Preform disinfection method and bottle making equipment

A disinfection method and preform technology, which is applied to household components, household appliances, and other household appliances, can solve the problems of high energy consumption, low initial temperature of preforms, and high preparation costs, and achieve cost savings and low energy consumption. , the effect of saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

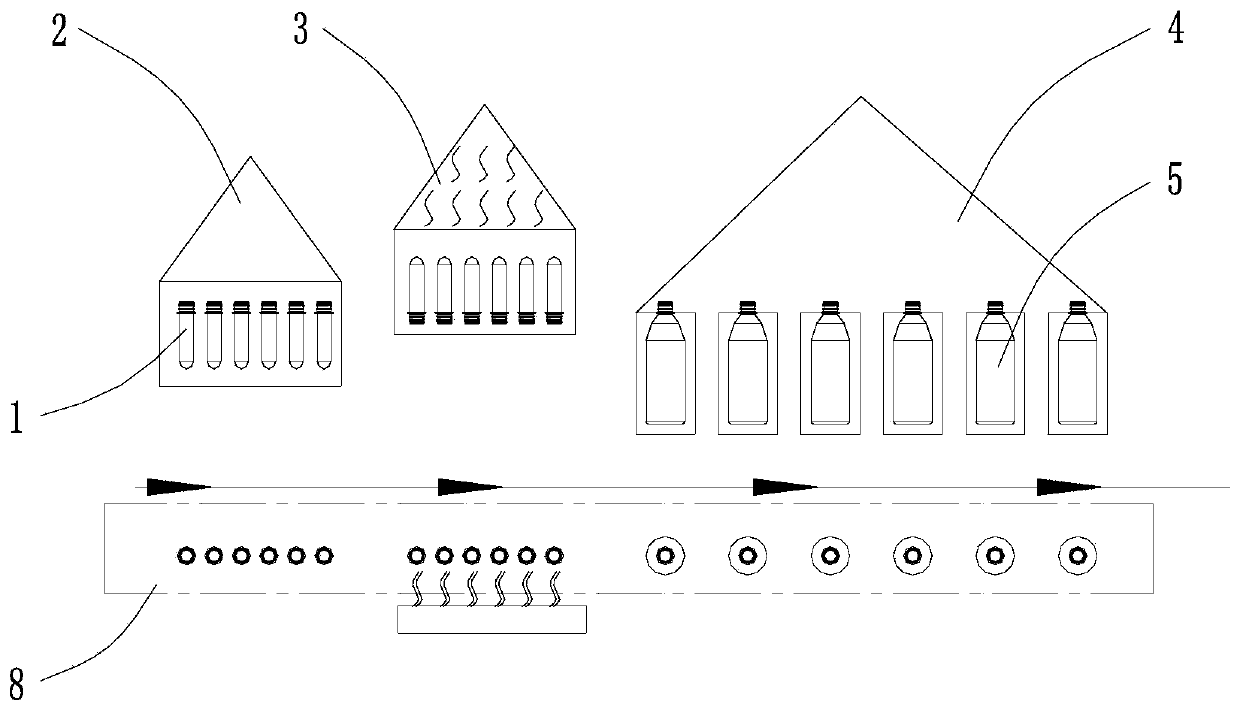

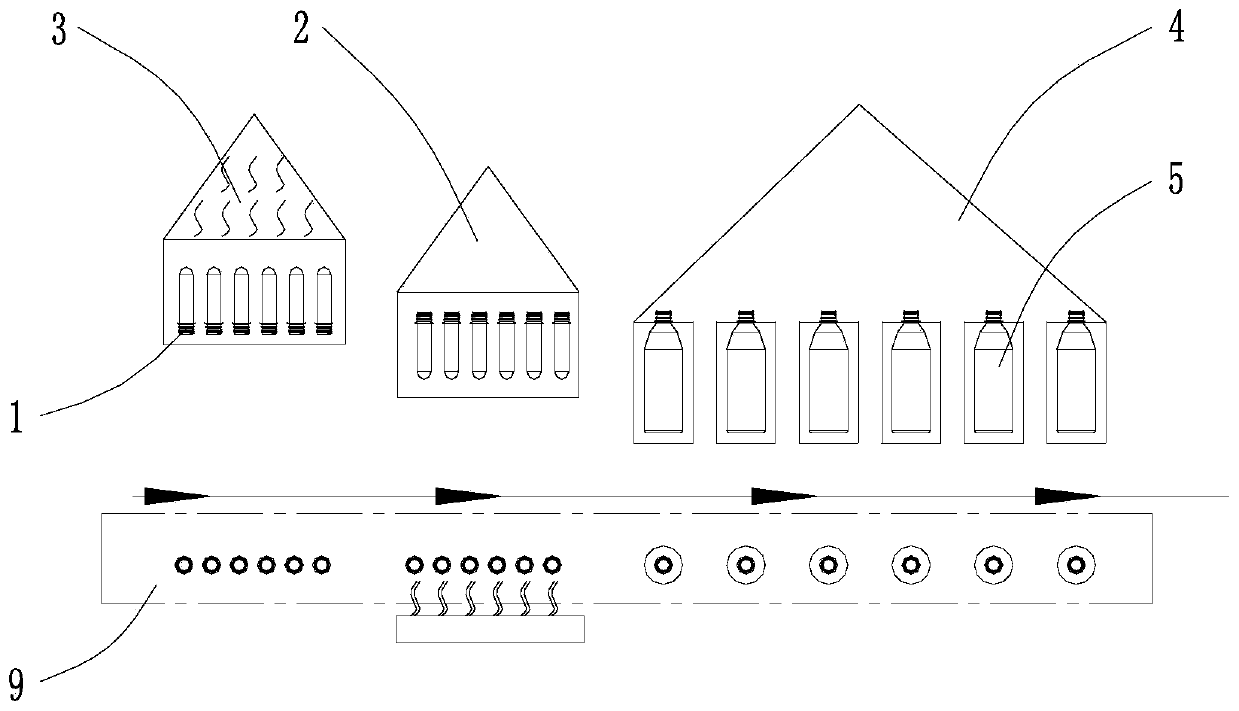

[0035] see Figure 1-3 As shown, the above-mentioned bottle making equipment is used to produce aseptic bottles 5 through plastic preforms 1, and the preforms 1 are continuously conveyed into the bottle making equipment, which includes The injection unit 2, the heating unit 3 and the molding unit 4.

