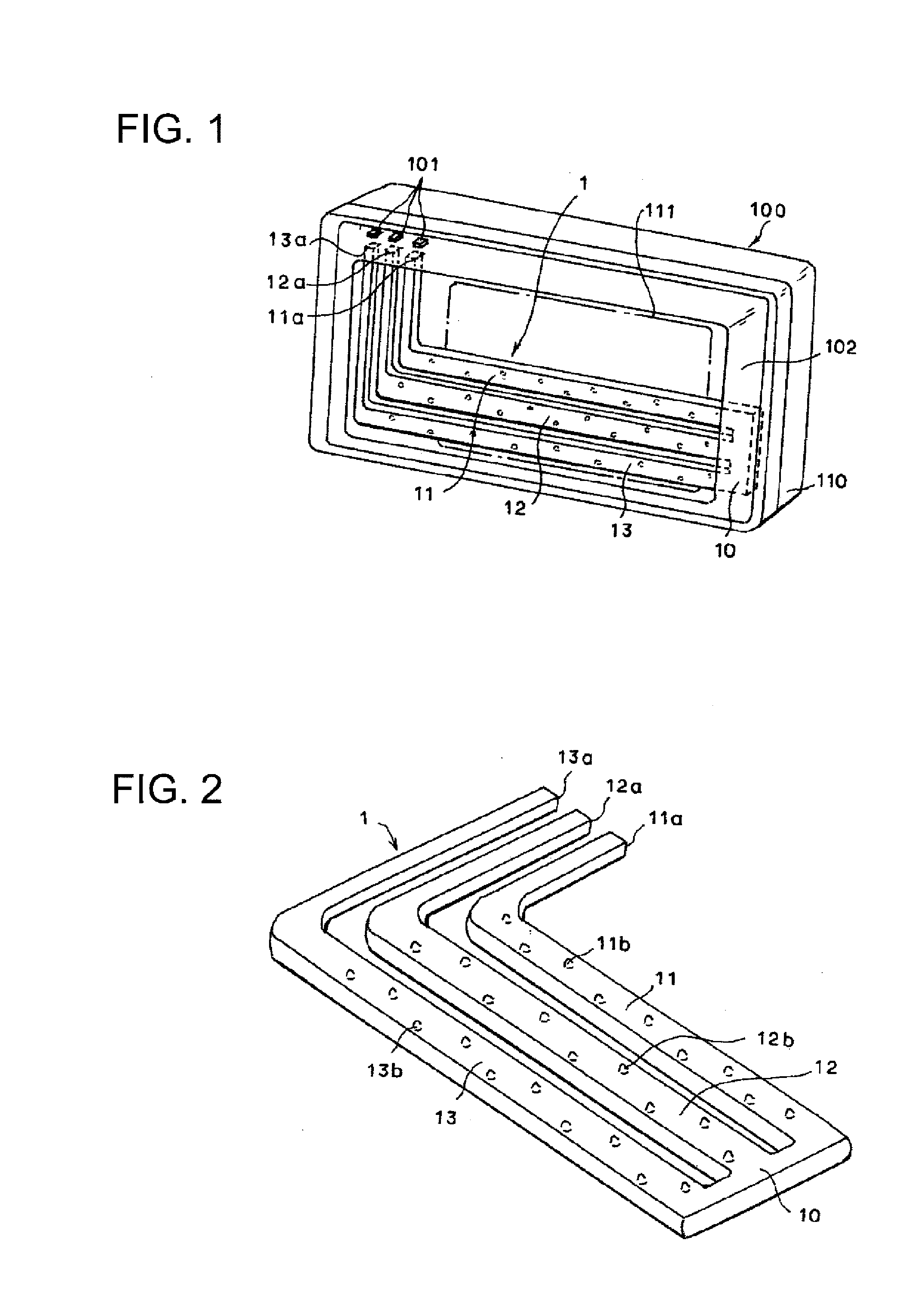

Resin molded product and molding method and molding apparatus thereof

InactiveUS20140147613A1Good lookingUniform brightnessLighting and heating apparatusLayered productsShell moldingEngineering

Owner:KOITO MFG CO LTD

Reinforcing mold for window sill coping templates

PendingCN107419897AControl molding qualityEasy constructionForms/shuttering/falseworksWindow sillArchitectural engineering

The invention discloses a reinforcing mold for window sill coping templates. The reinforcing mold comprises a first vertical rod, a second vertical rod and a connecting rod, wherein the first vertical rod and the second vertical rod are arranged in the vertical direction; the connecting rod is used for connecting the upper part of the first vertical rod and the upper part of the second vertical rod; a distance between the first vertical rod and the second vertical rod is the sum of the width of a coping and the thicknesses of the templates on the two sides of the coping and keels; through holes are respectively formed in the side walls of the first vertical rod and the second vertical rod, the heights of the through holes in the two sides are identical, and a counter-pulling screw rod is arranged in the through holes in the two sides in a penetrating manner, is arranged in the horizontal direction and is positioned at the top of the coping; tightening nuts are mounted at the outer side parts, positioned on the first vertical rod and the second vertical rod, of the counter-pulling screw rod; when the templates are fixed, the keels on the two sides are respectively reinforced at the lower parts of the inner sides of the first vertical rod and the second vertical rod. The reinforcing mold for the window sill coping templates effectively solves the problem that a building block is damaged when being punched in the lower part.

