Double-decker multiple unit base frame, base frame assembly position-fixing device and base frame assembly position-fixing method

A technology for positioning devices and EMUs, which is applied to the underframe, auxiliary devices, railway car bodies, etc., can solve the problems of low production efficiency, inability to meet the manufacturing requirements of the double-layer EMU underframe, and long synthesis manufacturing cycle, etc., and achieve improvement Production efficiency, improvement of base frame synthesis efficiency, and the effect of shortening the manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0106] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

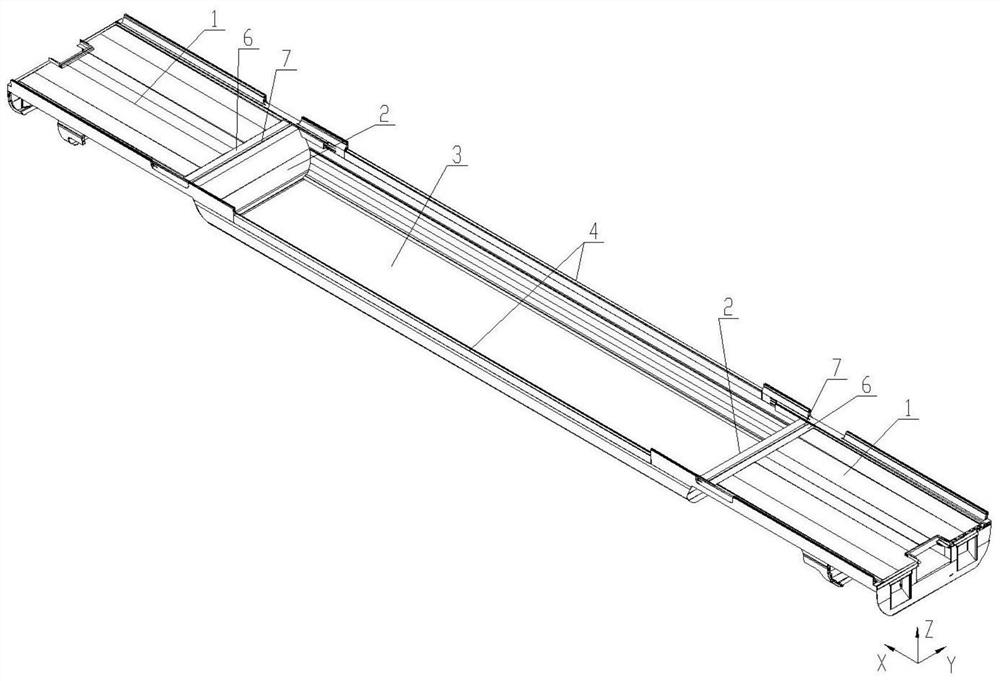

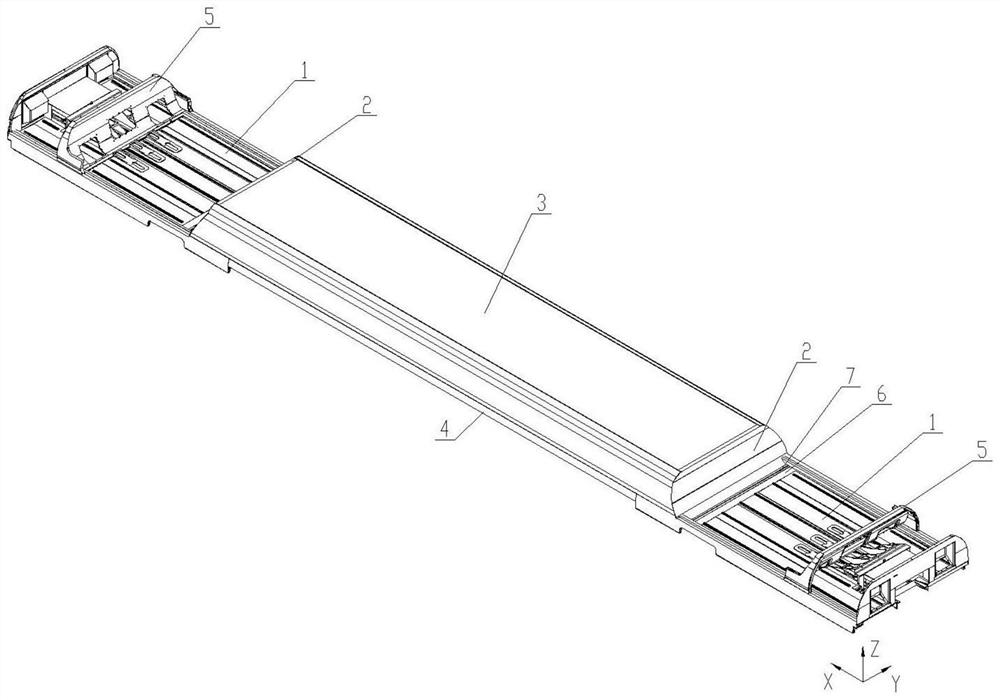

[0107] see Figure 1-5 shown;

