Sectional binding apparatus and sectional binding method for rotary targets

A rotating target and segmented technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of difficult control of casting uniformity, temperature limitation of binding, and uneven binding, etc. Achieve the effect of improving the bonding rate, reducing deformation, and strong equipment versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

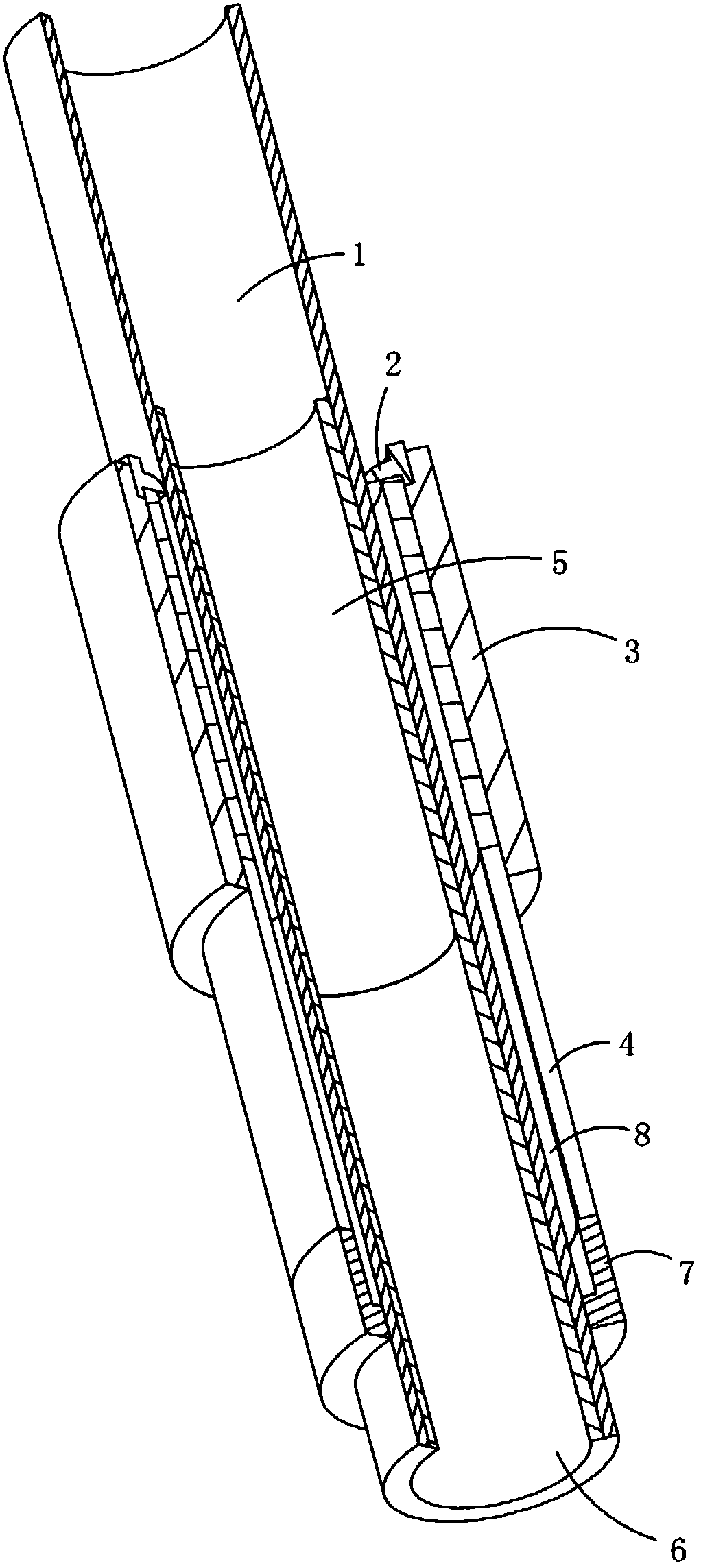

[0043] A rotating target segment binding device, figure 1 As shown, it includes a mobile locator 7 for positioning the back pipe 1, an external heating device 3, a moving guide rod 6 and an internal heating device 5. The lower part of the back pipe 1 is inserted in the mobile locator 7, and the back pipe 1 The lower part is positioned and fixed on the mobile locator 7. Make the back pipe 1 vertically installed on the mobile positioner 7 .

[0044] The bottom of the moving guide rod 6 is connected with a lifting mechanism, which is used to drive the moving guide rod 6 to move up and down. After the back tube 1 is fixed on the mobile positioner 7, the lifting mechanism drives the moving guide rod 6 to be inserted into the back tube 1. After the joints are bound, the lifting mechanism drives the moving guide rod 6 to move out from the back tube 1.

[0045] The mobile positioner 7 is equipped with a vibrating device, which vibrates the back pipe 1 during the casting process, so ...

Embodiment 2

[0053] A method for segmentally binding a rotating target, comprising the following steps:

[0054] a. Install the back tube 1, install the back tube 1 vertically on the mobile locator 7, and use the locator to locate the installation position of the back tube 1 and the starting position of the first metal layer on the back tube, so as to facilitate moving from the back tube The lower part of 1 begins to bind the first metal layer, and the section of the back pipe 1 forming the first metal layer is set with the first metal layer section;

[0055] b, install the external heating device 3, the external heating device 3 is coaxially sleeved on the outer edge of the bottom of the back pipe 1, and the external heating device 3 is fixed on the positioning frame, and the outer wall surface of the back pipe 1 and the external heating device 3 A first casting space in the shape of a ring for casting and forming the first metal layer is formed between them;

[0056] c. Install the inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com