Owner:THE FOURTH OF CHINA EIGHTH ENG BUREAU

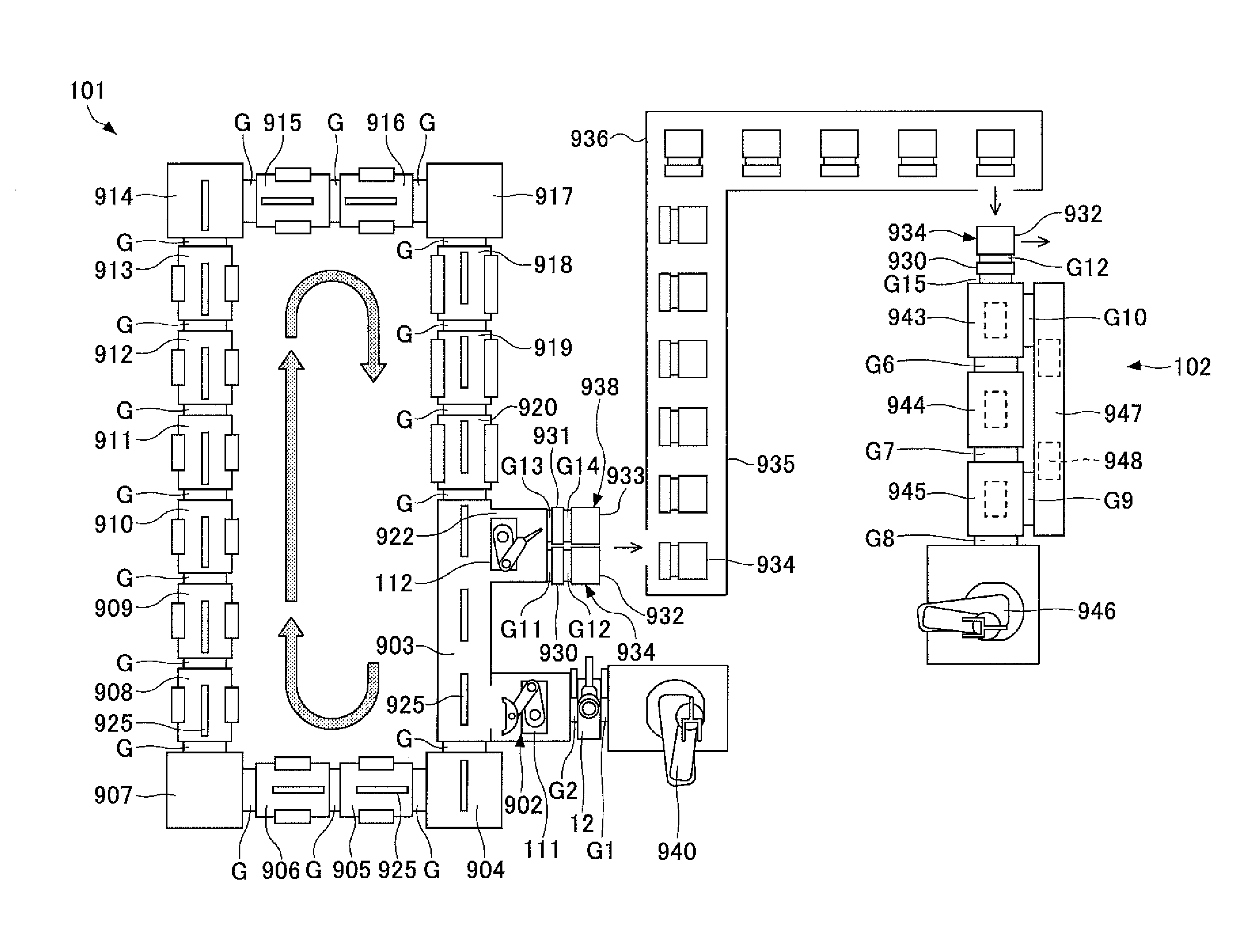

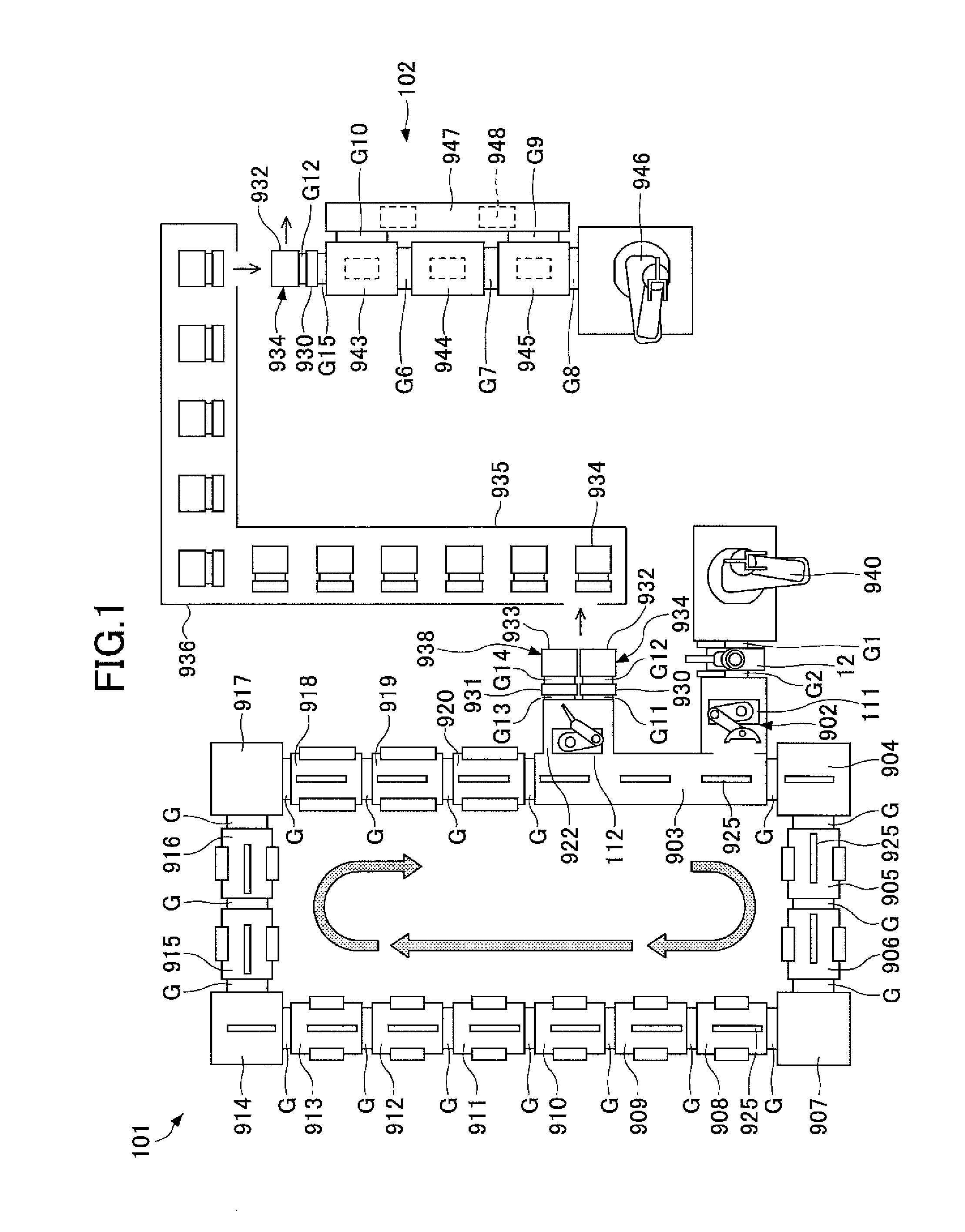

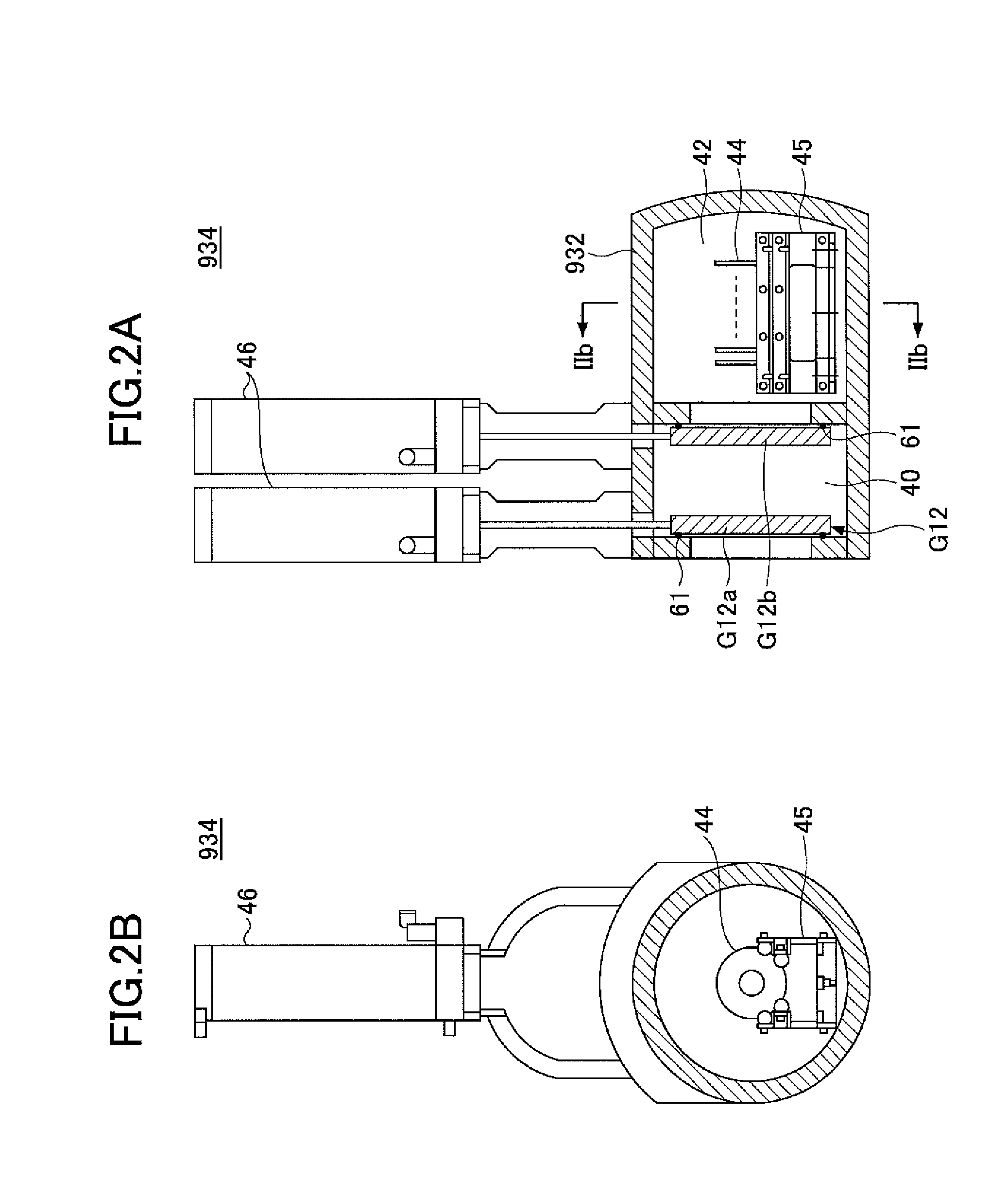

Magnetic recording medium fabrication method and apparatus

ActiveUS9196285B2Avoid molding qualityImprove productivityRecord information storageCard carriersGas phaseEngineering

A method of fabricating a magnetic recording medium sequentially forms a magnetic recording layer, a protection layer, and a lubricant layer on a stacked body. The stacked body is enclosed in a transfer container unit without exposing the stacked body to atmosphere after forming the protection layer on the stacked body by a deposition apparatus, and the transfer container unit is transported to a vapor-phase lubrication deposition apparatus. The stacked body is removed from the transfer container unit without exposing the stacked body to the atmosphere, in order to form the lubricant layer on the stacked body within the vapor-phase lubrication deposition apparatus.

