Method for constructing underground coal mine chamber of large cross section

A construction method and large-section technology, applied in mining equipment, earthwork drilling, blasting, etc., can solve problems such as low efficiency, achieve the effects of reducing labor intensity, ensuring support safety, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

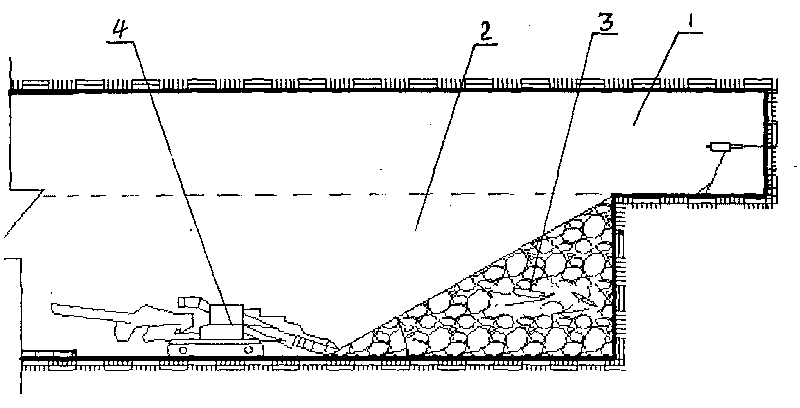

[0011] Take the Sihe Mine in Jincheng, Shanxi as an example. As a high-gas mine, the Sihe Mine has successively built two chambers for gas drainage pumping stations. meters, with a sectional area of 68M2. Net section: 7.5 meters wide, 8.5 meters high, sectional area 61M2, design and construction length 62 meters. The construction method of the large-section chamber in the coal mine is realized by using the following construction method: a. The chamber is selected in the area where the upper layer is gangue layer 1 and the lower layer is coal seam 2; b. The upper layer adopts blasting technology; c. The large gangue 3 produced in the end is crushed; d, the lower layer adopts a fully mechanized excavator 4 to cut coal, and the coal and the crushed gangue are discharged by the chute. The blasting process is specifically the process of drilling first and then blasting. The depth of the blasting holes is 1.6 meters (or 1.7 meters, or 1.8 meters). , 5 volumes of cutting holes, 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com