Building bricks sintered from fly ash and red sandstone, and preparation technique

A preparation process and technology of fly ash, applied in the field of building materials, can solve the problems of subsidence, waste of resources, softening of particles, etc., and achieve the effects of improving product quality, strengthening mixing effect, and sufficient hydration reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

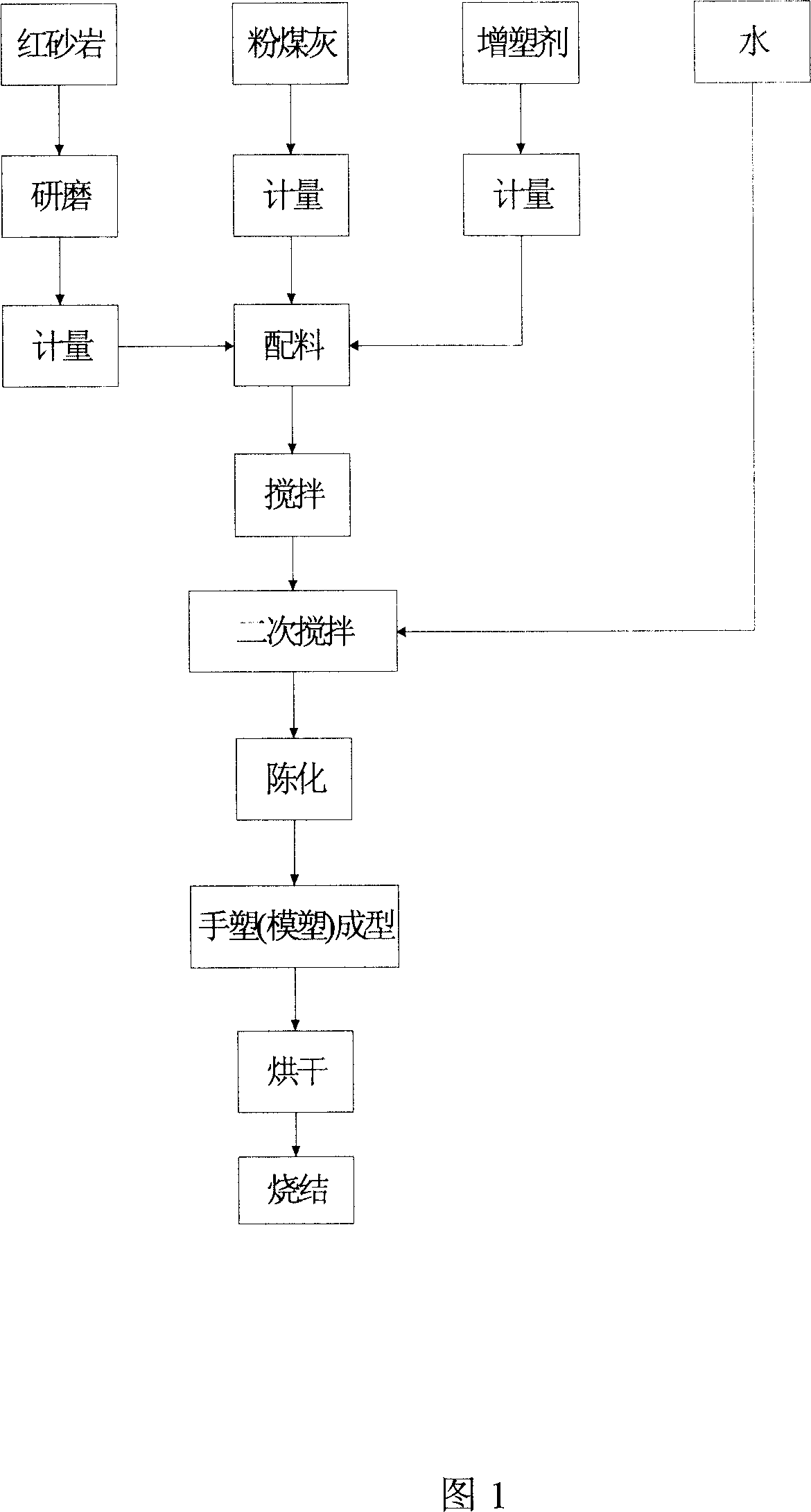

Method used

Image

Examples

Embodiment 1

[0019] 1. Grind the red sandstone, the particle size is 0.080mm square hole sieve and sieve the remaining 5%, then take fly ash, red sandstone and bentonite according to the weight ratio of 50:45:5, put them in the mixer, and stir the dry materials ;

[0020] 2. Take 22 parts by weight of water and pour it into the dry material one after another, and then use a mixer for secondary mixing;

[0021] 3. Aging the mixed mud for 1.5 hours to fully moisten the mud and dry it naturally or in an oven to dry its excess water to increase its plasticity;

[0022] 4. Hand mold the aged mud into adobe of load-bearing bricks;

[0023] 5. Dry the adobe made in an oven at 100°C;

[0024] 6. Sinter the dried adobe at 1080°C for 1.5 hours.

[0025] The compressive strength of the prepared load-bearing brick product is 17.58MPa, and the water absorption rate is 10.23%, meeting the national standard requirement of MU15 in GB / T5101-1998 "Sintered Ordinary Brick".

Embodiment 2

[0027] 1. Grind the red sandstone, the particle size is 0.080mm square hole sieve and sieve the remaining 5%, then take fly ash, red sandstone and kaolin according to the weight ratio of 55:40:5, put them in the mixer, and stir the dry materials ;

[0028] 2. Take 18 parts by weight of water and pour it into the dry material one after another, and then use a mixer for secondary mixing;

[0029] 3. Aging the mixed mud for 2 hours to fully moisten the mud, dry it naturally or dry its excess water in an oven to increase its plasticity;

[0030] 4. Molding the aged mud into adobe of porous brick;

[0031] 5. Dry the adobe made in an oven at 90°C;

[0032] 6. Sinter the dried adobe at 1050°C for 1.5 hours.

[0033] The obtained non-load-bearing brick product has a compressive strength of 13.56MPa and a porosity of 26.25%, meeting the national standard requirements of MU10 in GB13544-2000 "Sintered Porous Brick".

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com