High borosilicate glass pot mouth moulding device

A high borosilicate glass and molding device technology, applied in glass forming, glass re-molding, glass manufacturing equipment and other directions, can solve the problem of complex structure, unsuitable for high borosilicate glass pot spout pressing and molding, and inability to precisely control the pot Mouth molding quality and other problems, to achieve the effect of ingenious design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

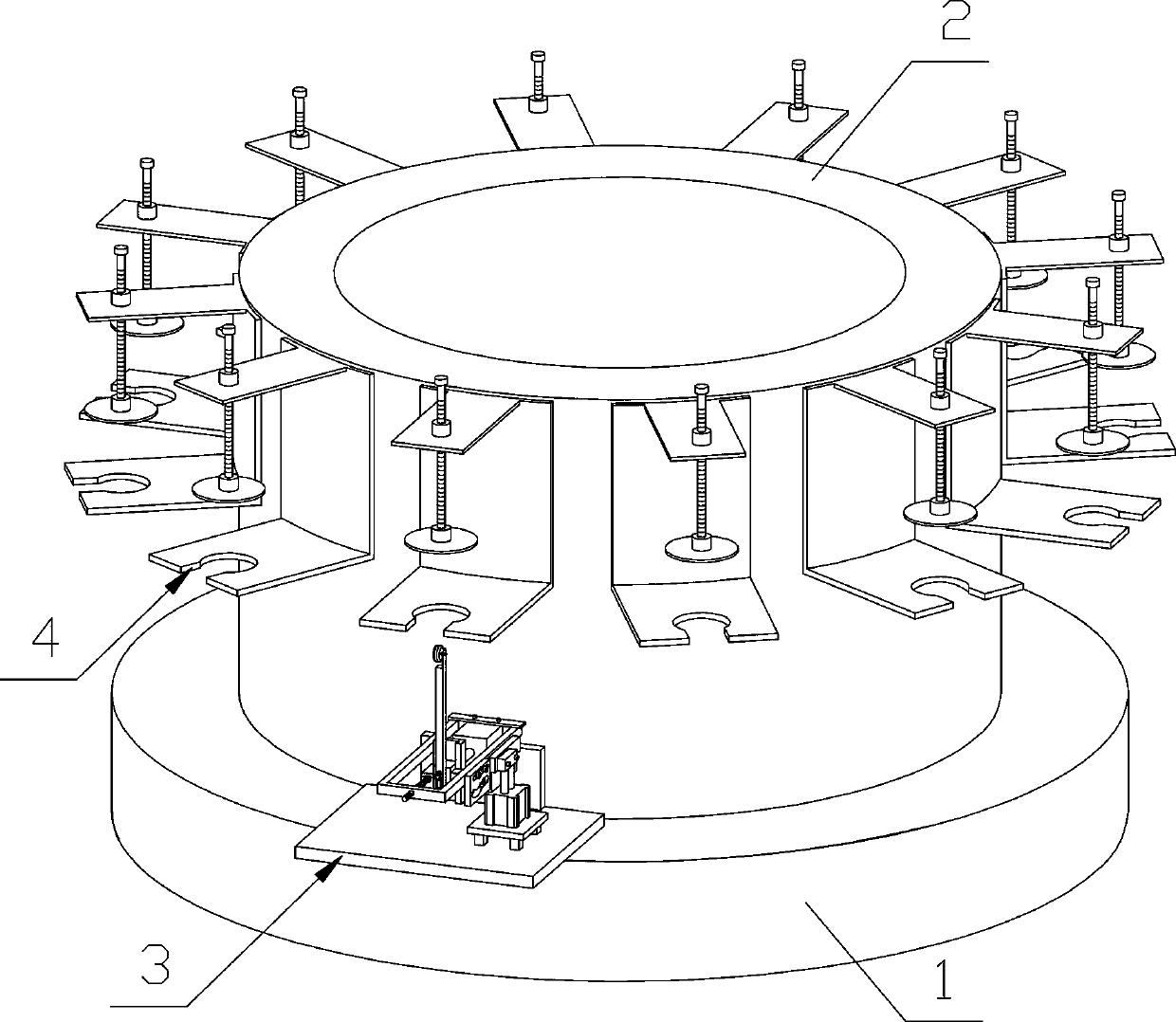

