Cooperative dough forming and dough kneading machine

The technology of a dough kneading machine and a dough bar is applied in the field of a cooperating dough dough mixing machine, which can solve the problems of insufficient dough elasticity, troublesome operation, and insufficient uniformity, and achieves the effects of fast processing speed, increased uniformity and good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

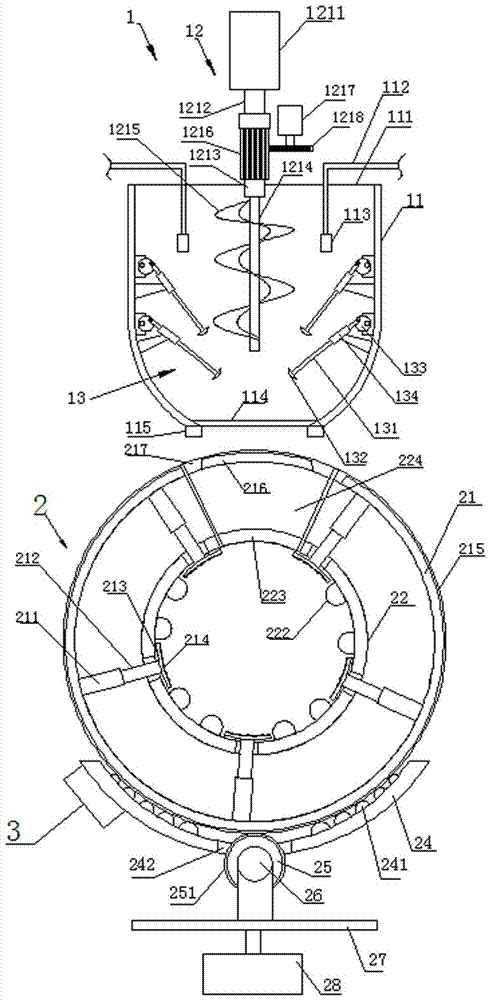

[0027] Such as figure 1 As shown, a kind of combined type dough kneading machine comprises a dough kneading device 1 and a dough kneading device 2 arranged in sequence; The beating device 13 distributed on the inner circumference of the cylinder 11; the beating device 13 includes a plurality of rods 131 that do telescopic movement and are directed towards the center of the bottom of the cylinder 1; the dough kneading device 2 includes a The first hollow spherical roller 21 of the first hollow spherical roller 21 and the second hollow spherical roller 22 fixedly sleeved in the first hollow spherical roller 21 at a distance; a plurality of cylinders 211 are evenly arranged on the inner wall of the first hollow spherical roller 21 and driven by the cylinders 211 A telescopic kneading rod 212; the second hollow spherical drum 22 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com