Convenient and adjustable reinforcing supporting structure of cast-in-situ wall column formwork and construction method of reinforcing supporting structure

A technology of supporting structure and cast-in-place wall, applied in the direction of formwork/formwork/work frame, formwork/formwork/work frame connector, building structure, etc. Deformation, surface verticality deviation and other problems, to achieve the effect of good adjustability, saving labor costs, and reducing labor consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention will be explained more clearly and completely through the description of preferred embodiments of the present invention in conjunction with the accompanying drawings.

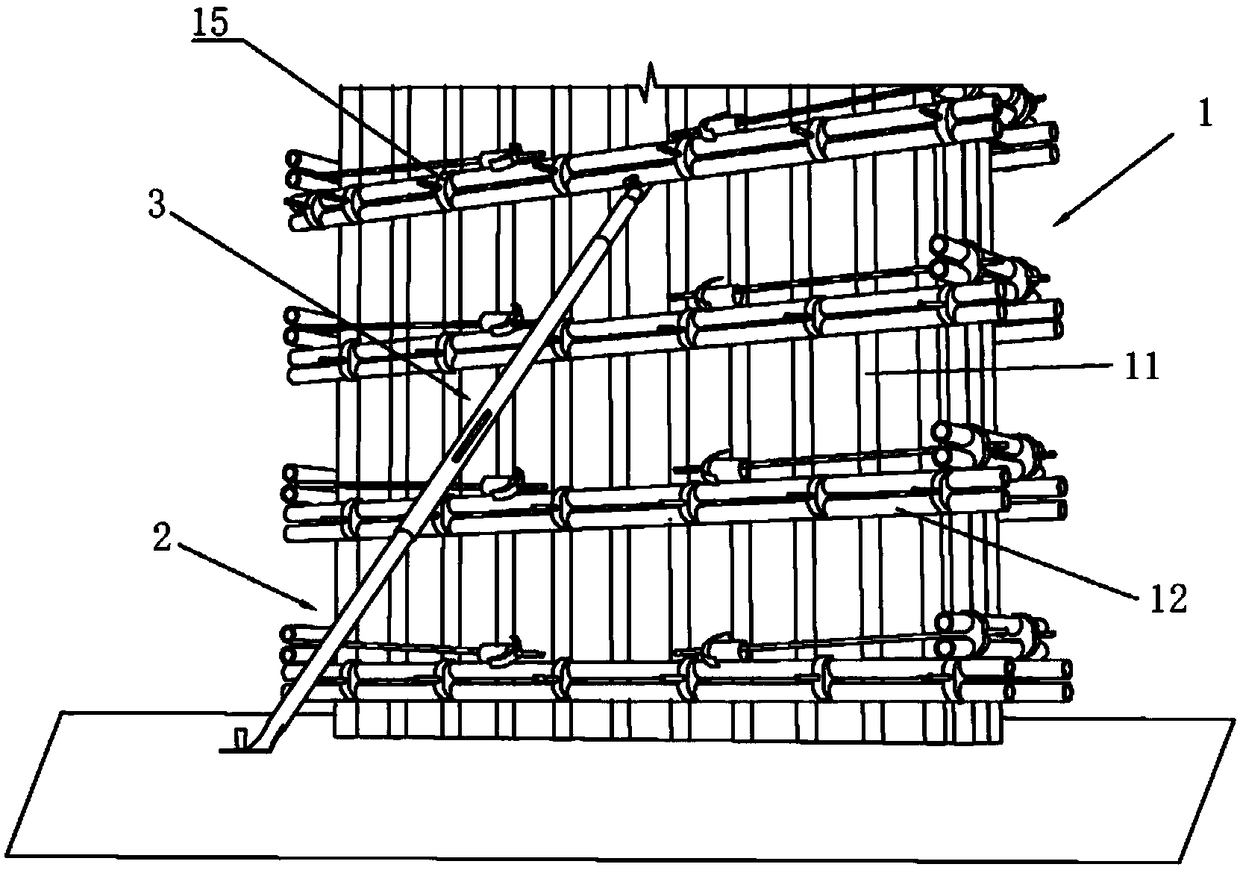

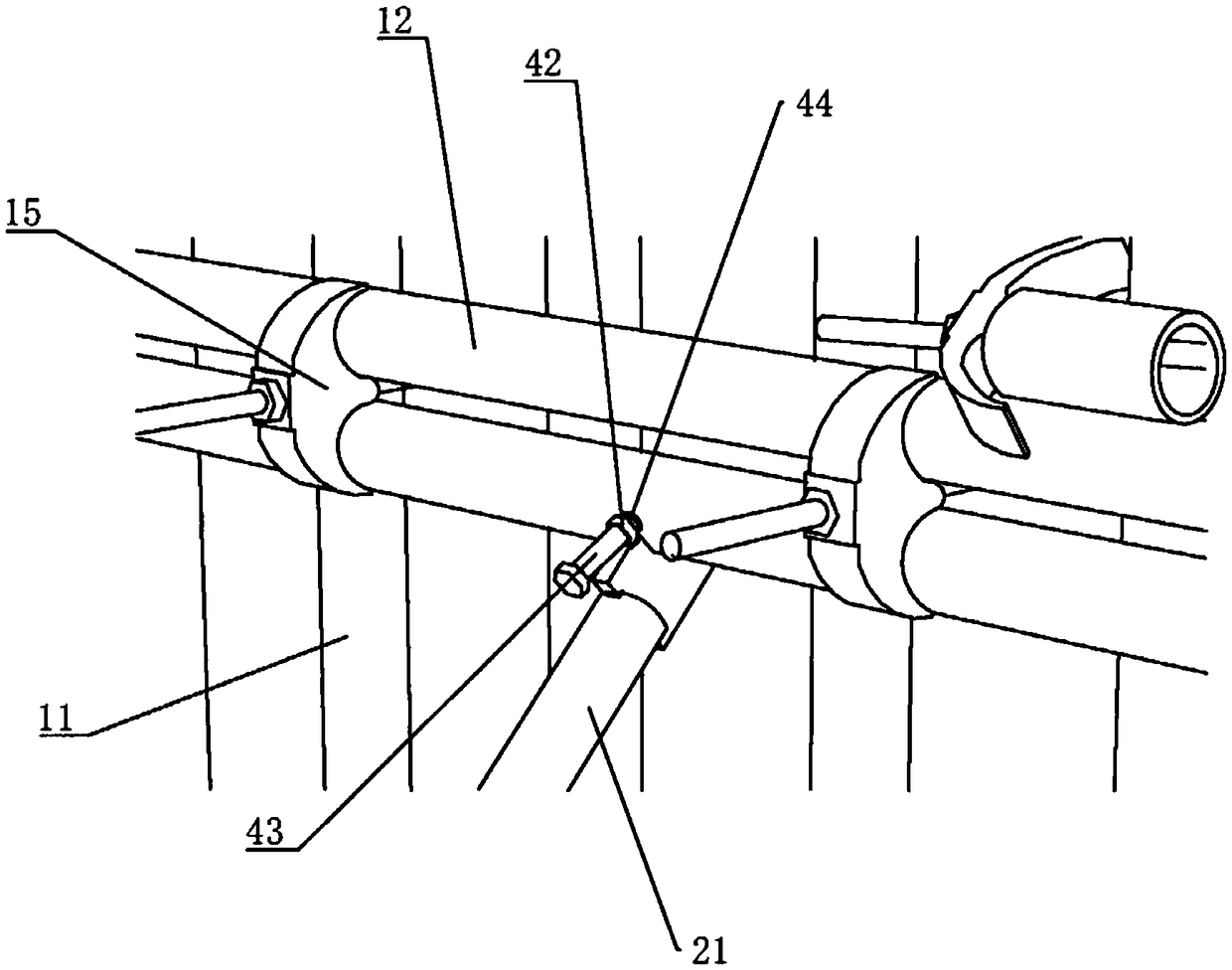

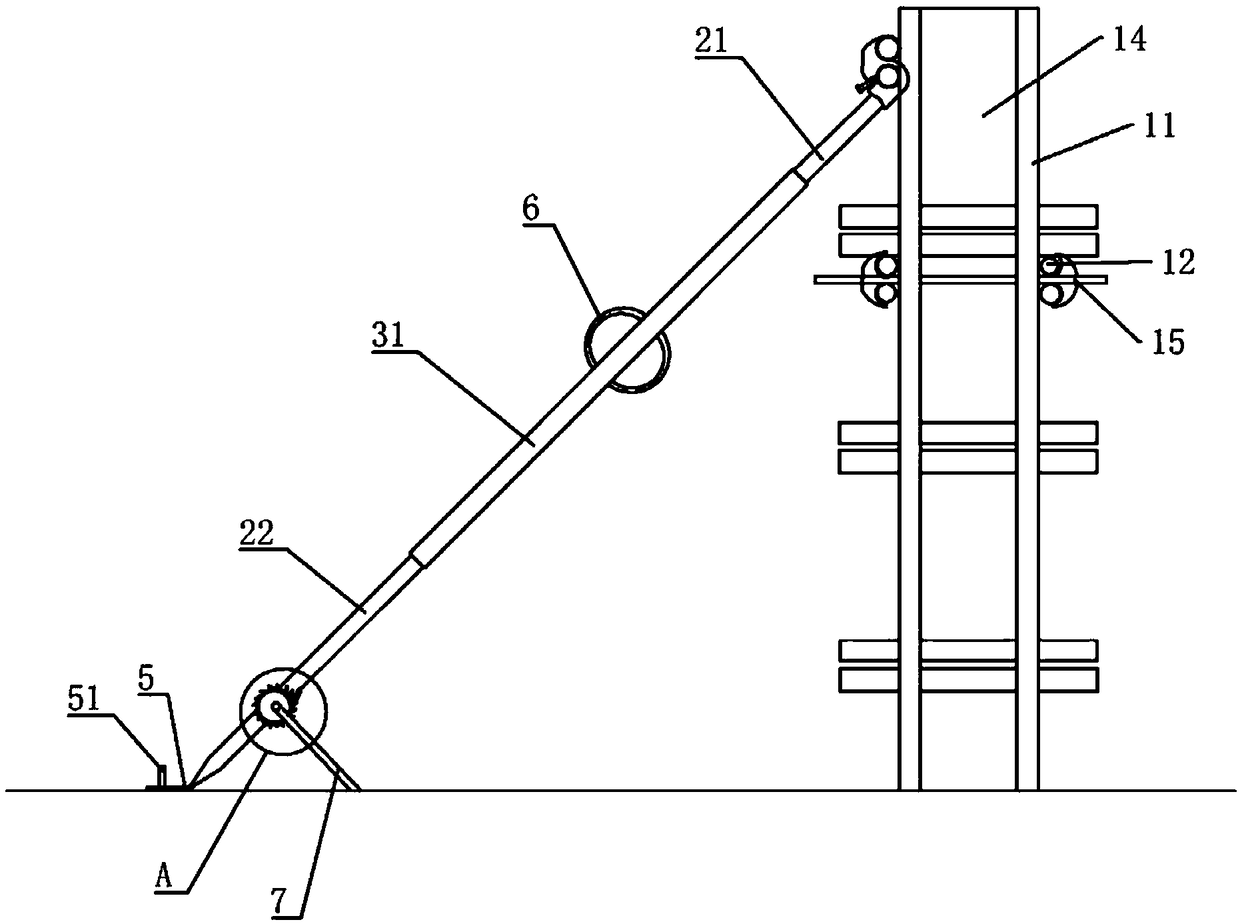

[0032] Such as figure 1 As shown, a convenient and adjustable cast-in-place wall column formwork reinforcement support structure of the preferred embodiment of the present invention includes a wall column cast-in-place formwork 1, and the wall column cast-in-place formwork 1 includes several vertical 50mm vertical steel pipes 11, vertical steel pipes 11 As a vertical back corrugation; some horizontal steel pipes 12 and a pair of black templates 13 arranged oppositely, the horizontal steel pipes 12 are in groups of two, and are tied by tension bolts 15 to realize reinforcement. refer to image 3 A pair of black templates 13 are respectively arranged between the vertical steel pipes 11 and the horizontal steel pipes 12 on both sides, and form a cast-in-place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com