Patents

Literature

89results about How to "Speed up the molding process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

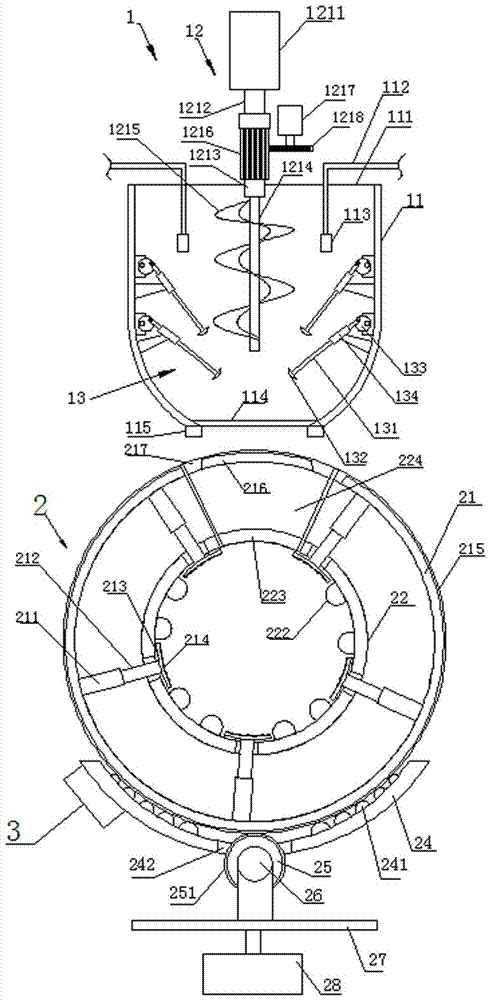

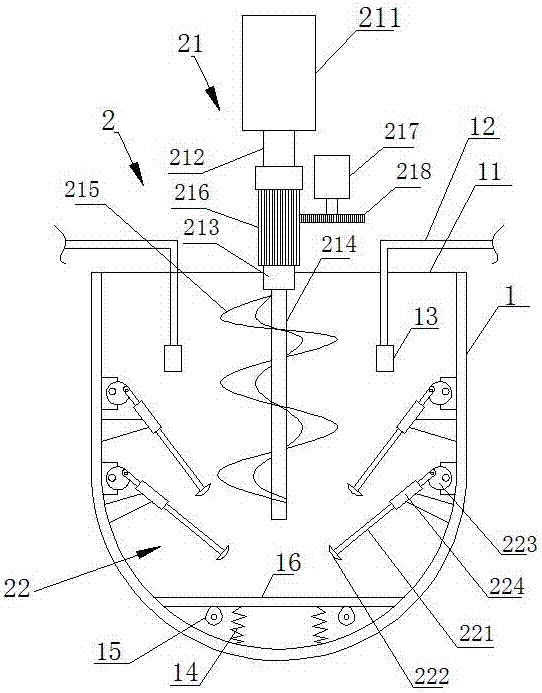

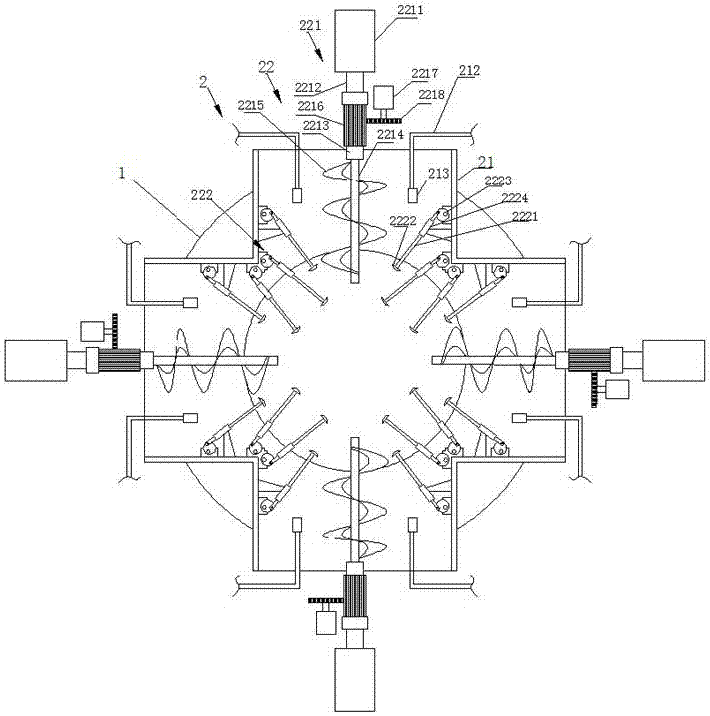

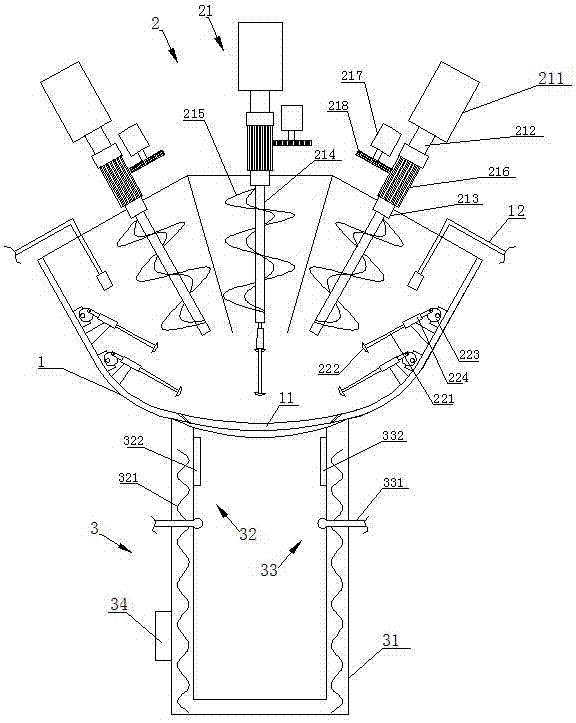

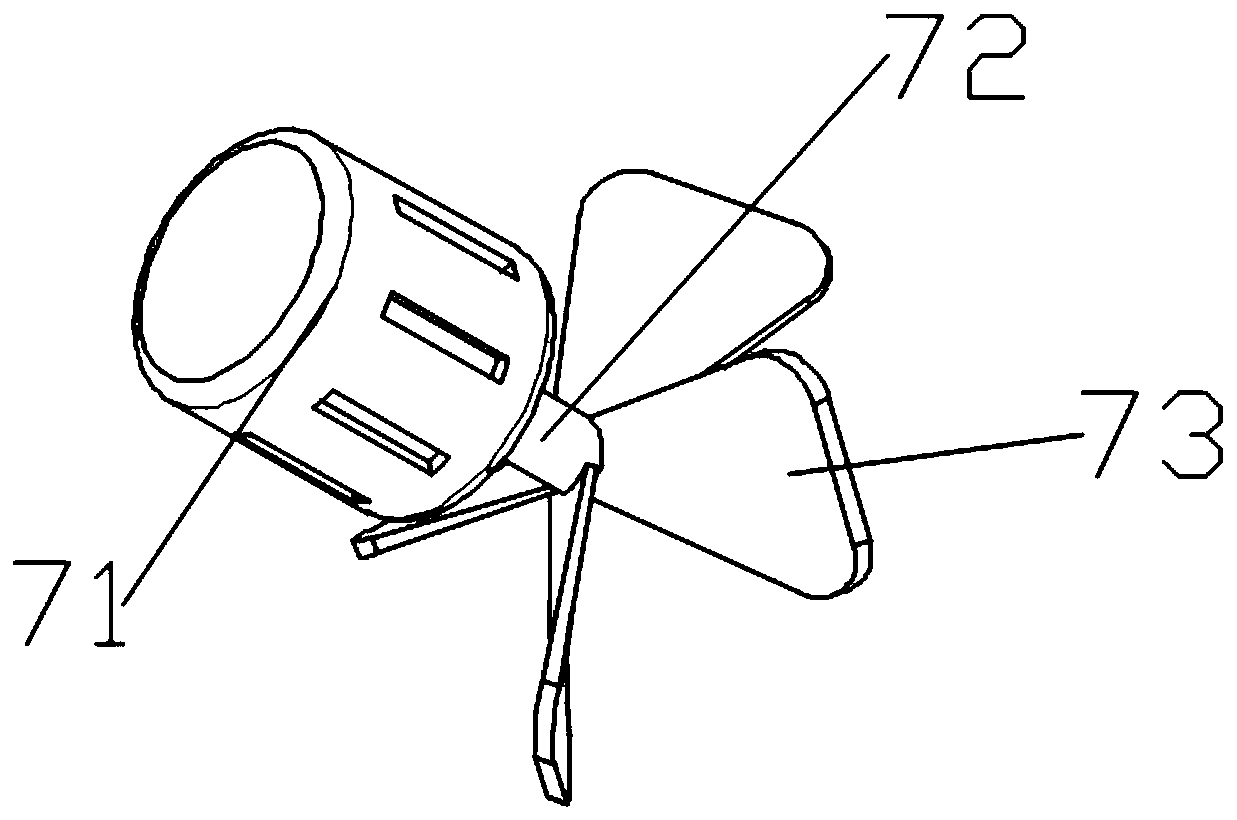

Cooperative dough forming and dough kneading machine

InactiveCN107006551AGood elasticityFast processingMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsHollow cylinderEngineering

The invention relates to a combined dough kneading machine, which comprises a kneading device and a kneading device arranged in sequence; The beating device; the beating device includes a plurality of rods for telescopic movement and towards the center of the bottom of the cylinder; the dough kneading device includes a first hollow spherical roller arranged under the cylinder and a fixed distance sleeved in the first hollow The second hollow spherical drum in the spherical drum; the inner wall of the first hollow spherical drum is evenly equipped with a plurality of cylinders and kneading rods driven by the cylinders; the second hollow spherical drum is provided with a plurality of dough The through hole through which the rod penetrates; the inner wall of the second hollow spherical roller is provided with a plurality of protrusions at intervals; the lower part of the first hollow spherical roller is provided with an arc-shaped supporting plate that cooperates with the lower part of the first hollow spherical roller.

Owner:林娜娜

Organometallic precursor compounds

ActiveUS20050215805A1Easy to depositSpeed up the molding processGroup 8/9/10/18 element organic compoundsGroup 6/16 organic compounds without C-metal linkagesCoatingInorganic chemistry

This invention relates to organometallic precursor compounds represented by the formula (L)M(L′)2(NO) wherein M is a Group 6 metal, L is a substituted or unsubstituted anionic ligand and L′ is the same or different and is a π acceptor ligand, a process for producing the organometallic precursor compounds, and a method for producing a film, coating or powder from the organometallic precursor compounds.

Owner:SAMSUNG ELECTRONICS CO LTD

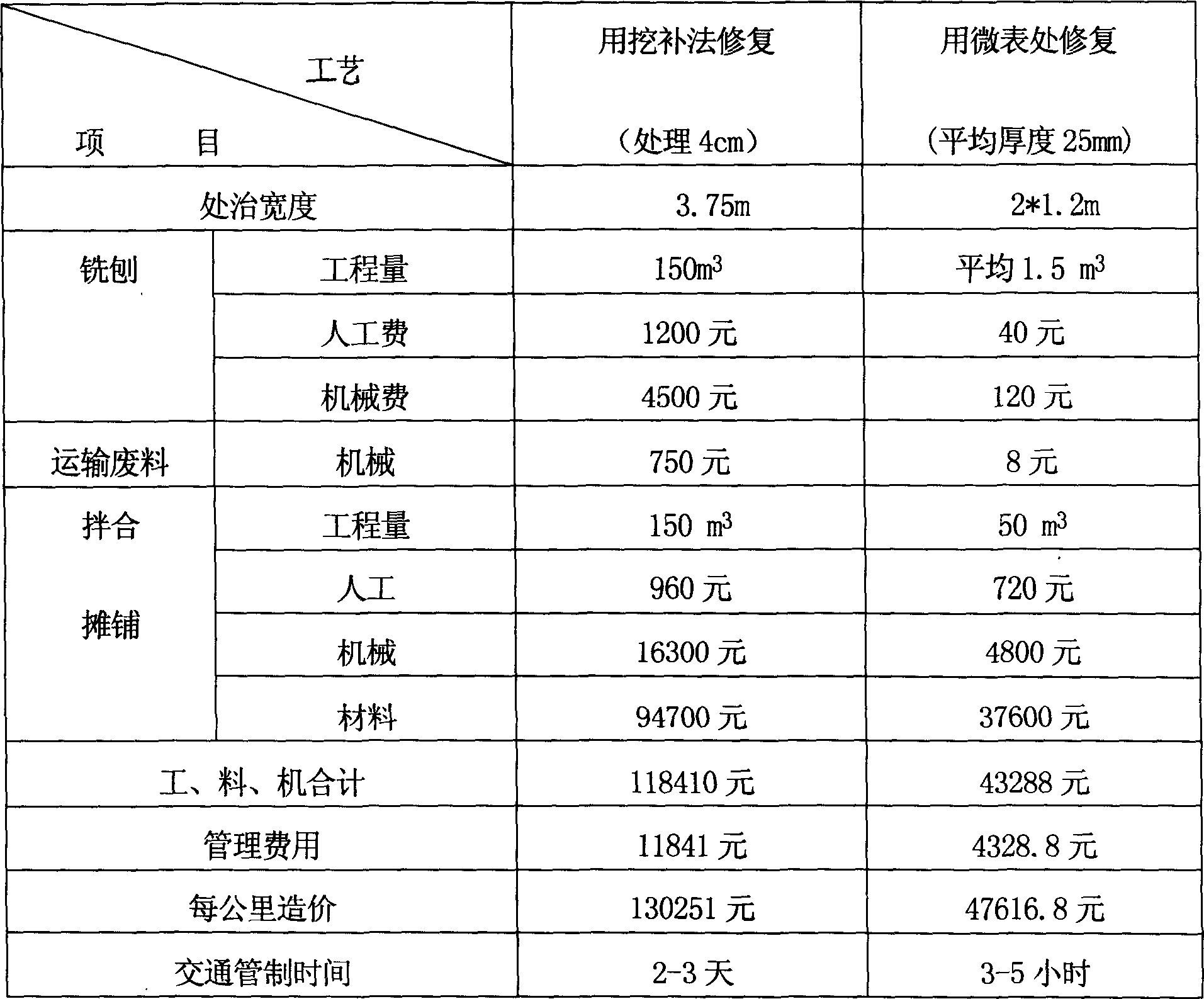

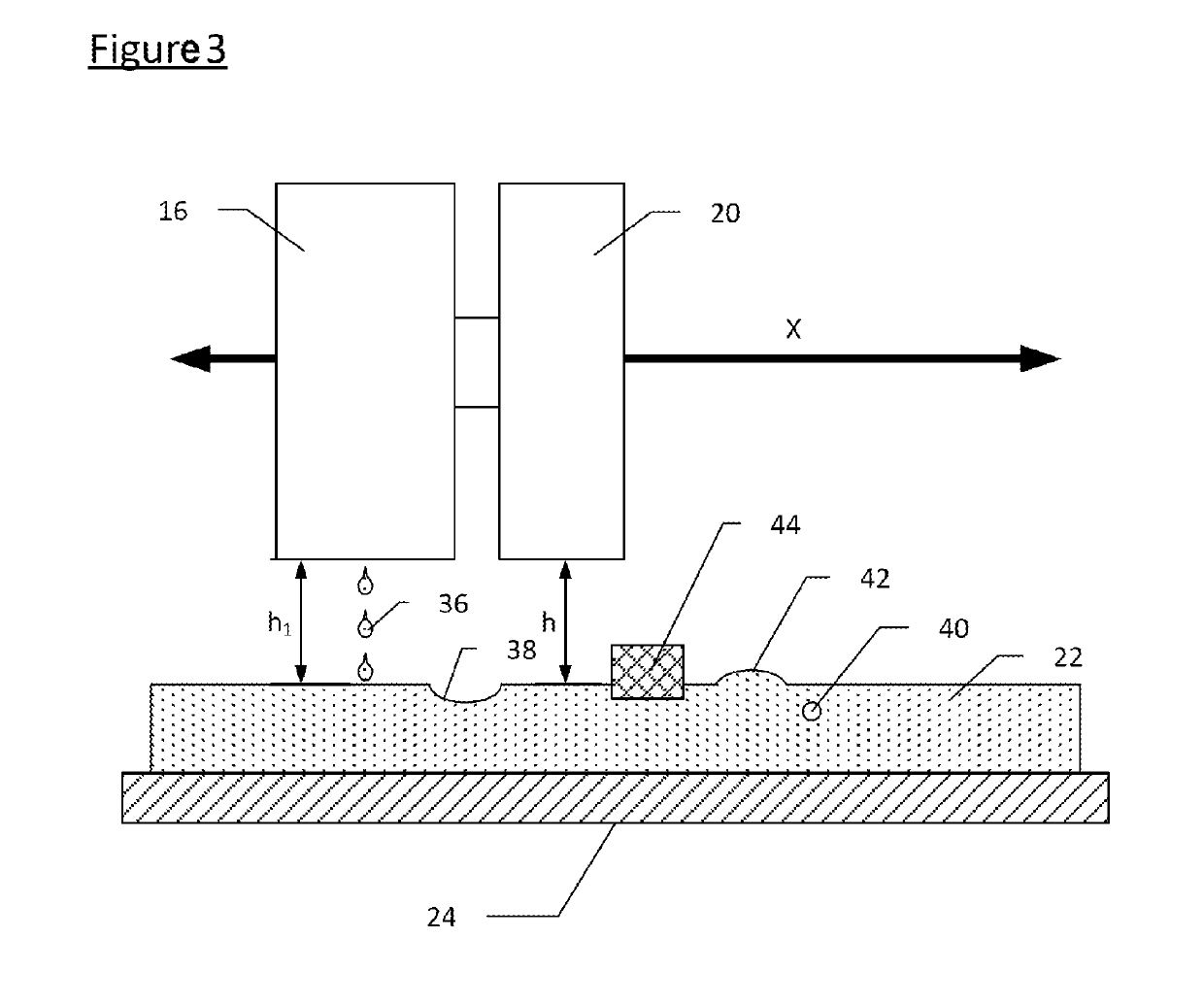

Reconditioning tracks on asphalt pavement by using thin paste mixture of modified emulsified asphalt and construction method thereof

InactiveCN1687526AImprove skid resistanceImprove flatnessIn situ pavingsRoads maintainenceMixed materialsRoad surface

This is a kind of restoring the tracks of the bitumen road surface with the modified emulsified bitumen watery slurry mixed materials and its job practice. Spread single layer modified emulsified bitumen watery slurry mixed materials on the bitumen road surface of 10 - 20 mm depth, and spread double layer modified emulsified bitumen watery slurry mixed materials on the bitumen road surface of 20 - 40 mm depth. The job practice of single layer modified emulsified bitumen watery slurry mixed materials is: close down the traffic, process the original road surface, lay samples, spread, appearance control, joint slots, initial maintenance and quality inspection. Other building steps of the lower layer job practice of the double layer modified emulsified bitumen watery slurry mixed materials are the same as that of single layer, except that the allocated proportion of the single layer modified emulsified bitumen watery slurry mixed materials is different and without quality inspection. The upper layer building steps are: spread, initial maintenance and quality inspection. It has such advantages as high abrading-resistant performance, thin structure layer, long using life, high building speed, fast molding, short building period, fast traffic opening, long building season, low resource waste, no deleterious gas euduction and so on.

