Method for preparing high-early-strength oil well cement from industrial waste residue

A technology of oil well cement and steel slag, which is applied in the direction of cement production, etc., can solve the problem of rare oil well cement clinker, and achieve the effect of good cementing quality, simple on-site operation and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

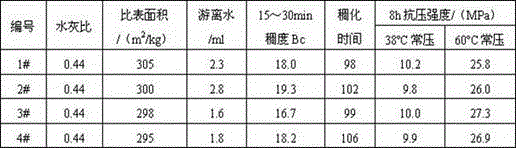

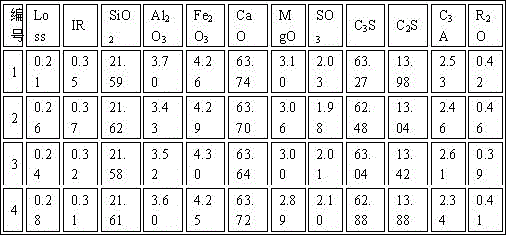

[0014] The raw meal of the rapid-hardening early-strength oil well cement of the present invention is composed of the following raw materials in mass percentage: 60-75% of limestone, 10-15% of red sandstone, 3-6% of phosphorus slag, 4-7% of steel slag and calcium-increasing slag 15%.

[0015] Its preparation method comprises the following steps:

[0016] ①. Raw meal homogenization: the raw meal of each component is ground and homogenized by a raw meal grinding system;

[0017] ②. Clinker calcination: put the homogenized raw material in step ① into the kiln to calcine the clinker;

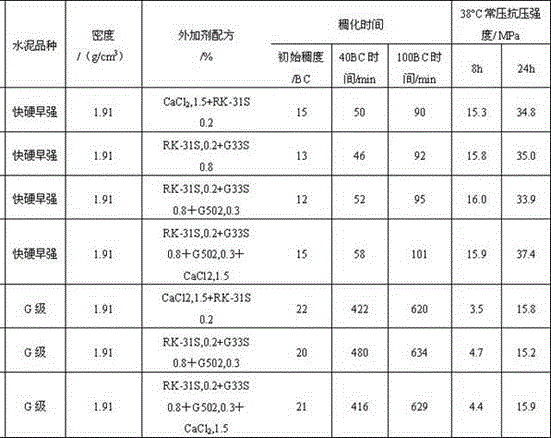

[0018] ③. Cement preparation: In the clinker fired in step ②, 0.5-2.5% of silica fume and 2.5-4.5% of gypsum are added to the clinker for cement grinding.

[0019] The clinker in the step ② is controlled by the following quality control indicators: lime saturation coefficient KH=0.930±0.02; silicic acid rate SM=2.75±0.10; aluminum oxygen rate IM=0.80±0.1; tricalcium aluminate C3A≤2.5% .

[0020]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com