Heat insulation decoration plate and preparation method thereof

A decorative plate and decorative coating technology, applied in the field of building materials, can solve the problems of easy falling off and heavy weight of inorganic thermal insulation decorative plates, and achieve the effects of easy demoulding, thermal insulation service life and enhanced thermal insulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

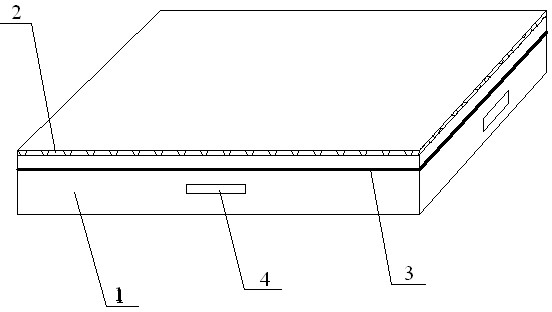

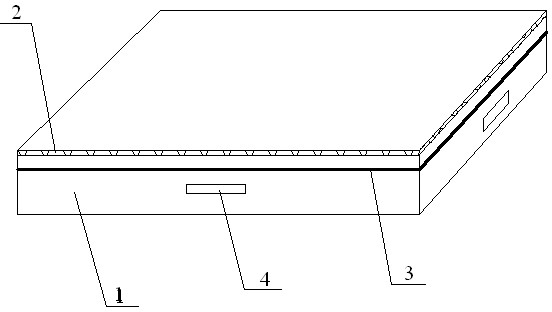

[0056] Such as figure 1 As shown, the thermal insulation decorative board described in this embodiment includes a thermal insulation body 1 and a decorative coating 2 sprayed on the outer layer of the thermal insulation body.

[0057] The thermal insulation body 1 described in this embodiment is prepared from the following components by weight: 8.5 parts of fly ash floating beads, 38 parts of closed-cell perlite, 43 parts of sulphoaluminate cement, 8.5 parts of bentonite, 0.04 part of cellulose ether, 0.09 part of short fiber, 0.04 part of wood fiber and 0.4 part of rubber powder.

[0058] The closed-cell rate of the closed-cell perlite is above 97%, and the closed-pore rate of the fly ash floating beads is above 90%.

[0059] The viscosity of the cellulose ether is 80000cps.

[0060] The side of the thermal insulation body 1 is formed with a groove 4, and a connecting piece can be inserted into the groove 4 to connect and fix the adjacent thermal insulation decorative board a...

Embodiment 2

[0069] Such as figure 1 As shown, the thermal insulation decorative board described in this embodiment includes a thermal insulation body 1 and a decorative coating 2 sprayed on the outer layer of the thermal insulation body.

[0070] The thermal insulation green body 1 described in this embodiment is prepared from the following components by weight: 10.5 parts of fly ash floating beads, 30 parts of closed-cell perlite, 520 parts of aluminate cement, 7 parts of bentonite, 0.06 part of cellulose ether, 0.07 part of short fiber, 0.06 part of wood fiber and 0.3 part of rubber powder. A grid cloth 3 is laid on the inner layer of the thermal insulation body.

[0071] The closed-cell rate of the closed-cell perlite is above 97%, and the closed-pore rate of the fly ash floating beads is above 90%.

[0072] The viscosity of the cellulose ether is 90000 cps.

[0073] The thermal insulation body also includes a grid cloth 3 laid on the inner layer, and a groove 4 is formed on the sid...

Embodiment 3

[0082] Such as figure 1 As shown, the thermal insulation decorative board described in this embodiment includes the thermal insulation body 1 and the decorative coating 2 sprayed on the outer layer of the thermal insulation body 1 .

[0083] The thermal insulation body described in this embodiment is prepared from the following components by weight: 9.5 parts of fly ash floating beads, 34 parts of closed-cell perlite, 48 parts of sulphoaluminate cement, 7.8 parts of bentonite, fiber 0.05 part of plain ether, 0.08 part of short fiber, 0.05 part of wood fiber and 0.34 part of rubber powder. The inner layer of the thermal insulation body is laid with mesh cloth 3 to enhance the tensile strength.

[0084] The closed-cell rate of the closed-cell perlite is above 97%, and the closed-pore rate of the fly ash floating beads is above 90%.

[0085] The viscosity of the cellulose ether is 100000 cps.

[0086] The thermal insulation body also includes a grid cloth 3 laid on the inner l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com