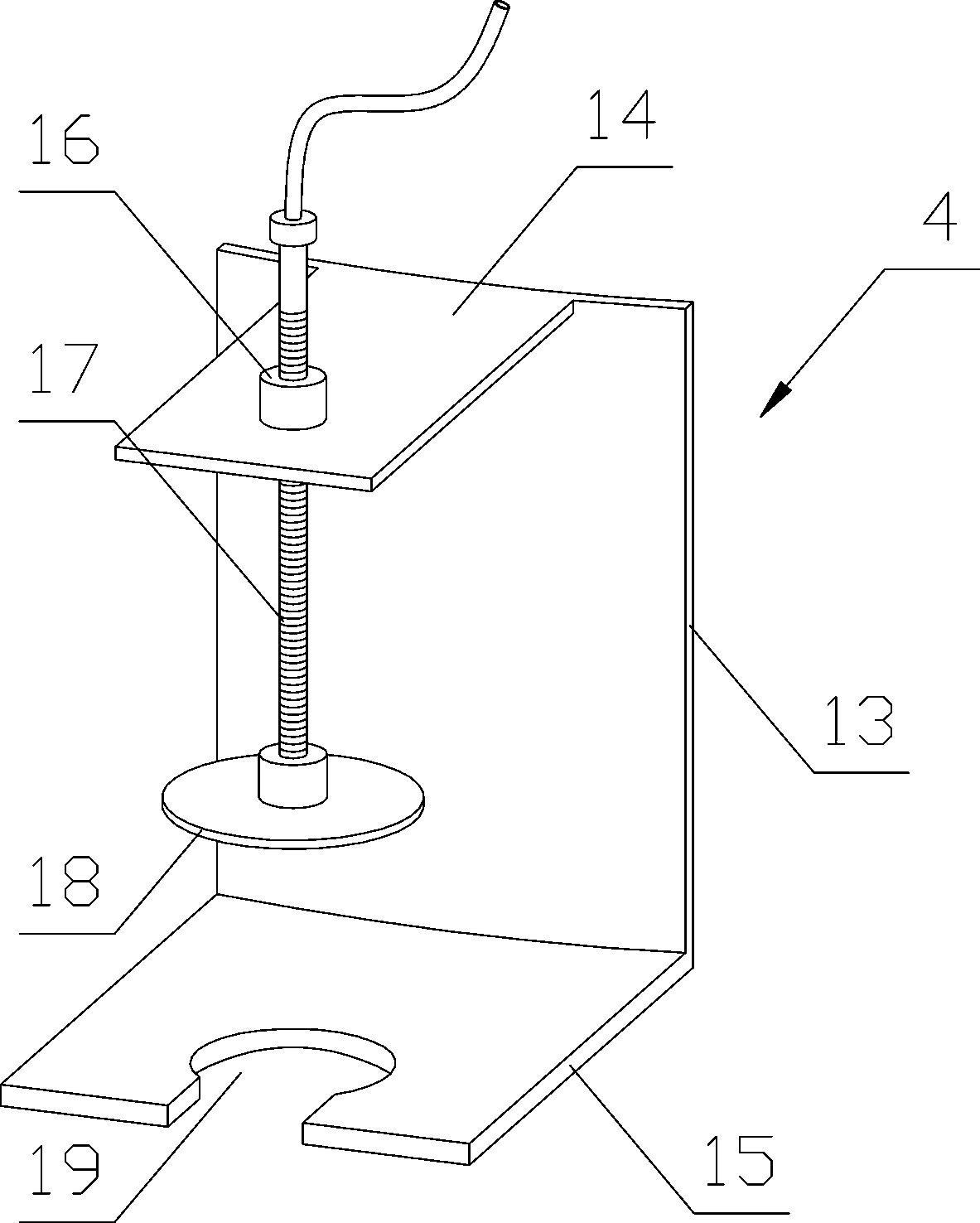

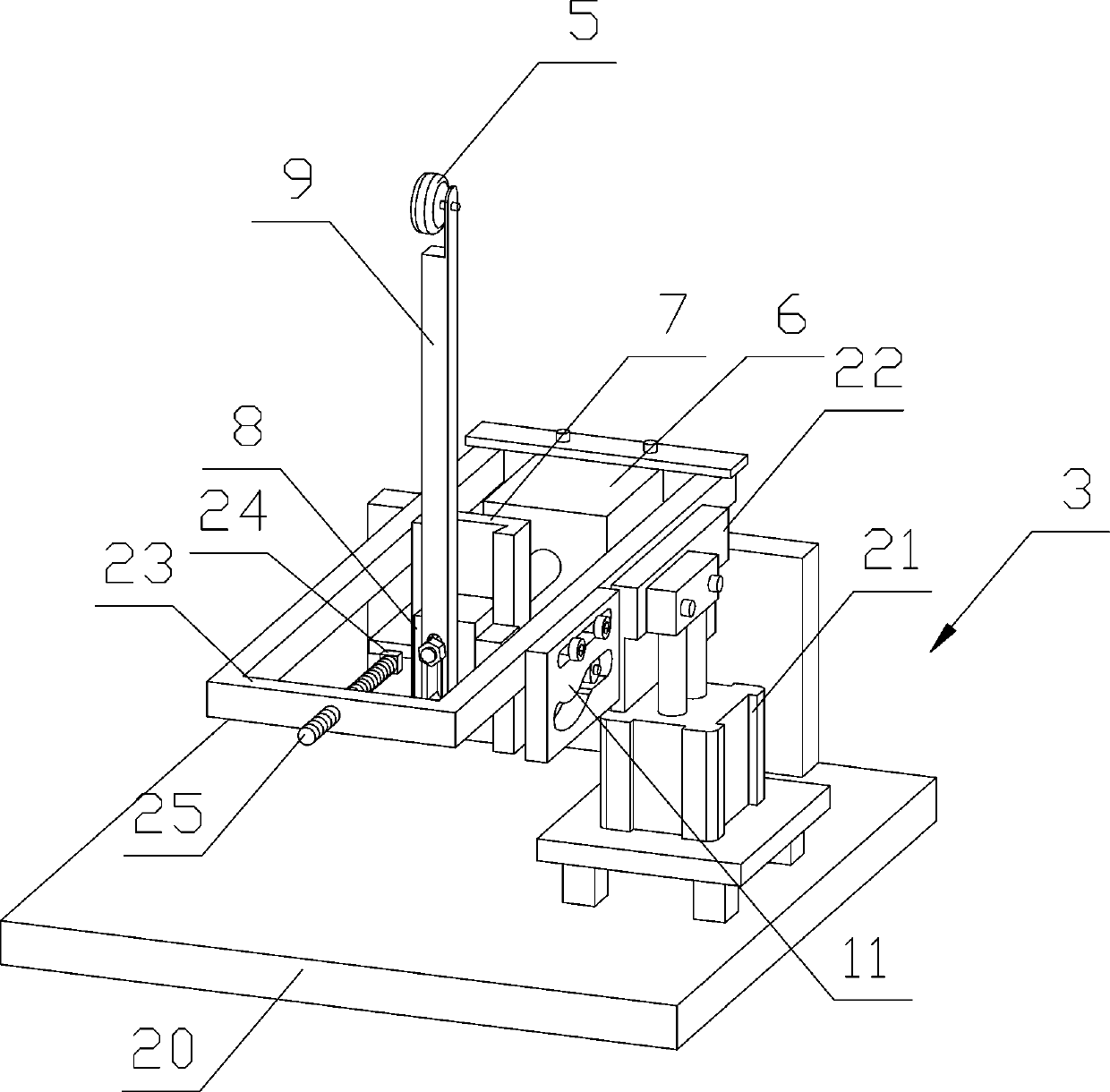

[0017] see Figure 1-4 , a high borosilicate glass pot spout forming device, including a base 1 and an indexing turntable mechanism 2 and a spout molding mechanism 3 arranged on the base 1, and several sets of indexing turntable mechanisms 2 are mounted on the indexing turntable mechanism 2 uniformly along the circumference Arranged clamping mechanism 4, each set of clamping mechanism 4 clamps and fixes the inverted high borosilicate glass pot; indexing turntable mechanism 2 rotates the same pot at regular intervals according to the number of clamping mechanisms 4 arranged Angle, each set of clamping mechanism 4 realizes the matching operation with the spout molding mechanism 3 sequentially under the drive of the indexing turntable mechanism 2; the spout molding mechanism 3 includes the molding wheel 5 and its driving mechanism, and the driving mechanism has The radially arranged cylinder A6 of the mechanism 2 is fixed with a chute 7 at the telescopic end of the cylinder A6, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com