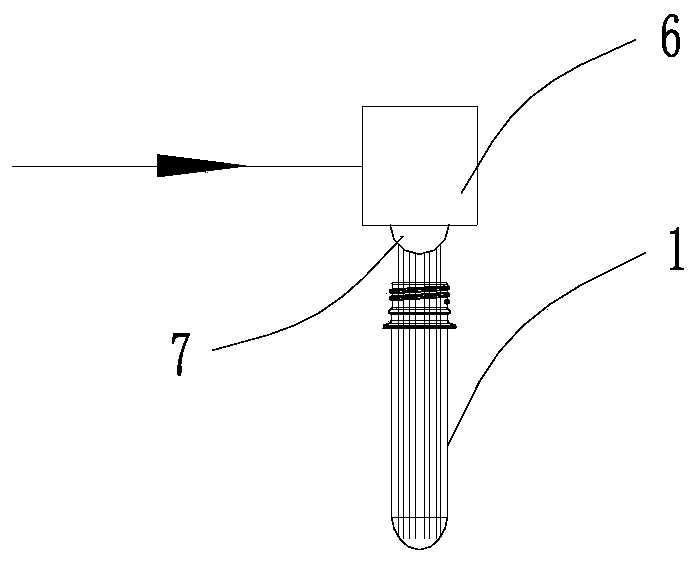

[0036] The preform 1 is tubular as a whole, and one end of the tubular preform 1 is closed, and the other end has the same shape as the neck of the bottle 5 after molding. Since the bottle-making equipment is used to prepare aseptic bottles 5, it is necessary to sterilize the preform 1 before blowing, that is, to make the preform 1 have a certain degree of sterility. This sterilization step is used to at least sterilize the inner surface of the preform 1 (the inner surface includes the inner wall and the inside of the neck).

[0037] The spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com