Owner:RESONAC CORPORATION

Forming mold for automobile exhaust pipe

The invention discloses a forming mold for an automobile exhaust pipe, and belongs to the technical field of mold equipment. The forming mold for the automobile exhaust pipe comprises a movable mold set, a fixed mold set, a movable mold cavity, a fixed mold cavity, a shooting moving oil cylinder, a pushing mechanism and a cooling system. The movable mold cavity and the fixed mold cavity are each internally provided with a core bend pipe part and a core straight pipe part, the ends, away from each other, of the core bent pipe parts and the core straight pipe parts are correspondingly and slidably connected into bent pipe grooves and straight pipe grooves, and the core bent pipe parts and the core straight pipe parts are all provided with cooling grooves in a drilled mode. The forming mold facilitates the disassembly of casting parts, realizes the cooling function in the core pulling process, and solves the problem of the forming quality of the exhaust pipe caused by adhesion of impurities in the core pulling process due to poor cooling of a core; and through the real-time monitoring of the pressure in an air pipe, the core bent pipe parts are closely attached to the core straight pipe parts, and at the same time, the leakproofness of the movable mold cavity and the fixed mold cavity can further be ensured.

Owner:江苏久祥汽车电器集团有限公司

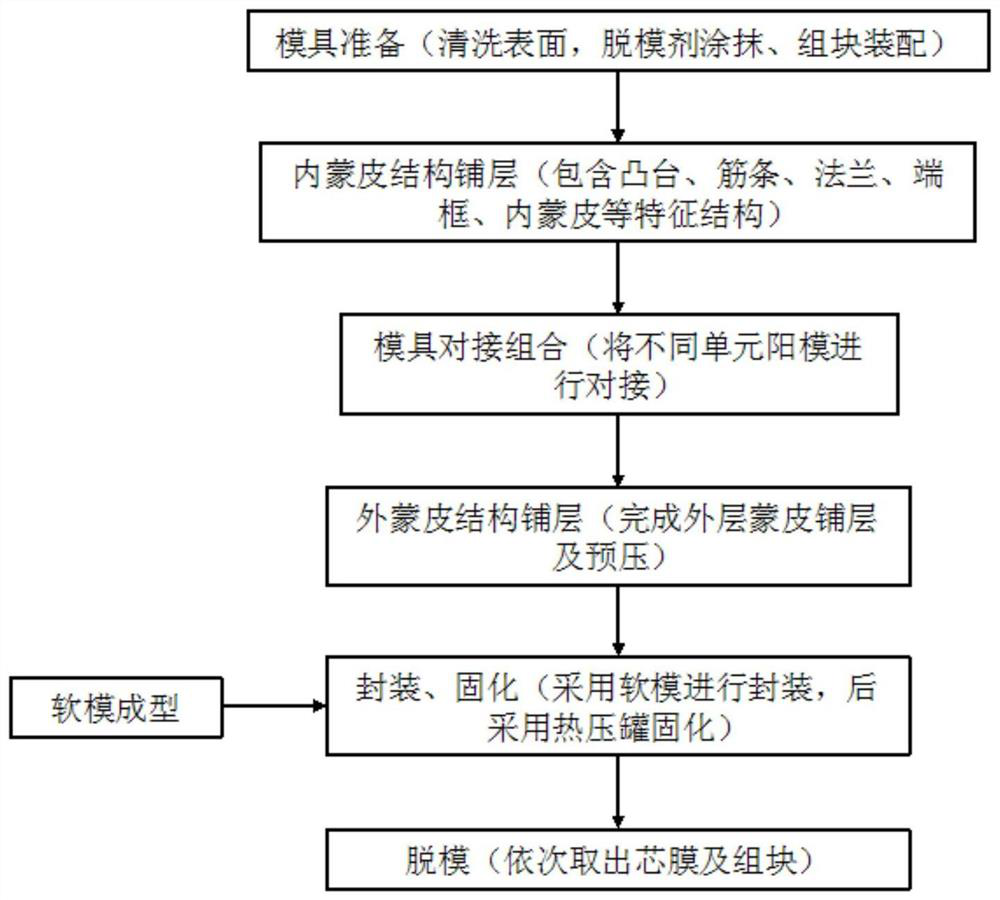

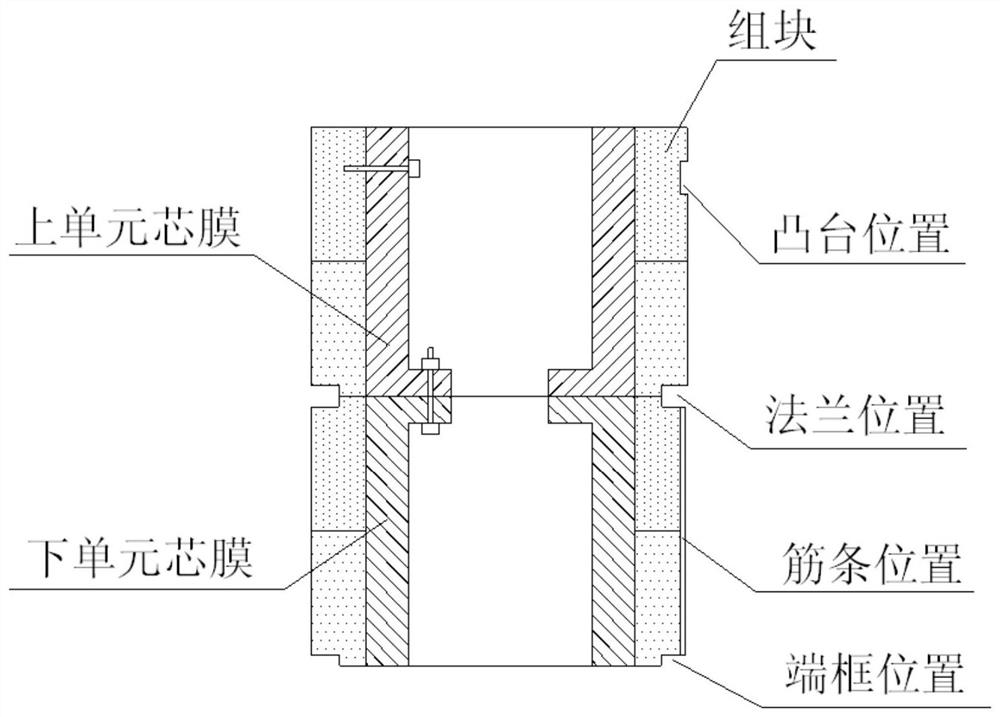

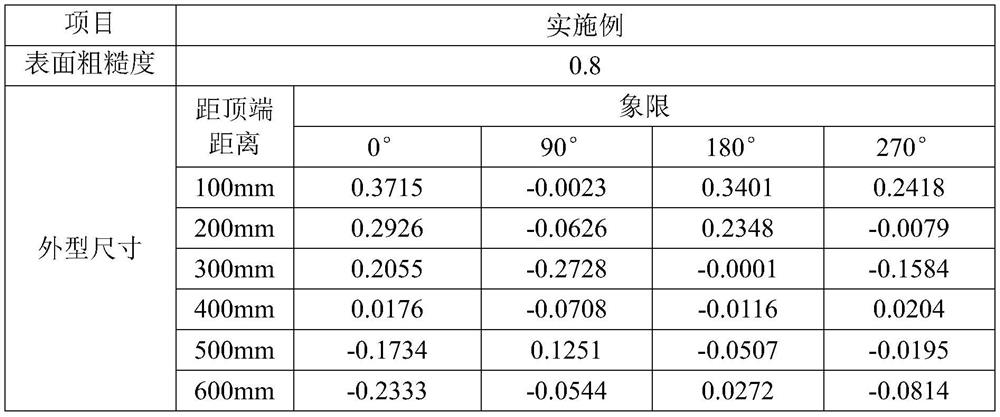

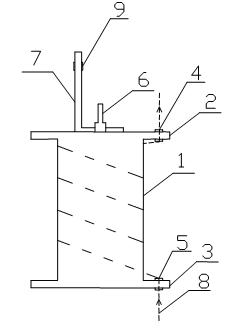

Integrated forming method for composite material cabin section

ActiveCN113829638AGuaranteed dimensional position accuracyAvoid molding qualityWeight reductionFiberStructural engineering

The invention provides an integrated forming method for a composite material cabin section, and belongs to the technical field of composite material forming. The integrated forming method comprises the following steps: designing molds corresponding to different area units of an inner molded surface of the cabin section, and taking the partitioned molds as male molds to carry out structural laying such as ribs, bosses, flanges, end frames and inner skins on the outer side surfaces of the partitioned molds; then combining the molds in different areas, and then carrying out outer skin structure laying to form an integrated overall structure; and finally, packaging the outer molded surface of the integrated overall structure by adopting a soft mold, and carrying out curing forming. The forming method adopted by the invention is simple in operation steps, can effectively realize integrated forming of the cabin section with a complex structure, and can guarantee the fiber continuity of the internal characteristic structure of the cabin section; and the prepared cabin section has relatively high inner and outer molded surface size precision, so that the subsequent processing and assembling efficiency is effectively improved, and the integrated forming method has a relatively good application prospect and a relatively good popularization value.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Twist contraction preventing device for over-twisted yarns

The invention discloses a twist contraction preventing device for over-twisted yarns. A top plate, a yarn storage tube and a rotating bottom plate are arranged at one time from top to bottom, and the top plate, the yarn storage tube and the rotating bottom plate are connected through a main shaft, wherein the top plate is provided with a yarn outlet guide ring, and the rotating bottom plate is provided with a yarn inlet guide ring. The device can effectively improve non-uniform tension and prevent twist contraction in the channel bobbin forming process. Therefore, the forming quality of a bobbin is controlled, the hardness of the bobbin is ensured, and the hardness of the bobbin is uniform.