Owner:西安高远公路养护技术有限公司

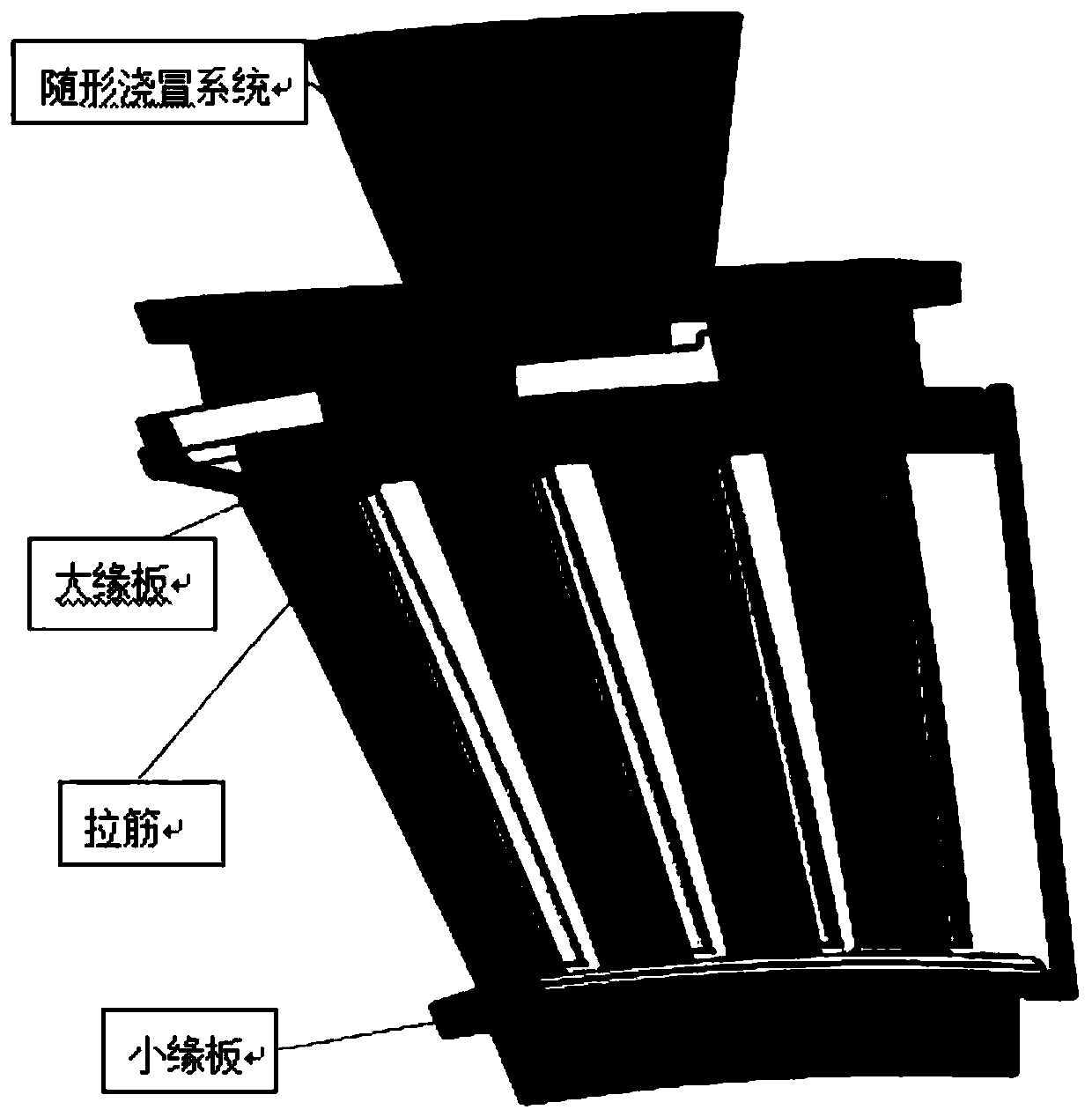

Casting forming process of complex high temperature alloy multi-union guide vane casting

The invention discloses a casting forming process of a complex high temperature alloy multi-union guide vane casting, and belongs to the technical field of precision casting. The process is characterized in that a casting body wax mold is prepared, and the casting body wax mold and a rigging system are assembled into a module; the module is coated with refractory coating layer by layer, is sent into a dewaxing kettle for dewaxing, and is sent into a baking furnace for high temperature pre-baking; the exterior of a shell is wrapped in a step type and is tied with refractory insulation cotton; ahigh temperature alloy rod is remelted and smelted to obtain high temperature alloy metal liquid; before pouring, the shell is sent into the baking furnace again, and then is sent into a vacuum induction casting furnace, and the high temperature alloy metal liquid is poured into the shell; and after pouring is completed, heat preservation is carried out, and shell removal, cutting, sand blastingand polishing are carried out after furnace exiting. The casting forming process effectively reduces or eliminates casting defects such as looseness and cracking easily generated at the connecting positions of hot joint vanes and small edge plates, the yield is improved to 75% to 80%, and the process is suitable for complex high temperature alloy multi-union guide vane casting.

Owner:AEROSPACE HIWING HARBIN TITANIUM IND

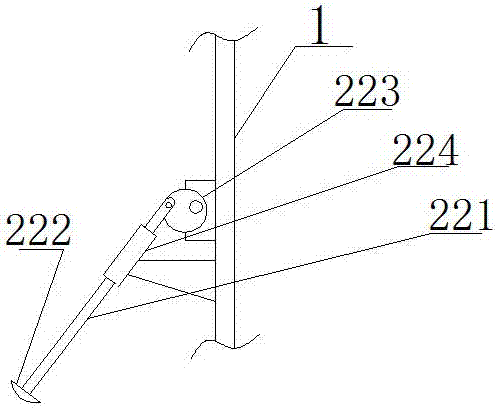

Flour mixing machine

InactiveCN107019010AIncrease elasticityUniform elasticityMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsEngineeringMotor shaft

The invention relates to a noodle kneading machine, comprising a cylinder body and a dough kneading device arranged in the cylinder body; a dough inlet is arranged at the upper end of the cylinder body; a telescopic water inlet pipe which can be stretched The end is a cylindrical self-rotating nozzle; the kneading device includes a stirring device that can be raised and lowered as in the cylinder and a beating device that is evenly distributed on the inner periphery of the cylinder; the beating device includes a plurality of The stroke rod; one end of the stroke rod toward the center of the bottom of the cylinder is provided with a hemispherical hammer, and the other end is hinged on the outer periphery of a turntable; the turntable is driven by a first motor, and the motor shaft is eccentric on the turntable Setting; the middle part of the strike rod is slidingly sleeved in a limit sleeve.

Owner:林娜娜

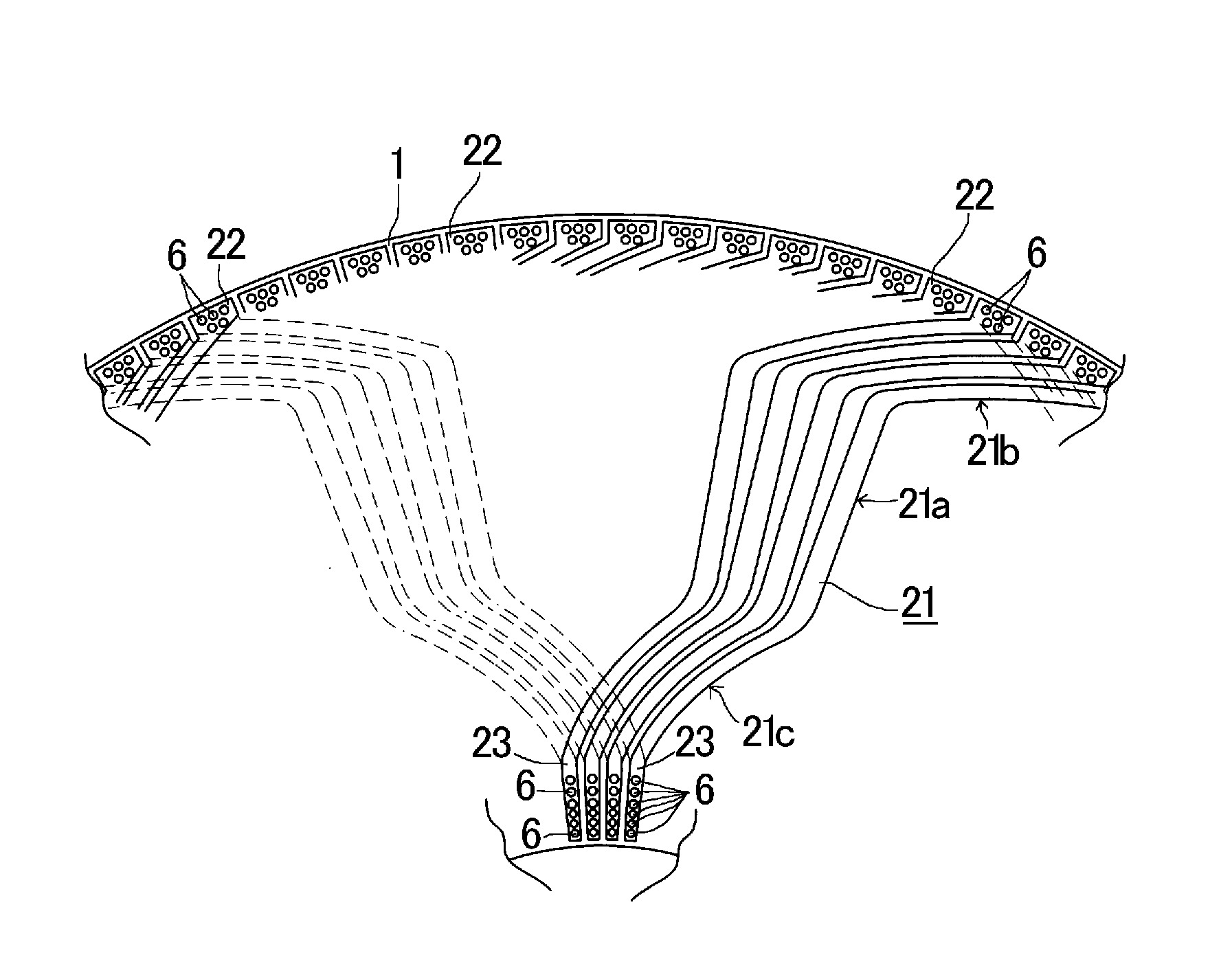

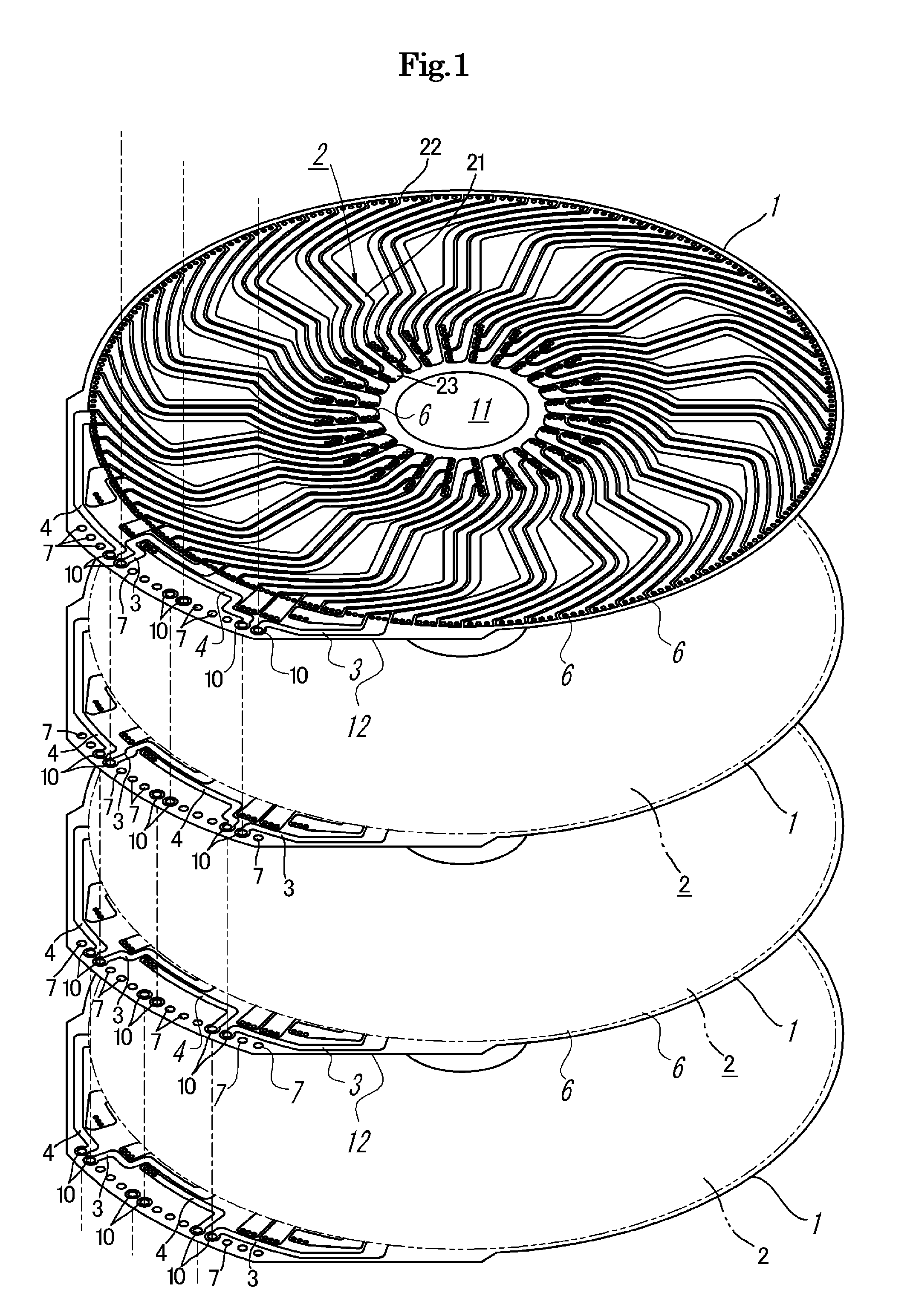

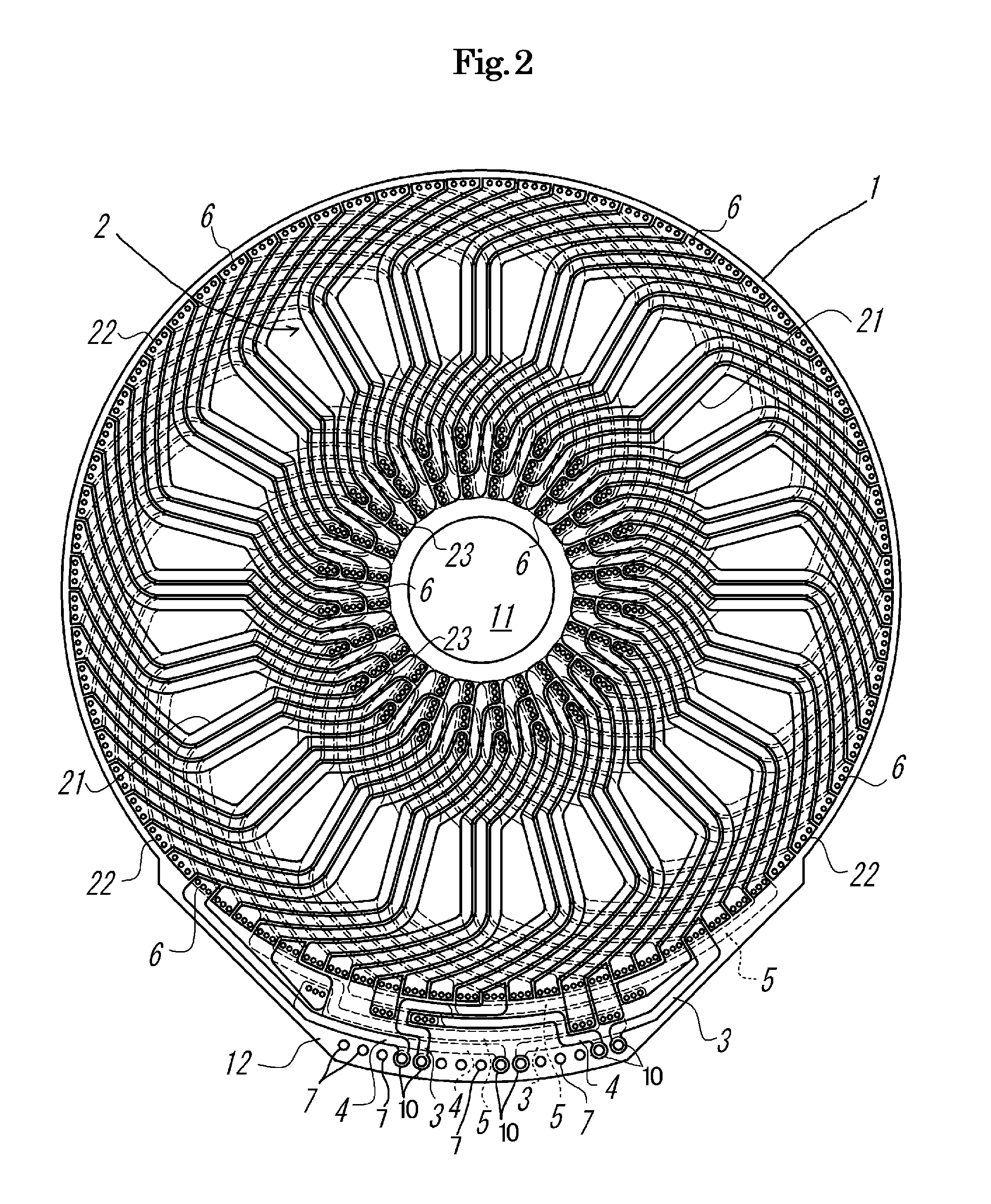

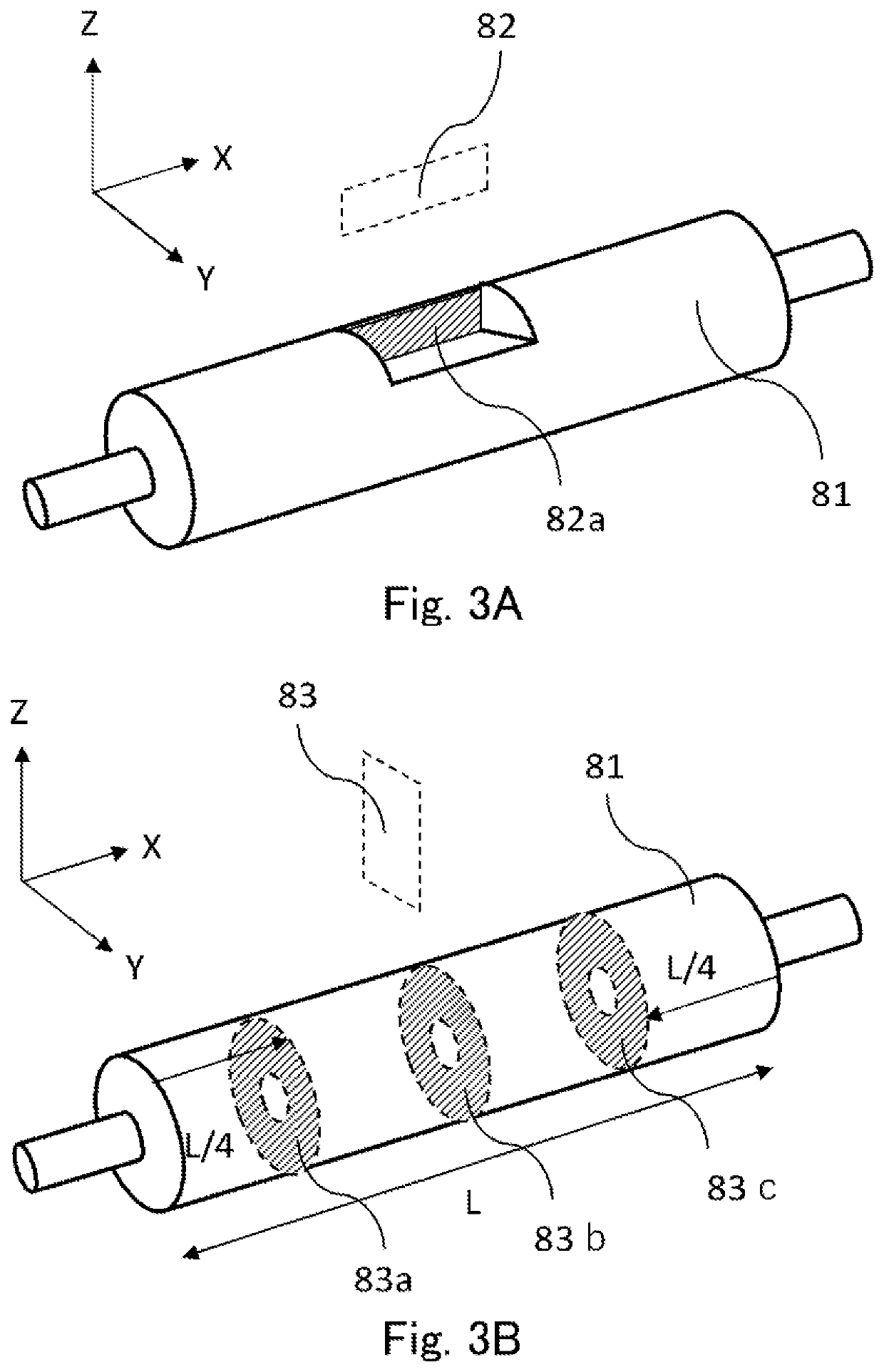

Coil apparatus

ActiveUS20120126927A1Lamination work can be facilitatedReduce manufacturing costCoilsWindings conductor shape/form/constructionElectrical conductorEngineering

Owner:COSMO MECHANICS CO LTD

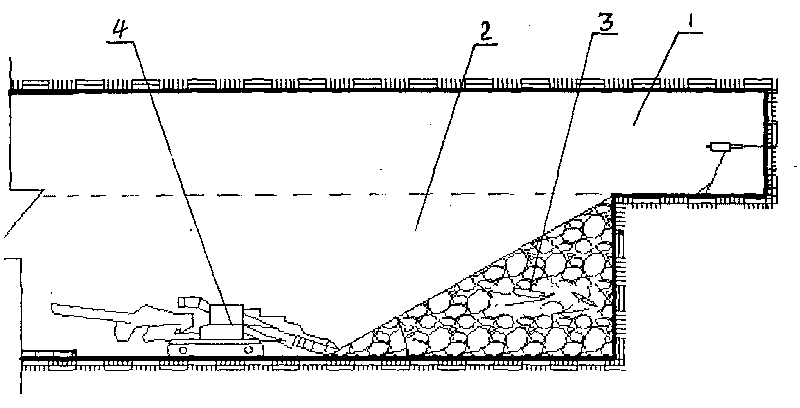

Method for constructing underground coal mine chamber of large cross section

ActiveCN101718199AOmit punchingSave the process of blastingBlastingTunnelsCoal waterMining engineering

The invention relates to a method for constructing an underground coal mine chamber, in particular to a method for constructing an underground coal mine chamber of large cross section, aiming at solving the problem that the prior method for digging and blasting the underground coal mine chamber of large cross section has low efficiency. The method for constructing the underground coal mine chamber of large cross section comprises the following steps: a, selecting an area having gangue on the upper layer and coal on the lower layer to construct the underground coal mine chamber; b, digging and blasting the upper layer of the area; c, breaking the large gangue generated from digging and blasting the upper layer of the area into pieces; and d, cutting the coal in the lower layer of the area with a fully-mechanized coal winning machine and conveying the coal and the broken gangue out. The method for constructing the underground coal mine chamber of large cross section integrates the digging by blasting with the digging by the machine, omits the procedures of perforating the coal layer, blasting and the like, effectively increase the production efficiency, reduces the labor intensity of the worker, adopts the machine unit to cut the coal layer, causes less vibration to the coal side, obviously improves the forming and supporting effect and ensures the safety of supporting two sides of the high tunnel.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD +1

