a roll up banner

A technology of roll-up banners and extension springs, applied in signs, display devices, instruments, etc., can solve the problems of high labor intensity, low processing efficiency, and waste of labor, and achieve the effects of saving labor, fast assembly, and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

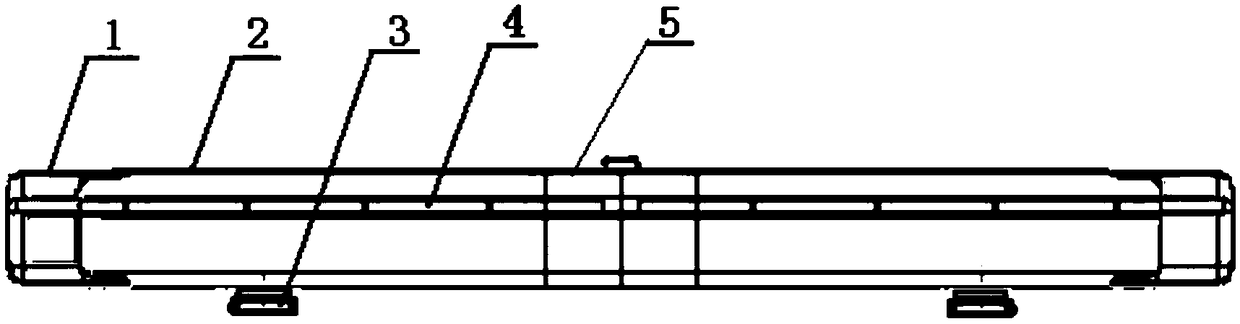

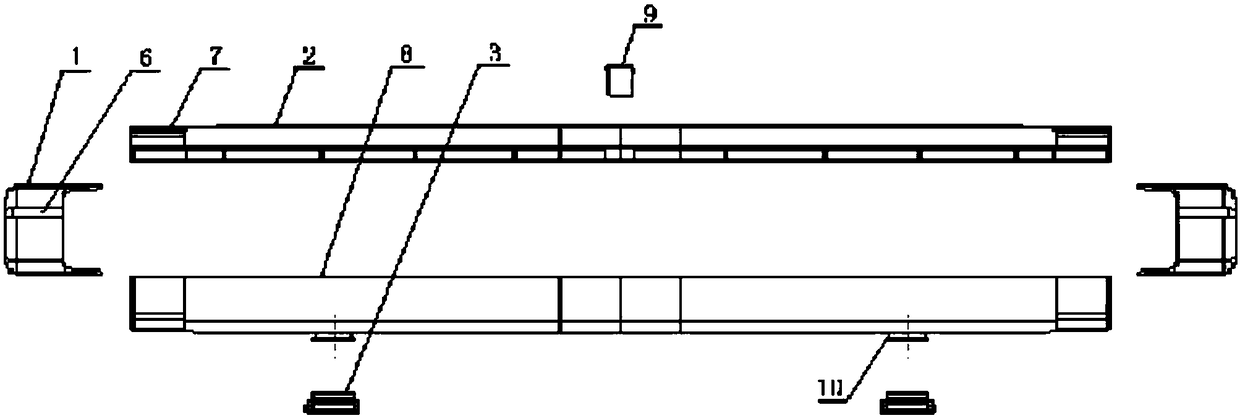

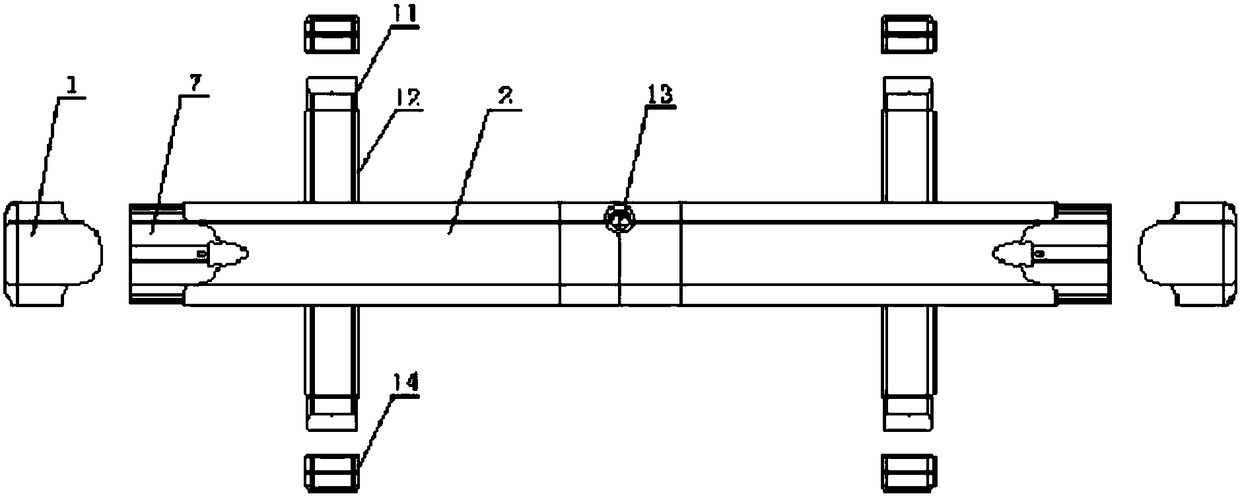

[0034] A roll-up banner, which is composed of a housing 5, a tension spring (not shown in the figure), a support rod (not shown in the figure) and a foot 3, a tension spring is installed in the housing, and in the middle of the upper part of the housing The position is inserted with a support rod, and feet are symmetrically installed on the lower part of the shell. The two side walls 16 of the bracket are respectively formed with an upper installation groove and a lower installation groove 15. After the upper installation groove and the lower installation groove are fastened together, they form a tension spring installation opening for the extension spring to be installed. There is a picture expansion port 4 at the seam, and a support rod in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com