Mildtype well point dewatering construction method of deep foundation pit of red sandstone stratum

A light-weight well point and construction method technology, applied in infrastructure engineering, construction, etc., can solve problems such as easy blockage of pipelines, hidden safety hazards, and reduced precipitation effect, so as to achieve less construction supporting equipment, improve precipitation effect, and reduce precipitation effect obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

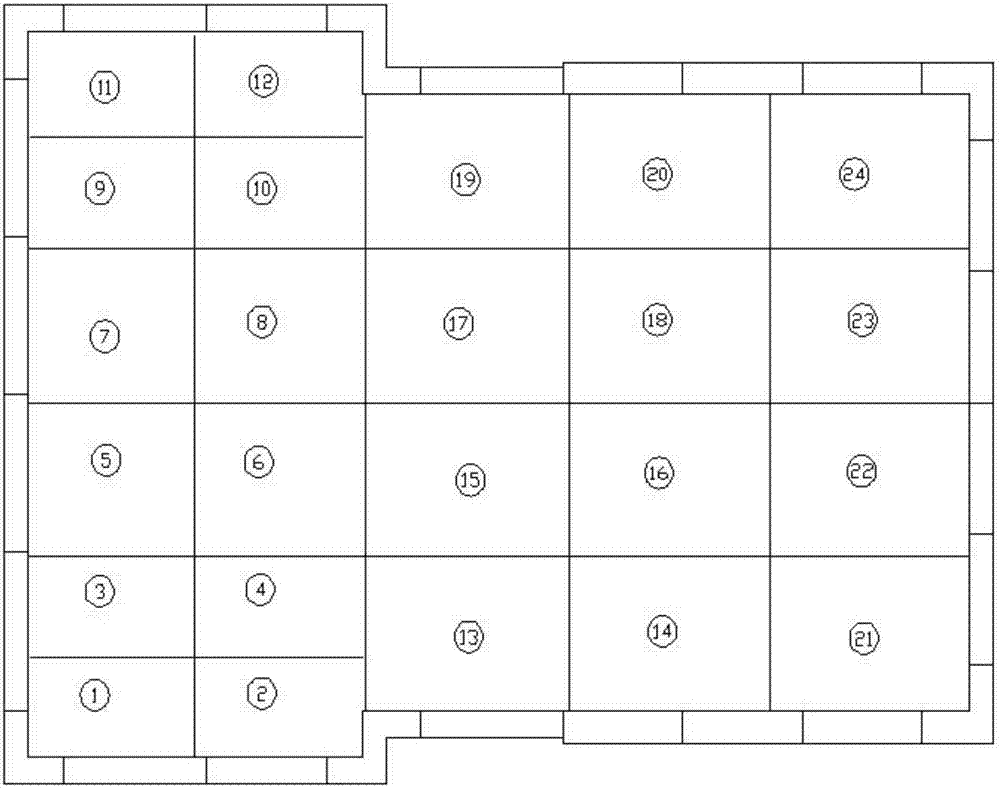

[0030] A light well point dewatering construction method for deep foundation pits in red sandstone formations, comprising the following steps:

[0031] A. Foundation pit excavation

[0032] Excavation of the foundation pit shall stop at 2m from the base;

[0033] B. Prefabricated well point materials

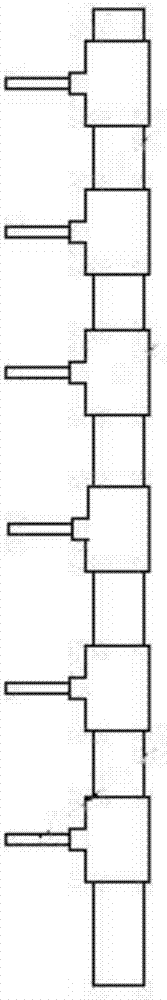

[0034] The light well point includes multiple sets of water collection pipes and point well pipes. There are 4-8 light well point joints on the water collection pipe. The light well point joints are connected with the point well pipes. wrapped gauze;

[0035] C. The first light well point construction

[0036] The steel pipe generates water pressure through the pump body, and the water outlet end of the steel pipe is a flat mouth shape, and the steel pipe sprays water to flush the red yarn rock into a well;

[0037] D. Quick insertion point well pipe

[0038] After flushing reaches the design depth, pull out the steel pipe and insert the point well pipe, and connect the poi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com