Brick making slurry bubble removing system and application method thereof

A technology for defoaming and brick materials, applied in chemical instruments and methods, manufacturing tools, clay preparation devices, etc., can solve the problems of reducing brick strength, quality influence of molding and firing, waste of raw materials, etc., and achieve molding and strength improvement. , The effect of convenient transportation and smooth transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

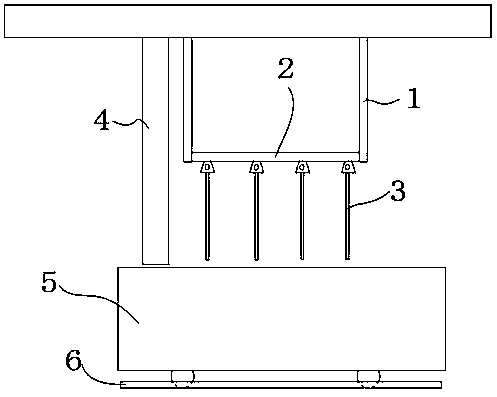

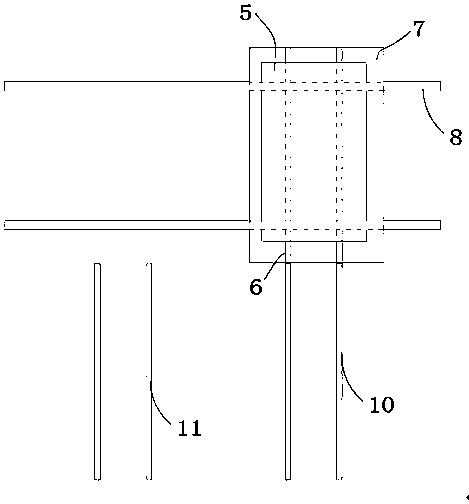

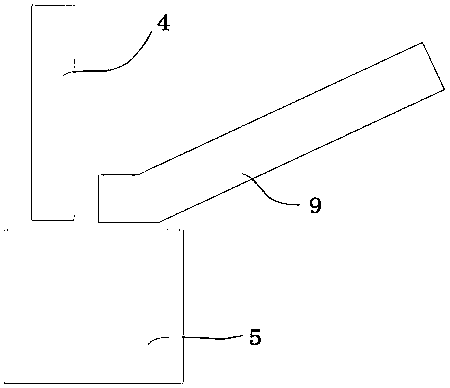

[0036] like Figure 1-4 As shown, the defoaming system of this embodiment includes a stirring device, a transport vehicle 5, a feeding channel and a track.

[0037] The stirring device includes a support roller and a stirring roller 3, the support roller includes a vertical support bar 1 perpendicular to the ground and a transverse support bar 2 parallel to the ground, and the top end of the stirring roller 3 for stirring the slurry is vertically fixed on the transverse support bar 2 , and the stirring roller 3 is hinged with the transverse support bar 2, and the transverse support bar 2 can move up and down in the vertical direction on the vertical support bar 1.

[0038] The track comprises a first track 6 and a second track 8 which are perpendicular to each other, the first track 6 is used to directly carry the vehicle 5, and the second track 8 is positioned below the first track 6, between the first track 6 and the second track 8 There is also a receiving platform 7 for r...

no. 2 example

[0050] On the basis of the above-mentioned first embodiment, a weight sensor is provided on the carrying platform of this embodiment, the weight sensor is connected with the controller, and the weight sensor is used to detect the weight of the slurry in the carrier vehicle. The weight sensor has a classification module, and the classification module It is used to select the power mode of the stirring roller at different levels according to the total amount of slurry;

[0051]The using method of this embodiment also includes the following steps:

[0052] First, the weight sensor detects the weight of the slurry in the vehicle to obtain a weight signal;

[0053] Then, the weight signal is transmitted to the controller;

[0054] Then, the grading module classifies to a certain level according to the weight signal, so as to control the power of the stirring roller, the stirring time and the stirring rate within a certain range.

[0055] In this embodiment, through the setting of...

no. 3 example

[0057] On the basis of the above-mentioned first embodiment, the brick-making slurry defoaming system of the present embodiment also includes a density detection device, which is connected to the controller, and the density detection device is used to detect the density of the slurry in the vehicle, The density detection device is arranged on the top of the carrier, and the density detection device includes a density sensor, and the density sensor can move along the vertical direction;

[0058] The method of use also includes the following steps:

[0059] First, the stirring roller enters the material through the downward movement of the vertical support rod and the horizontal support rod, and the stirring roller driven by the motor swings left and right to eliminate the air bubbles in the slurry. After a certain period of time;

[0060] Then, the density sensor moves into the slurry of the carrier vehicle to obtain the real-time density of the slurry and obtain a density sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com