Casting forming process of complex high temperature alloy multi-union guide vane casting

A guide vane and casting molding technology, which is applied in the direction of casting molding equipment, casting molds, casting mold components, etc., can solve the problems of low yield and achieve the effects of reducing casting defects, strengthening molding and feeding effects, and strengthening feeding effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

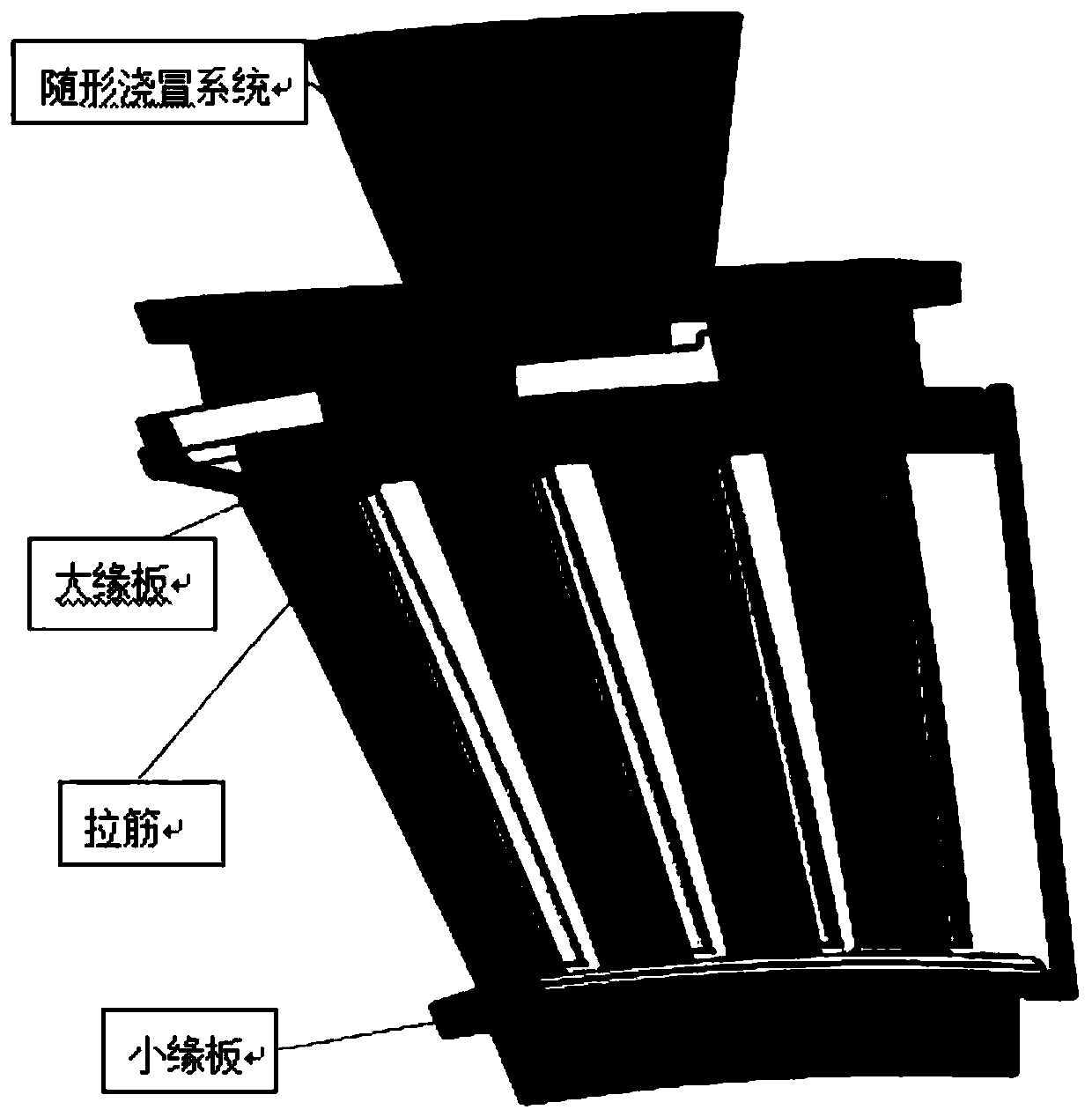

[0045] This embodiment provides a casting molding process of a complex high-temperature alloy multi-connected guide vane. The multi-connected guide vane includes a large edge plate, a small edge plate and a blade body. The process includes the following steps:

[0046] Step 1: Use a wax press to inject wax into the metal mold to prepare the casting body wax mold, and weld the casting body wax mold and the pouring system together to obtain the module;

[0047] Step 2: In a constant temperature and humidity room, coat the module with refractory paint layer by layer to prepare a molded shell; the specific requirements are shown in Table 1;

[0048] Step 3: Send the shell into the dewaxing kettle for dewaxing at a pressure of 0.4MPa~0.6MPa and a temperature of 140℃~160℃;

[0049] Step 4: Send the dewaxed shell into the roasting furnace for high-temperature pre-baking, and the high-temperature pre-baking temperature is 1050±20℃;

[0050] Step 5: After the high-temperature pre-roasting proces...

Embodiment 2

[0062] The difference between this embodiment and Embodiment 1 lies in: Step 5: The single layer thickness of the fire-resistant insulation cotton is 3 mm.

[0063] The high-temperature alloy multi-connected guide vane casting prepared in this embodiment has no obvious shrinkage, porosity, cracks and other casting defects. The overall quality is good, and the yield rate is as high as 78%, which overcomes the difficulty in controlling the processing technology of the multi-connected guide blade. There are many casting defects that lead to the problem of low yield.

Embodiment 3

[0065] The difference between this embodiment and Embodiment 1 lies in: Step 5: The thickness of a single layer of the fire-resistant insulation cotton is 10 mm.

[0066] The high-temperature alloy multi-connected guide blade castings prepared in this embodiment have no obvious shrinkage, porosity, cracks and other casting defects. The overall quality is good, and the yield rate is as high as 75%, which overcomes the difficulty of controlling the processing technology of multi-connected guide blades. There are many casting defects that lead to the problem of low yield.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com