Liner inner aligning mechanism, aligning device system and pipeline welding method thereof

A technology of internal alignment and gasket, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problem that the inner alignment mechanism of the gasket and the external welding equipment of the pipeline cannot rotate synchronously, so as to improve welding efficiency and welding quality, The effect of guaranteeing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

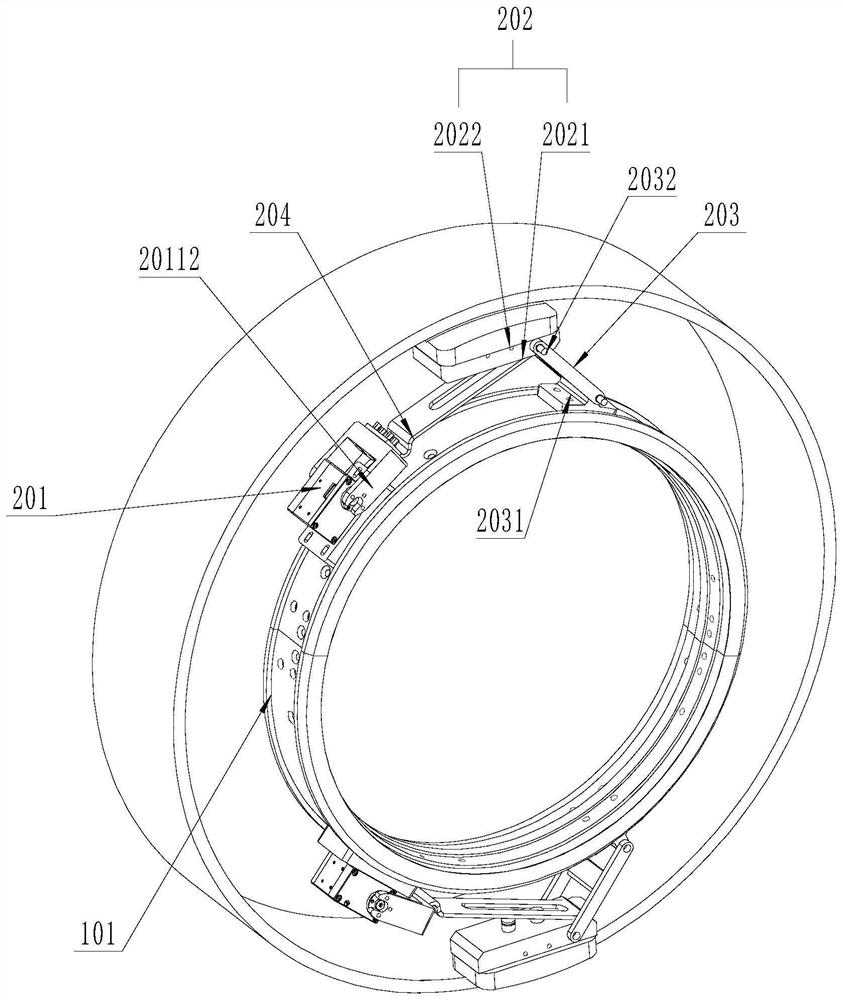

[0051] Such as Figure 1-3 As shown in the figure, a liner inner matching mechanism is used for butt jointing of the inner interface of the pipeline, and accepts molten iron welded at the gap between the liner and the inner wall of the pipeline inner interface. The inner matching mechanism of the liner includes:

[0052] Rotary mechanism 1 that provides rotational driving force for the mating mechanism in the liner;

[0053] Specifically, the rotating mechanism 1 can be directly driven by a motor, or can be driven by an internal gear driven by a motor. At the same time, the rotating mechanism 1 can have a reverse rotating drive mechanism, such as a motor with a reverse function, so as to realize rotation. Pause and / or forward and reverse rotation of mechanism 1.

