Greenness preservation machine of fresh leaves

A silage and fresh leaf technology, applied in the field of fresh leaf silage, can solve the problems of affecting the quality of tea leaves, waste of energy and oxygen supply, uneven humidification of tea leaves, etc. Parts, is conducive to the effect of process balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

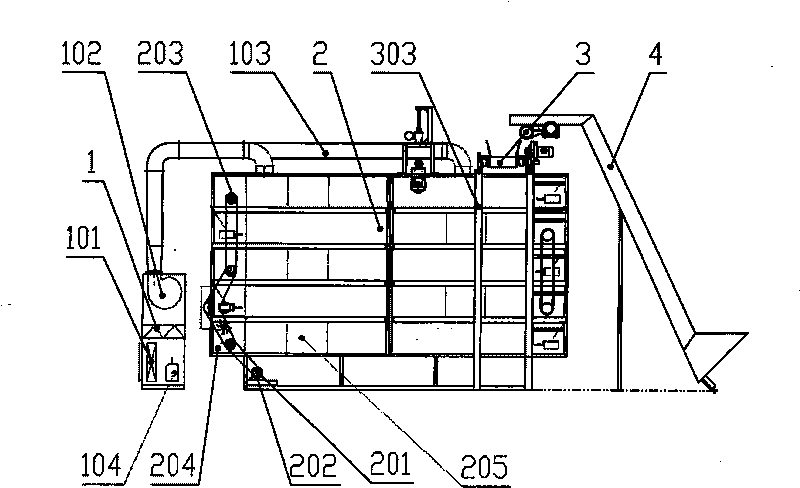

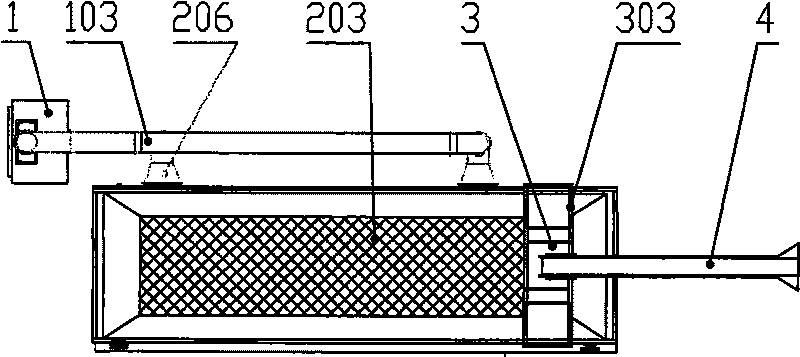

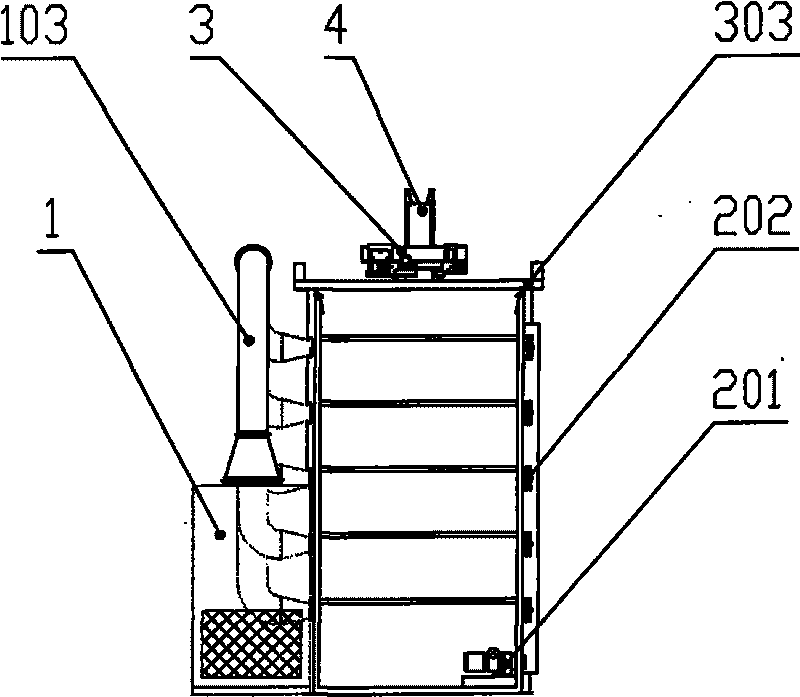

[0018] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4-Figure 6 As shown, the present invention mainly includes the air supply and humidification system 1, the silage main machine 2, the reciprocating distribution machine 3 and the oblique feeding 4. The air supply and humidification system 1 is composed of a coil 101, a fan 102, an air supply pipe 103 and an electrode humidifier 104; the electrode humidifier 104 can also be a water curtain humidifier or an ultrasonic humidifier to supply the host Moist air, to reach the fresh-keeping effect of fresh tea leaves; The main machine 2 of the green storage is composed of a motor 201, a sprocket wheel 202, a screen plate 203, a discharge port 204, an observation window 205, an air supply port 206 and a uniform leaf lifting mechanism 20).

[0019] Green storage host 2 of the present invention is provided with multilayer green storage area, can store more tealeaves. Silage main frame 2 is provided with observation 205...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com