Owner:JIANGSU HUAJIA SILK

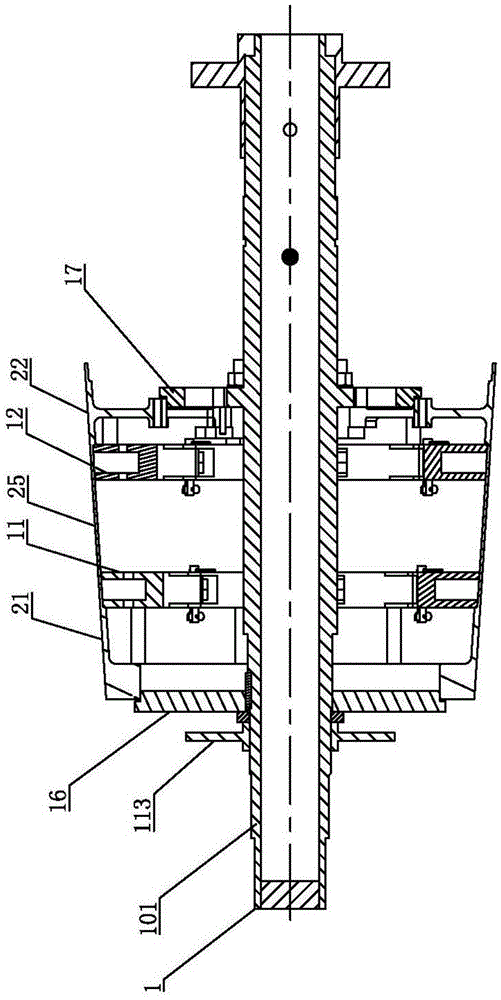

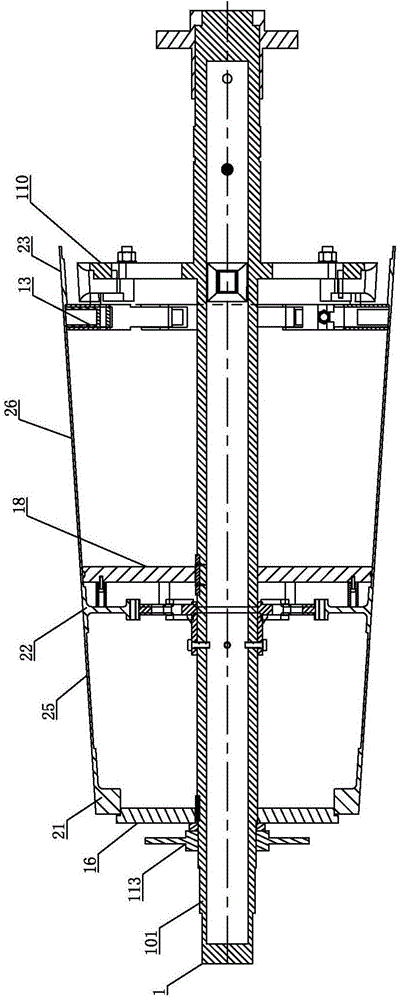

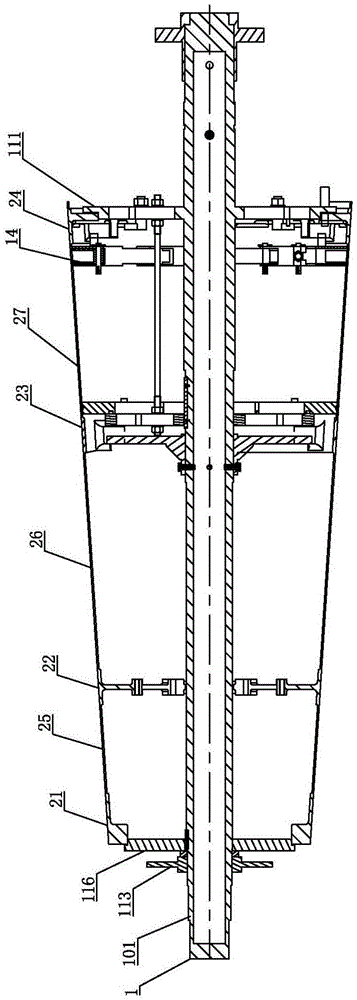

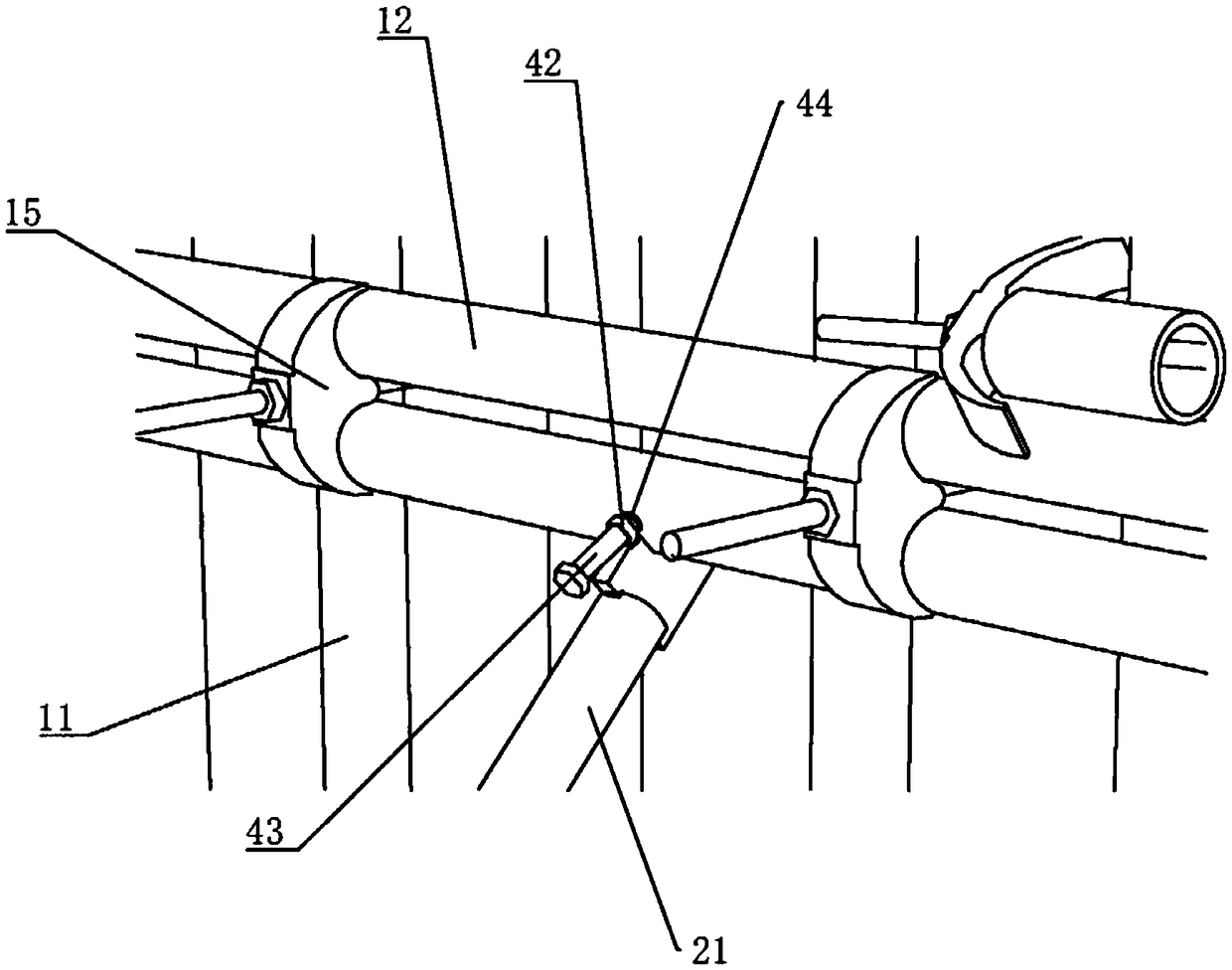

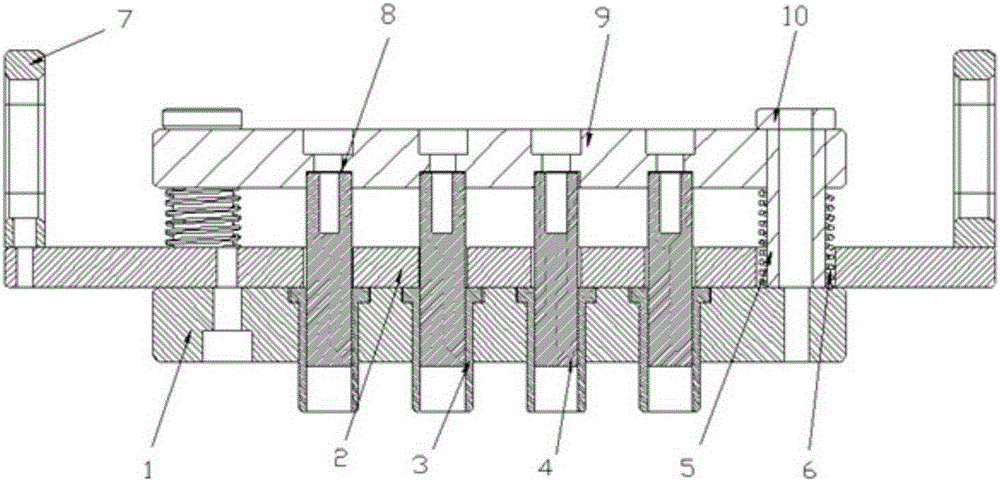

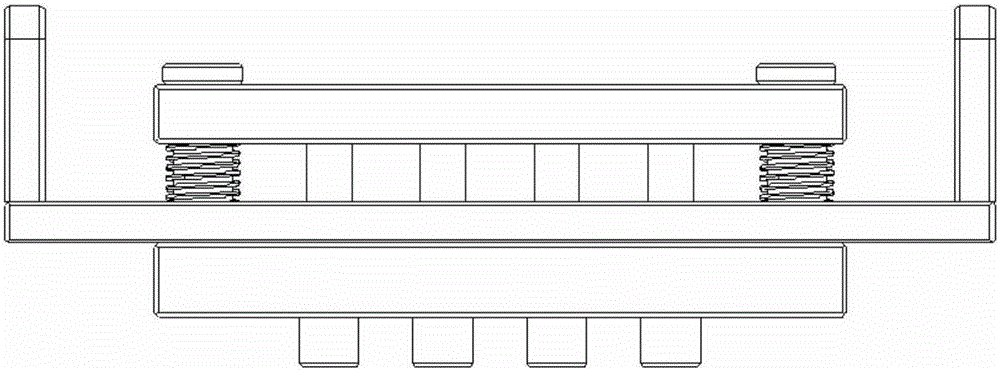

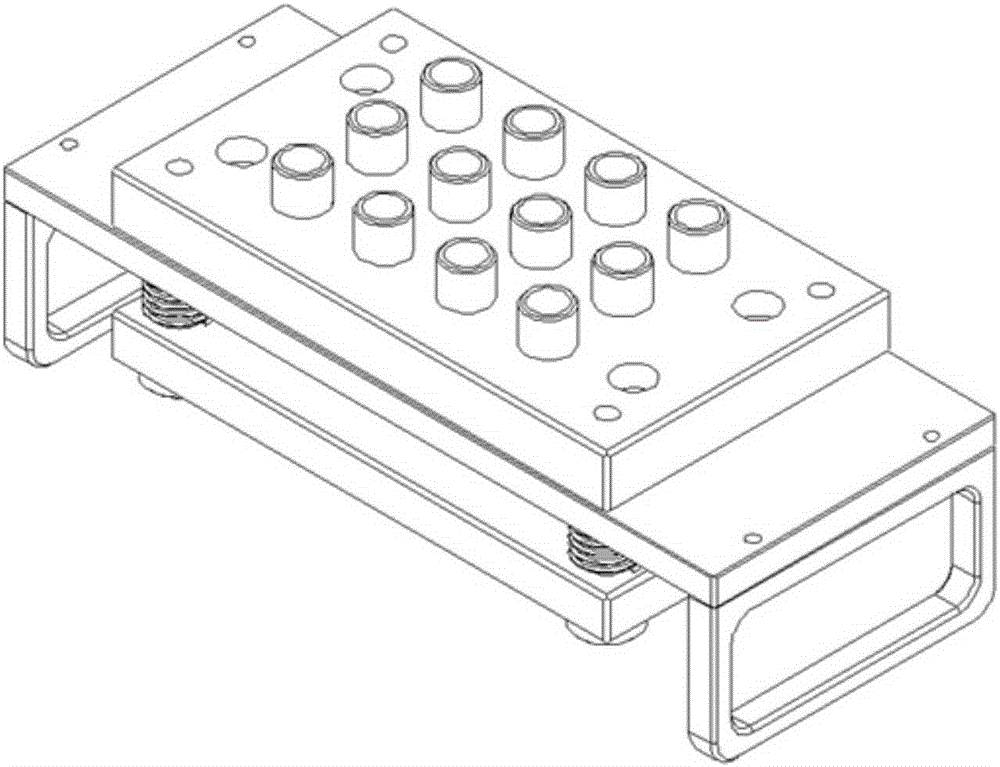

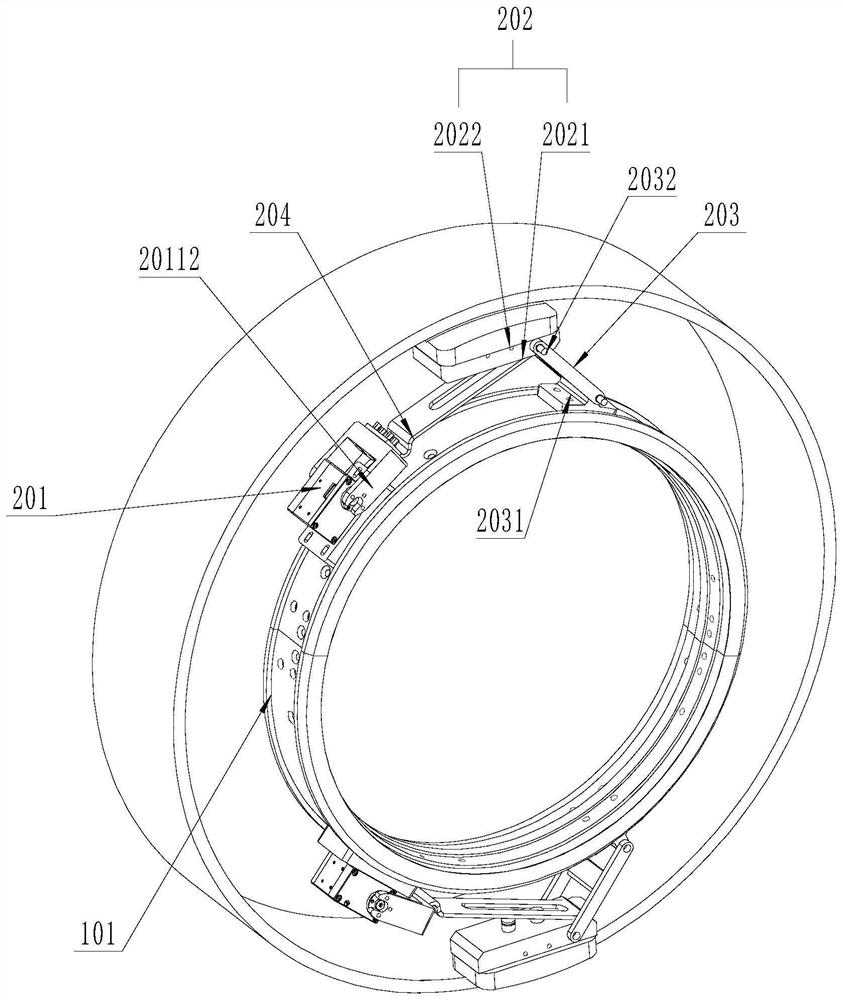

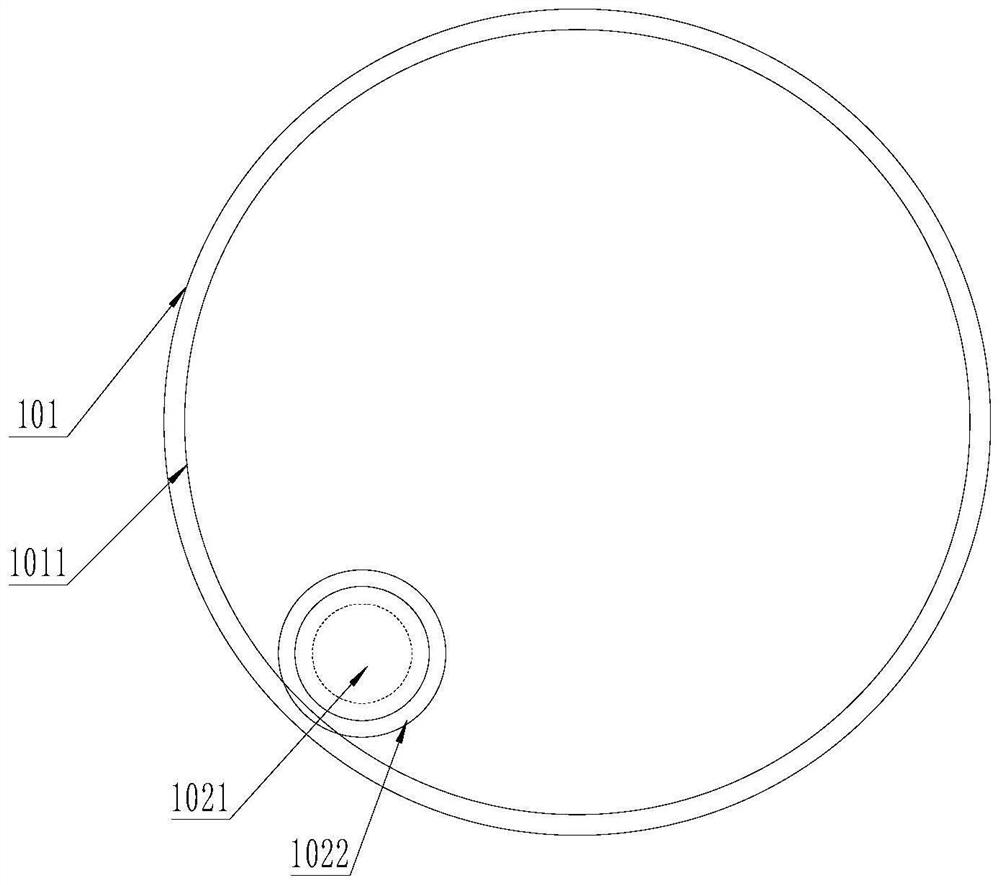

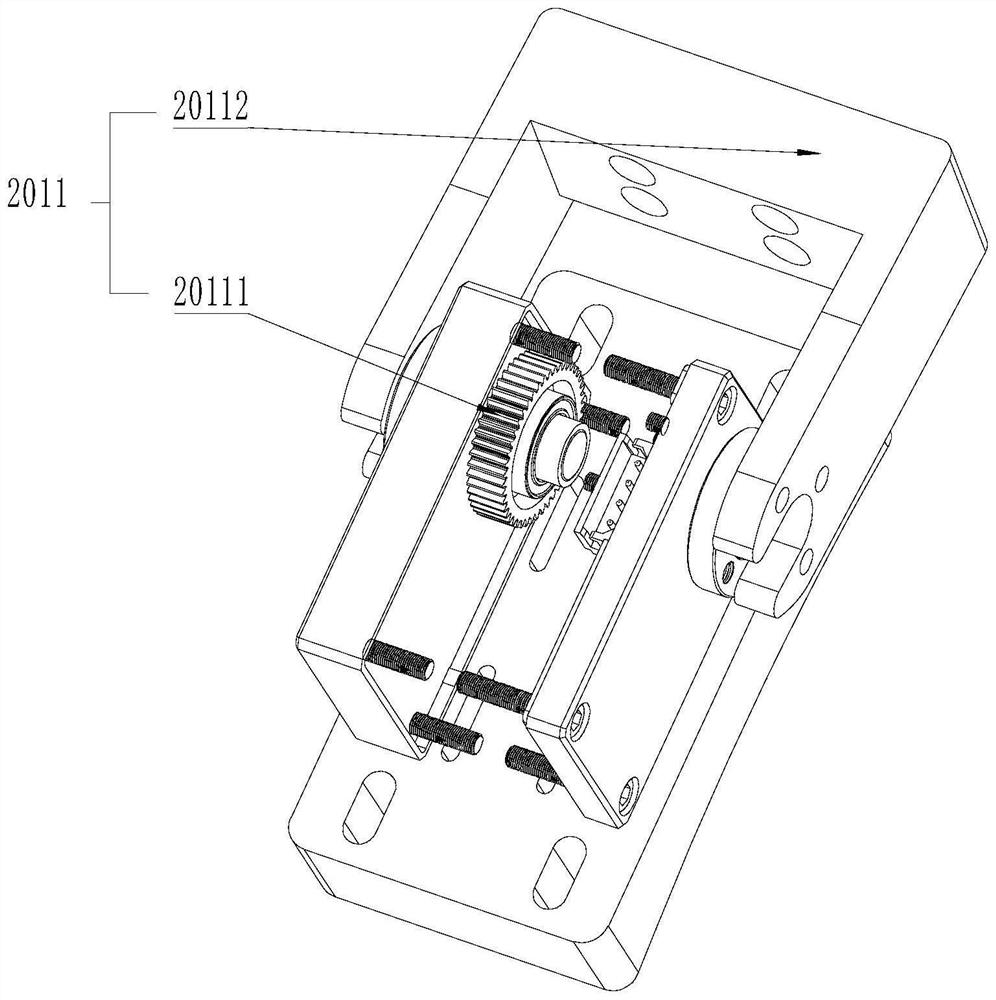

Liner inner aligning mechanism, aligning device system and pipeline welding method thereof

PendingCN114211197APlay a role of synchronous follow-upAvoid molding qualityWelding/cutting auxillary devicesAuxillary welding devicesWeld seamMechanical property

The invention relates to a liner inner aligning mechanism, an aligning device system and a pipeline welding method thereof, and the liner inner aligning mechanism and pipeline outer welding equipment synchronously rotate by driving a rotating ring to rotate, so that a synchronous following effect is achieved. When the backing mechanism can be finely adjusted under the action of the flexible elastic piece, the backing mechanism is tightly attached to the welding seam so as to control the forming quality of the welding seam on the back face during backing welding, and the welding efficiency and the welding quality of backing welding are improved; through the arrangement of the ceramic layer, the problem that the mechanical property of a welding seam is affected due to the fact that copper permeates into