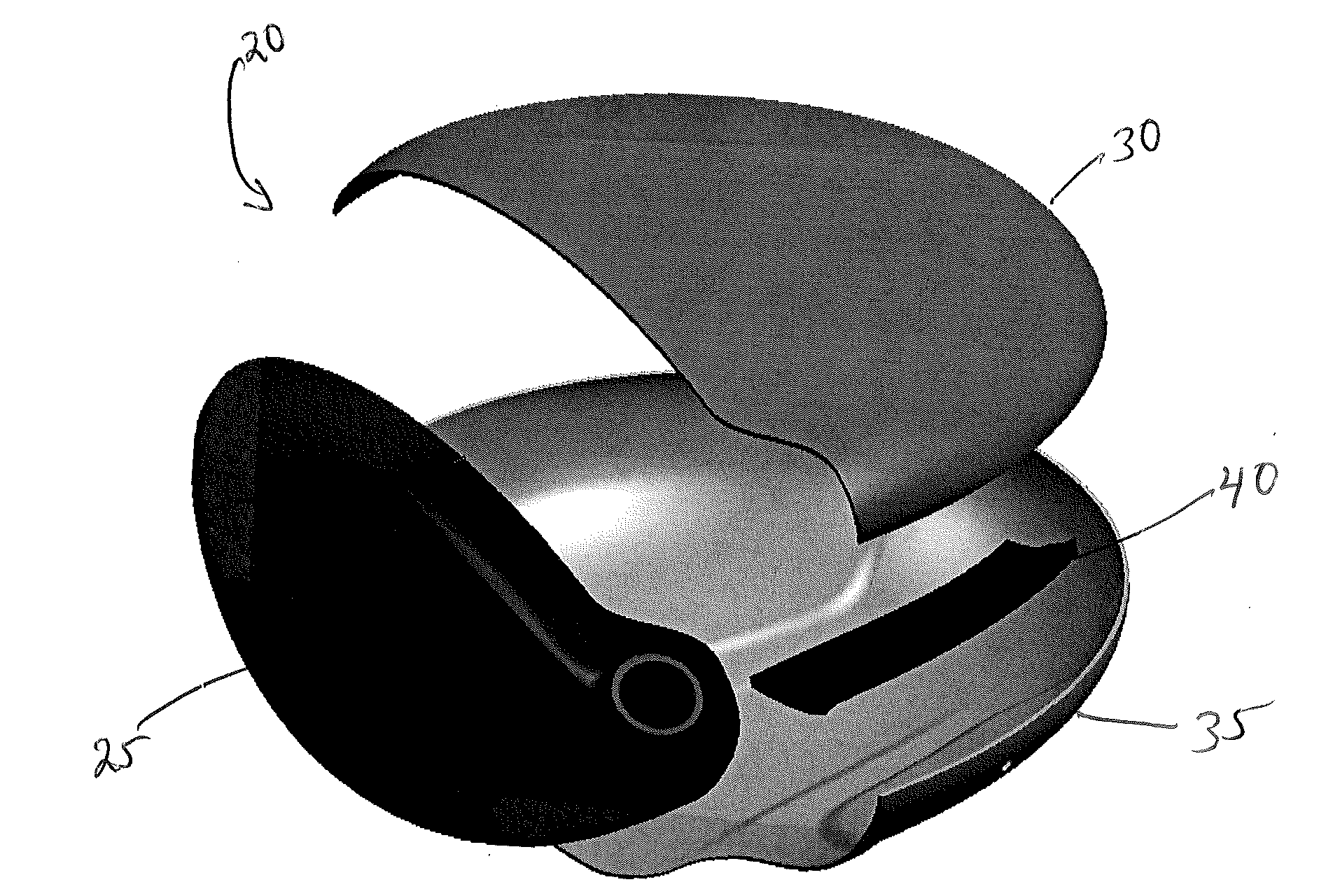

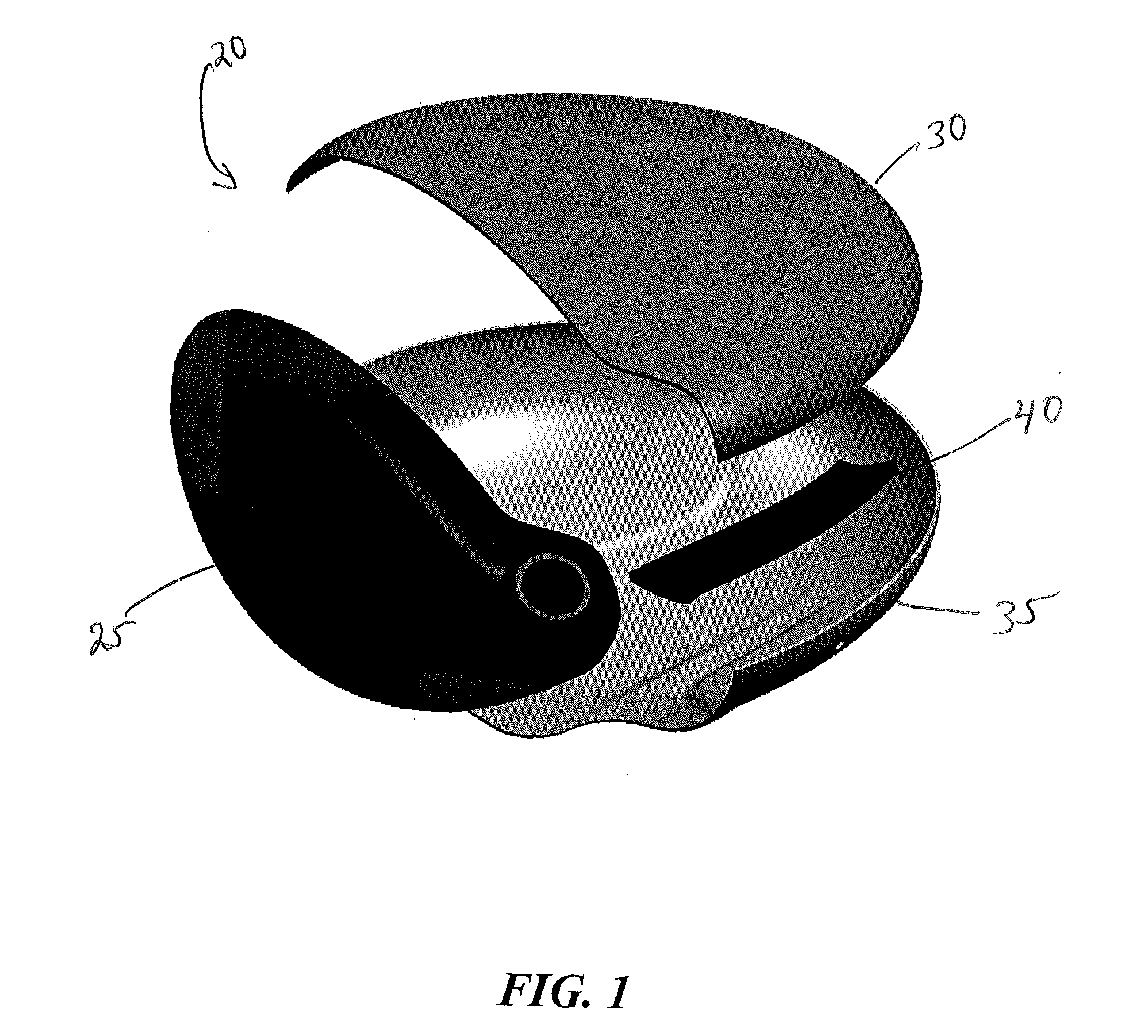

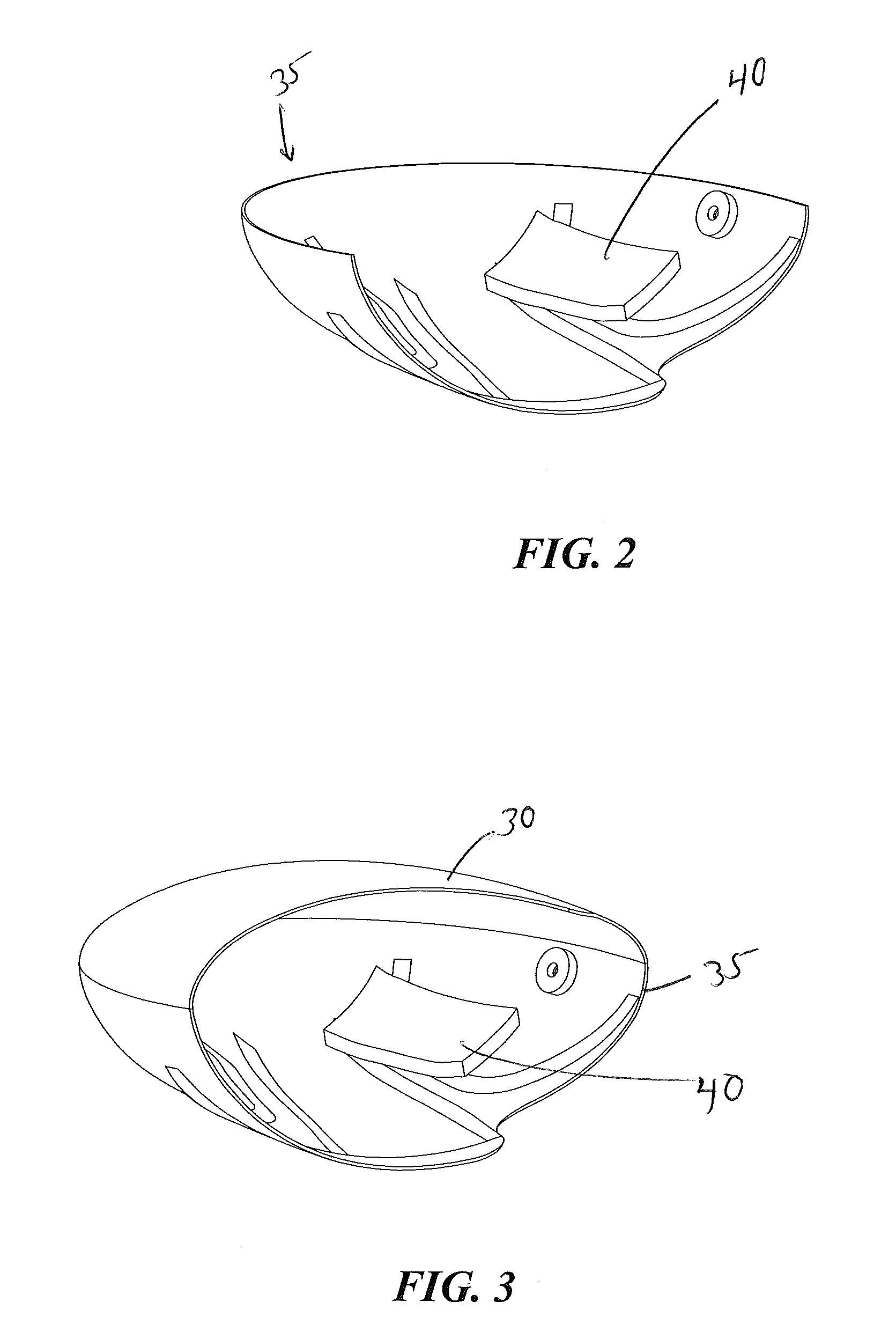

Method for constructing a multiple piece golf club head

InactiveUS20090293259A1Achieve consistencyImprove automationMetal rolling stand detailsMetal working apparatusEngineeringGolf Ball

Owner:CALLAWAY GOLF CO

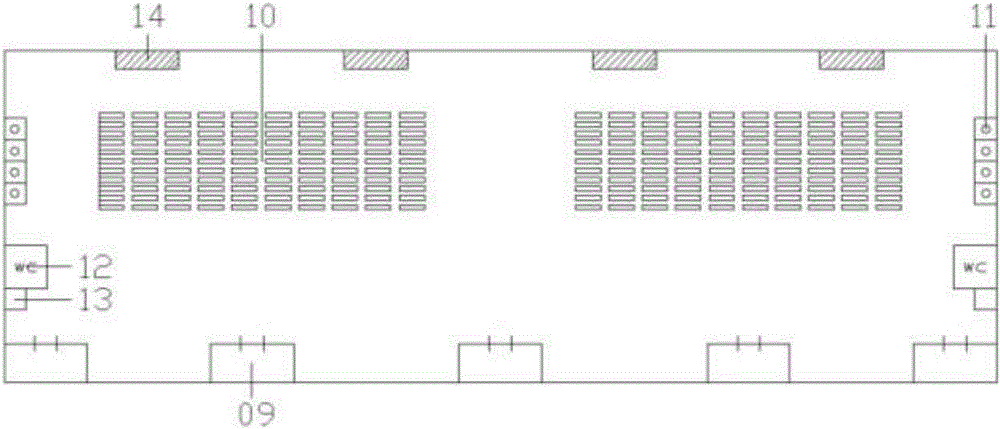

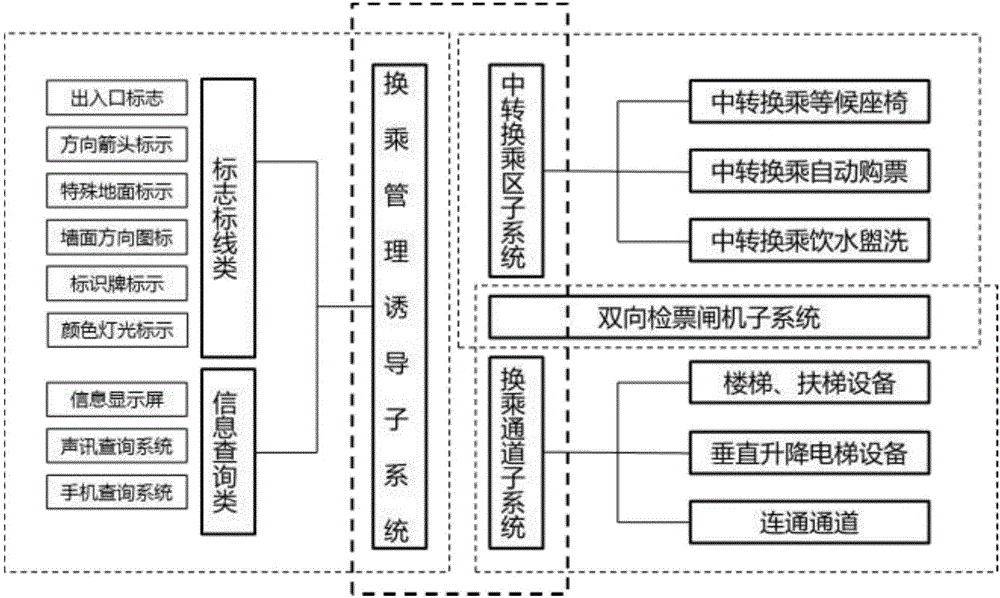

Instation passenger transfer system of railway passenger station and setting method thereof

InactiveCN106741016AReduce transit linksShorten the timeRailway traffic control systemsQuality of serviceTime information

The invention provides an instation passenger transfer system of a railway passenger station and a setting method thereof, wherein the passenger transfer system comprises an independent transfer zone, which includes a waiting zone, a self-service ticket machine and a railway real-time information display screen; a transfer channel, which is separated from a departure channel and connects the transfer zone and a transfer station; a bidirectional ticket checking brake, which is arranged between the transfer channel and the transfer zone so that transfer passengers can check in and access the transfer zone at the same time; a transfer management inducing logo, which comprises a mark line type prompt logo and a query prompt logo which are distributed at the transfer channel and the transfer station to continuously guide transfer passengers to the transfer station. The instation passenger transfer system changes the traditional mode that the transfer passengers have to leave station first and then enter the station, thus the transfer passengers at railway station can realize the high-efficient transfer, and the passenger transportation service quality and efficiency of the railway are improved.

Owner:TONGJI UNIV

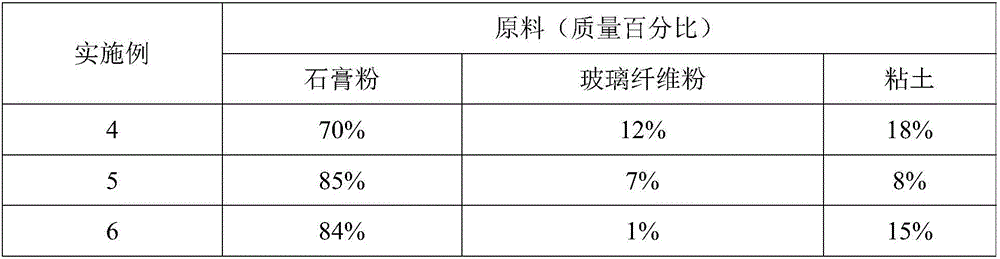

Binding agent, preparation method and grinding wheel

The invention relates to a binding agent, a preparation method and a grinding wheel, and belongs to the technical field of abrasives and grinding tools. The binding agent is mainly prepared from the following raw materials by mass percent: 70% to 85% of gypsum, 1% to 12% of glass fiber powder and 8% to 18% of clay. According to the binding agent, the raw materials coact with each other in a limited dosage proportion range, so that a compound high-temperature sintered product has relatively high strength, proper hardness and good plasticity; during preparation of the grinding wheel, the binding agent is mixed with water according to a suitable proportion, the forming speed is high, sintering is not carried out in the follow-up steps, and only natural drying or accelerated drying is required; sintering is not required, and the hardening speed is high, so that various problems like cracking and foaming occurring in traditional ceramic bond sintering are avoided; the binding agent is applicable to grinding wheels for low-speed and high-precision grinding, and the prepared grinding wheel is sharp and is high in grinding efficiency; the binding agent is applicable to various abrasives, the holding force for the abrasives is good, and the binding agent has universality; and the raw materials of the binding agent are easy to obtain, the cost is low, and the binding agent is applicable to large-scale industrial production.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

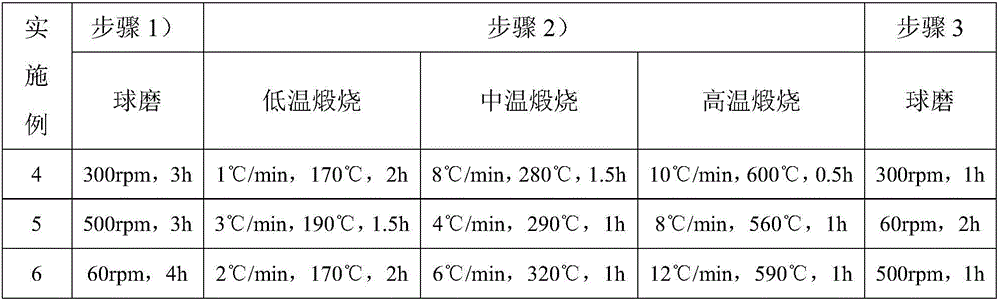

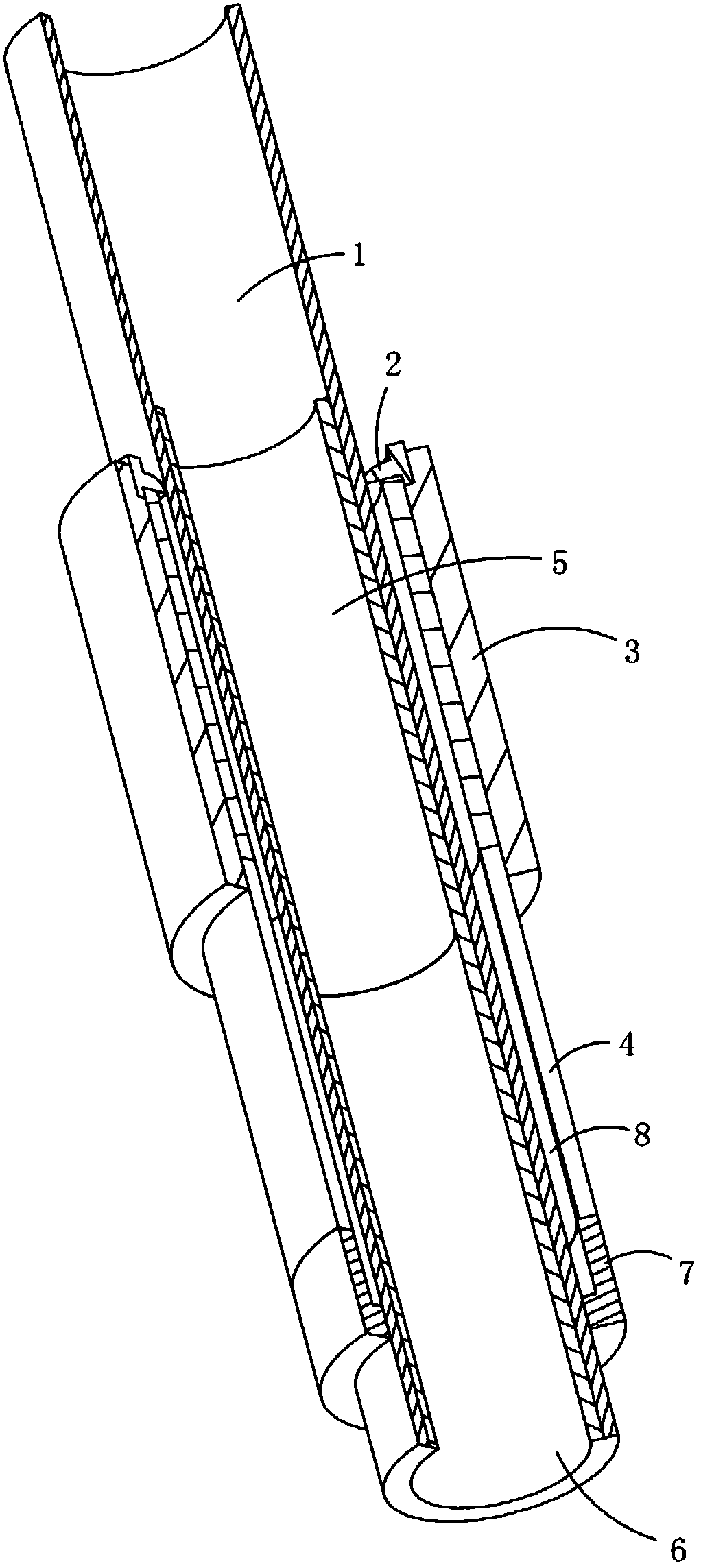

Sectional binding apparatus and sectional binding method for rotary targets

PendingCN108677151AReduce the number of configurationsSimple structureVacuum evaporation coatingSputtering coatingMetalMaterials science

According to the present invention, through the positioning matching of the external heating device and the internal heating device, the multiple sections of the metal layer casting spaces are sequentially formed on the back surface of the back pipe, the multiple sections of the metal layers are sequentially casted on the back surface of the back pipe, and the two adjacent metal layers are connected to form the integration; and with the apparatus and the method, the back pipe molding metal layers with any lengths can be produced, the structure is simple, the number of the heating elements andthe number of various detection elements can be reduced, the adjusting is flexible according to the material of the metal layer, the binding welding rate is improved, the welding quality is improved,the deformation is reduced, the rotary targets with different specifications and different lengths can be produced, the versatility of the device is strong, and the use is convenient.

