Straight tube fine-drawing device

A straight tube thinning and straight tube technology, which is applied in the field of nylon straight tube thinning equipment, can solve the problems of high cost and development risk, and achieve the effect of mass production operation, compact structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

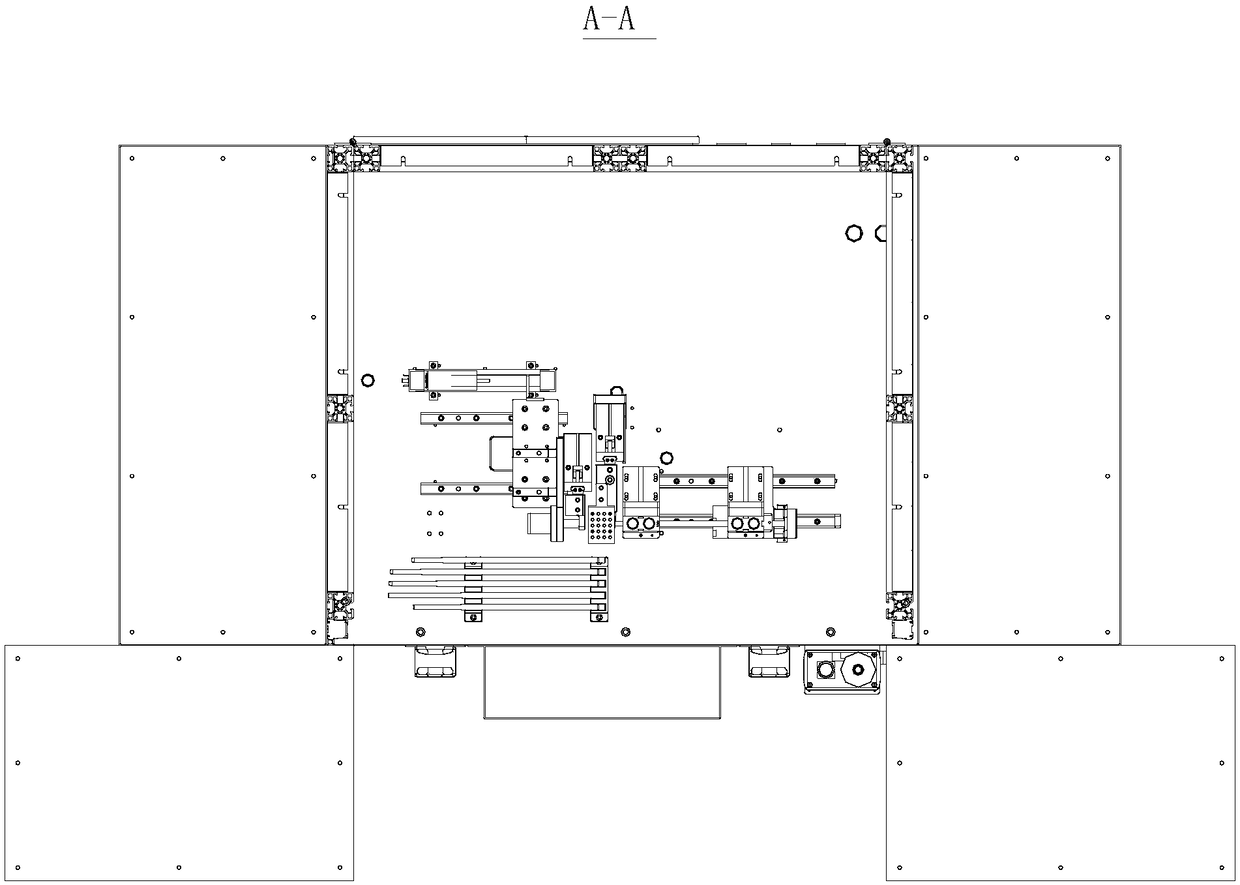

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

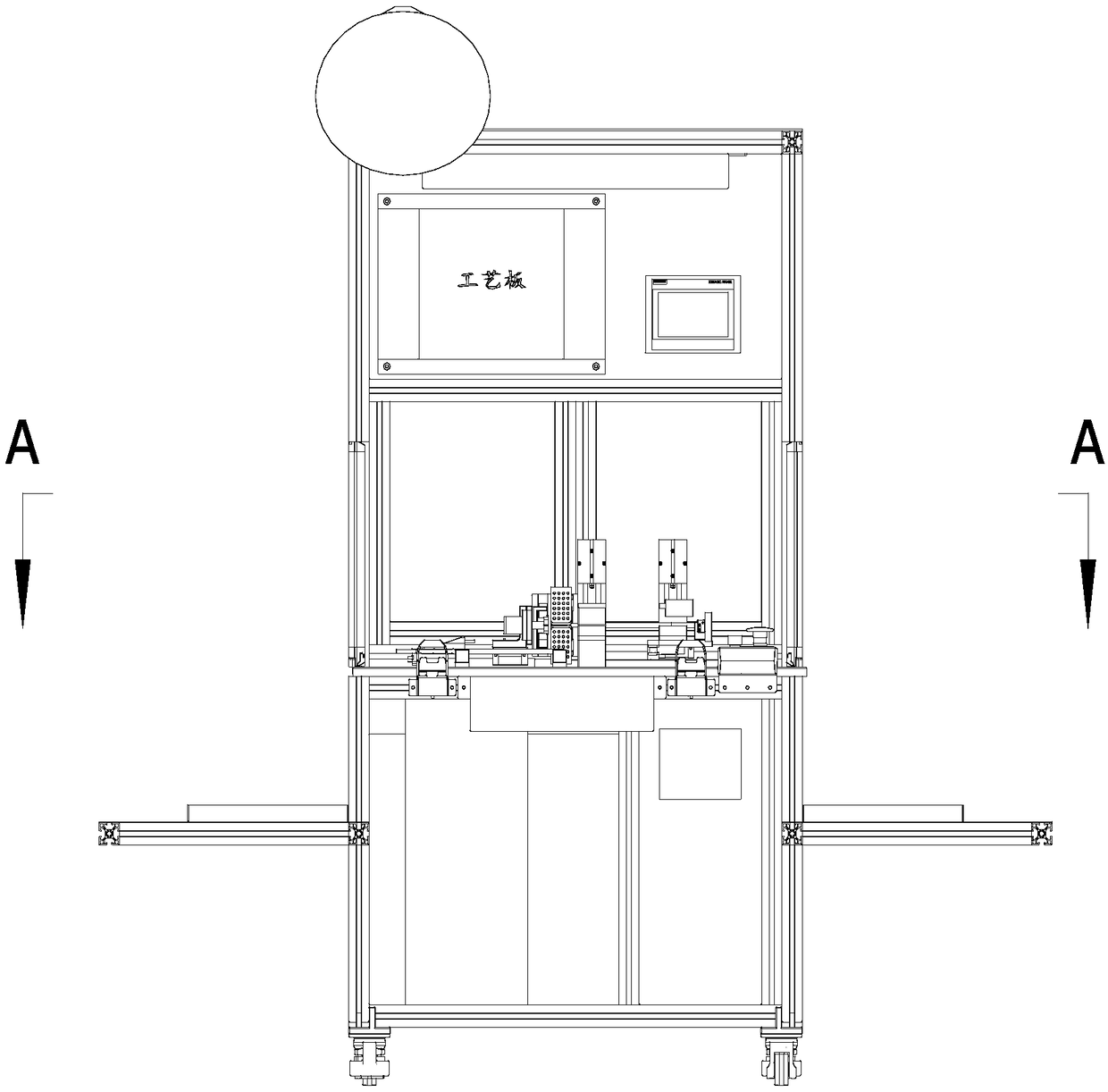