[0108] Invented double-deck EMU chassis, including:

[0109] Two end chassis 1;

[0110] Two partition walls 2;

[0111] a floor 3 for connecting the two partition walls 2; and

[0112] Two side beams 4, which are used to connect the two end chassis 1; also include

[0113] a transition connection structure, which is used to connect the partition wall 2 and the end chassis 1;

[0114] One side of the transition connection structure is fixedly connected to the end chassis 1 in a plug-in manner, and the other side is fixedly connected to the partition wall 2 in an overlapping manner, so that the end chassis 1 and the partition wall 2 can be divided into blocks.

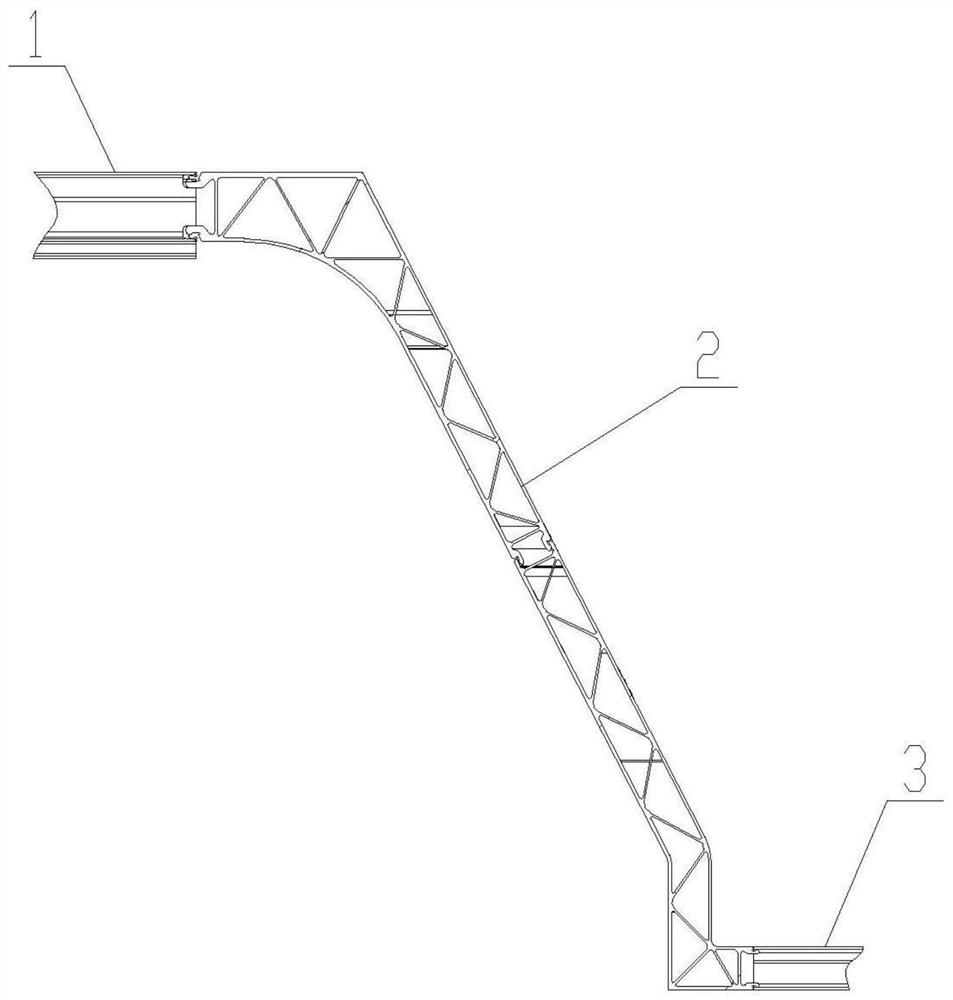

[0115] Specifically, see figure 1 As shown, in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com