Owner:东莞市欧莱溅射靶材有限公司 +1

Environment-friendly light weight decorative heat insulation board and preparation method thereof

The invention discloses an environment-friendly light weight decorative heat insulation board, which is prepared from the following raw materials in parts by weight: 10 to 20 parts of waste glass, 8-14 parts of construction waste, 7-12 parts of closed-cell perlite, 5-10 parts of polyethylene, 9-16 parts of iron tailings, 10-20 parts of cement, 5-11 parts of epoxy resin, 12-26 parts of bentonite, 6-12 parts of calcined kaolin, 3-6 parts of polyester fibers, 2-5 parts of zirconium silicate, 2-4 parts of tungsten carbide, 1-3 parts of aluminum oxide, 2-3 parts of glass fibers, 4-8 parts of modified longan shell powder, 2-3 parts of foaming agent and 2-4 parts of active agent. The environment-friendly light weight decorative heat insulation board is scientific and reasonable in formula; the prepared product is good in heat insulation effect, low in heat conductivity coefficient, and high in breaking strength and shock strength.

Owner:温州月煌科技有限公司

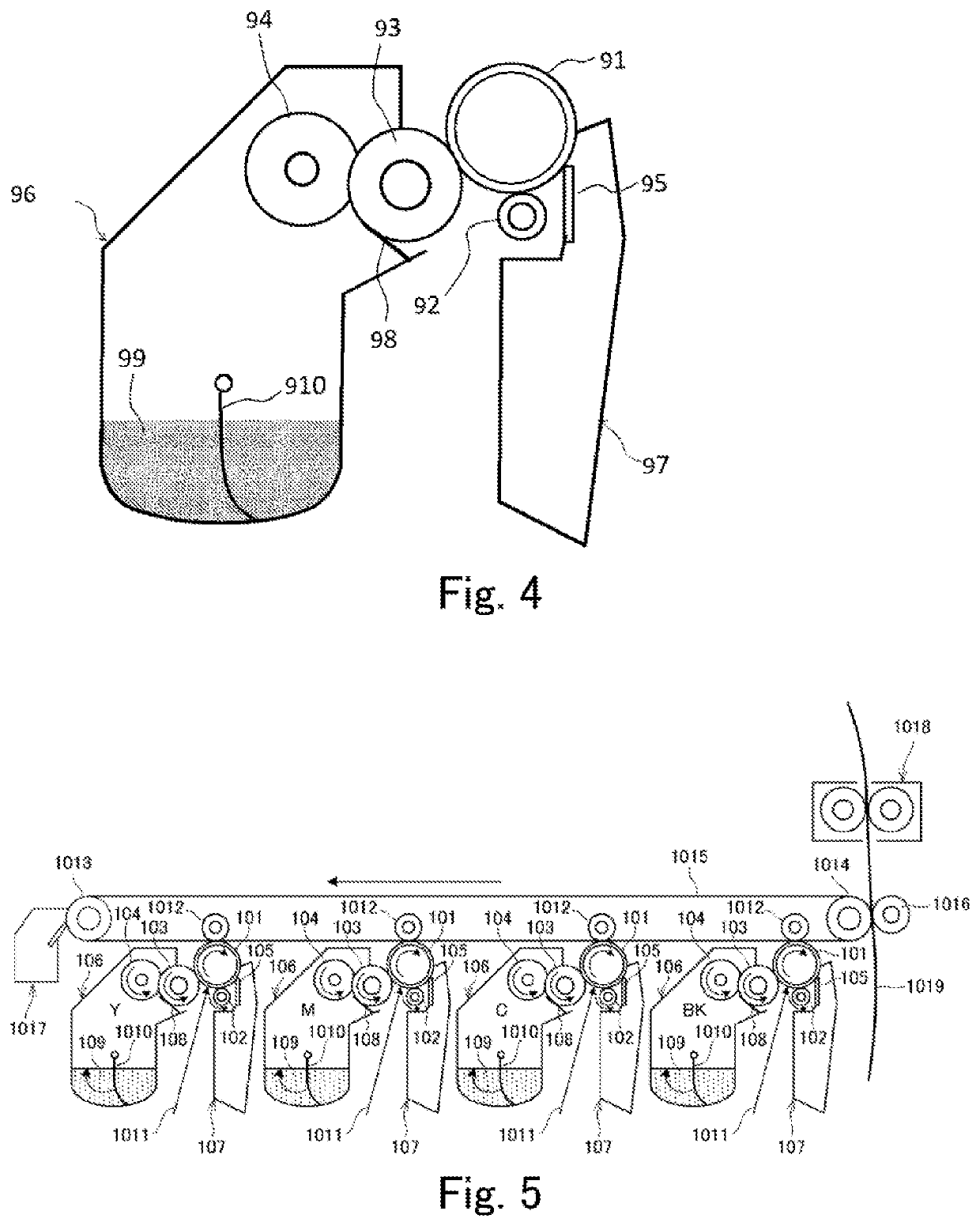

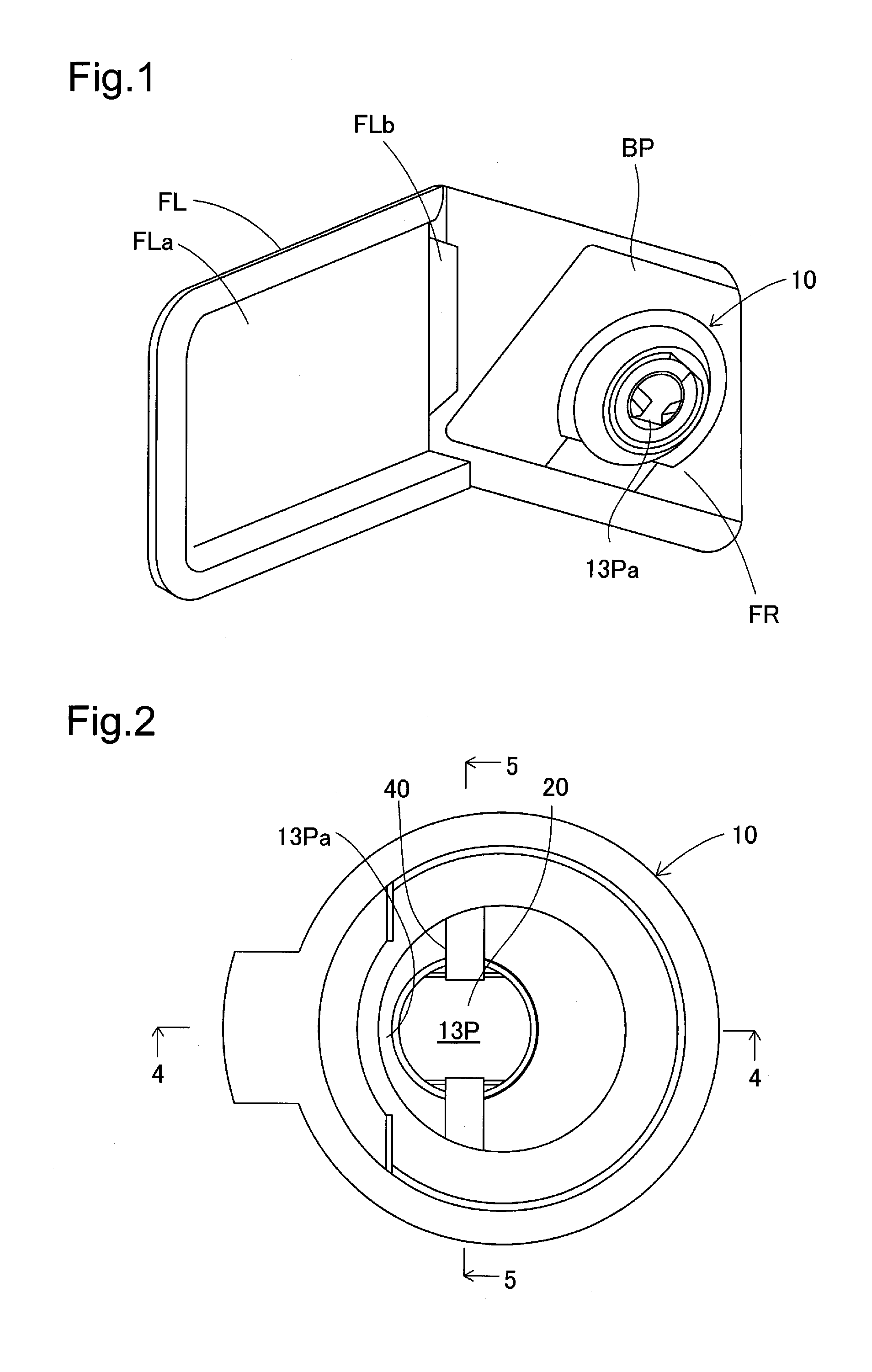

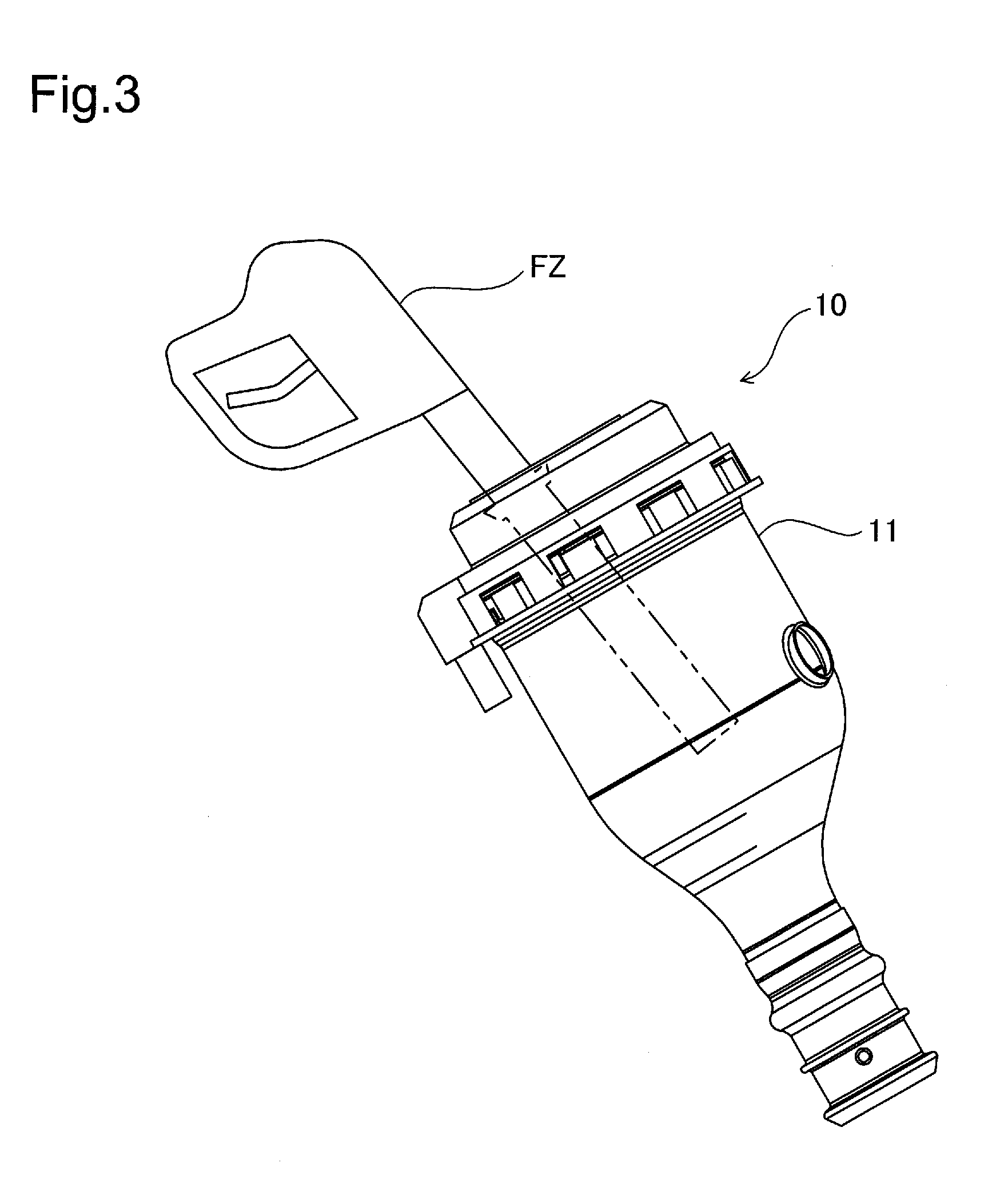

Electrophotographic apparatus, process cartridge and cartridge set

ActiveUS11061342B2Speed up the molding processLong-term repeated durabilityElectrographic process apparatusDevelopersElectric resistivitySilicon dioxide

Owner:CANON KK

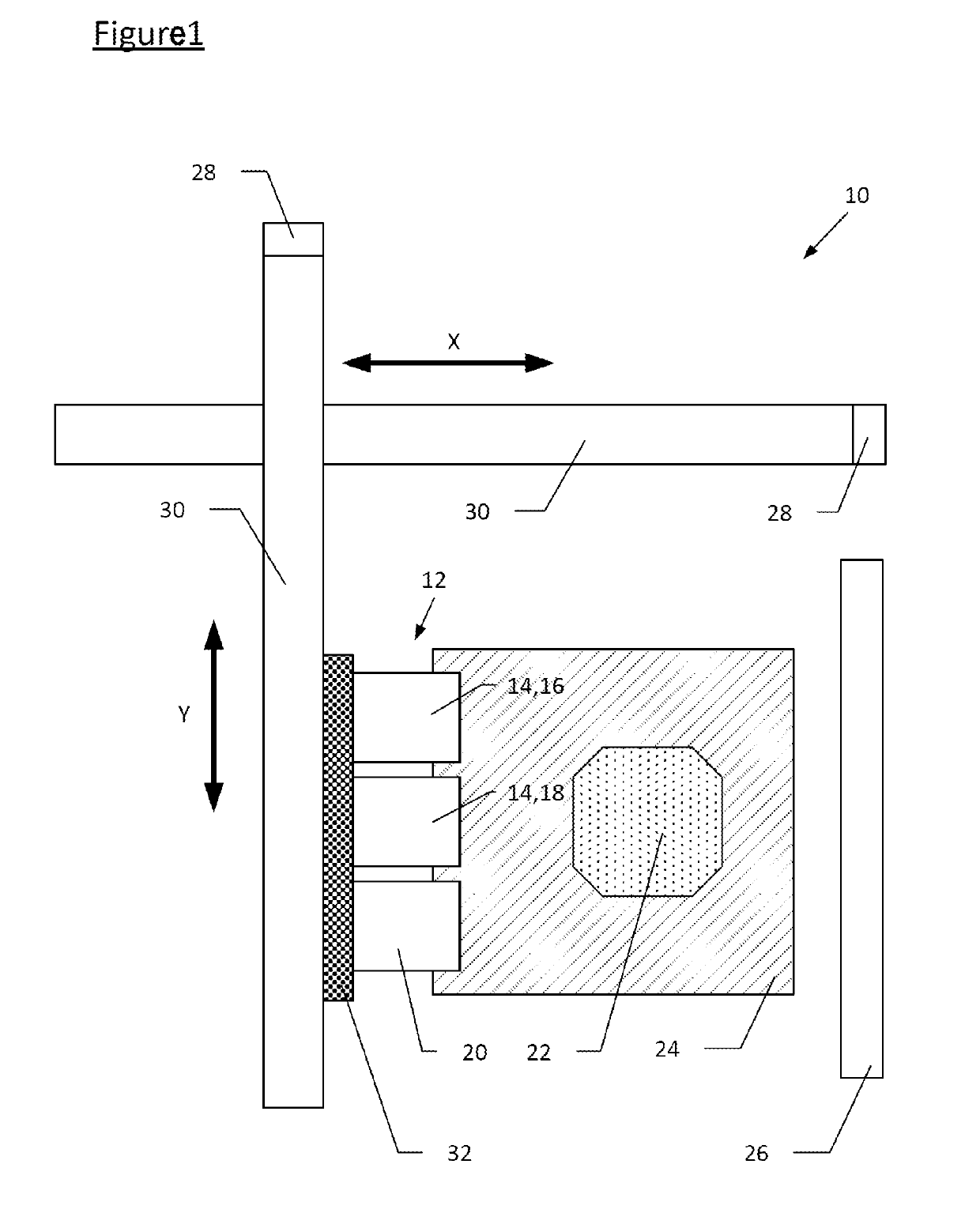

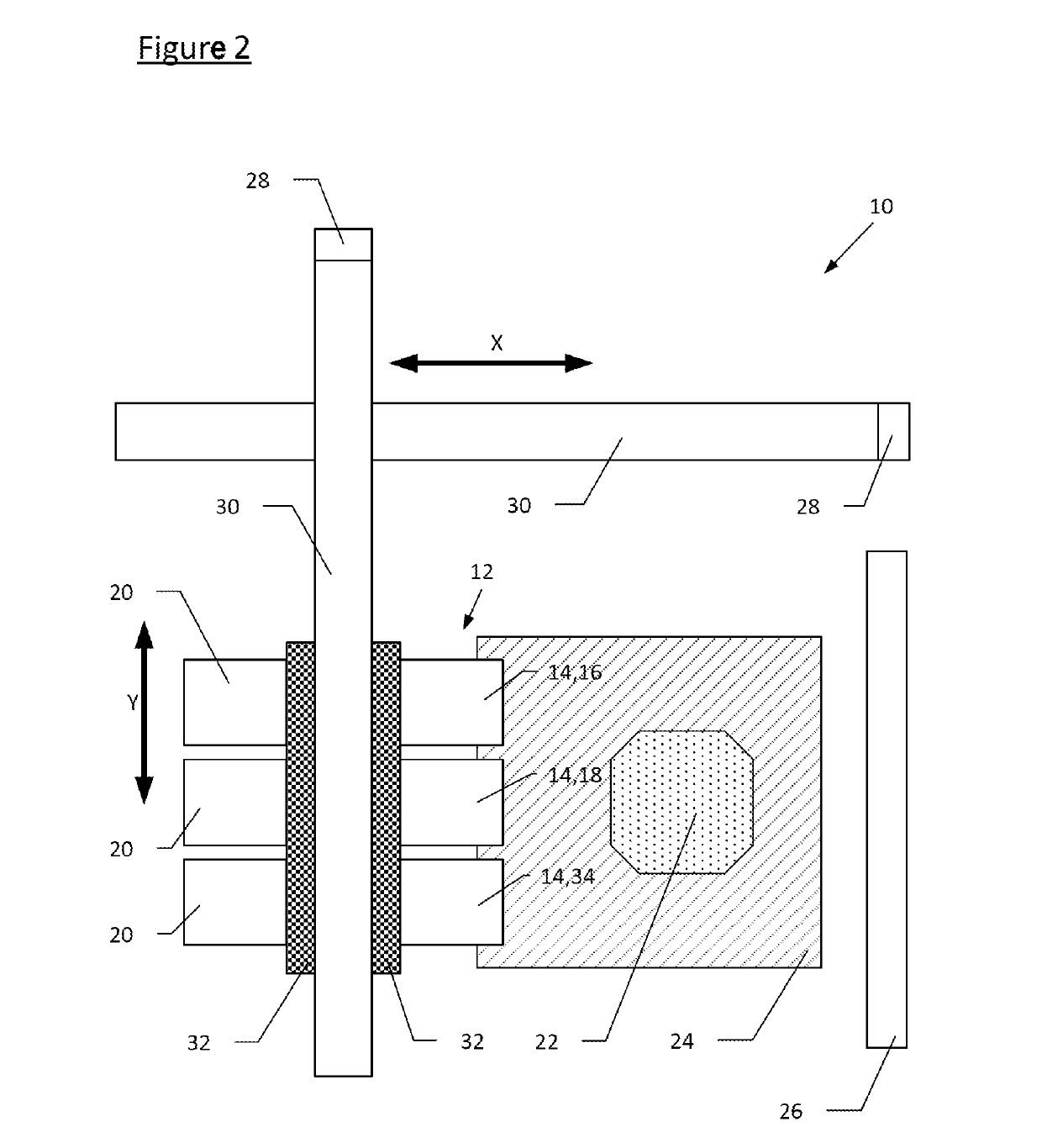

3D printer and method for producing objects

InactiveUS20190217545A1Avoid contaminationAvoid deformationProgramme controlComputer control3d printerManufacturing engineering

Owner:WACKER CHEM GMBH

Organometallic precursor compounds

ActiveUS20070232820A1Easy to depositSpeed up the molding processGroup 6/16 element organic compoundsChemical vapor deposition coatingMetalCoating

This invention relates to organometallic precursor compounds represented by the formula (L)M(L′)2(NO) wherein M is a Group 6 metal, L is a substituted or unsubstituted anionic ligand and L′ is the same or different and is a π acceptor ligand, a process for producing the organometallic precursor compounds, and a method for producing a film, coating or powder from the organometallic precursor compounds.

