Powder warm-compaction near-net molded molybdenum-based rare earth alloy top and manufacturing technology thereof

A near-net-shape, rare-earth alloy technology, applied in the field of powder metallurgy warm-pressed near-net-shape molybdenum-based rare earth alloy plug and preparation, can solve the problems of poor fluidity, low recrystallization temperature, and easy brittle fracture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Structural arrangement for specific implementation.

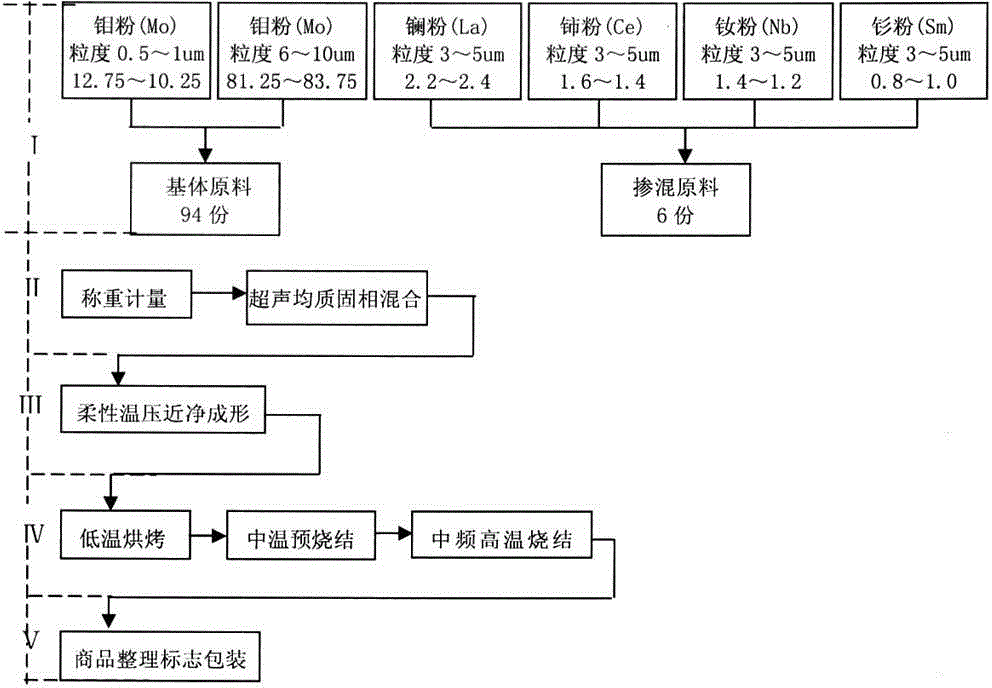

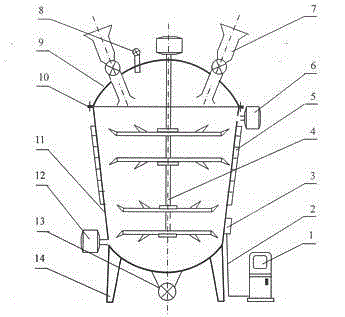

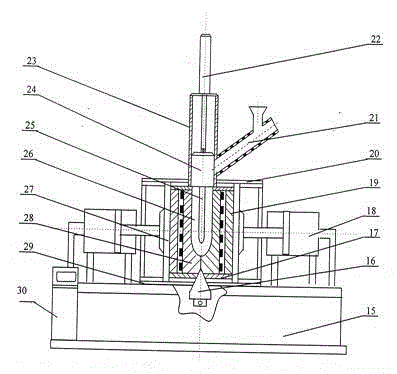

[0050] as attached figure 1 As shown, the powder smelting warm-pressed near-net-shaped molybdenum-based rare earth alloy plug and its preparation technology researched and designed by the patent of the present invention include scientific proportioning of multi-component materials (I), ultrasonic homogeneous solid-phase mixing (II), flexible warm-pressed near-net Net shaping (Ⅲ), continuous successive sintering and shaping (Ⅳ), commodity finishing and marking packaging (Ⅴ) are 5 relatively independent process technology units, and the special technical equipment, operation process procedures and technical parameters for their supporting applications.

[0051] as attached figure 1 As shown, the scientific proportioning process technology unit (I) of multi-component materials is composed of molybdenum powder with an average particle size of 6-10um and molybdenum powder with a particle size of 0.5-1um. , cerium powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com