Twist contraction preventing device for over-twisted yarns

A strong twist yarn and anti-twist technology, which is applied to spinning machines, continuous winding spinning machines, textiles and papermaking, etc. It can solve problems such as poor package formation, uneven hardness, and package twist shrinkage, and achieve improved tension Unevenness, uniform hardness, and the effect of preventing twist shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

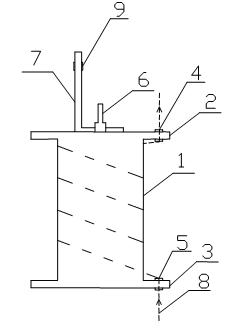

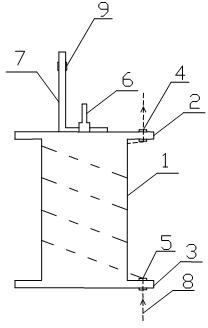

[0010] like figure 1 As shown, a strong twist yarn anti-twisting shrinkage device of the present invention is provided with an upper top plate 2, a yarn storage tube 1 and a rotating bottom plate 3 from top to bottom, and the upper top plate 2, yarn storage tube 1 and rotating bottom plate 3 pass through the main shaft 6 connection, wherein the upper top plate 2 is provided with a yarn guide ring 4, and the rotating bottom plate 3 is provided with a yarn guide ring 5.

[0011] A fixing frame 7 is also arranged on the upper top plate 2, and the anti-twisting shrinkage device of the strong twisted yarn is fixed through the fixed threaded hole 9 on the fixing frame 7.

[0012] The main body of the present invention is made of stainless steel, the yarn 8 can pass through the guide ring 5 installed on the rotatable bottom plate 3, and then be wound on the yarn storage tube 1, and then pass through the guide ring 4 on the upper top plate 2 after winding several times Exported and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com