Owner:PRAXAIR TECH INC +1

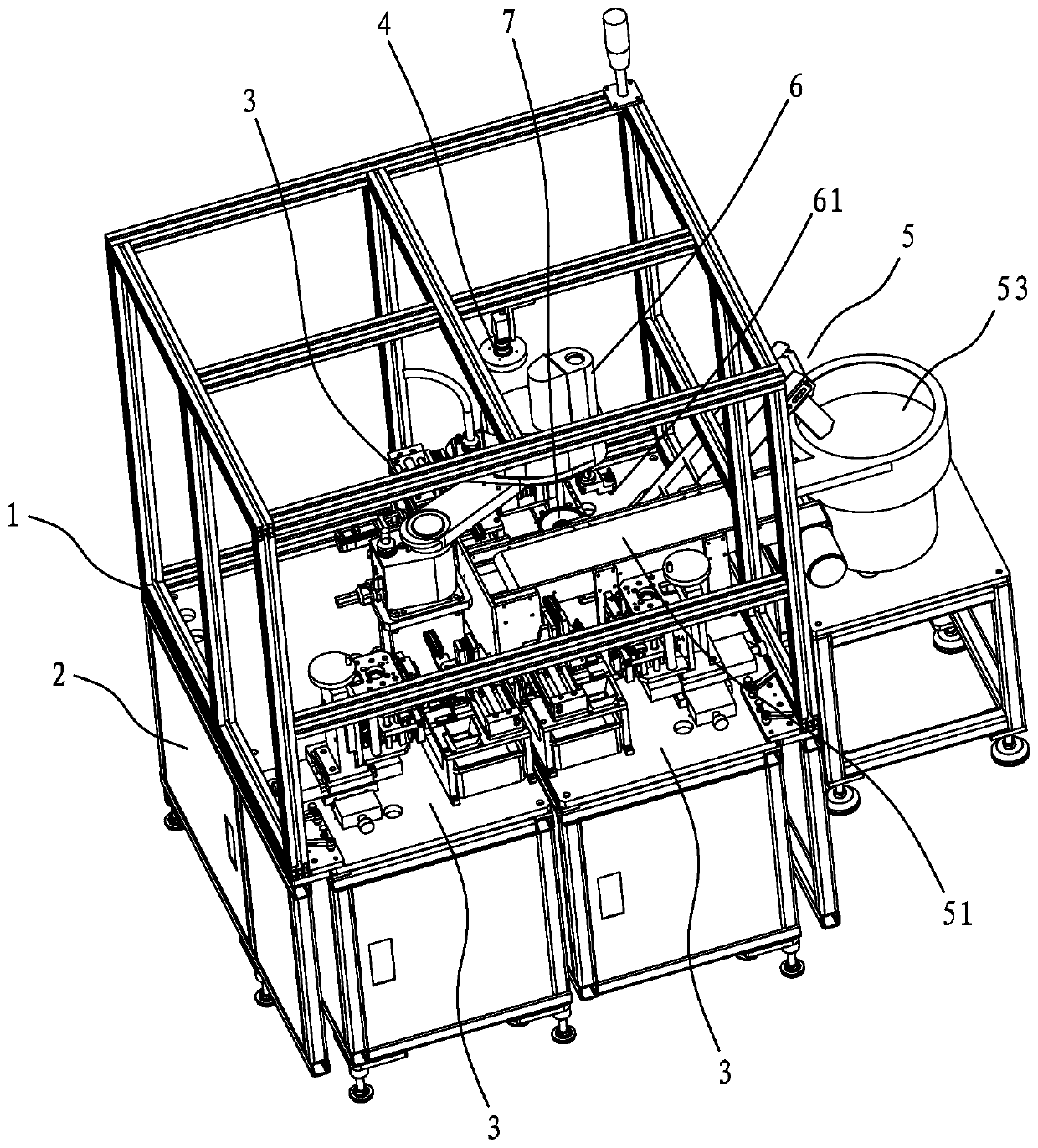

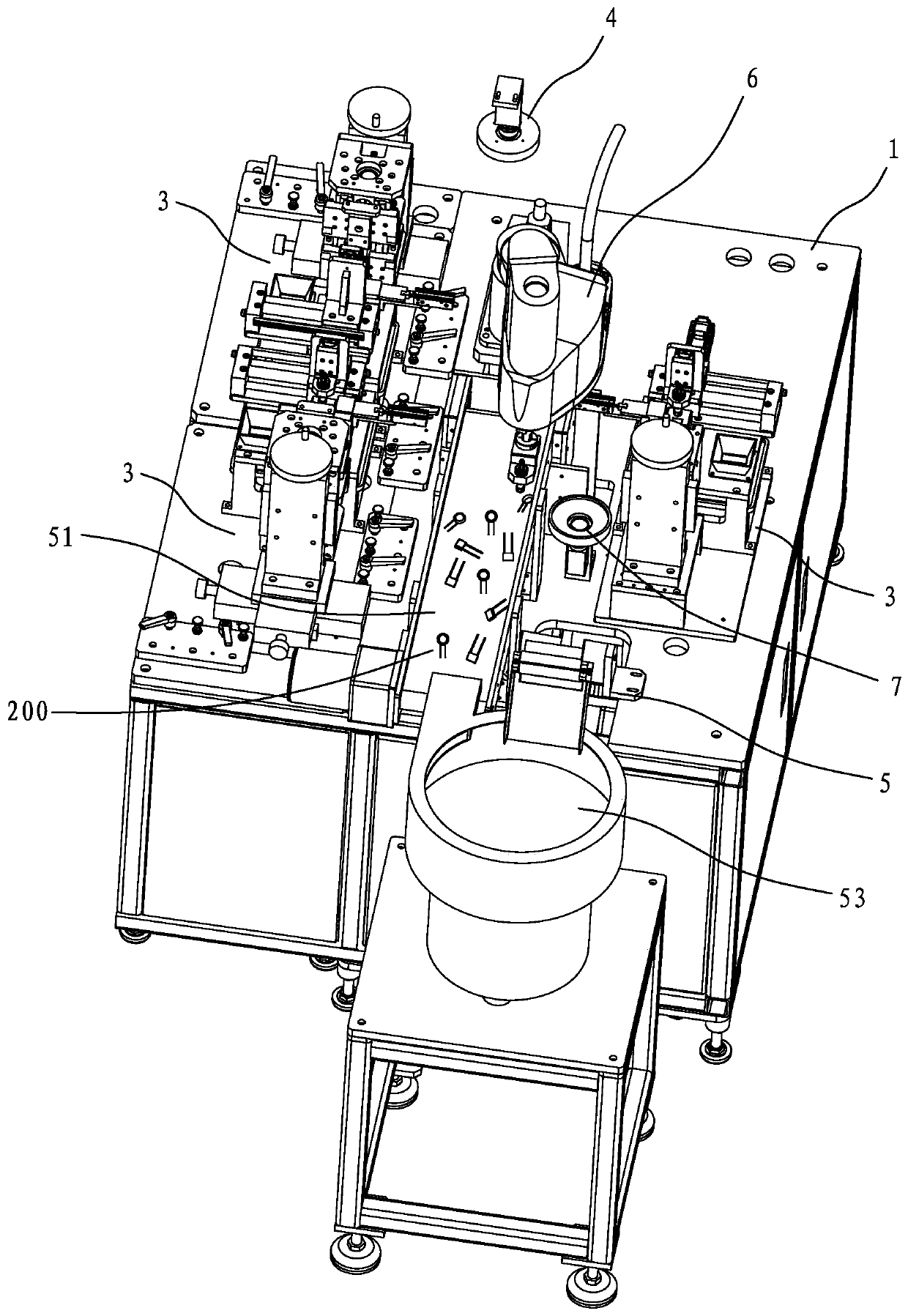

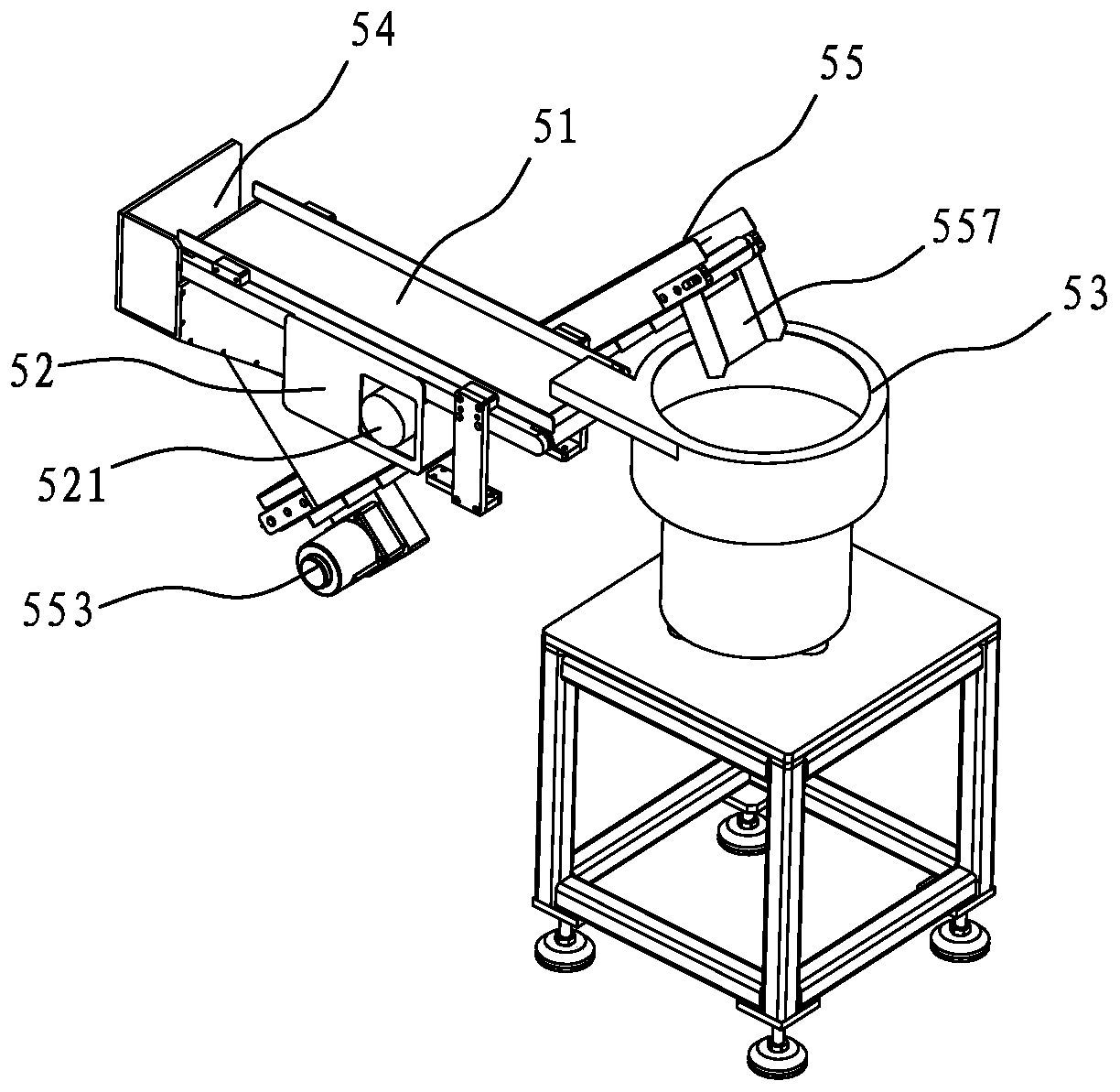

Electronic component full-automatic pin-shearing molding equipment based on vision robot

PendingCN109954822AImprove processing efficiencyReduce equipment cost and production costEmbedded systemVision based

The invention discloses electronic component full-automatic pin-shearing molding equipment based on a vision robot. The electronic component full-automatic pin-shearing molding equipment includes a machine table, an industrial personal computer, a four-axis manipulator, a feeding mechanism and a plurality of pin-shearing molding mechanisms for pin-shearing and molding a variety of different electronic components, a first vacuum suction nozzle is formed in the manipulator, a first camera for photographing downwards and a second camera for photographing upwards are arranged at the upper end of the machine table, the first camera photographs and detects the electronic components in the suction range of the first vacuum suction nozzle, the location and type of the designated electronic components are determined and fed back to the industrial personal computer, then the manipulator is controlled to move with the first vacuum suction nozzle to the location of the designated electronic components to suck and move to the position over the second camera to detect, and the manipulator adjusts the electronic components to the set angle and the set location according to feedback angle and location information of the electronic components from the second camera, and moves to the processing position of the pin-shearing molding mechanisms corresponding to the electronic components for pin-shearing and molding.

Owner:中山雅特生科技有限公司

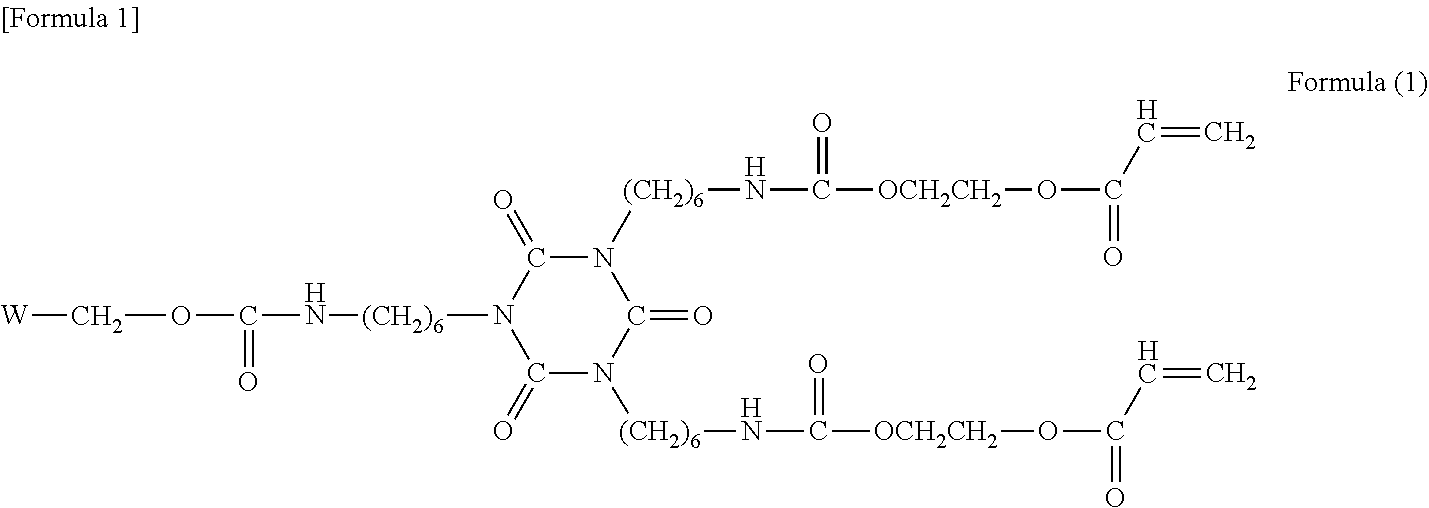

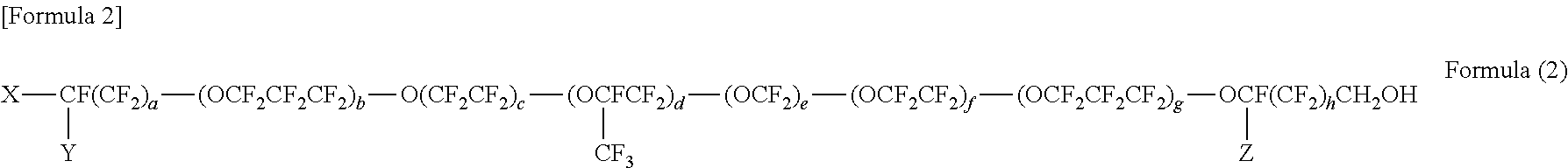

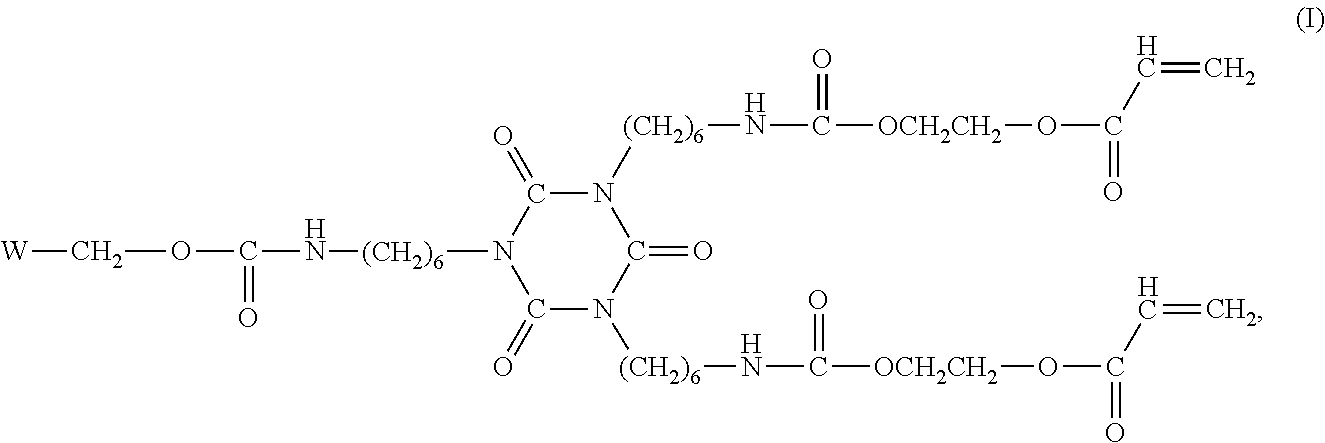

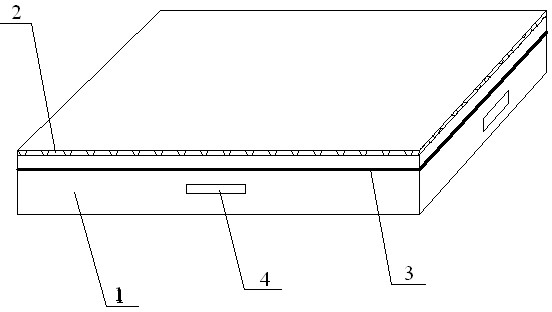

Transfer film, resin laminate, method for producing transfer film, and method for producing resin laminate

InactiveUS20120267042A1High surface tensionHigh transparencyFilm/foil adhesivesDecorative surface effectsTrioleinChemistry

An object of the present invention is to provide a transfer film in which the function layer such as an anti-reflective layer can be laminated using a film having high surface tension, and a laminate including a soil resistant layer formed by a wet method and having high water repellency and oil repellency and high transparency, scratch resistance, and sweat resistance can be provided, and a method for producing the transfer film. A transfer film according to the present invention is a transfer film including a transparent base material film and a soil resistant cured film laminated on the surface of the transparent base material film, wherein a water contact angle (1) of a surface of the soil resistant cured film not contacting the transparent base material film is not more than 100°, a water contact angle (2) of a surface of the soil resistant cured film contacting the transparent base material film is not less than 90°, and a contact angle (α) of triolein is not less than 55°.

Owner:MITSUBISHI RAYON CO LTD

Heat insulation decoration plate and preparation method thereof

The invention belongs to the field of building material and specifically relates to a light heat insulation decoration plate with decoration function for building wall insulation and a preparation method thereof. The heat insulation decoration plate comprises a heat insulation blank body and a decoration coating sprayed to the outer layer of the heat insulation blank body; and the heat insulationblank body is prepared by closed cell perlite, fly ash floating bead, cement, bentonite, cellulose ether, short fiber, wood fiber and rubber powder in parts by weight. The heat insulation blank body of the heat insulation decoration plate is formed by processing inorganic material and is light in weight, insulated and longer in service life; the cosmetic layer with the preset pattern is sprayed to the outer surface of the heat insulation blank body, so that integration of the heat insulation plate and the decorativeness is realized; and the problem that the current inorganic heat insulation decoration plate is heavy and easy to drop is solved as well.

