Flour mixing machine

A technology for dough mixers and noodle inlets, which is applied to dough mixers, structural components of mixing/kneading machines, baking, etc. It can solve problems such as unevenness and insufficient dough elasticity, and achieve improved uniformity, improved molding and Elasticity, the effect of improving mixing efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

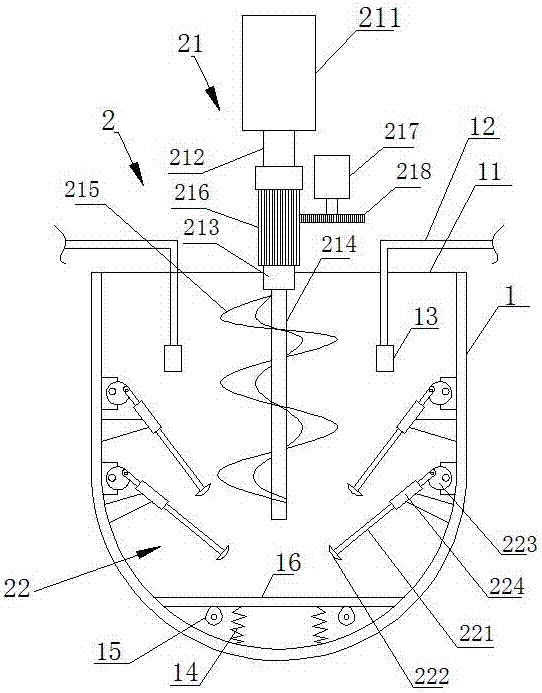

[0020] Such as figure 1 As shown, a dough mixing machine includes a cylinder 1 and a kneading device 2 arranged in the cylinder 1; the upper end of the cylinder 1 is provided with a noodle inlet 11; The telescopic water inlet pipe 12; the end of the telescopic water inlet pipe 12 is a cylindrical self-rotating nozzle 13; Peripheral striking device 22; the striking device 22 includes a plurality of strike rods 221 towards the center of the bottom of the cylinder body 1; one end of the strike rods 221 towards the center of the bottom of the cylinder body 1 is provided with a hemispherical hammer 222, and the other end Hinged on the outer periphery of a turntable 223; the turntable 223 is driven to rotate by a first motor, and the motor shaft is set eccentrically on the turntable 223;

[0021] Further, a tray 16 is provided at the inner bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com