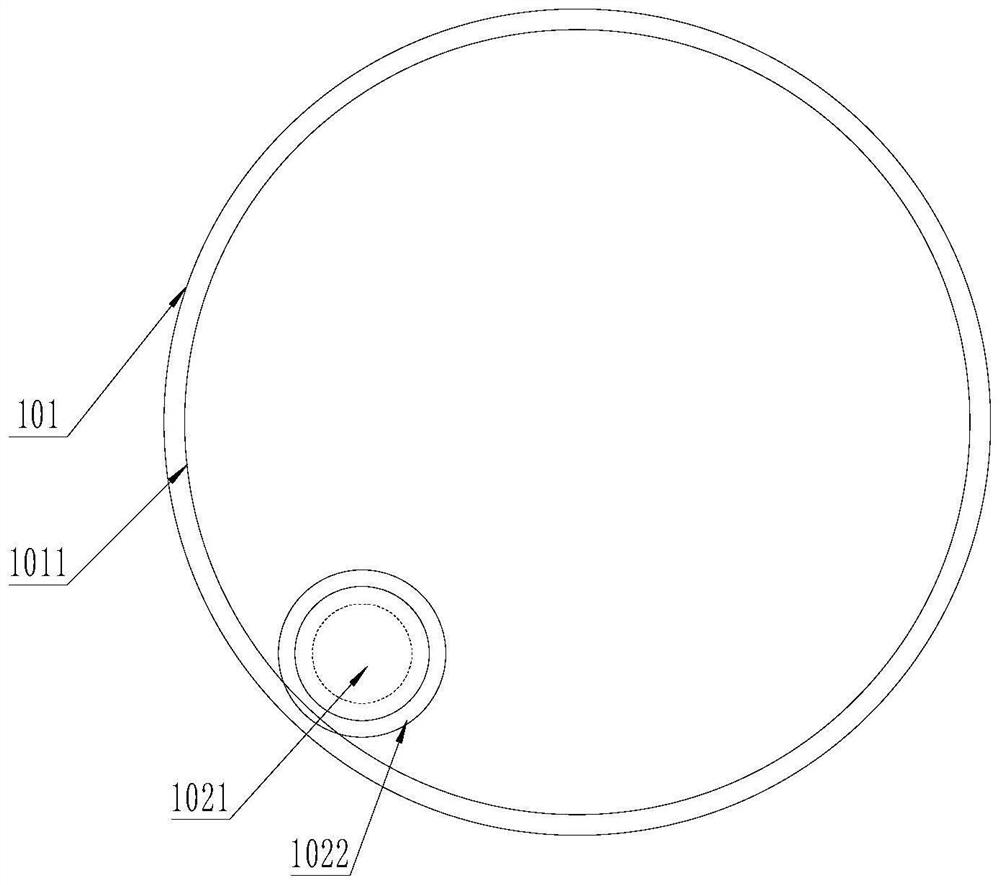

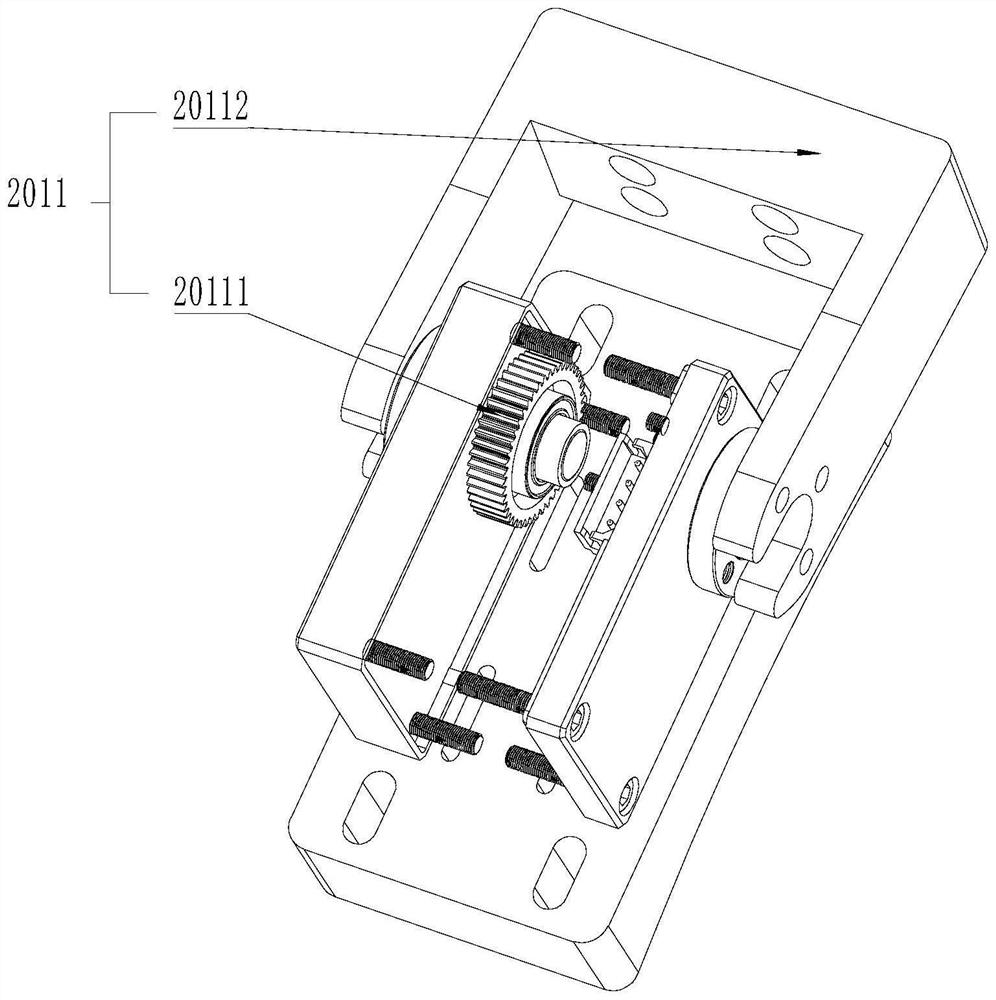

[0054] In this embodiment, the rotary mechanism 1 is driven by an internal gear driven by a motor as an example, as figure 2 As shown, specifically, the rotating mechanism 1 includes a rotating ring 101 and a driv...

Embodiment 2

[0082] A pipe liner inner mouthpiece system, comprising a traveling mechanism, a positioning mechanism, a tensioning mechanism and a liner inner mouthpiece mechanism described in Embodiment 1 above.

Embodiment 3

[0084] A pipeline welding method that can be followed synchronously, the method comprising:

[0085] S1, a kind of pipe liner inner counterpart system in embodiment 2 is placed in the pipe;

[0086] S2. Move and position the system to the position to be welded through the traveling mechanism and the positioning mechanism;

[0087] S3. Complete the assembly of the pipelines through the tensioning mechanism;

[0088] S4, the ceramic liner 2022 on the outer peripheral surface of the rotating ring 101 is completely attached to the groove of the inner wall of the pipeline through the movement of the steering gear 201;

[0089] Wherein, the movement of the steering gear 201 is that the rotating rocker mechanism 2011 on the steering gear realizes the rotation, drives the other end of the flexible shrapnel 204 to move upwards, and then makes the liner mechanism 202 close to the inner wall of the pipeline until the ceramic liner 2022 is closely attached to the inner wall of the pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com