Owner:安徽瑞蒙科技有限公司

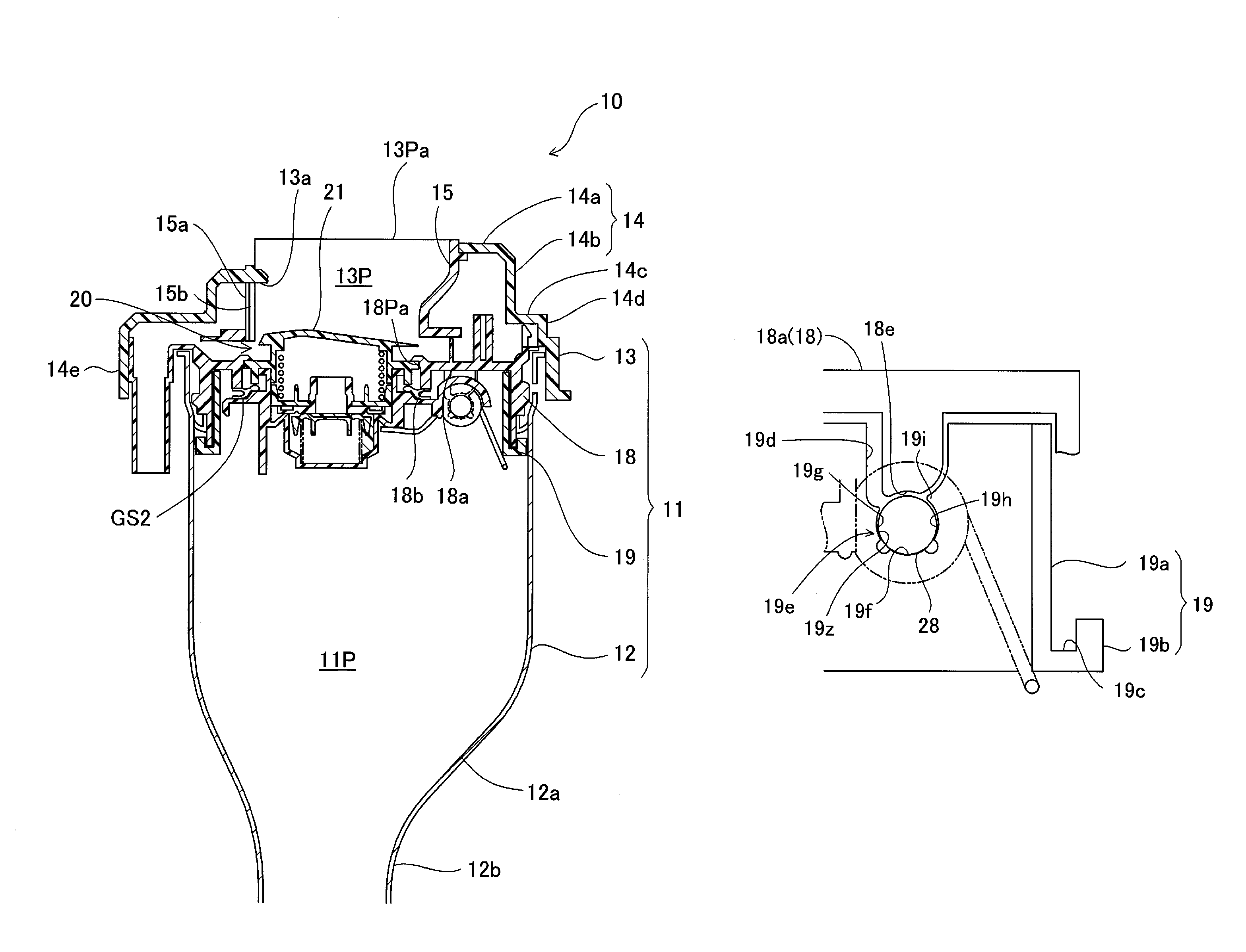

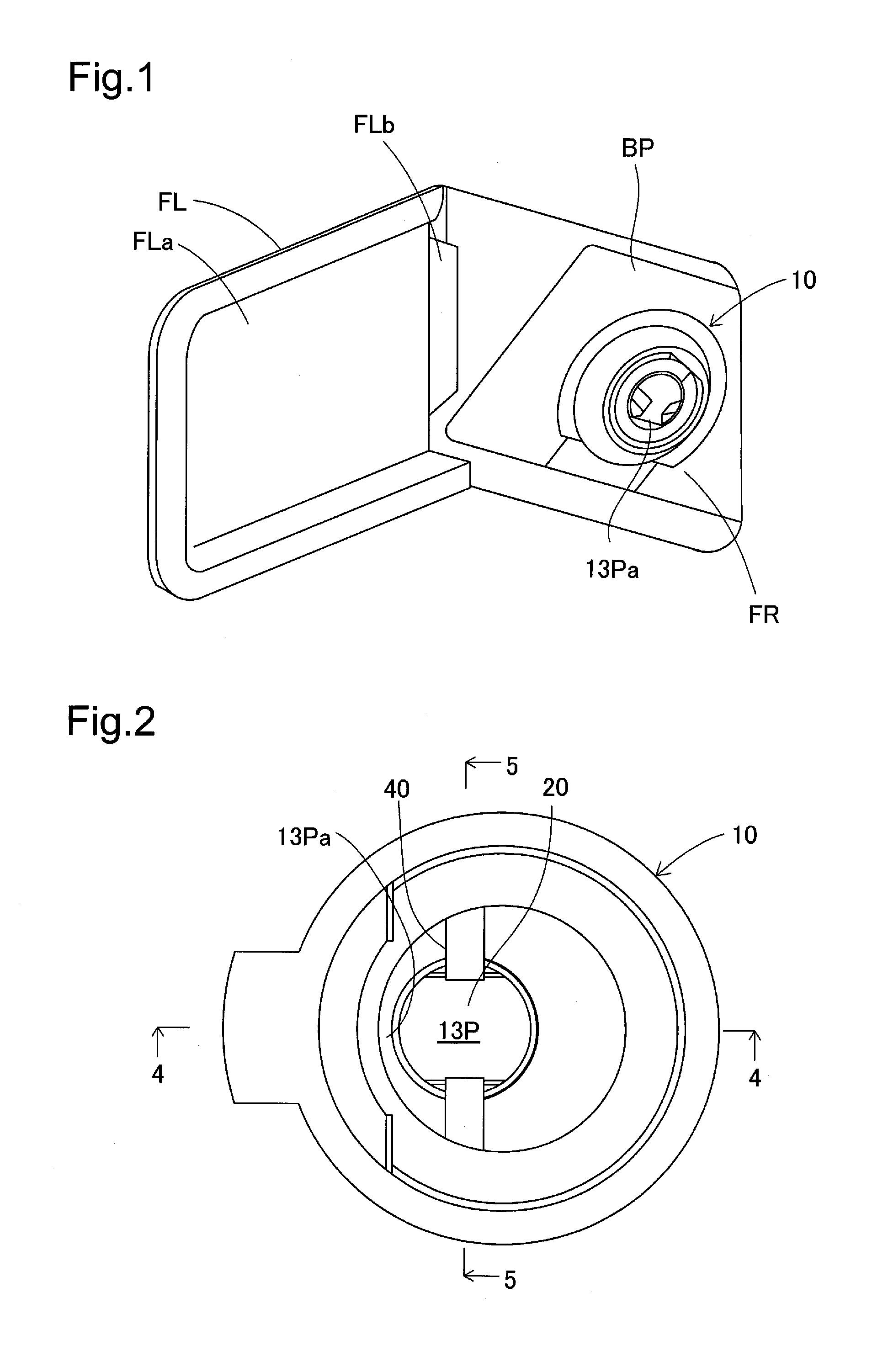

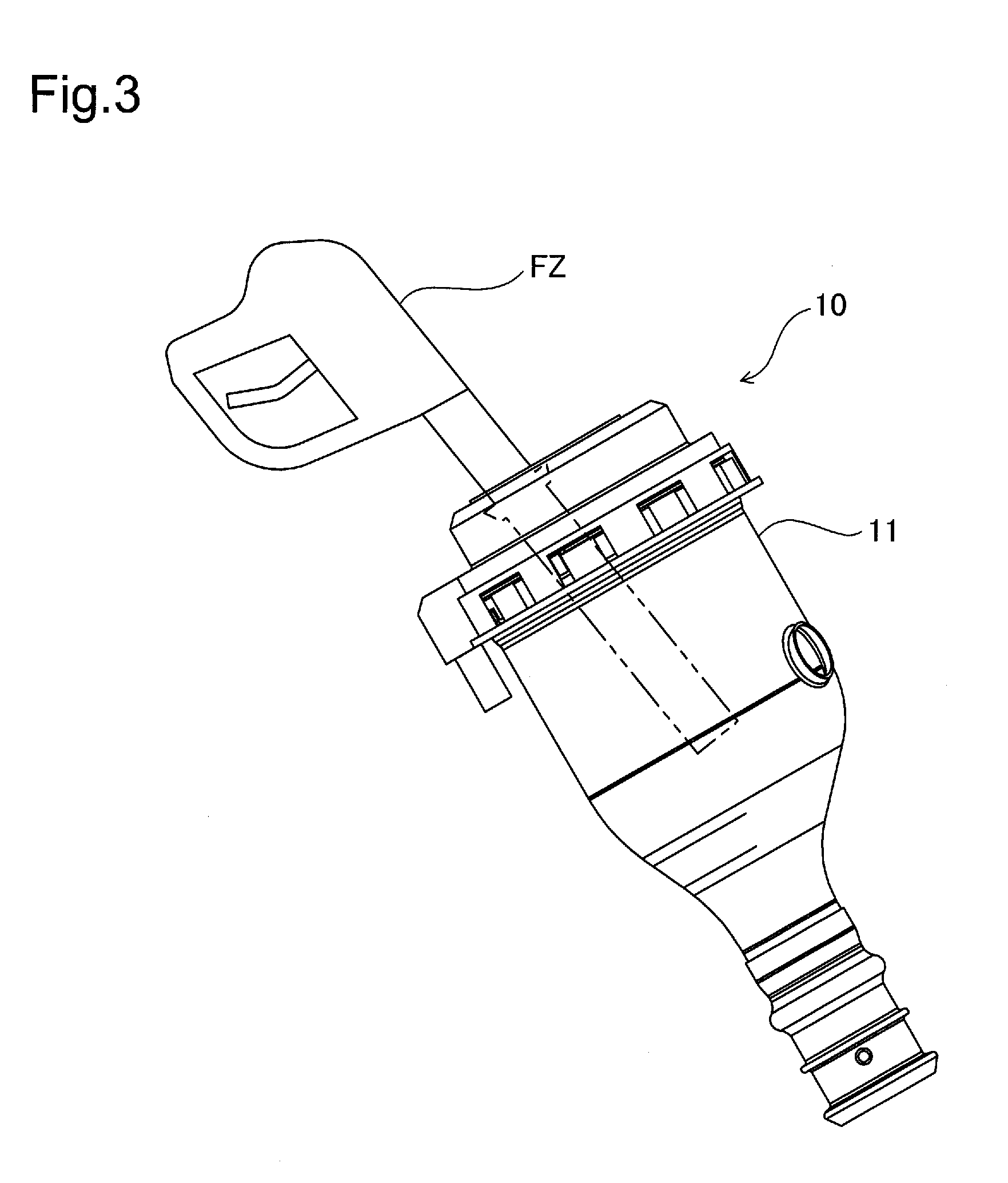

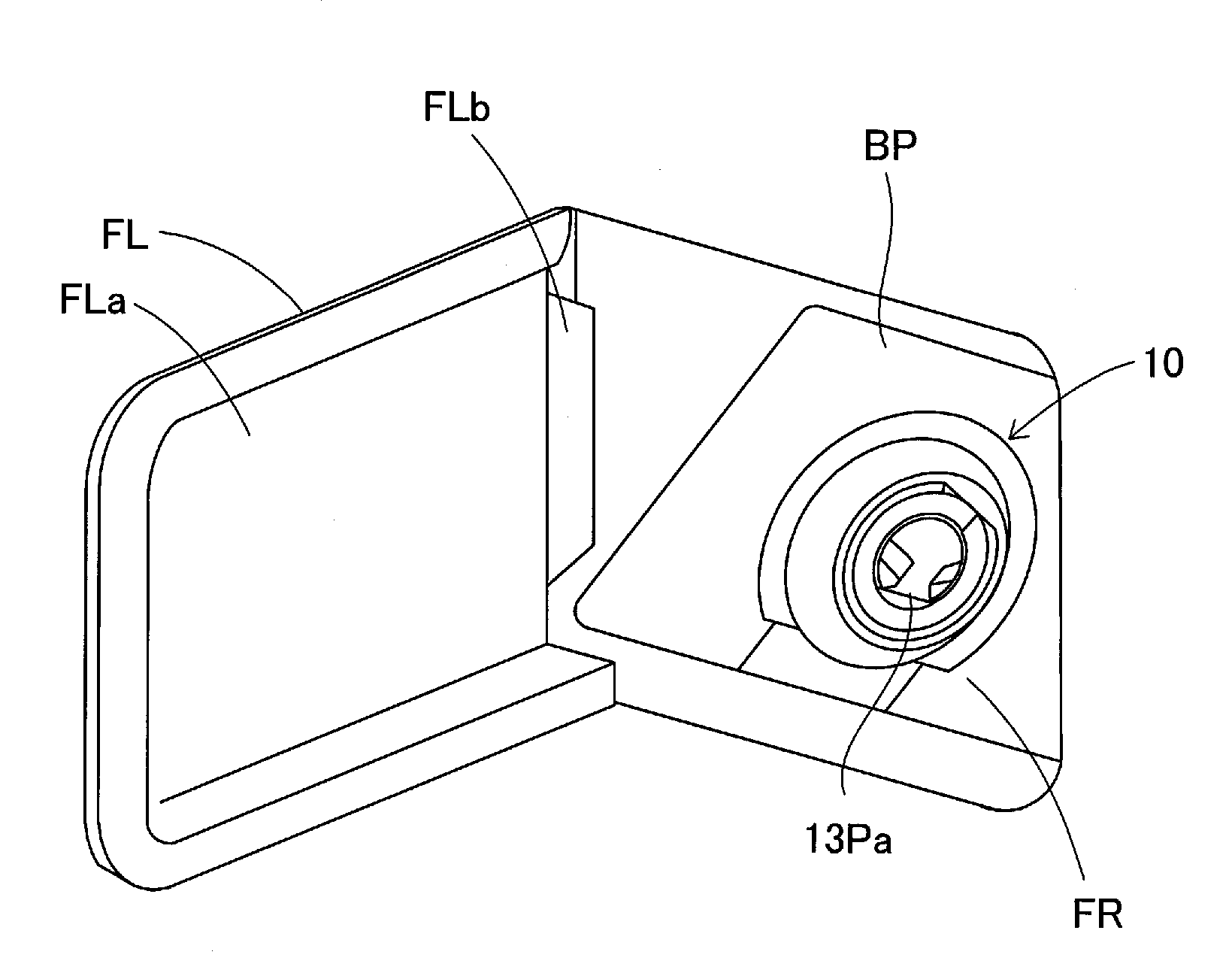

Fuel tank opening and closing device

ActiveUS8776845B2High forming precisionSpeed up the molding processSolid materialClosures to prevent refillingFuel tankEngineering

A fuel tank opening and closing device is equipped with a flap valve mechanism arranged inside the tank opening forming member, having an opening and closing member for which the inlet is opened and closed by being pressed by the tip of the fueling nozzle, a shaft provided at the tip of the opening and closing member, and a bearing mechanism provided on the tank opening forming member for supporting the shaft so as to be rotatable. The bearing mechanism has a shaft support recess in which the shaft is inserted and a plurality of shaft restriction projections provided projecting from the wall surface of the shaft support recess, and the shaft restricting projections have a cross section arc shaped shaft support surface such that there is contact with a portion of the outer periphery of the shaft.

Owner:TOYODA GOSEI CO LTD

Rapid flour kneading machine

InactiveCN106982879AIncrease elasticityUniform elasticityMixing/kneading structural elementsMixing/kneading with inclined rotationEngineeringMotor shaft

The invention relates to a fast flour kneading machine, comprising a basin body and a plurality of kneading noodle kneading devices arranged obliquely on the basin body; The kneading device in the body; the telescopic water inlet pipe facing the basin is arranged in the cylinder; the end of the telescopic water inlet pipe is a cylindrical self-rotating nozzle; the kneading device includes a stirring device that can be lifted and inserted into the basin along the cylinder and striking devices evenly distributed on the inner periphery of the cylinder; the striking devices include a plurality of striking rods facing the basin; one end of the striking rods facing the basin is provided with a hemispherical hammer, and the other end is hinged on the outer periphery of a turntable above; the turntable is driven and rotated by a first motor, and the shaft of the motor is set eccentrically on the turntable; the middle part of the striker is slidably set in a limit sleeve; the bottom of the basin is provided with an opening and closing port; the A fermentation device is arranged below the opening and closing opening.

