Formed coke adopting semi-coke powder as main raw material, preparation method and application

A technology of the main raw material, semi-coke powder, applied in the field of coke preparation, can solve the problems of poor low-temperature mechanical strength of coke, poor heat resistance of coke, and high cost of coke, so as to improve the molding and use performance, High molding rate and remarkable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

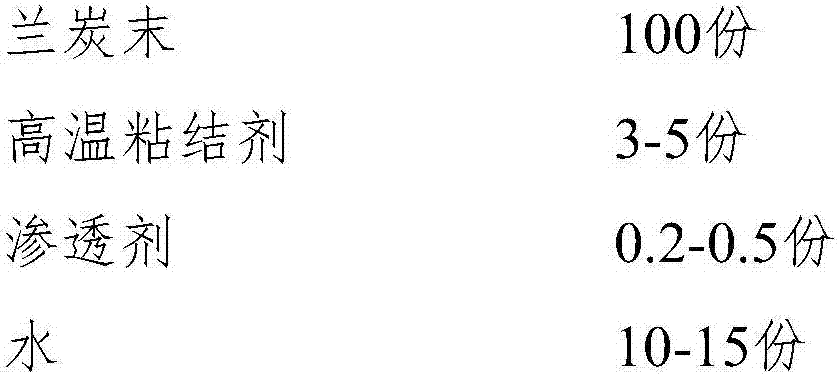

[0043] A form coke with semi-coke powder as the main raw material, the form coke is prepared from the following raw materials:

[0044]

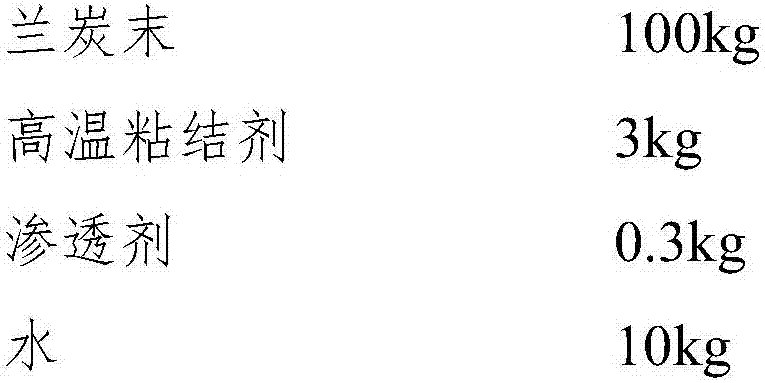

[0045] Wherein, the composition of the high-temperature adhesive is: 20% phenolic resin, 20% hydroxymethyl ethyl cellulose, 40% kaolin, 5% borax, 5% Span 21, γ-aminopropyltrimethoxysilane 10%. The composition of the penetrating agent is: 60% of sodium dodecylbenzenesulfonate and 40% of sodium dodecylsulfate.

Embodiment 2

[0047] A form coke with semi-coke powder as the main raw material, the form coke is prepared from the following raw materials:

[0048]

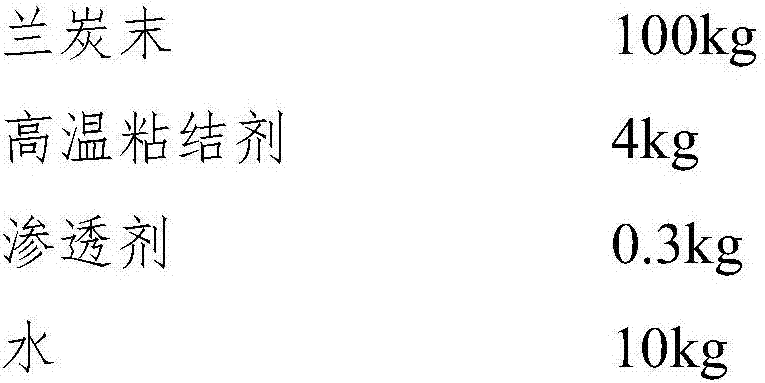

[0049] Wherein, the composition of the high-temperature adhesive is: 20% phenolic resin, 20% hydroxymethyl ethyl cellulose, 40% kaolin, 5% borax, 5% Span 21, γ-aminopropyltrimethoxysilane 10%. The composition of the penetrating agent is: 60% of sodium dodecylbenzenesulfonate and 40% of sodium dodecylsulfate.

Embodiment 3

[0051]A form coke with semi-coke powder as the main raw material, the form coke is prepared from the following raw materials:

[0052]

[0053] Wherein, the composition of the high-temperature binder is: polyvinyl alcohol 20%, hydroxymethylpropyl cellulose 20%, bentonite 40%, borax 5%, Tween 21 5%, γ-aminopropyl triethoxy base silane 10%. The composition of the penetrating agent is: 60% of sodium lauryl sulfate and 40% of lauryl betaine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com