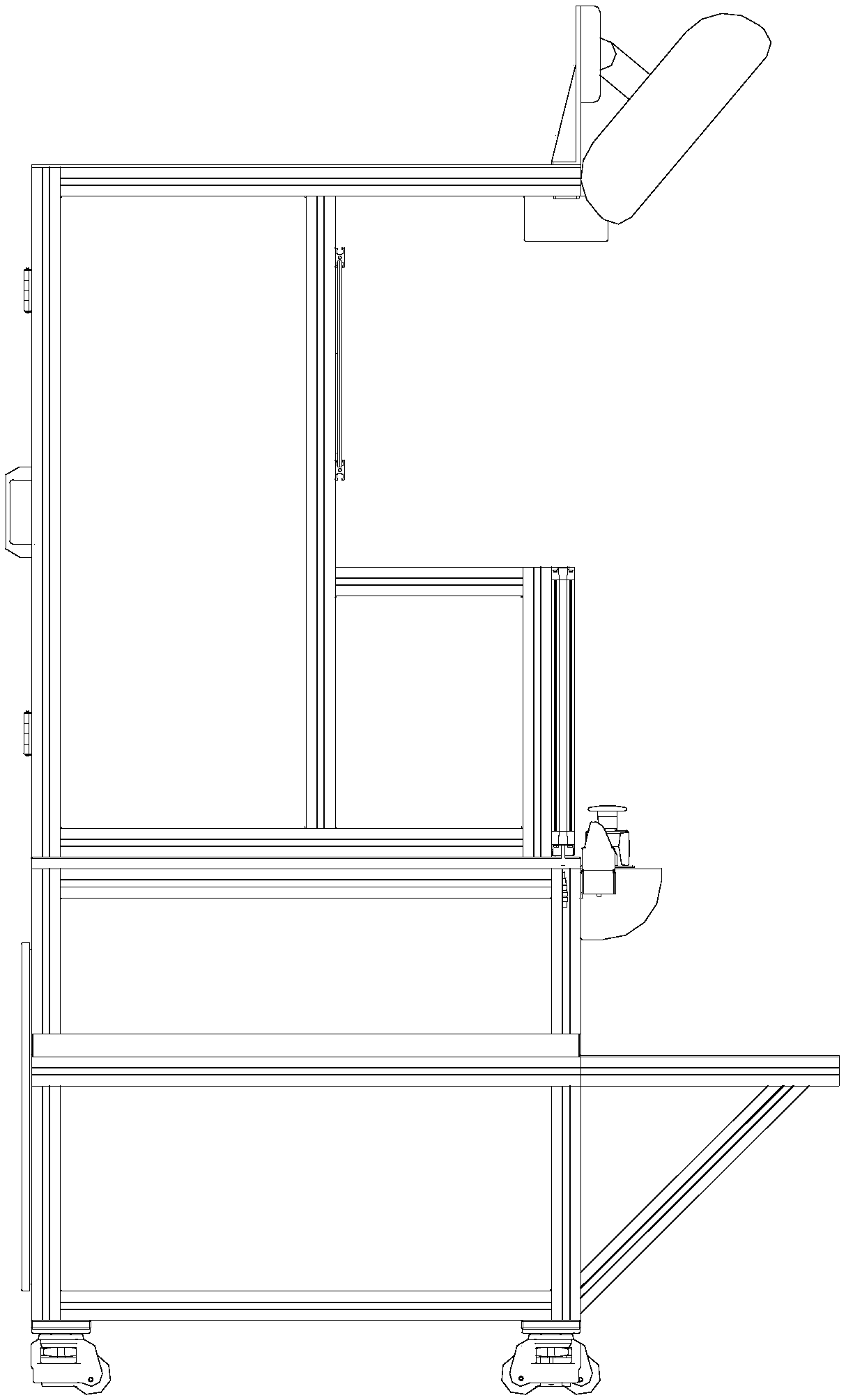

[0026] This embodiment relates to a straight tube thinning device, which includes a frame on which a workbench is formed, a shelf 8 is arranged around the workbench outside the frame, and a shelf frame 9 is formed on the shelf 8, surrounding the workbench. The table is provided with a protective baffle, and a lighting lamp is installed on the top of the protective baffle to provide illumination for the workbench.

[0027] Taking nylon straight pipe (also referred to as straight pipe hereinafter) as an example, a mandrel is pierced in the straight pipe, and an end cap is provided at the end of the mandrel, and the end face of the straight pipe presses against the end cap to form the working workpiece 6 .

[0028] The key part of the thinning equipment is the stretching and heating tool installed on the workbench. The stretching and heating tool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com