the welding seam easily in the welding process of a traditional copper liner inner aligning device is solved, the ceramic layer does not make direct contact with steel pipes on the two sides of the welding seam, and the service life of the ceramic layer is guaranteed.

Owner:电王智焊科技天津有限公司

Formwork for improving utilization rate of aluminum alloy formwork body on non-standard layer

InactiveCN112523496AIncrease stiffnessEasy to operateForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksStructural engineeringMechanical engineering

The invention discloses a formwork for improving the utilization rate of an aluminum alloy formwork body on a non-standard layer. The formwork comprises the aluminum alloy formwork body and wood formwork bodies, a first back arris rod, a second back arris rod, a third back arris rod and a fourth back arris rod are sequentially installed on the two sides of the aluminum alloy formwork body from bottom to top through first opposite-pull screws, a first adjustable inclined strut is installed on the side, away from the aluminum alloy formwork body, of the first back arris rod, a second adjustableinclined strut is installed on the side, away from the aluminum alloy formwork body, of the fourth back arris rod, the wood formwork bodies are arranged on the two sides of the top of the aluminum alloy formwork body, a second opposite-pull screw is installed between the wood formwork bodies on the two sides, and the second opposite-pull screw is sleeved with an opposite-pull screw sleeve. Therefore, the formwork for improving the utilization rate of the aluminum alloy formwork body on the non-standard layer is simple and reasonable in structure, the utilization rate of the aluminum formwork body is improved, meanwhile, the overall stability is improved, the rigidity of the formwork is enhanced, the percent of pass of construction quality is improved, and stability and practicability are high.

Owner:BEIJING URBAN CONSTR NORTH CONSTR

Resin molding apparatus and cleaning method

PendingUS20210351045A1Avoid molding qualityInhibit deteriorationBrush bodiesSemiconductor/solid-state device manufacturingPolymer scienceElectronic component

A resin molding apparatus and a cleaning method of a workpiece which can prevent a workpiece from being carried into a mold die in a state where particles (dust) are adhered to the workpiece, and can prevent deterioration of molding quality. A resin molding apparatus according to the present invention, in which a workpiece with an electronic component mounted on a carrier and a mold resin are carried into a mold die, includes: a press part having the mold die for clamping and resin-sealing the workpiece and the mold resin; and a cleaning apparatus for cleaning a back surface of the workpiece conveyed to the press part, wherein the electronic component is not mounted on the back surface. The cleaning apparatus is arranged at a position overlapping a conveyance path of the workpiece on the upstream side of the press part.

