Stirrup component for controlling width of mortar joint and use method of stirrup component

A horse bench and ash joint technology, applied in building construction, building material processing, construction and other directions, can solve the problems of reducing the contact area, neglecting the bonding effect, weakening the overall stability of the infill wall, etc. Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

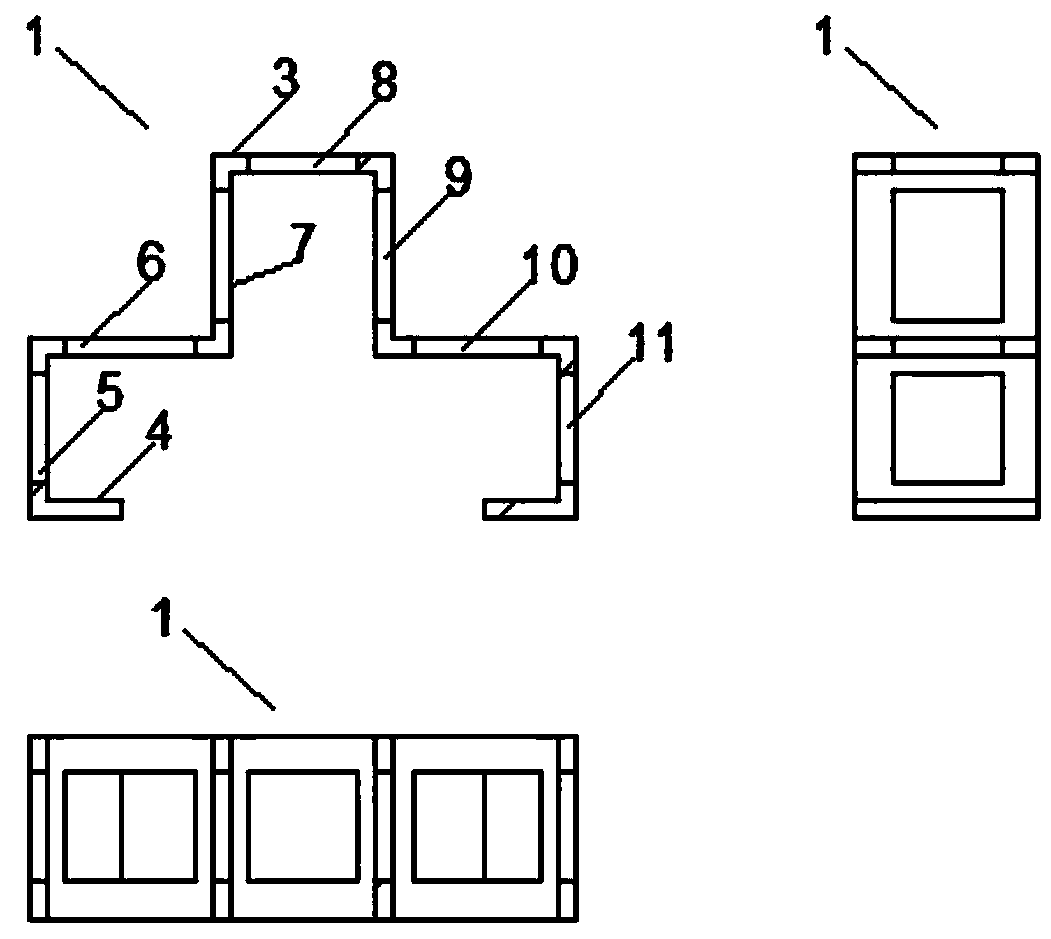

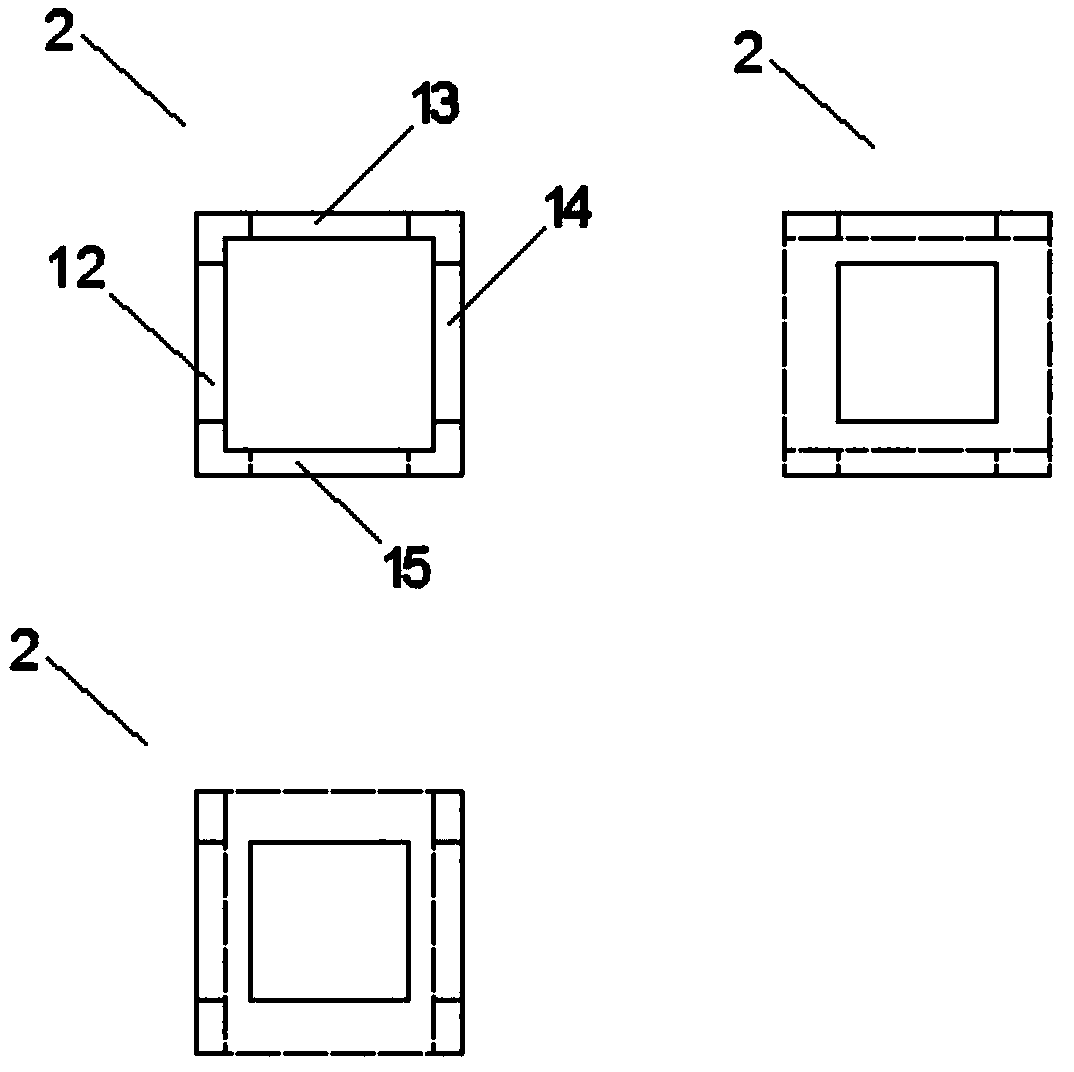

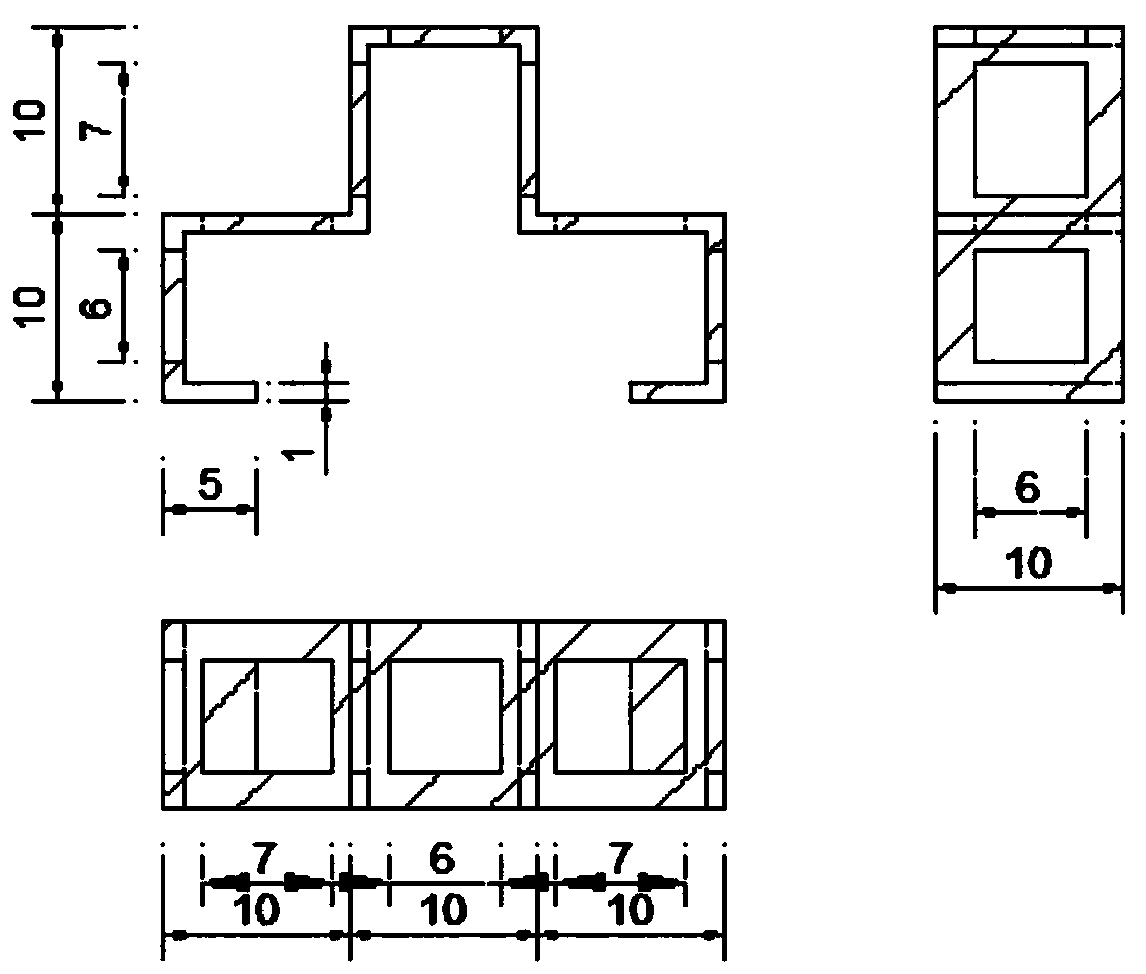

[0027] Such as Figure 1 ~ Figure 2 Shown: a horse stool component for controlling the width of the gray joint, the first horse stool 1, the second horse stool 2 and the steel frame, the first horse stool is a "convex" shape with an opening at the bottom, the first horse stool The horse stool is a horse stool that controls the width of the mortar joints between the upper adjacent brickwork and the thickness of the mortar joints with the lower brickwork. The second horse stool 2 is a special horse stool for the edge of the wall. The first horse stool 1 The corners of the first horse stool are provided with a steel skeleton, which makes the first horse stool rigid as a whole and can bear the load of the upper brick masonry without deformation. The two sides of the bottom of the first horse stool are supporting legs 4, and the first horse stool The horse stool 1 and the second horse stool 2 are provided with mortar passage holes, and the mortar passage holes include the first mor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com