Owner:林娜娜

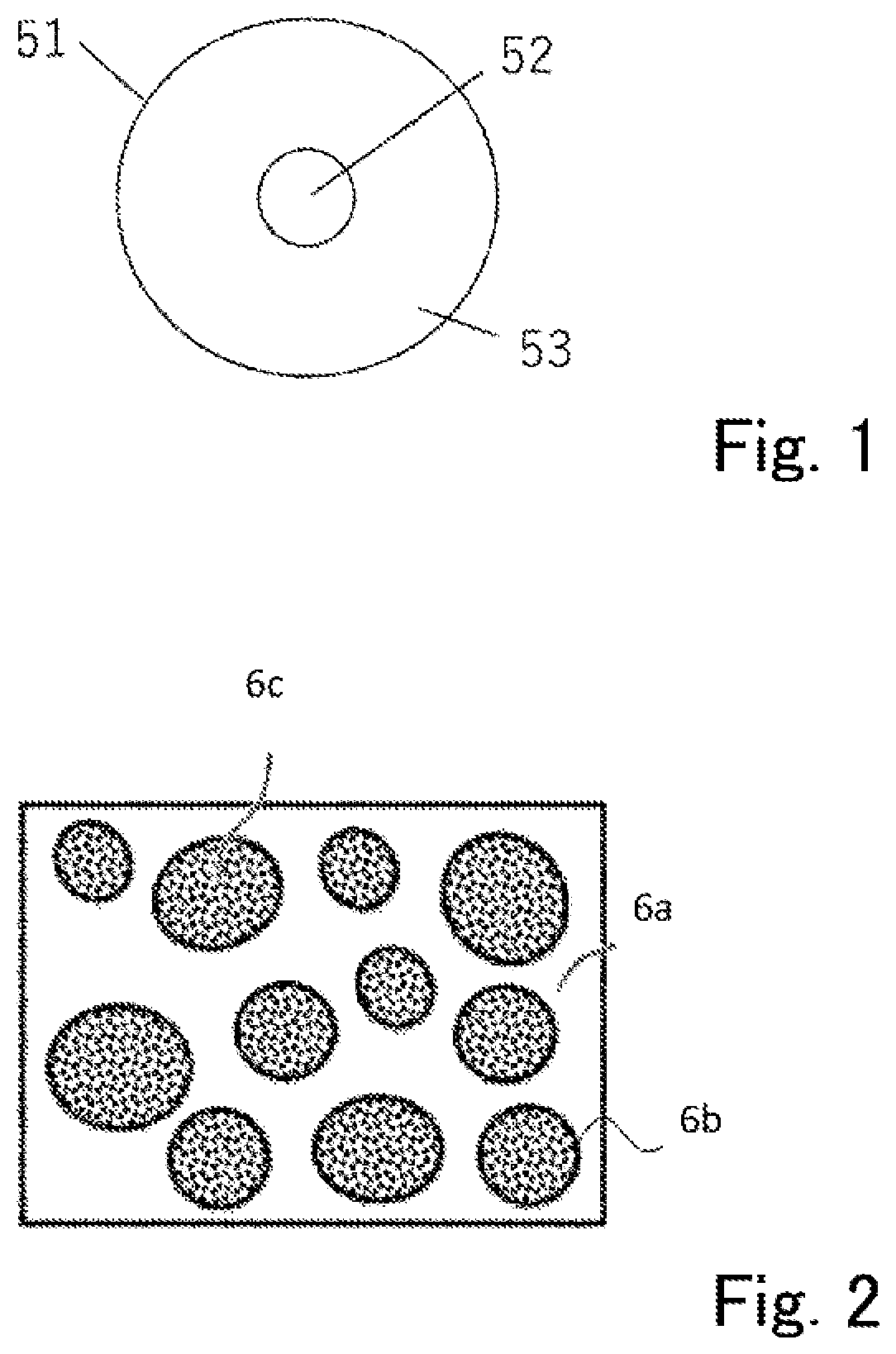

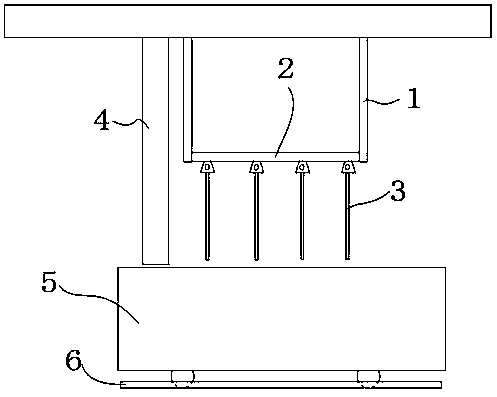

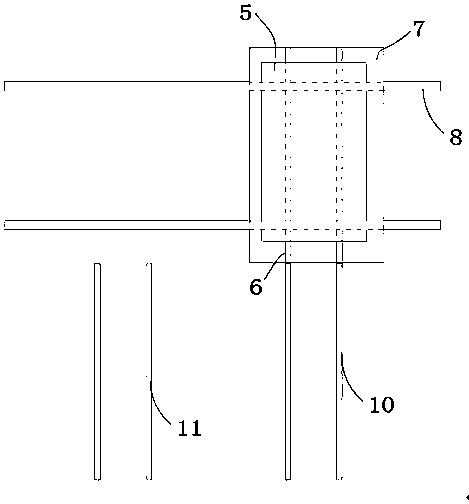

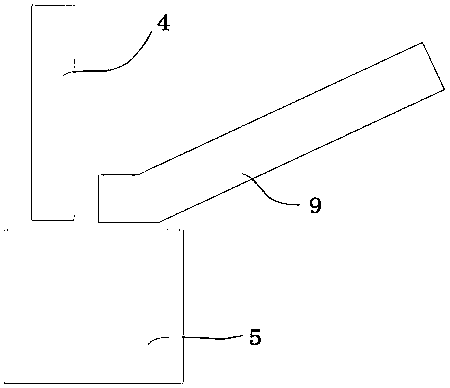

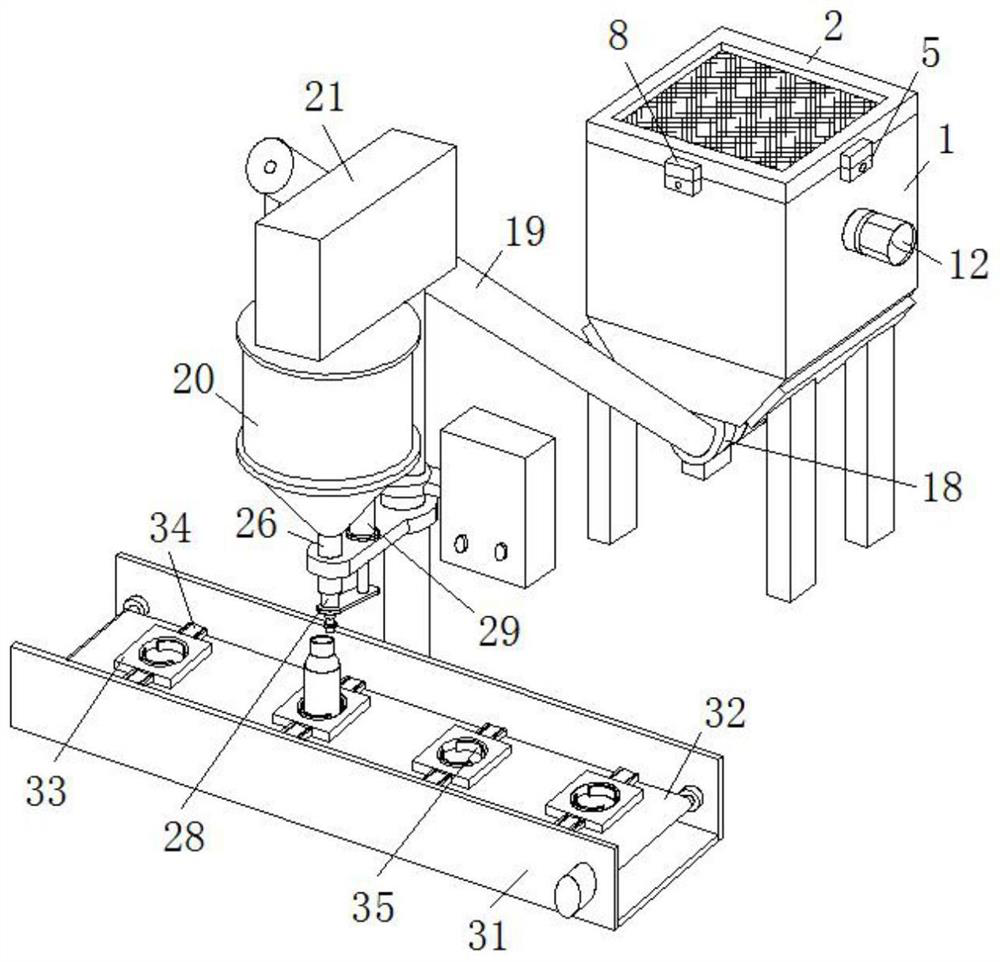

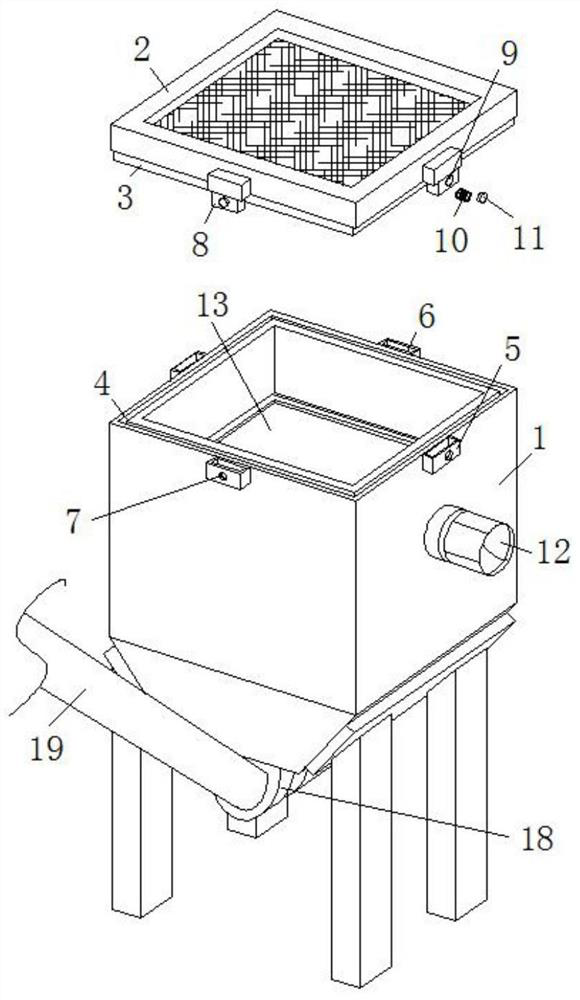

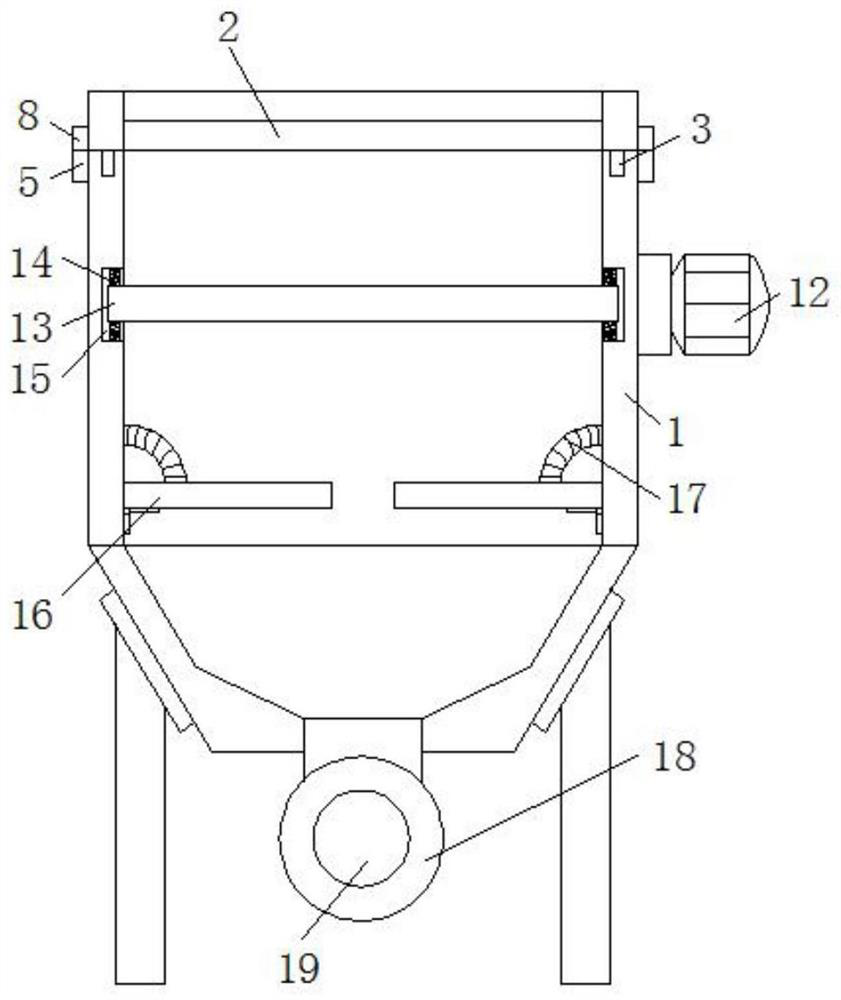

Brick making slurry bubble removing system and application method thereof

ActiveCN107718260ASpeed up the molding processHigh strengthFeeding arrangmentsAuxillary shaping apparatusBrickSlurry

The invention discloses a bubble removing method in the brick preparing process and a bubble removing system used for removing bubbles with the method. In the brick preparing process, slurry can be subjected to cycling through a conveying channel, bubbles can be generated in the cycling process, and bubble removing treatment is conducted on the slurry at the bubble generating part through the bubble removing method and the bubble removing system. The bubble removing system used in the method comprises a stirring device, a carrying vehicle and a feeding channel, wherein the stirring device comprises a supporting roller and stirring rollers, the stirring rollers are fixed to the lower portion of the supporting roller in a hinged manner, and the stirring rollers can move up and down through the supporting roller. In addition, different tracks are set for materials contained in the carrying vehicle before and after stirring operation, and conversion of the running track and direction of the carrying vehicle is achieved through the vehicle inlet track and the vehicle outlet track.

Owner:NANTONG HENGDA MACHINERY MFG

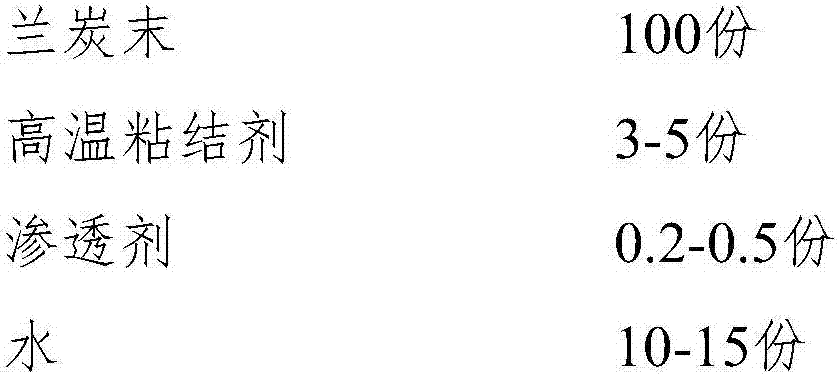

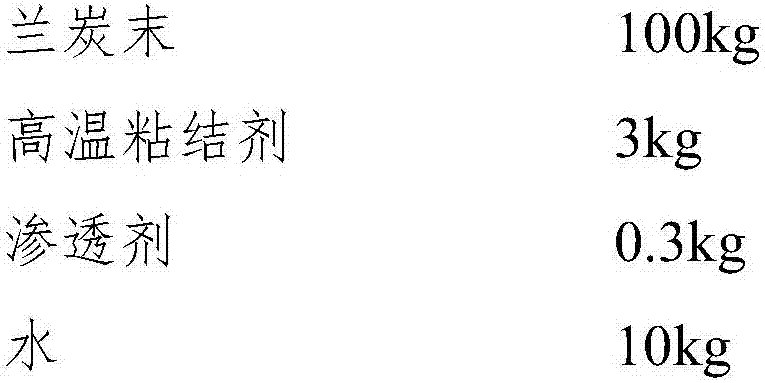

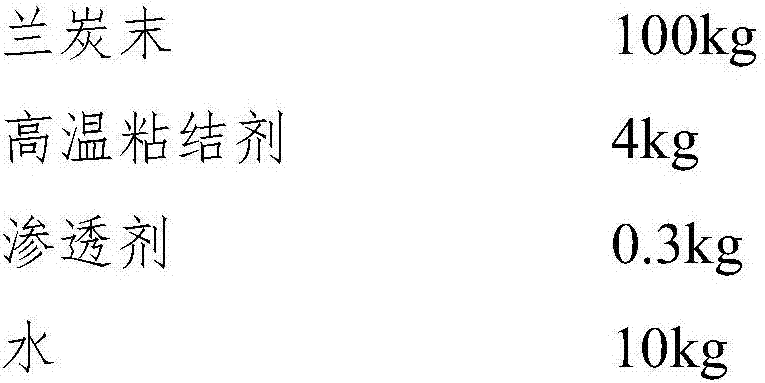

Formed coke adopting semi-coke powder as main raw material, preparation method and application

InactiveCN106867612AWell mixedSpeed up the molding processSolid fuelsCalcium carbideMetallurgyCross linker

The invention relates to formed coke adopting semi-coke powder as a main raw material, a preparation method and application. The formed coke is prepared from the following raw materials in parts by weight: 100 parts of the semi-coke powder, 3 to 5 parts of high temperature binder, 0.2 to 0.5 part of penetrating agent and 10 to 15 parts of water, wherein the high temperature binder is prepared from an organic binder, an inorganic binder, a wetting agent and a cross-linking agent. The formed coke produced by adopting the raw materials has the three-high one-low advantages of high forming rate, high mechanical strength, high temperature resistance and low cost; the optimum usage of the semi-coke powder is realized, and the resource waste is reduced.

Owner:鄂尔多斯市瀚博科技有限公司

High-stability anti-spilling powder filling device for cosmetic processing

The invention discloses a high-stability anti-spilling powder filling device for cosmetic processing. The high-stability anti-spilling powder filling device comprises a powder storage tank and a transmission rack; the upper end of the powder storage tank is detachably connected with a dustproof cover, the blowing end of a conveying fan is fixedly connected with a conveying pipe, and the lower endof the conveying pipe is fixedly connected with a stirring tank; the upper end of the stirring tank is fixedly connected with a stirring motor, the outer side of the stirring tank is fixedly connectedwith a second air cylinder, the movable end of the second air cylinder is fixedly connected with a mounting block, the mounting block is fixedly connected with a movable pipe, a conveying belt is fixedly mounted inside the transmission rack, and the outer side of the conveying belt is fixedly connected with a positioning frame; the outer side of the positioning frame is fixedly connected with a third air cylinder, and the movable end of the third air cylinder is fixedly connected with a clamping block. According to the high-stability anti-spilling powder filling device for the cosmetic processing, the overall scattering effect is improved, the overall forming and bottling effects are improved, meanwhile, the situation that leakage is generated in the overall filling process is prevented,and overall waste is reduced.

Owner:孙治国

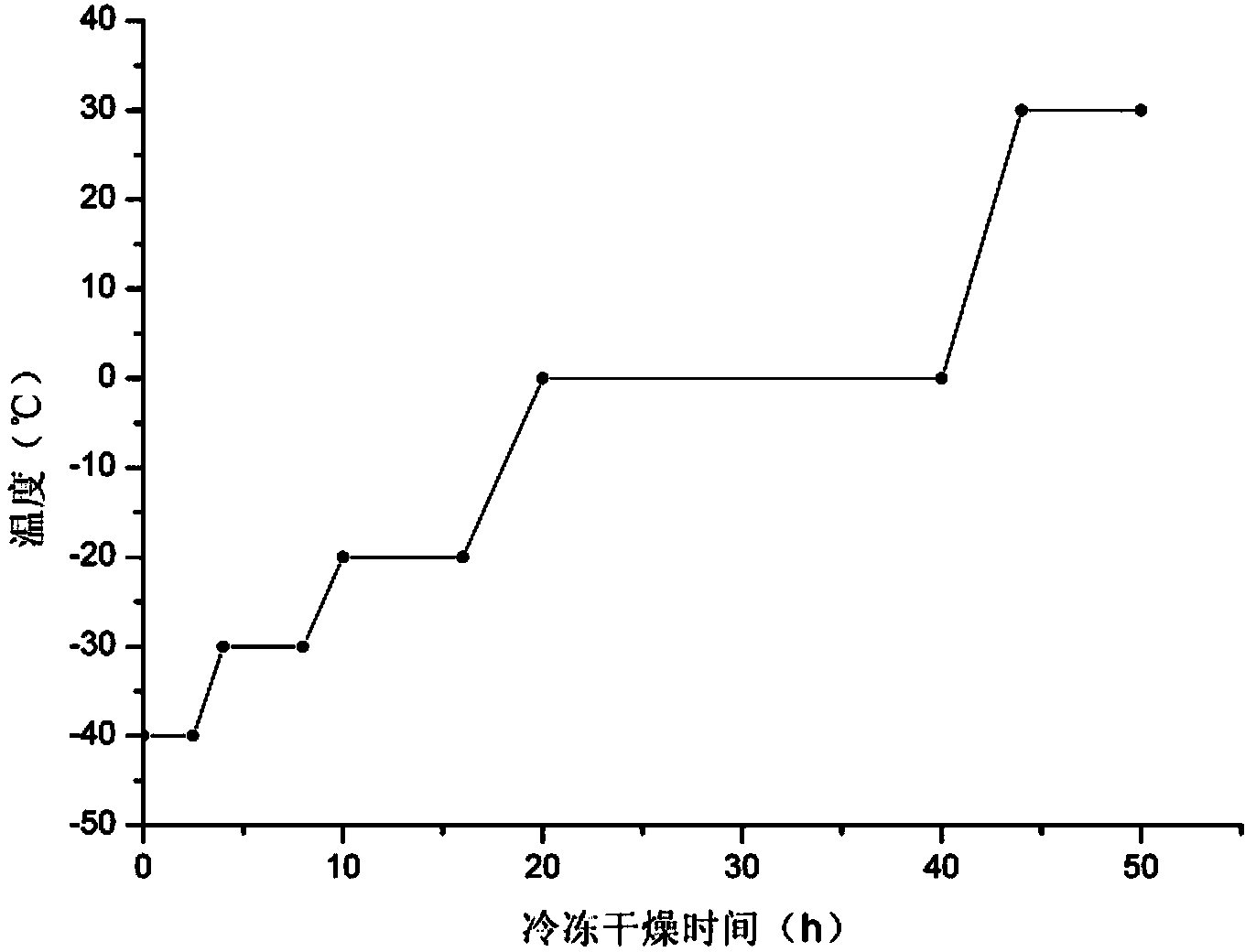

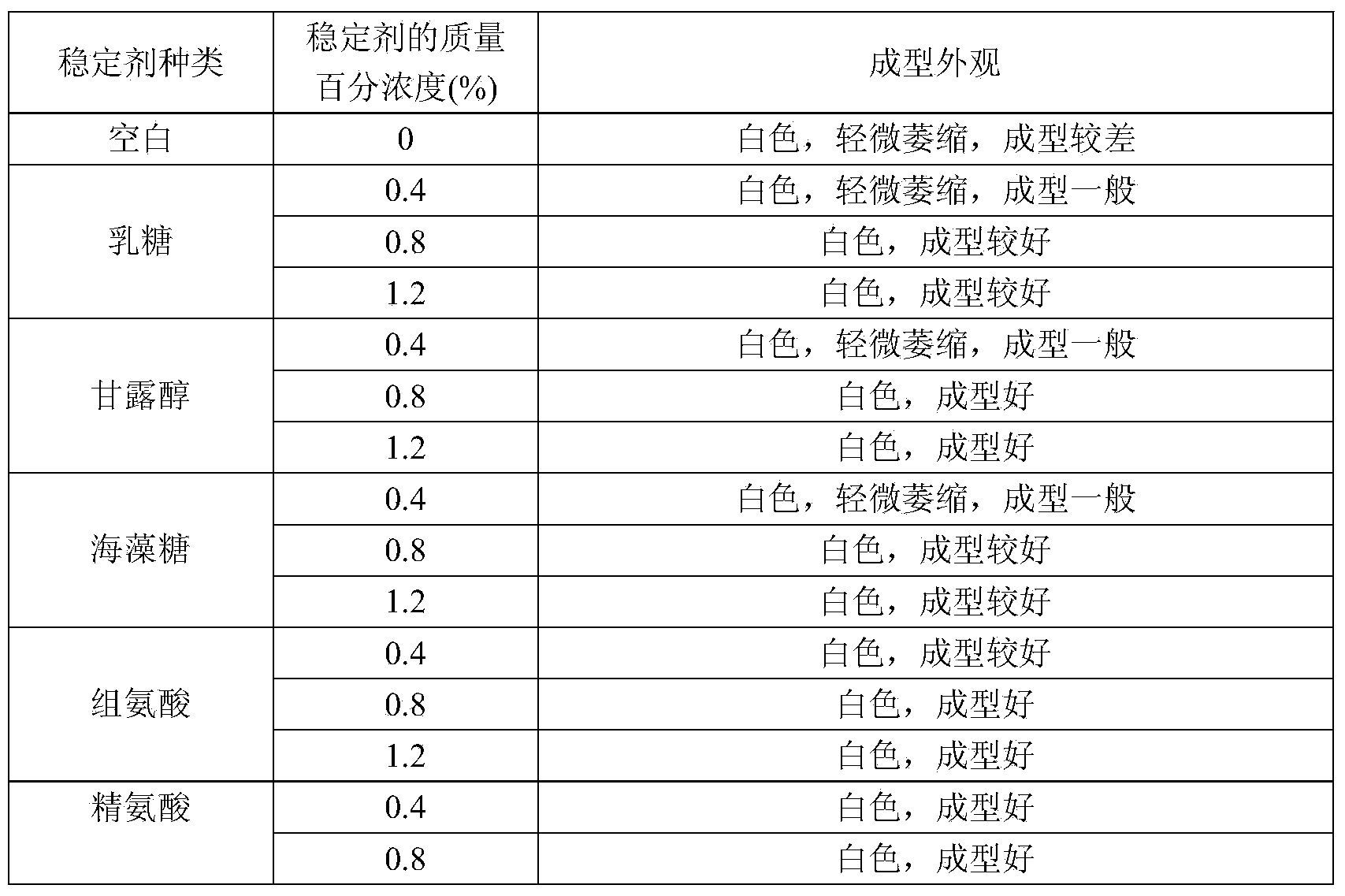

Lyophilized stabilizer composition of human plasma protein C and use of composition

ActiveCN103893135AEffectively maintain activityLittle loss of activityPowder deliveryPeptide/protein ingredientsMANNITOL/SORBITOLArginine

The invention discloses a lyophilized stabilizer composition of human plasma protein C. The composition is a combination of any one or more than two of lactose, mannitol, mycose, histidine, arginine, tyrosine, aspartic acid and salts thereof. By adopting the stabilizer disclosed by the invention, the protein C can be effectively protected, and the prepared protein C preparation is good in molded appearance, small in activity loss of protein C and high in recovery rate, and has a good clinical application prospect.

Owner:BLOOD TRASFUSION INST CHINESE ACAD OF MEDICAL SCI +1

Method for producing heavy-denier mucilage glue flat yarn

ActiveCN103603066ASpeed up the molding processHigh strengthFilament manufactureArtificial filament washing/dryingYarnCandle

The invention relates to a method for producing heavy-denier mucilage glue flat yarn. The method includes the steps that mucilage glue is pumped into a candle type filter through a metering pump to be filtered, the filtered mucilage glue enters a yarn spraying nozzle through a goose neck to be sprayed into yarn, sprayed yarn enters a primary coagulating bath groove to undergo primary solidification forming, then, the yarn is guided to a secondary solidification forming groove through a yarn guiding mechanism to undergo secondary solidification forming, the yarn enters a washing groove to undergo primary washing after the secondary solidification forming is conducted, the yarn is laid on a conveying net of a united refiner in parallel to undergo regeneration, washing, desulfuration, blanching, pH value adjustment, oiling and drying after the primary washing is conducted, finally, the yarn is formed to be in a cylinder shape or a strand shape, and carbon disulfide is recycled in the primary solidification forming process and the secondary solidification forming process of the yarn. The carbon disulfide is recycled, the strength and the elongation of the heavy-denier mucilage glue flat yarn produced through the process completely meet the requirements, and the method is quite beneficial for development of downstream markets.

