Electronic component full-automatic pin-shearing molding equipment based on vision robot

A technology of electronic components and forming equipment, which is applied in the field of fully automatic cutting and forming equipment for electronic components based on vision robots, can solve the problems of high equipment cost, low production efficiency, and small quantity of a single item, and reduce equipment costs and production costs. Improved processing efficiency and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing:

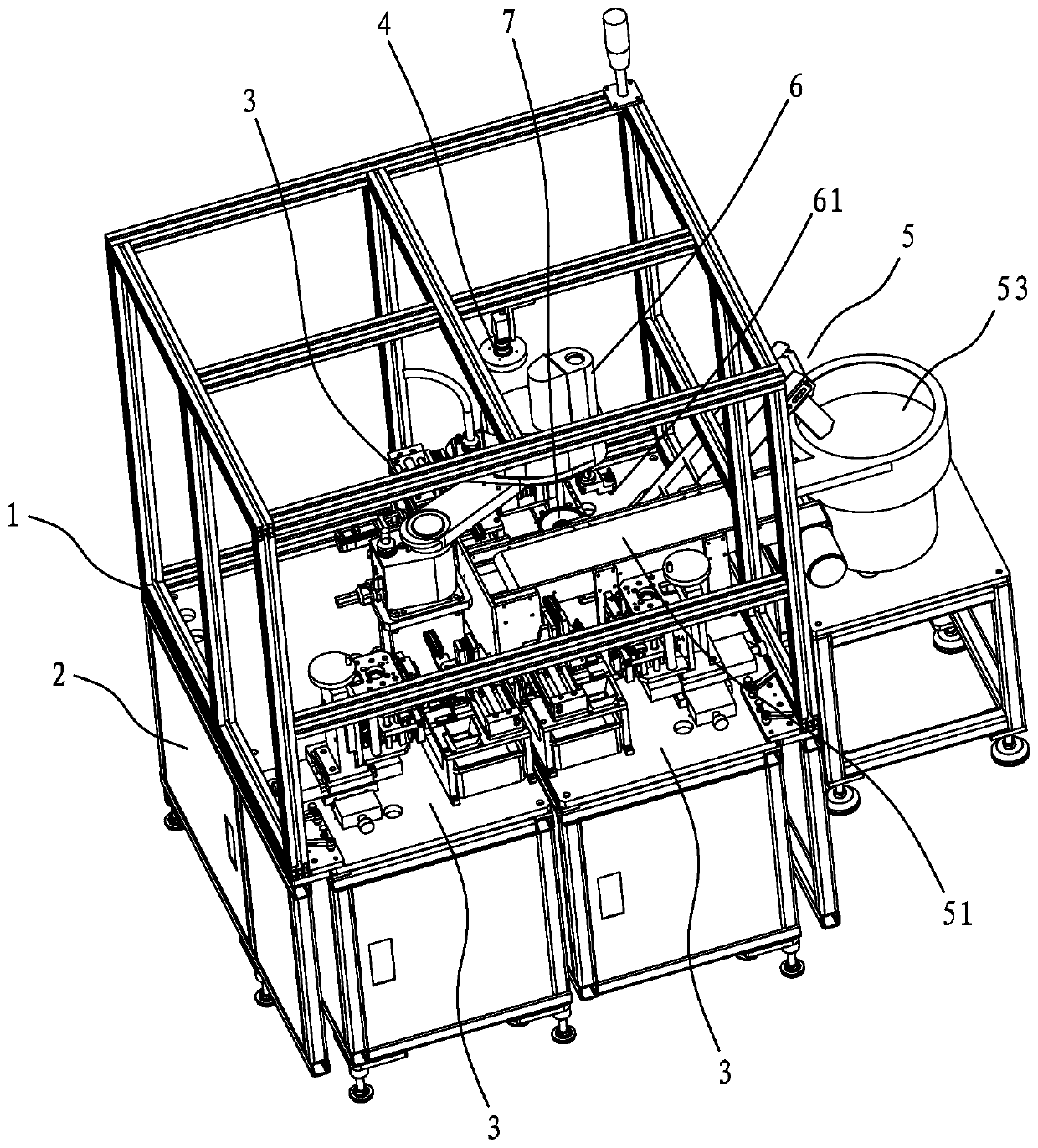

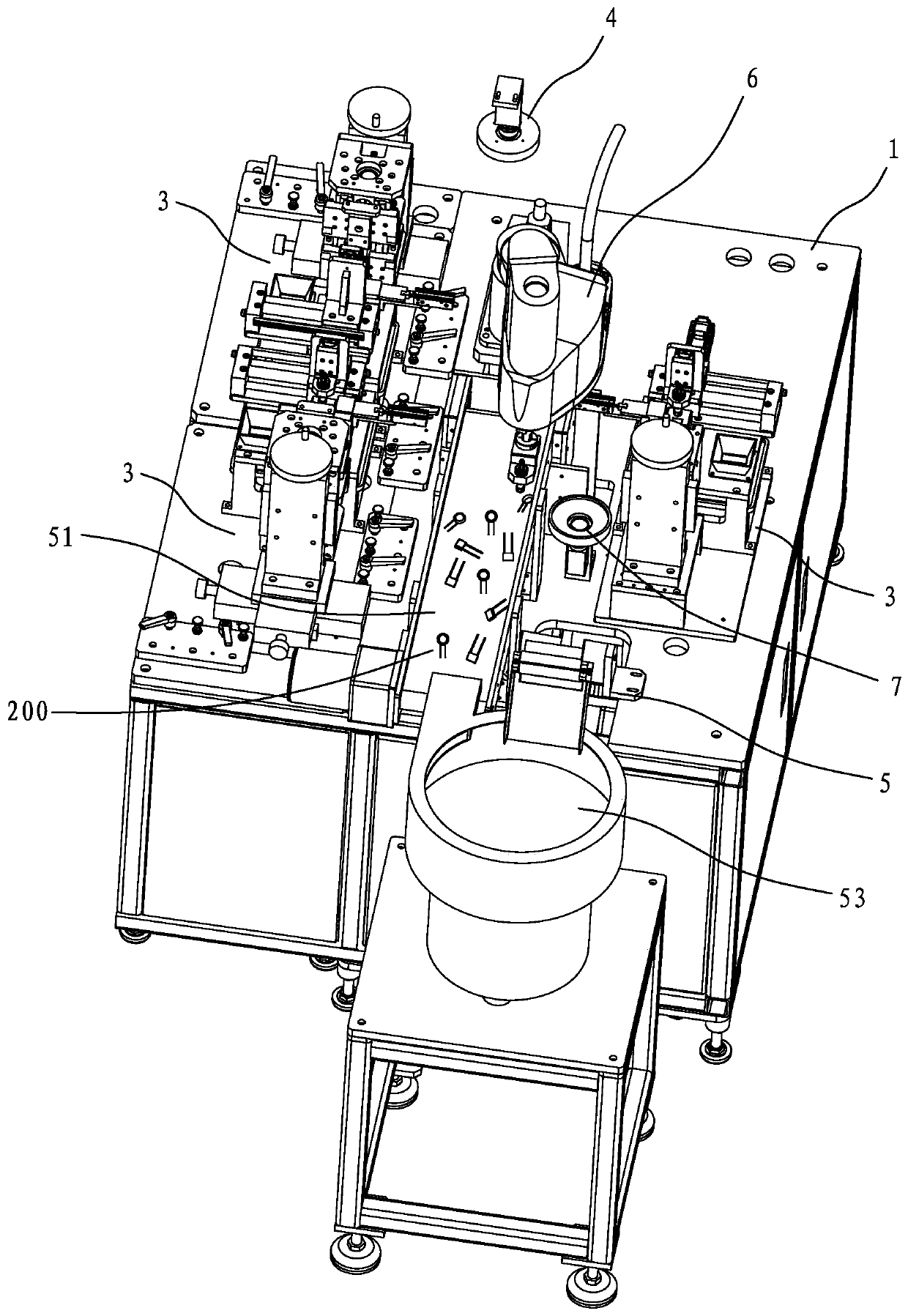

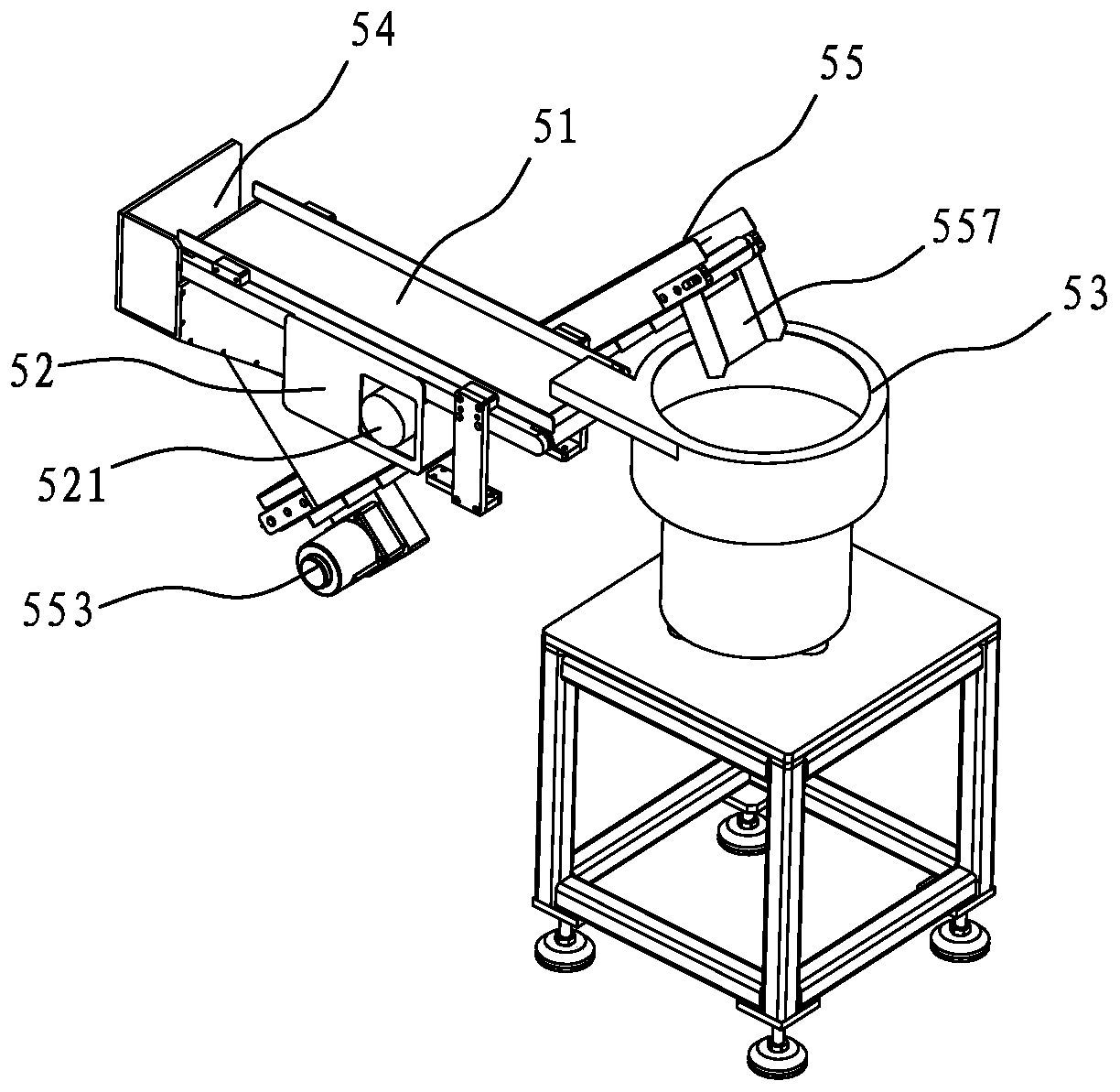

[0041] Such as Figure 1 to Figure 11 The shown one is based on the vision robot electronic component full-automatic cutting foot forming equipment, comprises machine platform 1 and industrial control computer 2, and described machine platform 1 is provided with a plurality of for cutting the foot of multiple different specified electronic components and Formed scissors forming mechanism 3, the machine 1 is provided with a four-axis manipulator 6, the manipulator 6 is provided with a first vacuum suction nozzle 61 for sucking electronic components, and the machine 1 is provided with a random Circularly supply various electronic components 200 in random states to the feeding mechanism 5 within the suction range of the first vacuum suction nozzle 61, and the upper end of the machine table 1 is provided for taking pictures downwards to detect the position of the electronic com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com