Owner:APIC YAMADA CORP

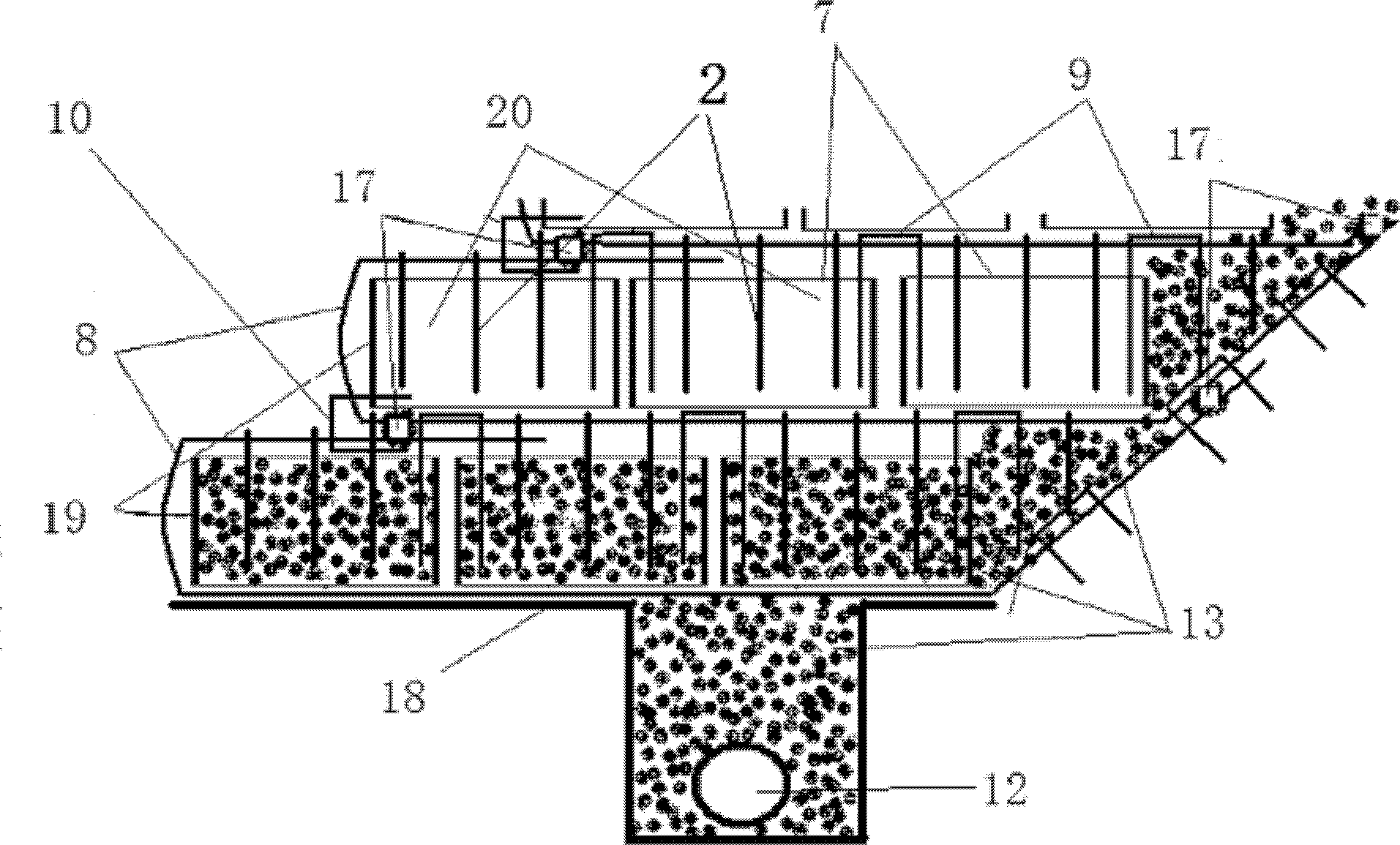

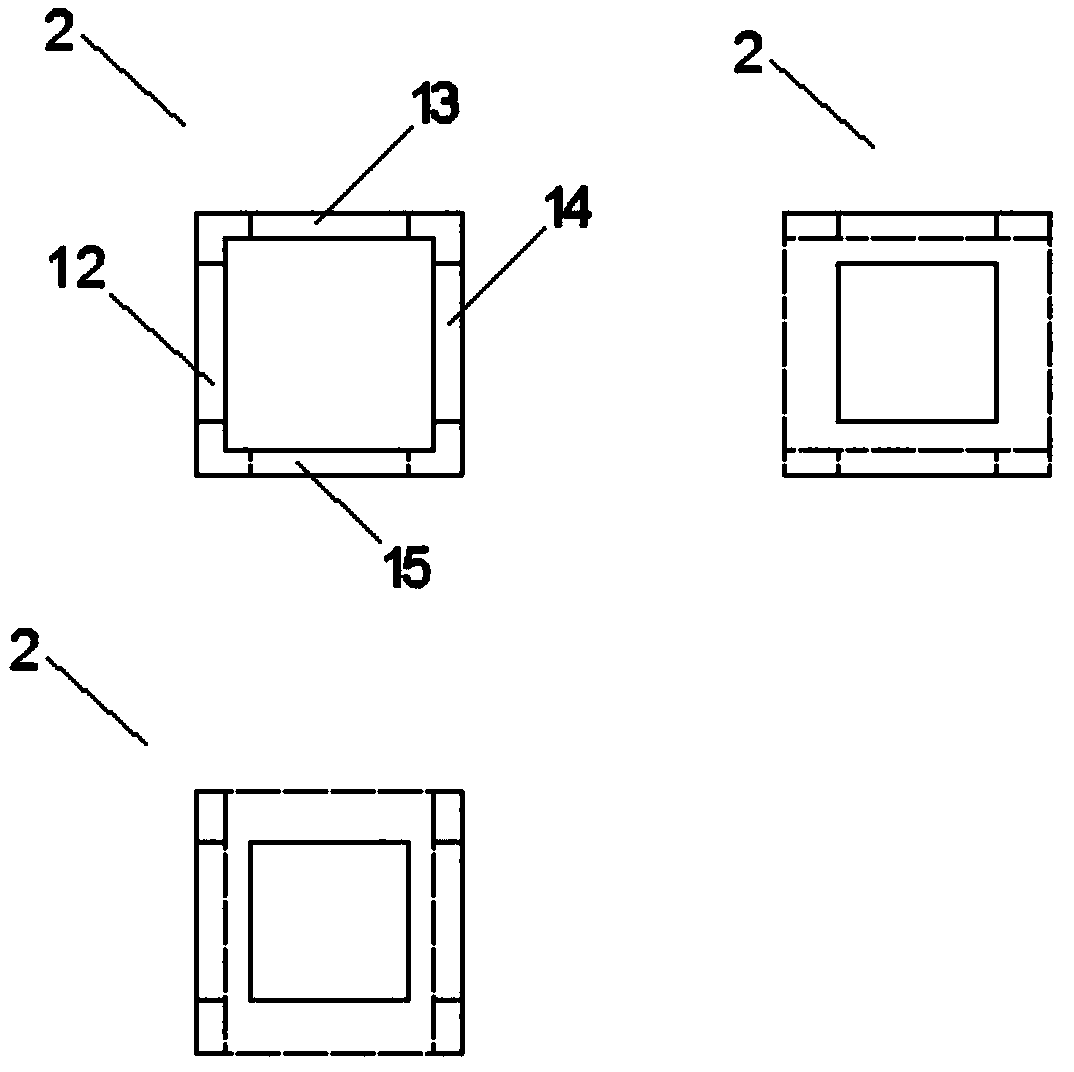

Pre-compacted reinforced soil block flexible supporting structure

ActiveCN102561368BAvoid crowdingShort construction periodProtective foundationExcavationsSoil aggregateCrushed stone

The invention discloses a pre-compacted reinforced soil block flexible supporting structure, wherein the intermediate course is a layered integral body formed by wrapping plural horizontal annular reinforced pre-compacted soil blocks (7) with vertical annular geogrids (8) at each layer and connecting by a nail, soil aggregate (13) is filled between the horizontal annular reinforced pre-compacted soil block (7) at the inner side and a side slope to form an inner side drainage layer (16), the vertical annular geogrids (8) at two layers are connected through a connection rod (17), the horizontal annular reinforced pre-compacted soil blocks (7) at each layer are connected with each other via a nail (9), and the pre-compacted horizontal annular wrapped reinforced soil block in a bottom water permeable layer (3) and a slope top water permeable layer (1) is formed by filling soil aggregate (13) in a horizontal annular geogrid (19) and compacting on field. The invention is suitable for rapid repair of water damaged or collapsing road slope of expansive soil, red clay and red sandstone, and has low application cost, no road occupation in construction, convenient process and fast construction speed.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Formwork support for groove reservation of waterproof flashing and use method of formwork support

InactiveCN113175212AEasy to install and useStrong maneuverabilityForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksWater stopWood panel

The invention relates to a formwork support for groove reservation of a waterproof flashing and a use method of the formwork support, and aims to solve the problems that in the prior art, a threaded hole is formed in a flashing due to an inner wall formwork supporting method and the cost of a selected water stop screw is relatively high; when a groove is formed in the flashing in the later period, the whole flashing is damaged, cracks occur and the waterproof effect becomes poor; and during conventional flashing formwork supporting, when wood laths are used for groove reserving in the early stage of formwork supporting, the width between supported formworks cannot be adjusted. According to the formwork support for groove reservation of the waterproof flashing, a supporting device is arranged above a flashing formwork, so that the formwork can be effectively clamped, and the width between the formworks can be adjusted according to construction requirements; and a groove reserving device is arranged on the flashing formwork, so that the groove for installing water and electricity in the later period can be reserved while flashing forming is achieved, a whole is formed after flashing pouring, and the overall waterproof effect is facilitated.