Owner:YIBIN GRACE +2

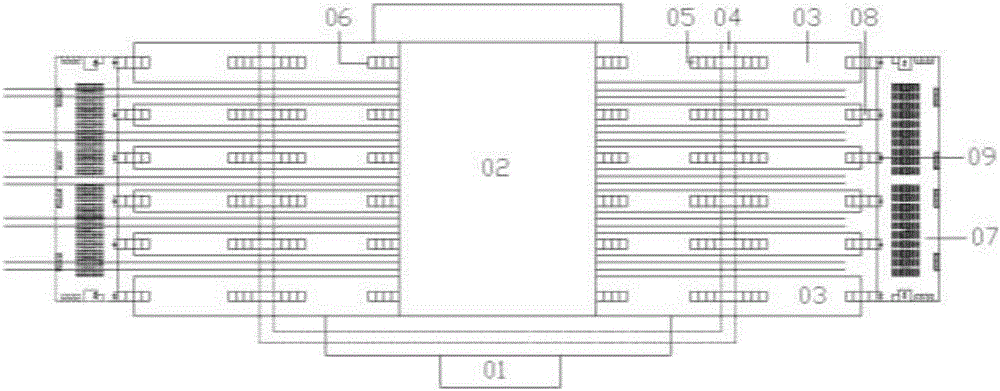

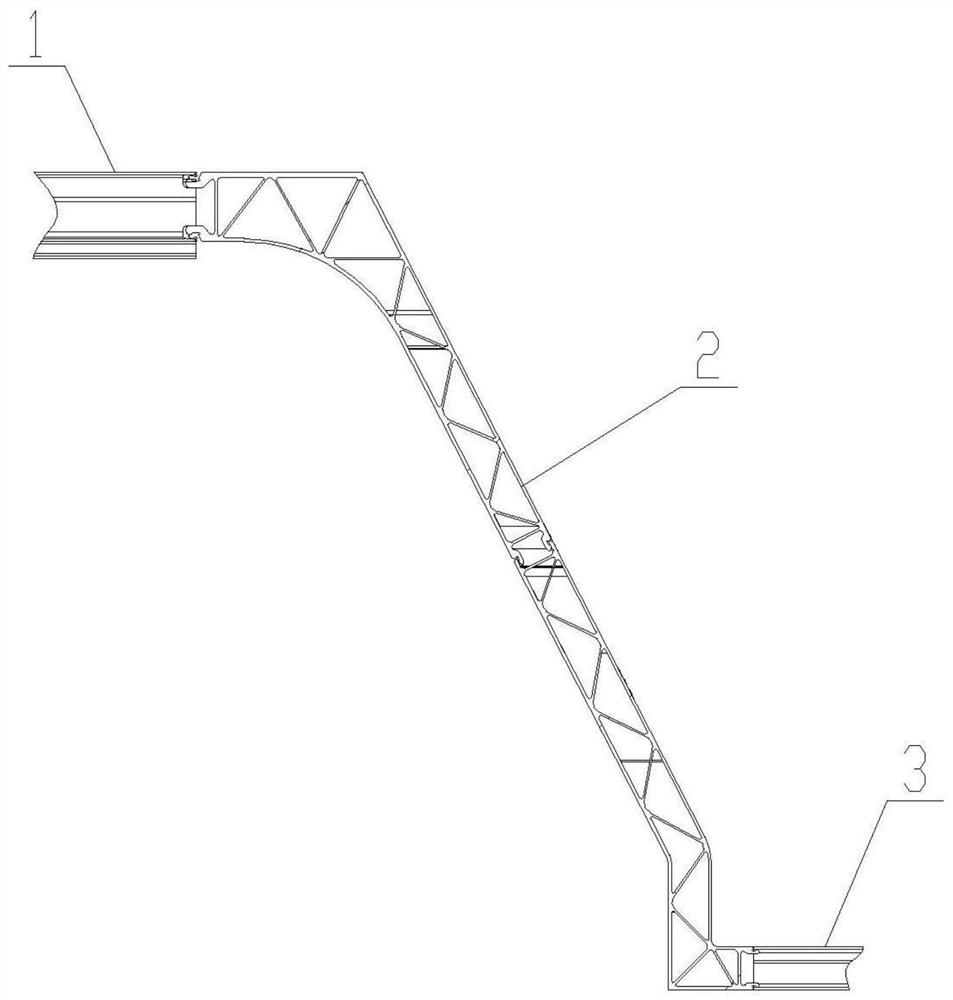

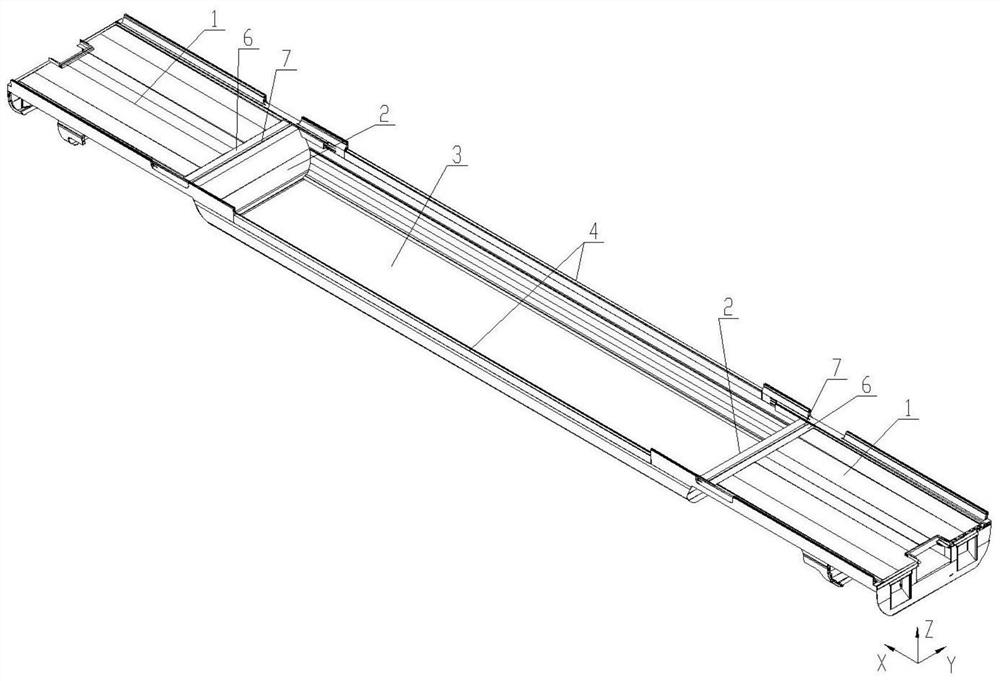

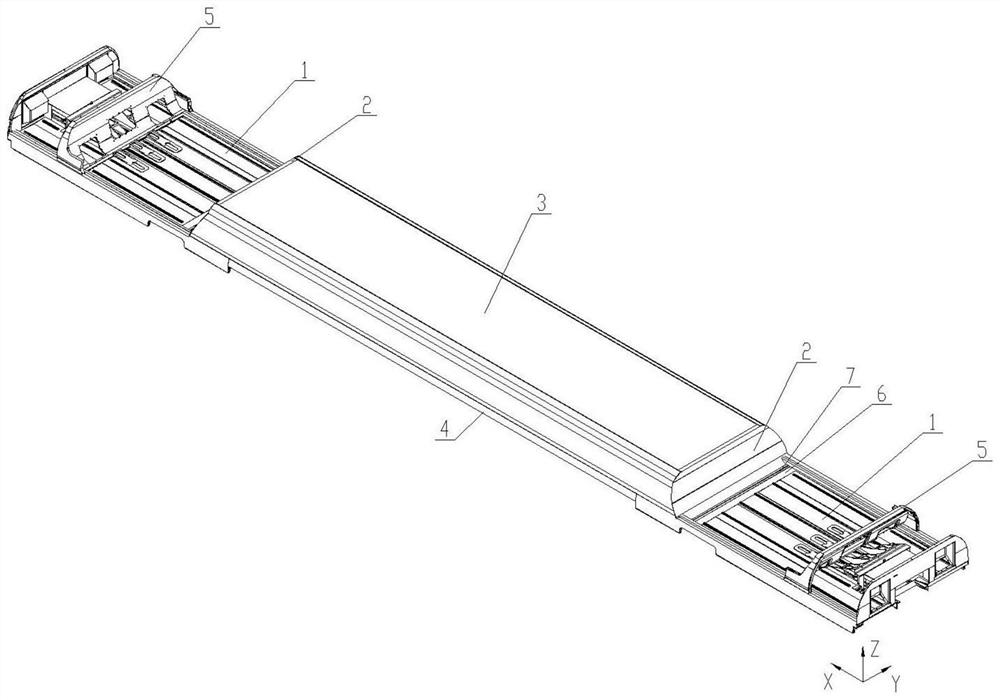

Double-decker multiple unit base frame, base frame assembly position-fixing device and base frame assembly position-fixing method

ActiveCN112092851AShorten the manufacturing cycleImprove versatilityWelding/cutting auxillary devicesAuxillary welding devicesLap jointMechanical engineering

The invention discloses a double-decker multiple unit base frame, a base frame assembly position-fixing device and a base frame assembly position-fixing method, and belongs to the technical field of high-speed railway vehicle manufacturing. The double-decker multiple unit base frame comprises two end base frames, two partition walls, a floor for connecting the two partition walls, two edge beams for connecting the two end base frames, and transition connecting structures for connecting the partition walls and the end base frames, wherein one side of each of the transition connecting structuresis fixedly connected to the corresponding end base frame in an inserted manner, and the other side thereof is fixedly connected to the corresponding partition wall in a lap joint manner, so that themodularization of the end base frames and the partition walls is achieved. The base frame assembly position-fixing device comprises a platform, wherein the platform is provided with two supporting mechanisms, two assembling mechanisms, a plurality of supporting and clamping mechanisms, four position-fixing devices capable of forming a rectangle, and supporting and pressing mechanisms for connecting the partition walls and the transition connecting structures. The double-decker multiple unit base frame, the base frame assembly position-fixing device and the base frame assembly position-fixing method have the beneficial effects of reducing the assembling difficulty of the base frame, shortening the manufacturing period of base frame assembly, and improving the production efficiency.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

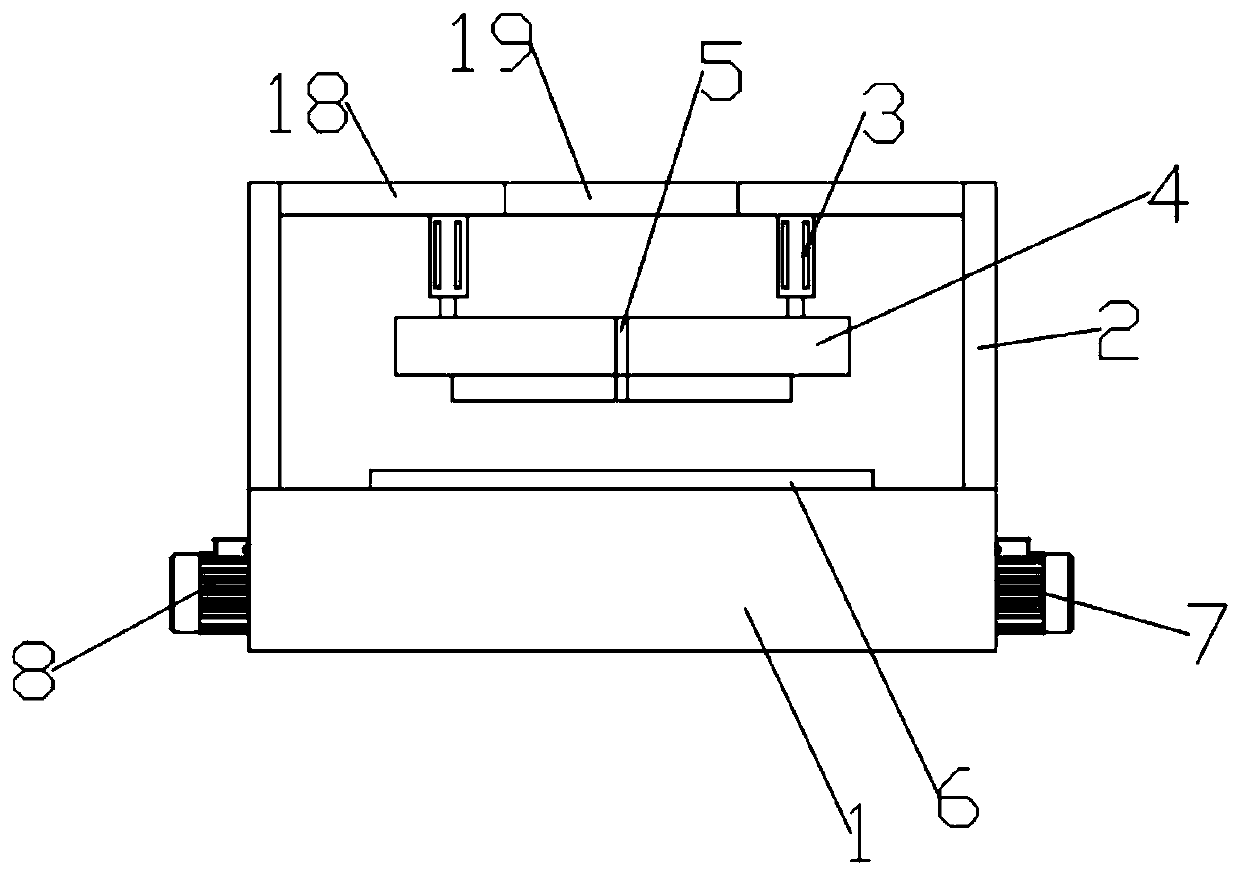

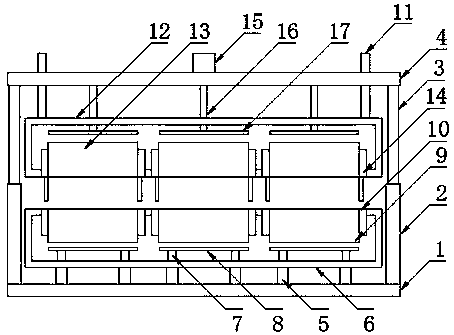

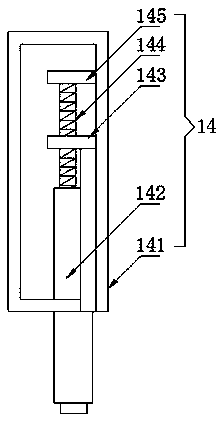

Efficient heat dissipation injection mold

InactiveCN111438891AImprove cooling effectSpeed up the molding processEngineeringInjection moulding

The embodiment of the invention relates to the field of injection molds, and particularly discloses an efficient heat dissipation injection mold. A base is included and provided with an installing groove, a female mold is fixedly arranged in the installing groove, and a mold cavity is formed in the top face of the female mold. Supporting stand columns are fixedly arranged on the top face of the end portion of the base, a supporting beam is fixedly arranged at the top ends of the supporting stand columns, and electric telescopic rods for adjusting the height position where a male mold is located in the vertical direction are arranged on the bottom face of the supporting beam. The base is further provided with a heat dissipation mechanism for conducting heat dissipation on the female mold. When the injection mold provided in the embodiment is used, through stretching and contracting of the electric telescopic rods, the male mold can be pushed to move in the vertical direction till the male mold and the female mold are in a mold assembly state, and then, an injection molding port is utilized for injecting materials in a fusion state into the mold cavity. Meanwhile, the heat dissipation mechanism is used for conducting heat dissipation treatment on the female mold so that the forming speed of materials in the mold cavity can be increased, and accordingly the injection molding efficiency is improved.

Owner:王晓旭

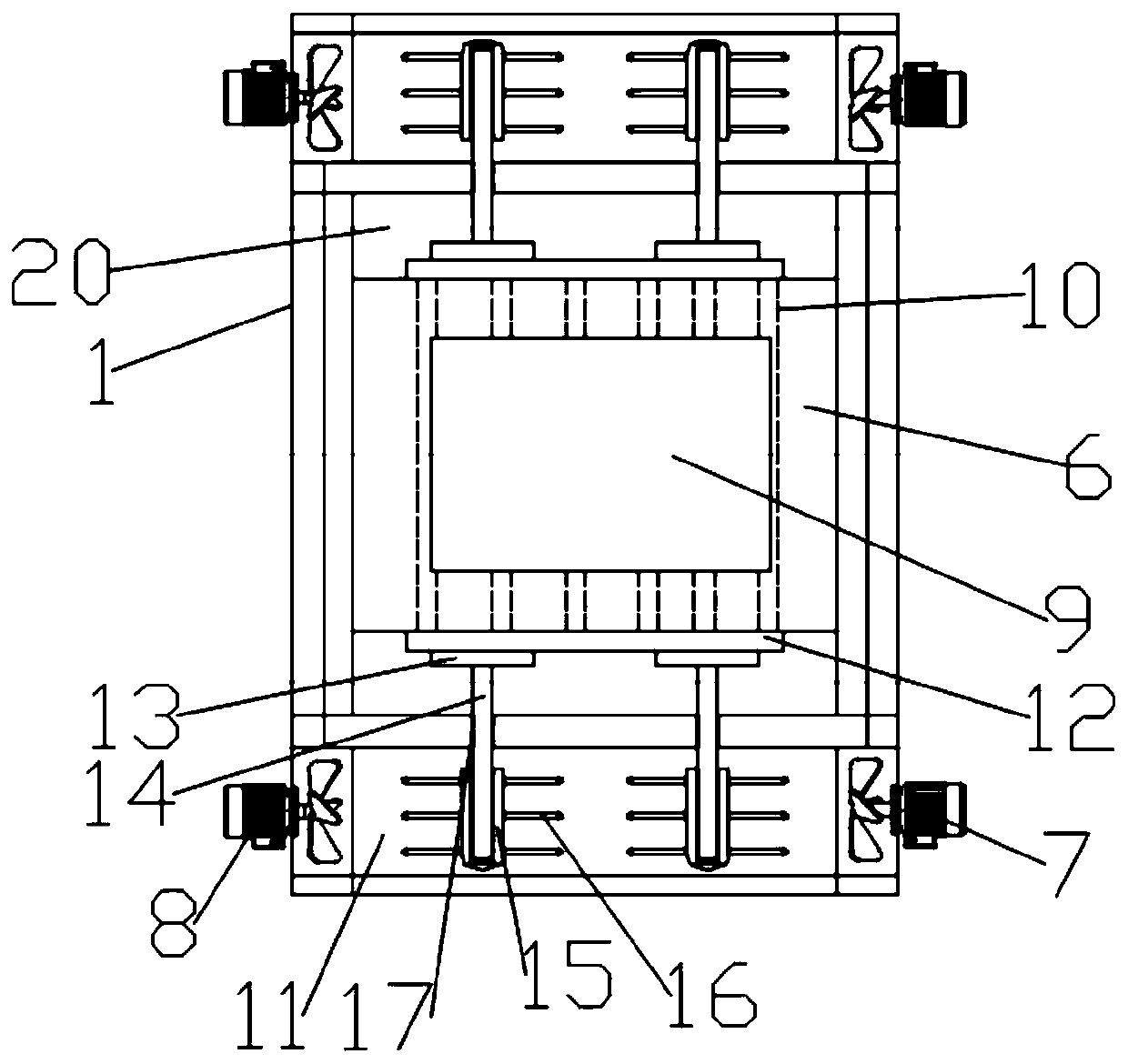

Combined mold for concrete block production

InactiveCN110843089APrevent seepageGuarantee processing qualityDischarging arrangementMouldsConstruction engineeringStructural engineering

The invention discloses a combined mold for concrete block production in the technical field of concrete block production. The combined mold comprises a lower template, a guiding sleeve is arranged oneach of the left and right sides of the top of the lower template, a guiding column is movably connected with the inner wall of each guiding sleeve in an inserted mode, an upper template is connectedwith the top of each guiding column, supporting pipes are evenly arranged at the top of the lower template, a fixed template is connected with the top of each supporting pipe, a spring ejecting rod is movably arranged in the inner cavity of each supporting pipe, a top plate is connected with the top of each spring ejecting rod, a lower molding cavity is formed in the upper end of the fixed template, a limiting groove is formed in the outer wall of each of the left and right sides of the lower molding cavity, a moving rod is arranged on the inner wall of each of the left and right sides of theupper template, and a moving template is connected with the bottom of each moving rod. According to the combined mold, the appearance of the flash is reduced, the workload is reduced in the follow-upconcrete block processing process, two-way pushing is conducted on the molded block, the concrete block molding process is accelerated accordingly, and the removal of concrete from the mold is facilitated.

Owner:吴中区甪直磊鑫模具厂

Fuel tank opening and closing device

A fuel tank opening and closing device is equipped with a flap valve mechanism arranged inside the tank opening forming member, having an opening and closing member for which the inlet is opened and closed by being pressed by the tip of the fueling nozzle, a shaft provided at the tip of the opening and closing member, and a bearing mechanism provided on the tank opening forming member for supporting the shaft so as to be rotatable. The bearing mechanism has a shaft support recess in which the shaft is inserted and a plurality of shaft restriction projections provided projecting from the wall surface of the shaft support recess, and the shaft restricting projections have a cross section arc shaped shaft support surface such that there is contact with a portion of the outer periphery of the shaft.

Owner:TOYODA GOSEI CO LTD

Organometallic precursor compounds

ActiveUS7244858B2Easy to depositSpeed up the molding processGroup 8/9/10/18 element organic compoundsGroup 6/16 organic compounds without C-metal linkagesMetalCoating

This invention relates to organometallic precursor compounds represented by the formula (L)M(L′)2(NO) wherein M is a Group 6 metal, L is a substituted or unsubstituted anionic ligand and L′ is the same or different and is a π acceptor ligand, a process for producing the organometallic precursor compounds, and a method for producing a film, coating or powder from the organometallic precursor compounds.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com