Owner:SHANGHAI BAOYE GRP CORP +1

A plasma casting rapid prototyping equipment and rapid prototyping method

ActiveCN105922568BSimple structureReasonable designAdditive manufacturing apparatusCeramic shaping apparatusDistance detectionPlasma generator

The invention discloses plasma casting rapid molding equipment and a rapid molding method. The equipment comprises a monitoring system, a plasma beam processing system, and a plurality of printing platforms. Each printing platform comprises a horizontal printing table, a printing table position adjusting device and an electric walking device. The plasma beam processing system includes a plasma generator, a printing position adjusting device, a gas supply device and a wire sending device. The monitoring system includes a walking controller, a plurality of walking position detection units, a temperature detection unit, a distance detection unit and a printing distance adjusting controller. The method comprises the following steps: 1, acquisition of a 3D model of a workpiece to be molded, and hierarchical slicing processing; 2, scanning path filling; 3, printing path acquisition; and 4, printing layer by layer from top to bottom. The invention has the advantages of reasonable design, simple operation, high molding efficiency, good usage effect, no need of enclosed moulding chamber, protection atmosphere or vacuum environment, and direct molding of workpiece in atmosphere environment.

Owner:中研碧诚(北京)科技有限公司

Stirrup component for controlling width of mortar joint and use method of stirrup component

InactiveCN109025324ASolve the problem that the width is difficult to controlAvoid molding qualityBuilding material handlingBrick masonryStirrup

The invention discloses a stirrup component for controlling width of a mortar joint and a use method of the stirrup component, and belongs to the technical field of masonry structure construction. Thestirrup component is simple in structure and low in cost. The invention can thoroughly solve the problem that the width of the mortar joint is difficult to control. The stirrup component is combinedto mortar of the mortar joint and the mortar can still contact closely with brick masonry on the upper part and the side part via reserved holes of the stirrup component. On the premise of ensuring the masonry strength, a condition of non-uniform thickness of the mortar joint due to decrease of a horizontal mortar joint thickness and a vertical mortar joint width caused by deformation of the masonry mortar generated in an early phase with low strength by the load effect of the brick masonry on the upper part, so that normal proceeding of masonry construction in low-temperature and moisture environment can also be conducted, control of mortar joint molding quality in any severe conditions is realized, and the construction quality is further improved, the construction time and labor cost aresaved, the construction progress is accelerated and the construction period is shortened on the premise of reducing mortar waste and controlling the horizontal mortar joint thickness and the verticalmortar joint width in advance. The component is high in strength, flexible in arrangement, simple and convenient to install and distinct in effect.

Owner:CHINA MCC17 GRP

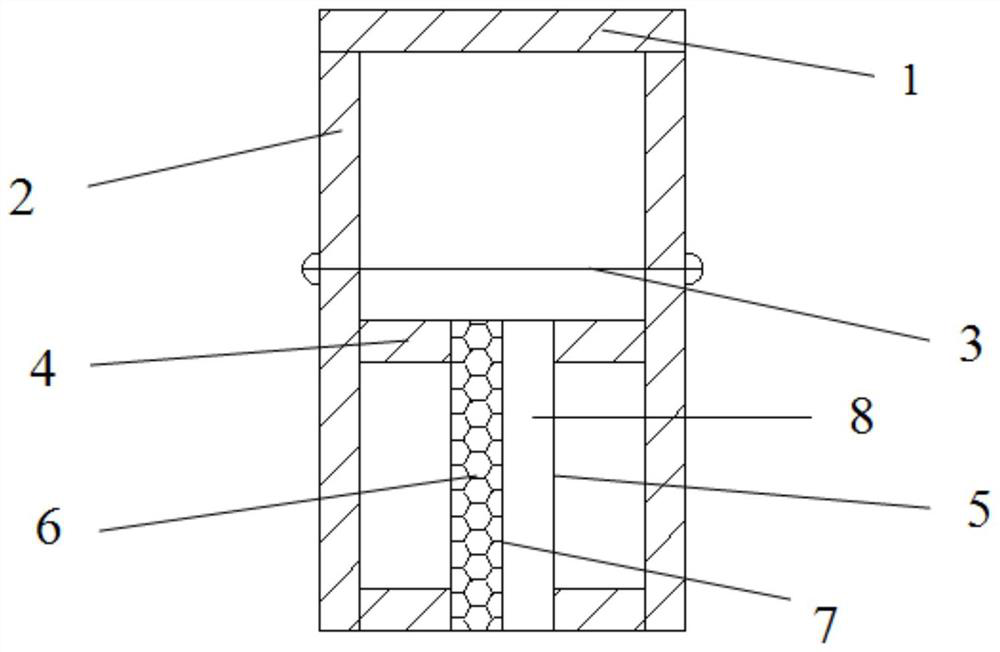

A textile fiber press molding device

A textile fiber pressing forming device comprises an upper die, a lower die and an outer sleeve. The upper die comprises an upper die body and an upper die cavity. The lower die comprises a lower diebody and a lower die cavity. The upper die cavity and the lower die cavity are in up-down butt joint to form a forming cavity. The height of the outer sleeve is larger than the sum of the height of the upper / lower die. The part, around the upper die cavity, of the bottom face of the upper die body is provided with a concentric upper inner / outer sliding rail. The part, around the lower die cavity,of the top face of the lower die body is provided with a concentric lower inner / outer sliding groove. The lower inner sliding groove is in sliding fit with an upper inner sliding rail inserted in thelower inner sliding groove. The lower outer sliding groove is in sliding fit with an upper outer sliding rail inserted in the lower outer sliding groove. The upper die body is internally provided witha plurality of upper ventilation ways communicating with the upper die cavity. The lower die body is internally provided with a plurality of lower ventilation ways communicating with the lower die cavity. The outer ends of the lower ventilation ways communicate with an air outlet of an air spraying device through the air inlet area. According to the design, the shape of fiber cotton is not limited, the material utilization rate is improved, adjustability is high, and product interior uniformity can be improved.

Owner:武汉奥利维亚科技有限公司

A preform disinfection method and bottle making equipment

ActiveCN111231273BReduce consumptionAvoid molding qualityDomestic articlesHeatBottleBiomedical engineering

The invention discloses a preform sterilization method and bottle-making equipment. The sterilization method for sterilizing a plastic preform used for molding in a device for producing aseptic bottles includes at least the following steps: (1) by The ultrasonic atomizer turns the disinfectant into a disinfectant mist, and sprays the disinfectant mist on the preform to adhere a substantially uniform thin layer of the disinfectant on at least the inner surface of the preform to be disinfected; (2) The preform thus treated is radiantly heated to raise at least the inner surface of the preform to a first temperature greater than or equal to the activation temperature of the sterilizing solution to sterilize at least the inner surface of the preform. The present invention provides a method for sterilizing a preform and a bottle making device. After ultrasonically atomizing the disinfectant, it is sprayed directly to make it evenly adhere to the surface of the preform without heating the disinfectant to the steam temperature, the energy consumption is relatively low, and the energy consumption is relatively low. It also avoids the loss caused by making the disinfectant into the disinfectant vapor.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

Magnetic recording medium fabrication method and apparatus

ActiveUS20140099437A1Avoid molding qualityImprove productivityRecord information storageMagnetic layer protectionGas phaseEngineering

A method of fabricating a magnetic recording medium sequentially forms a magnetic recording layer, a protection layer, and a lubricant layer on a stacked body. The stacked body is enclosed in a transfer container unit without exposing the stacked body to atmosphere after forming the protection layer on the stacked body by a deposition apparatus, and the transfer container unit is transported to a vapor-phase lubrication deposition apparatus. The stacked body is removed from the transfer container unit without exposing the stacked body to the atmosphere, in order to form the lubricant layer on the stacked body within the vapor-phase lubrication deposition apparatus.

Owner:RESONAC CORP

A selective plasma melting rapid prototyping equipment and rapid prototyping method

ActiveCN105922570BSimple structureReasonable designAdditive manufacturing apparatusCeramic shaping apparatusPlasma generatorMonitoring system

The invention discloses a selective plasma melting rapid prototyping device and a rapid prototyping method. The device is composed of a monitoring system, a plasma beam processing system, a horizontal printing table and a powder feeding device; the plasma beam processing system includes a plurality of plasma beam processing systems processing device; each plasma beam processing device is composed of a plasma generator, a printing position adjustment device and a gas supply device; the monitoring system includes a plurality of plasma beam processing monitoring devices; each plasma beam processing monitoring device includes a temperature A detection unit, a horizontal movement controller, a distance detection unit, and a printing distance adjustment controller; the method includes steps: 1. Acquisition of a three-dimensional model of the workpiece to be formed and processing of layered slices; 2. Filling of the scanning path; 3. Acquisition of the printing path; 4. Print layer by layer from bottom to top. The invention has the advantages of reasonable design, convenient operation, high molding efficiency and good application effect, and can be directly carried out in atmospheric environment without the need of protective atmosphere or vacuum environment.

Owner:中研碧诚(北京)科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com